engine Seat Altea 2007 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2007, Model line: Altea, Model: Seat Altea 2007Pages: 302, PDF Size: 9.17 MB

Page 218 of 302

Checking and refilling levels

216

WARNING

•

The coolant additive is toxic. There is a toxic risk. Always keep the

coolant additive in the original container which should be stored out of the

reach of children. The same applies to coolant that you have drained off.

•

The coolant additive G 12+ must be added in sufficient quantities to

provide anti-freeze protection at the coldest ambient temperatures that

can be expected. At extremely cold ambient temperatures, the coolant

could freeze, causing the vehicle to breakdown. As the heater would also

not work in this situation, there is a risk of suffering exposure!Caution

•

Other additives may give considerably inferior corrosion protection. The

resulting corrosion in the cooling system can lead to a loss of coolant,

causing serious damage to the engine.

•

The coolant additive G 12+ (purple) ca n be mixed with the additive G 12

(red) or G 11. Never mix G12 (red colour) with G 11.

Checking the coolant level and topping up

The correct coolant level is important for fault-free func-

tioning of the engine cooling system.Before opening the bonnet, read and observe the warnings ⇒ in

“Safety instructions on working in the engine compartment” on

page 208.

Opening the coolant expansion tank

– Switch off the engine and allow it to cool.

– To prevent scalding, cover the cap on the expansion tank with a thick cloth and carefully unscrew the cap ⇒.

Checking coolant level

– Look into the open coolant expansion tank and read the coolant level.

Fig. 163 In the engine

compartment: Coolant

expansion tank cap

altea_ingles_0706.book Seite 216 Mittwoch, 30. August 2006 3:48 15

Page 219 of 302

Checking and refilling levels217

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

– If the level is underneath the “MIN” mark, top up with coolant.

To p p i n g u p c o o l a n t

–Only use new coolant.

– Do not fill above the “MAX” mark.

Closing the coolant expansion tank

–Screw the cap on again tightly .The position of the coolant expansion reservoir is shown in the corresponding

engine compartment diagram ⇒page 272.

Make sure that the coolant meets the required specifications ⇒page 215.

Do not use a different type of additive if coolant additive G 12+ is not avail-

able. In this case use only water and bring the coolant concentration back up

to the correct level as soon as possible by putting in the specified additive

⇒ page 215.

Always top up with new coolant.

Do not fill above the “MAX” mark. Otherwise the excess coolant will be forced

out of the cooling system when the engine is hot.

The coolant additive G 12+ (dyed purple) may be mixed with G 12 (dyed red)

and also with G 11.

WARNING

Any work carried out in the engine compartment or on the engine must be

carried out cautiously.•

When working in the engine compartment, always observe the safety

warnings ⇒ page 208.

•

When the engine is warm or hot, th e cooling system is pressurised! Do

not unscrew the cap on the expansion tank when the engine is hot. This is

a burn injury risk.Caution

•

When mixed with other additives the col our of G 12 will change to brown.

If this occurs you should have the coolant changed immediately. Failure to do

so will result in engine damage!

•

If a lot of coolant has been lost, wait for the engine to cool down before

putting in cold coolant. This avoid s damaging the engine. Large coolant

losses are an indication of leaks in the cooling system. See a specialised

workshop immediately and have the cooling system checked. Otherwise,

there is a risk of engine damage.WARNING (continued)

altea_ingles_0706.book Seite 217 Mittwoch, 30. August 2006 3:48 15

Page 220 of 302

Checking and refilling levels

218Washer fluid and windscreen wiper bladesTopping up washer fluid

The water for cleaning the windscreen should always be

mixed with washer fluid.The windscreen washer and the headlight washing system are supplied with

fluid from the windscreen washer fluid container in the engine compartment.

The reservoir is located on the right-hand side of the engine compartment.

Plain water is not enough to clean th e windscreen and headlights. We recom-

mend that you always add a product to the windscreen washer fluid.

Approved windscreen cleaning products exist on the market with high deter-

gent and anti-freeze properties, thes e may be added all-year-round. Please

follow the dilution instructions on the packaging.

WARNING

Any work carried out in the engine compartment or on the engine must be

carried out cautiously.•

When working in the engine compartment, always observe the safety

warnings ⇒page 208.Caution

•

Never put radiator anti-freeze or other additives into the windscreen

washer fluid.

•

Always use approved windscreen cleansing products diluted as per

instructions. If you use other washer fluids or soap solutions, the tiny holes

in the fan-shaped nozzles could become blocked.

Fig. 164 In the engine

compartment: Cap of

windscreen washer fluid

reservoir.

altea_ingles_0706.book Seite 218 Mittwoch, 30. August 2006 3:48 15

Page 223 of 302

Checking and refilling levels221

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

If this is not sufficient, refer to a qualified workshop.

WARNING

Do not drive unless you have good visibility through all windows!•

Clean the windscreen wiper blades and all windows regularly.

•

The wiper blades should be changed once or twice a year.Caution

•

A damaged or dirty window wiper could scratch the rear window.

•

Never use fuel, nail varnish remover, paint thinner or similar products to

clean the window.

•

Never move the windscreen wiper by hand. This could cause damage.

Brake fluidChecking the brake fluid level

The brake fluid is checked at the intervals given in the service

schedule.– Read the fluid level at the transparent brake fluid reservoir. It should always be between the “MIN” and “MAX” marks.The position of the brake fluid reservoir is shown in the corresponding engine

compartment diagram ⇒page 272. The brake fluid reservoir has a black and

yellow cap.

The brake fluid level drops slightly when the vehicle is being used as the

brake pads are automatically adjusted as they wear.

Fig. 168 In the engine

compartment: Brake fluid

reservoir cover

altea_ingles_0706.book Seite 221 Mittwoch, 30. August 2006 3:48 15

Page 224 of 302

Checking and refilling levels

222However, if the level goes down noticeably in a short time, or drops below the

“MIN” mark, there may be a leak in the brake system. A display on the instru-

ment panel will warn you if the brake fluid level is too low ⇒page 72.

WARNING

Before opening the bonnet to check the brake fluid level, read and observe

the warnings ⇒page 208.Changing the brake fluid

The brake fluid must be renewed every two years.We recommend that you have the brake fluid changed by an Authorised

Service Centre.

Before opening the bonnet, please read and follow the warnings ⇒ in

“Safety instructions on working in the engine compartment” on page 208 in

“Working in the engine compartment”.

Brake fluid absorbs moisture. In the cour se of time, it will absorb water from

the ambient air. If the water content in the brake fluid is too high, the brake

system could corrode. This also considerably reduces the boiling point of the

brake fluid. Heavy use of the brakes may then cause a vapour lock which

could impair the braking effect.

For this reason the brake fluid must be renewed every two years.

It is important that you use only use brake fluid compliant with the US

standard FMVSS 116 DOT 4. We recommend the use of Genuine SEAT brake

fluid.

WARNING

Brake fluid is poisonous. Old brake fluid impairs the braking effect.

•

Before opening the bonnet to check the brake fluid level, read and

observe the warnings ⇒page 208.

•

Brake fluid should be stored in the closed original container in a safe

place out of reach of children. There is a toxic risk.

•

Have the brake fluid changed every two years at the latest. Heavy use

of the brakes may cause a vapour lock if the brake fluid is left in the system

for too long. This would seriously affect the efficiency of the brakes and the

safety of the vehicle. This may cause an accident.Caution

Brake fluid could damage the paintwork. Wipe off any brake fluid from the

paintwork immediately.

For the sake of the environment

Brake fluid must be drained and disposed of in the proper manner observing

environmental regulations.

WARNING (continued)

altea_ingles_0706.book Seite 222 Mittwoch, 30. August 2006 3:48 15

Page 225 of 302

Checking and refilling levels223

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

BatteryWarnings on handling the battery

WARNING

Always be aware of the danger of injury and chemical burns as well as the

risk of accident or fire when working on the battery and the electrical

system:•

Wear eye protection. Protect your eyes , skin and clothing from acid and

particles containing lead.

•

Battery acid is very corrosive and caustic. Wear protective gloves and

eye protection. Do not tilt the batteries. This could spill acid through the

vents. Rinse battery acid from eyes immediately for several minutes with

clear water. Then seek medical care immediately. Neutralize any acid

splashes on the skin or clothing with a soapy solution, and rinse off with

plenty of water. If acid is swallowed by mistake, consult a doctor immedi-

ately.

•

Fires, sparks, naked lights and smoking are prohibited. When handling

cables and electrical equipment, avoid causing sparks and electrostatic charge. Never short the battery terminals. High-energy sparks can cause

injury.

•

A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.

•

Keep children away from acid and batteries.

•

Before working on the electrical system, you must switch off the

engine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bulb is changed, you need only switch

off the light.

•

Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alar m will otherwise be triggered.

•

When disconnecting the battery from the vehicle electrical system,

disconnect first the negative ca ble and then the positive cable.

•

Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never

reverse the polarity of the connections. This could cause an electrical fire.

•

Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery that has

frozen. A flat battery can freeze at temperatures around 0°C.

•

Ensure that the vent hose is always connected to the battery.

•

Never use a defective battery. This may be fatally explosive. Replace a

damaged battery immediately.Caution

•

Never disconnect the battery if the ignition is switched on or if the engine

is running. This could damage the electrical system or electronic compo-

nents.

•

Do not expose the battery to direct sunlight over a long period of time, as

the intense ultraviolet radiation can damage the battery housing.

Wear eye protection

Battery acid is very corrosive and caustic. Wear protec-

tive gloves and eye protection!

Fires, sparks, naked lights and smoking are prohibited!

A highly explosive mixture of gases is released when the

battery is under charge.

Keep children away from acid and batteries!

WARNING (continued)

altea_ingles_0706.book Seite 223 Mittwoch, 30. August 2006 3:48 15

Page 226 of 302

Checking and refilling levels

224•

If the vehicle is left standing in cold conditions for a long period, protect

the battery from frost. If it “freezes” it will be damaged.

Checking the electrolyte level

The electrolyte level should be checked regularly in high-

mileage vehicles, in hot countries and in older batteries.– Open the bonnet and open the battery cover at the front ⇒ in

“Safety instructions on working in the engine compartment” on

page 208 ⇒ in “Warnings on handling the battery” on

page 223.

– Check the colour display in the "magic eye" on the top of the battery.

– If there are air bubbles in the window, tap the window gently until they disperse.The position of the battery is shown in the corresponding engine compart-

ment diagram ⇒page 272.

The round window (“magic eye”) on the top of the battery changes colour,

depending on the charge level and electrolyte level of the battery.

If the colour in the window is colourless or bright yellow, the electrolyte level

of the battery is too low. Have the battery checked by a qualified workshop.

The colours green and black are used by the workshops for diagnostic

purposes.

Charging and changing the vehicle battery

The battery is maintenance-free and is checked during the

inspection service. All work on the vehicle battery requires

specialist knowledge.If you often drive short distances or if the vehicle is not driven for long

periods, the battery should be checked by a qualified workshop between the

scheduled services.

If the battery has discharged and you have problems starting the vehicle, the

battery might be damaged. If this happens, we recommend you have the

vehicle battery checked by an Authorised Service Centre where it will be re-

charged or replaced.

Charging the battery

The vehicle battery should be charged by a qualified workshop only, as

batteries using special technology have been installed and they must be

charged in a controlled environment.

Replacing a vehicle battery

The battery has been developed to suit the conditions of its location and has

special safety features.

Genuine SEAT batteries fulfil the maintenance, performance and safety spec-

ifications of your vehicle.

WARNING

•

We recommend you use only maintenance-free or cycle free leak-proof

batteries that comply with the standards T 825 06 and VW 7 50 73. This

standard applies as of 2001.

•

Before starting any work on the batteries, you must read and observe

the warnings ⇒ in “Warnings on handling the battery” on page 223.

altea_ingles_0706.book Seite 224 Mittwoch, 30. August 2006 3:48 15

Page 234 of 302

If and when

232If and whenTools, tyre repair kit and spare wheelVehicle To ols

The vehicle onboard tools are located under the floor panel in

the luggage compartment.– Lift the cover of the luggage compartment, by pulling it up with a

finger in the fitting.

– Take the onboard tools out of the vehicle.The tool kit includes:•

Jack*

•

Hook for removing wheel covers* or hub caps*

•

Box spanner for wheel bolts*

•

Reversible screwdriver with handle (including hexagonal interior) for the

wheel bolts. The screwdriver is a combination tool.

•

To wi ng e ye

•

Adapter for the anti-theft wheel bolts*

Some of the items listed are only prov ided on certain models / model years,

or are optional extras.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts. It is impossible to tighten the bolts with the torque

required, risk of accident.

•

The jack supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads, risk of injury.

•

Use the jack only on firm, level ground.

•

Never start the engine when the vehicle is on the jack, risk of accident.

•

I f wo r k is t o b e ca r r i e d o u t un d e r n ea th the vehicle, this must be secured

by suitable stands. Otherwise, there is a risk of injury.WARNING (continued)

altea_ingles_0706.book Seite 232 Mittwoch, 30. August 2006 3:48 15

Page 236 of 302

If and when

234

Note•

Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the ve hicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

–Apply the handbrake firmly.

– Engage the first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

– Take the vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

–Pull off the hub cap. Also refer to ⇒page 235, fig. 172 .

– Slacken the wheel bolts .

– Raise the car with the jack in the corresponding zone.

– Ta k e o f f the wheel and then put on the spare wheel.

– Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the box

spanner.

–Replace the hub cap.

altea_ingles_0706.book Seite 234 Mittwoch, 30. August 2006 3:48 15

Page 244 of 302

If and when

242

– Put the tools back in the luggage compartment.NoteThe compressor should not operate more than 6 minutes.FusesChanging a fuse

If a fuse has blown it must be replaced

Fuse cover underneath the steering wheel

– Switch off the ignition and the component concerned.

– Identify the fuse for the failed component ⇒page 244.

– Take the plastic clip from inside the fuse cover, fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

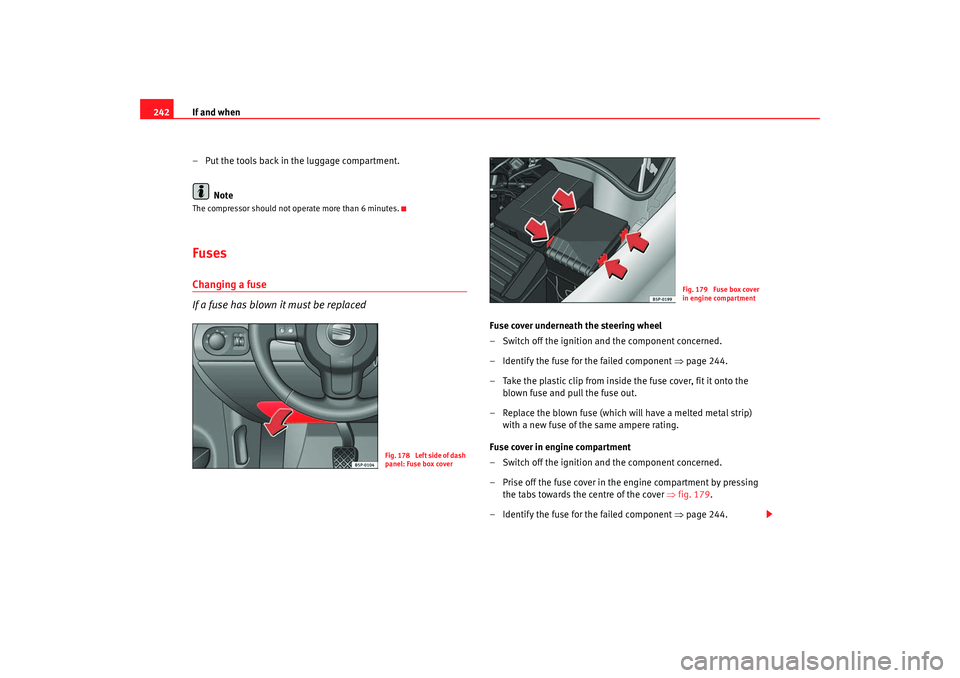

Fuse cover in engine compartment

– Switch off the ignition and the component concerned.

– Prise off the fuse cover in the engine compartment by pressing the tabs towards the centre of the cover ⇒fig. 179 .

– Identify the fuse for the failed component ⇒page 244.

Fig. 178 Left side of dash

panel: Fuse box cover

Fig. 179 Fuse box cover

in engine compartment

altea_ingles_0706.book Seite 242 Mittwoch, 30. August 2006 3:48 15