engine Seat Altea 2010 Manual Online

[x] Cancel search | Manufacturer: SEAT, Model Year: 2010, Model line: Altea, Model: Seat Altea 2010Pages: 310, PDF Size: 7.46 MB

Page 253 of 310

If and when251

Safety First

Operating instructions

Practical tips

Technical Data

If and whenTools, tyre repair kit and spare wheelVehicle Tools

The vehicle onboard tools are located under the floor panel in

the luggage compartment.– Lift the cover of the luggage compartment, by pulling it up with a

finger in the fitting.

– Take the onboard tools out of the vehicle.The tool kit includes:•Jack*•Hook for removing wheel covers* or hub caps*•Box spanner for wheel bolts*•Reversible screwdriver with handle (including hexagonal interior) for the

wheel bolts. The screwdriver is a combination tool.•To wi n g e ye•Adapter for the anti-theft wheel bolts*

Some of the items listed are only provided in certain models / model years,

or are optional extras.WARNING

•Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts as with this it is not possible to tighten the bolts to the

required torque. Risk of accident.

•The jack supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads. Risk of injury.•Use the jack only on a firm, level ground.•Never start the engine when the vehicle is on the jack. Risk of accident.•If work is to be carried out underneath the vehicle, this must be secured

by suitable stands. Otherwise, there is a risk of injury.WARNING (continued)

altea_EN Seite 251 Mittwoch, 26. August 2009 6:00 18

Page 255 of 310

If and when253

Safety First

Operating instructions

Practical tips

Technical Data

reliably seal punctures up to a size of about 4 mm caused by the penetration

of a foreign body into the tyre.

Note

•Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.Wheel changePreparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the vehicle. They should wait in a safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

– Apply the handbrake firmly.

– Engage the first gear, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

–Take the vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.Changing a wheelChange the wheel as described below

– Remove the wheel cover. Also refer to ⇒page 254, fig. 176 .

–Slacken the wheel bolts .

– Raise the car with the jack in the corresponding zone.

– Remove the wheel and then put on the spare wheel.

– Lower the vehicle.

– Tighten the wheel bolts firmly with the box spanner.

–Replace the hub cap.

altea_EN Seite 253 Mittwoch, 26. August 2009 6:00 18

Page 263 of 310

If and when261

Safety First

Operating instructions

Practical tips

Technical Data

Completing th e repa ir

– Remove the compressor hose from the valve.

–Fit the valve cap.

– Unplug the compressor from the socket.

– Return all tools to their proper storing location.

Note•If the vehicle is equipped with tyre pressure control, enter the new tyre

pressures using the SET button on the central console.•The compressor should never be allowed to run for longer than 6

minutes.

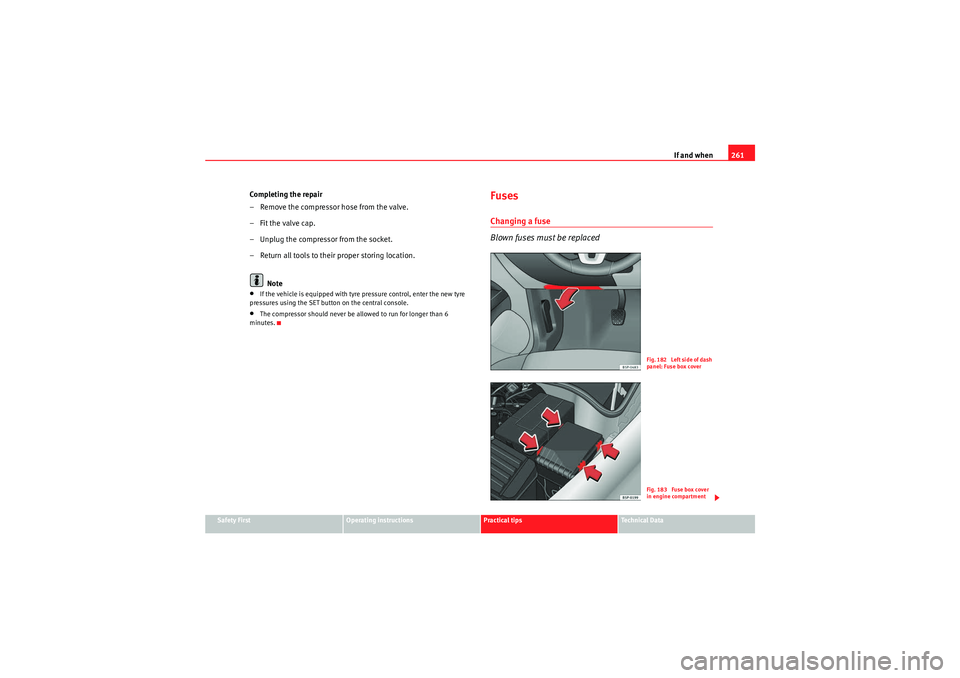

FusesChanging a fuse

Blown fuses must be replaced

Fig. 182 Left side of dash

panel: Fuse box coverFig. 183 Fuse box cover

in engine compartment

altea_EN Seite 261 Mittwoch, 26. August 2009 6:00 18

Page 264 of 310

If and when

262

Fuse cover underneath the steering wheel

– Switch off the ignition and the component concerned.

– Identify the fuse for the failed component ⇒page 264.

– Take the plastic clip from inside the fuse cover, fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

Fuse cover in engine compartment

– Switch off the ignition and its failed electrical component.

– Prise off the fuse cover in the engine compartment by pressing the tabs towards the centre of the cover ⇒page 261, fig. 183 .

– Identify the fuse for the failed component ⇒ page 264.

– Take the plastic clip from inside the fuse cover (at left-hand end of the dash panel), fit it onto the blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

– Carefully fit the fuse cover back on to ensure no water can enter the fuse box.The individual electrical circuits are protected by fuses. The fuses are located

behind a cover at the left-hand end of the dash panel and on the left-hand

side of the engine compartment.

The electric windows are protected by circuit breakers. These reset automat-

ically after a few seconds when the overload (caused for example by frozen

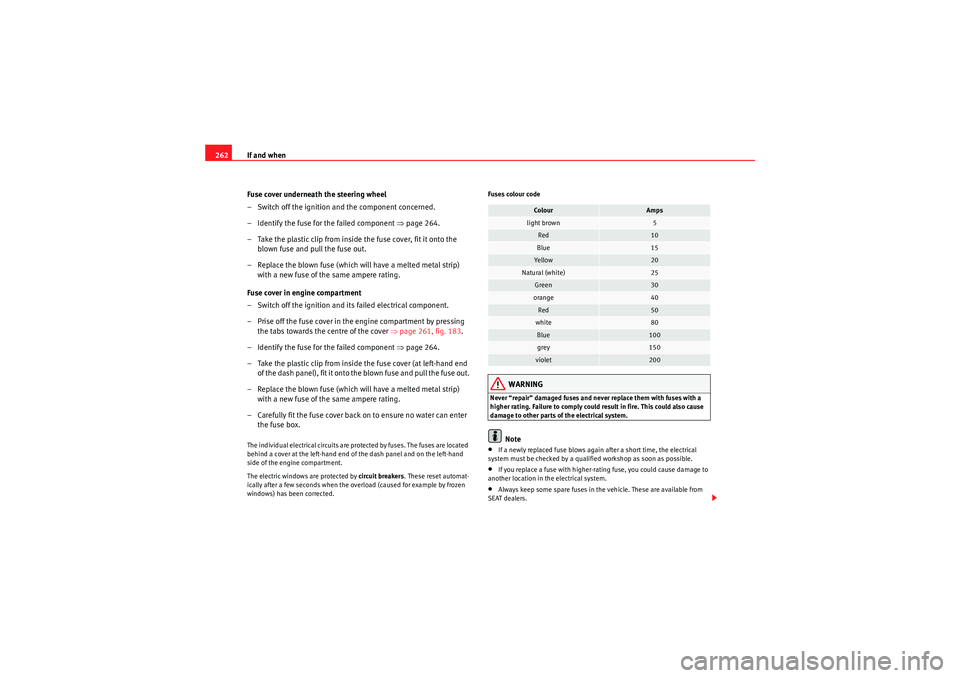

windows) has been corrected. Fuses colour code

WARNING

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could result in fire. This could also cause

damage to other parts of the electrical system.

Note

•If a newly replaced fuse blows again after a short time, the electrical

system must be checked by a qualified workshop as soon as possible.•If you replace a fuse with higher-rating fuse, you could cause damage to

another location in the electrical system.•Always keep some spare fuses in the vehicle. These are available from

SEAT dealers.

Co lo ur

Amps

light brown

5

Red

10

Blue

15

Yellow

20

Natural (white)

25

Green

30

orange

40

Red

50

white

80

Blue

100

grey

150

violet

200

altea_EN Seite 262 Mittwoch, 26. August 2009 6:00 18

Page 266 of 310

If and when

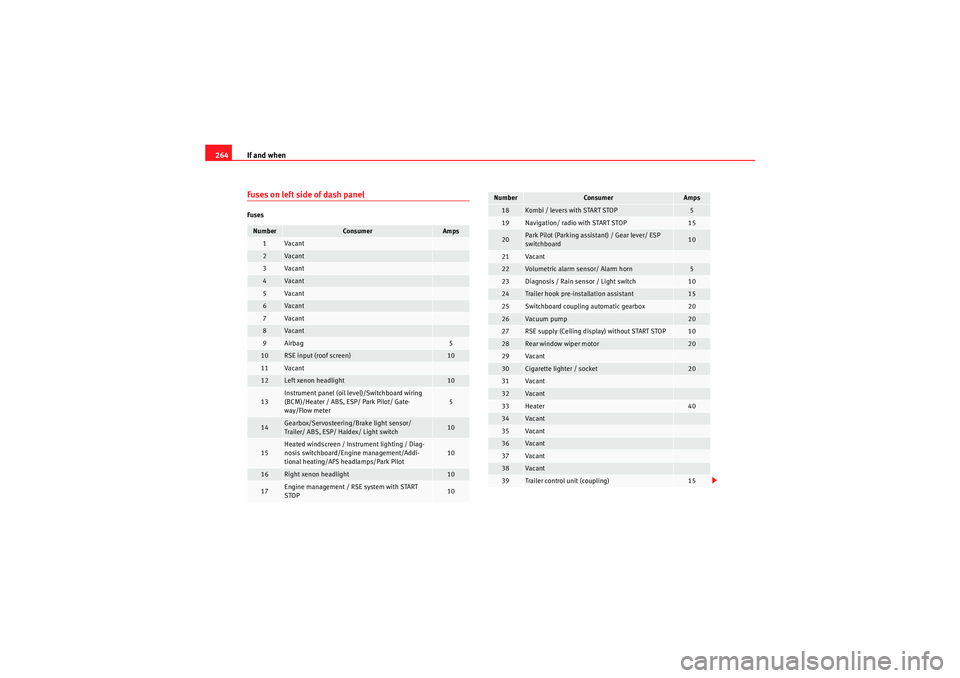

264Fuses on left side of dash panelFusesNumber

Consumer

Amps

1

Va can t

2

Va can t

3

Va can t

4

Va can t

5

Va can t

6

Va can t

7

Va can t

8

Va can t

9

Airbag

5

10

RSE input (roof screen)

10

11

Va can t

12

Left xenon headlight

10

13

Instrument panel (oil level)/Switchboard wiring

(BCM)/Heater / ABS, ESP/ Park Pilot/ Gate-

way/Flow meter

5

14

Gearbox/Servosteering/Brake light sensor/

Trailer/ ABS, ESP/ Haldex/ Light switch

10

15

Heated windscreen / Instrument lighting / Diag-

nosis switchboard/Engine management/Addi-

tional heating/AFS headlamps/Park Pilot

10

16

Right xenon headlight

10

17

Engine management / RSE system with START

STOP

10

18

Kombi / levers with START STOP

5

19

Navigation/ radio with START STOP

15

20

Park Pilot (Parking assistant) / Gear lever/ ESP

switchboard

10

21

Vacant

22

Volumetric alarm sensor/ Alarm horn

5

23

Diagnosis / Rain sensor / Light switch

10

24

Trailer hook pre-installation assistant

15

25

Switchboard coupling automatic gearbox

20

26

Vacuum pump

20

27

RSE supply (Ceiling display) without START STOP

10

28

Rear window wiper motor

20

29

Vacant

30

Cigarette lighter / socket

20

31

Vacant

32

Vacant

33

Heater

40

34

Vacant

35

Vacant

36

Vacant

37

Vacant

38

Vacant

39

Trailer control unit (coupling)

15

Number

Co nsum er

Amps

altea_EN Seite 264 Mittwoch, 26. August 2009 6:00 18

Page 267 of 310

If and when265

Safety First

Operating instructions

Practical tips

Technical Data

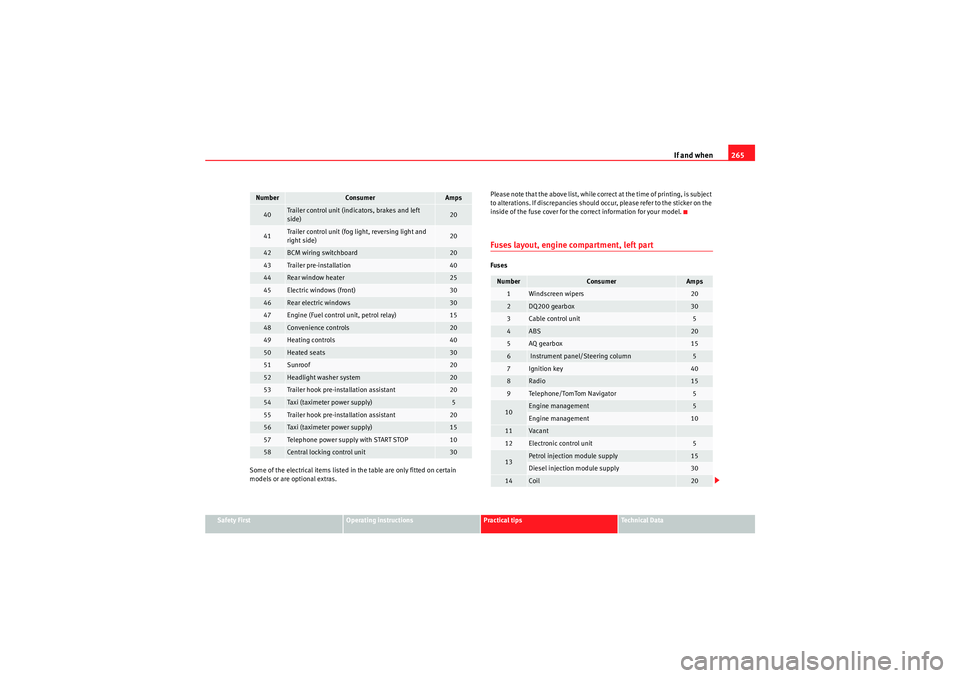

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras. Please note that the above list, while correct at the time of printing, is subject

to alterations. If discrepancies should occur, please refer to the sticker on the

inside of the fuse cover for the correct information for your model.

Fuses layout, engine compartment, left partFuses

40

Trailer control unit (indicators, brakes and left

side)

20

41

Trailer control unit (fog light, reversing light and

right side)

20

42

BCM wiring switchboard

20

43

Trailer pre-installation

40

44

Rear window heater

25

45

Electric windows (front)

30

46

Rear electric windows

30

47

Engine (Fuel control unit, petrol relay)

15

48

Convenience controls

20

49

Heating controls

40

50

Heated seats

30

51

Sunroof

20

52

Headlight washer system

20

53

Trailer hook pre-installation assistant

20

54

Taxi (taximeter power supply)

5

55

Trailer hook pre-installation assistant

20

56

Taxi (taximeter power supply)

15

57

Telephone power supply with START STOP

10

58

Central locking control unit

30

Number

Consumer

Amps

Number

Consumer

Amps

1

Windscreen wipers

20

2

DQ200 gearbox

30

3

Cable control unit

5

4

ABS

20

5

AQ gearbox

15

6

Instrument panel/Steering column

5

7

Ignition key

40

8

Radio

15

9

Telephone/TomTom Navigator

5

10

Engine management

5

Engine management

10

11

Vaca nt

12

Electronic control unit

5

13

Petrol injection module supply

15

Diesel injection module supply

30

14

Coil

20

altea_EN Seite 265 Mittwoch, 26. August 2009 6:00 18

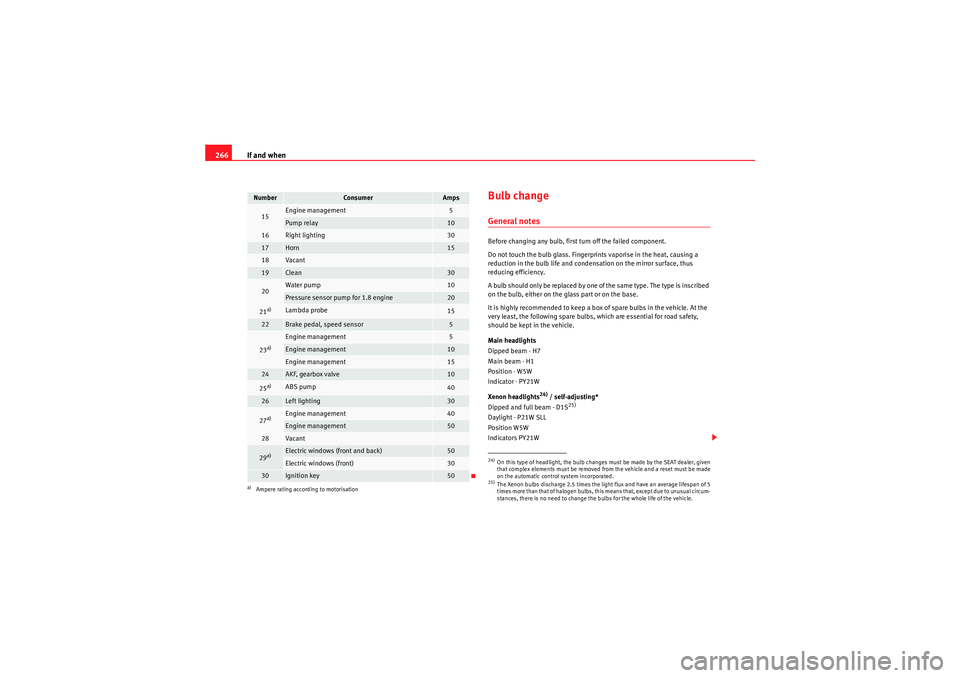

Page 268 of 310

If and when

266

Bulb changeGeneral notesBefore changing any bulb, first turn off the failed component.

Do not touch the bulb glass. Fingerprints vaporise in the heat, causing a

reduction in the bulb life and condensation on the mirror surface, thus

reducing efficiency.

A bulb should only be replaced by one of the same type. The type is inscribed

on the bulb, either on the glass part or on the base.

It is highly recommended to keep a box of spare bulbs in the vehicle. At the

very least, the following spare bulbs, which are essential for road safety,

should be kept in the vehicle.

Main headlights

Dipped beam - H7

Main beam - H1

Position - W5W

Indicator - PY21W

Xenon headlights

24) / self-adjusting*

Dipped and full beam - D1S

25)

Daylight - P21W SLL

Position W5W

Indicators PY21W

15

Engine management

5

Pump relay

10

16

Right lighting

30

17

Horn

15

18

Vacant

19

Clean

30

20

Water pump

10

Pressure sensor pump for 1.8 engine

20

21a)

Lambda probe

15

22

Brake pedal, speed sensor

5

23a)

Engine management

5

Engine management

10

Engine management

15

24

AKF, gearbox valve

10

25a)

ABS pump

40

26

Left lighting

30

27a)

Engine management

40

Engine management

50

28

Vacant

29a)

Electric windows (front and back)

50

Electric windows (front)

30

30

Ignition key

50

a)Ampere rating according to motorisationNumber

Consumer

Amps

24)On this type of headlight, the bulb changes must be made by the SEAT dealer, given

that complex elements must be removed from the vehicle and a reset must be made

on the automatic control system incorporated.25)The Xenon bulbs discharge 2.5 times the light flux and have an average lifespan of 5

t im es m o re t han tha t o f ha lo gen bu lbs , th is m ea ns t ha t, excep t du e to un u su a l ci rcu m -

stances, there is no need to change the bulbs for the whole life of the vehicle.

altea_EN Seite 266 Mittwoch, 26. August 2009 6:00 18

Page 277 of 310

If and when275

Safety First

Operating instructions

Practical tips

Technical Data

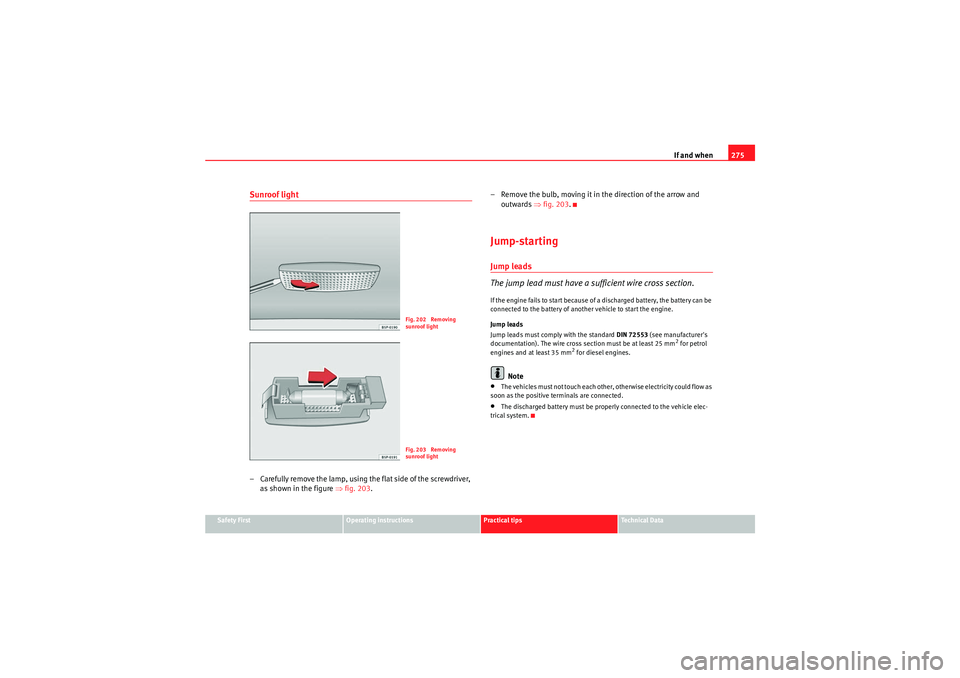

Sunroof light– Carefully remove the lamp, using the flat side of the screwdriver,

as shown in the figure ⇒fig. 203 . – Remove the bulb, moving it in the direction of the arrow and

outwards ⇒fig. 203 .

Jump-startingJump leads

The jump lead must have a sufficient wire cross section.If the engine fails to start because of a discharged battery, the battery can be

connected to the battery of another vehicle to start the engine.

Jump leads

Jump leads must comply with the standard DIN 72553 (see manufacturer's

documentation). The wire cross section must be at least 25 mm

2 for petrol

engines and at least 35 mm

2 for diesel engines.

Note

•The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.•The discharged battery must be properly connected to the vehicle elec-

trical system.

Fig. 202 Removing

sunroof lightFig. 203 Removing

sunroof light

altea_EN Seite 275 Mittwoch, 26. August 2009 6:00 18

Page 278 of 310

If and when

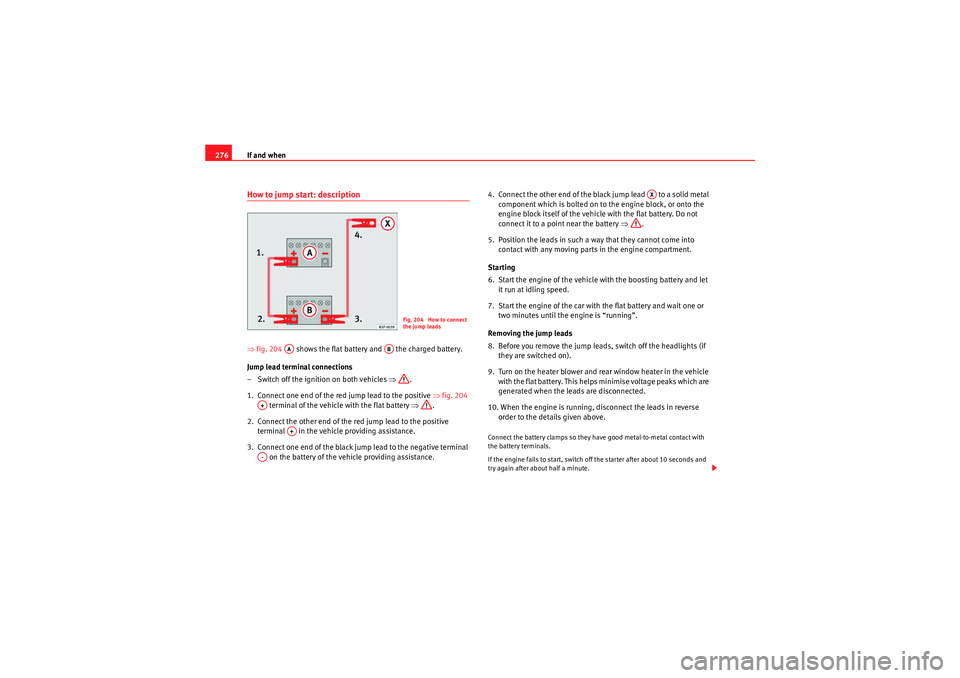

276How to jump start: description⇒ fig. 204 shows the flat battery and the charged battery.

Jump lead terminal connections

– Switch off the ignition on both vehicles ⇒.

1. Connect one end of the red jump lead to the positive ⇒fig. 204

terminal of the vehicle with the flat battery ⇒ .

2. Connect the other end of the red jump lead to the positive terminal in the vehicle providing assistance.

3. Connect one end of the black jump lead to the negative terminal on the battery of the vehicle providing assistance. 4. Connect the other end of the black jump lead to a solid metal

component which is bolted on to the engine block, or onto the

engine block itself of the vehicle with the flat battery. Do not

connect it to a point near the battery ⇒ .

5. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

6. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

7. Start the engine of the car with the flat battery and wait one or two minutes until the engine is “running”.

Removing the jump leads

8. Before you remove the jump leads, switch off the headlights (if they are switched on).

9. Turn on the heater blower and rear window heater in the vehicle with the flat battery. This helps minimise voltage peaks which are

generated when the leads are disconnected.

10. When the engine is running, disconnect the leads in reverse order to the details given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

Fig. 204 How to connect

the jump leads

AA

AB

A+

A+

A-

AX

altea_EN Seite 276 Mittwoch, 26. August 2009 6:00 18

Page 279 of 310

If and when277

Safety First

Operating instructions

Practical tips

Technical Data

WARNING

•Please note the safety warnings referring to working in the engine

compartment ⇒page 226, “Working in the engine compartment”.•The battery providing assistance must have the same voltage as the flat

battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.•Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.•Keep sparks, flames and lighted cigarettes away from batteries, danger

of explosion. Failure to comply could result in an explosion.•Observe the instructions provided by the manufacturer of the jump

leads.•Do not connect the negative cable from the other vehicle directly to the

negative terminal of the flat battery. The gas emitted from the battery could

be ignited by sparks. Danger of explosion.•Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.•The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.•Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.•Do not bend over the batteries. This could result in chemical burns.Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

altea_EN Seite 277 Mittwoch, 26. August 2009 6:00 18