technical specifications Seat Altea 2012 Owner's Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Altea, Model: Seat Altea 2012Pages: 313, PDF Size: 4.47 MB

Page 265 of 313

263

If and when

Preparation work

Certain steps must be taken before repairing a tyre.

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

– Apply the handbrake firmly.

– Engage first gear , or put the selector lever to position P.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Check whether a repair is possible using the Tyre Mobility Sys-

tem “General information and safety notes.”

– Unscrew inflation cap from the affected wheel.

– Take the tyre repair kit out of the luggage compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in posi-

tion. This is for your own safety and also warns other road users.

CAUTION

Take special care if you have to repair a tyre on a slope.

Note

Please observe legal requirements when doing so. Tyre repair

The following sections describe the procedures for repairing

a tyre.

Using the sealing compound

– The instructions on the container give detailed information on

how to use the sealing compound.

Inflating the tyre.

– Remove the air compressor and hose from the container.

– Screw the retaining nut onto the valve.

– Plug the compressor cable into a 12 volt power point.

– Turn on compressor and monitor the pressure shown on the

pressure gauge.

Completing the repair

– Remove the compressor hose from the valve.

– Fit the valve cap.

– Unplug the compressor from the socket.

– Return all tools to their proper storing location.

Note

● If the vehicle is equipped with tyre pressure control, enter the new tyre

pressures using the SET button on the centre console.

● The compressor should never be allowed to run for longer than 6 mi-

nutes.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 267 of 313

265

If and when

The electric windows are protected by circuit breakers. These reset automat-

ically after a few seconds when the overload (caused for example by frozen

windows) has been corrected.

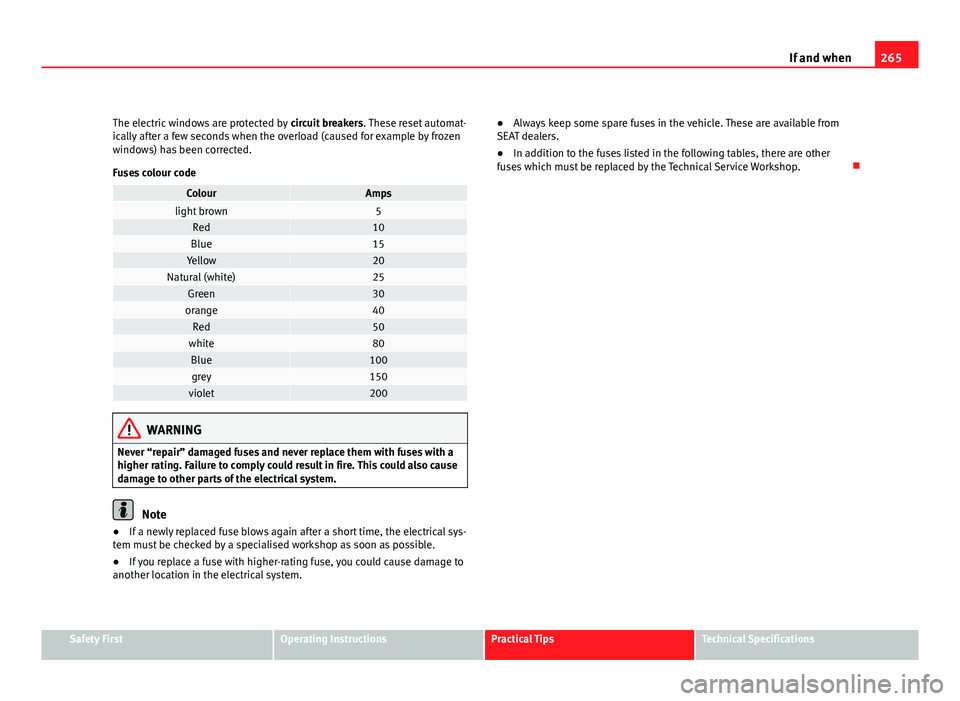

Fuses colour code

ColourAmpslight brown5Red10Blue15Yellow20Natural (white)25Green30orange40Red50white80Blue100grey150violet200

WARNING

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could result in fire. This could also cause

damage to other parts of the electrical system.

Note

● If a newly replaced fuse blows again after a short time, the electrical sys-

tem must be checked by a specialised workshop as soon as possible.

● If you replace a fuse with higher-rating fuse, you could cause damage to

another location in the electrical system. ●

Always keep some spare fuses in the vehicle. These are available from

SEAT dealers.

● In addition to the fuses listed in the following tables, there are other

fuses which must be replaced by the Technical Service Workshop.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 269 of 313

267

If and when

NumberConsumerAmps48Convenience controls2049Heating controls4050Heated seats3051Sunroof2052Headlight washer system2053Trailer hook pre-installation assistant2054Taxi (taximeter power supply)555Trailer hook pre-installation assistant2056Taxi (transmitter power supply)1557Telephone power supply with START STOP1058Central locking control unit30

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

Please note that the above list, while correct at the time of printing, is sub-

ject to alterations. If discrepancies should occur, please refer to the sticker

on the inside of the fuse cover for the correct information for your model.

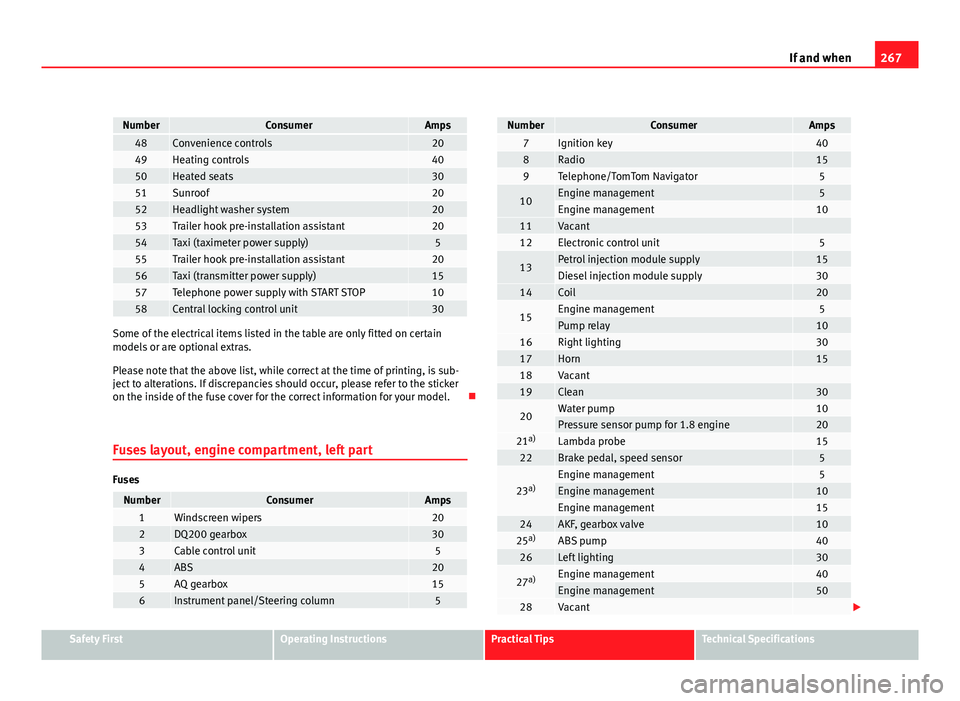

Fuses layout, engine compartment, left part

Fuses

NumberConsumerAmps1Windscreen wipers202DQ200 gearbox303Cable control unit54ABS205AQ gearbox156Instrument panel/Steering column5

NumberConsumerAmps7Ignition key408Radio159Telephone/TomTom Navigator5

10Engine management5Engine management1011Vacant 12Electronic control unit5

13Petrol injection module supply15Diesel injection module supply3014Coil20

15Engine management5Pump relay1016Right lighting3017Horn1518Vacant 19Clean30

20Water pump10Pressure sensor pump for 1.8 engine2021 a)Lambda probe1522Brake pedal, speed sensor5

23a)Engine management5Engine management10Engine management1524AKF, gearbox valve1025a)ABS pump4026Left lighting30

27a)Engine management40Engine management5028Vacant

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 271 of 313

269

If and when

Number plate light - C5W

Note

● Depending on weather conditions (cold or wet), the headlights, the fog

lights, the tail lights and the turn signals may be temporarily misted. This

has no influence on the useful life of the lighting system. By switching on

the lights, the area through which the beam of light is projected will quickly

be demisted. However, the edges may continue to be misted.

● Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the inter-

est of your own safety, but also that of all other road users.

● Due to the difficulty in accessing some of the bulbs, any replacement

work should be done by a SEAT dealer. However, the following is a descrip-

tion of how to change the lamps except for the fog lights* and interior

lamps.

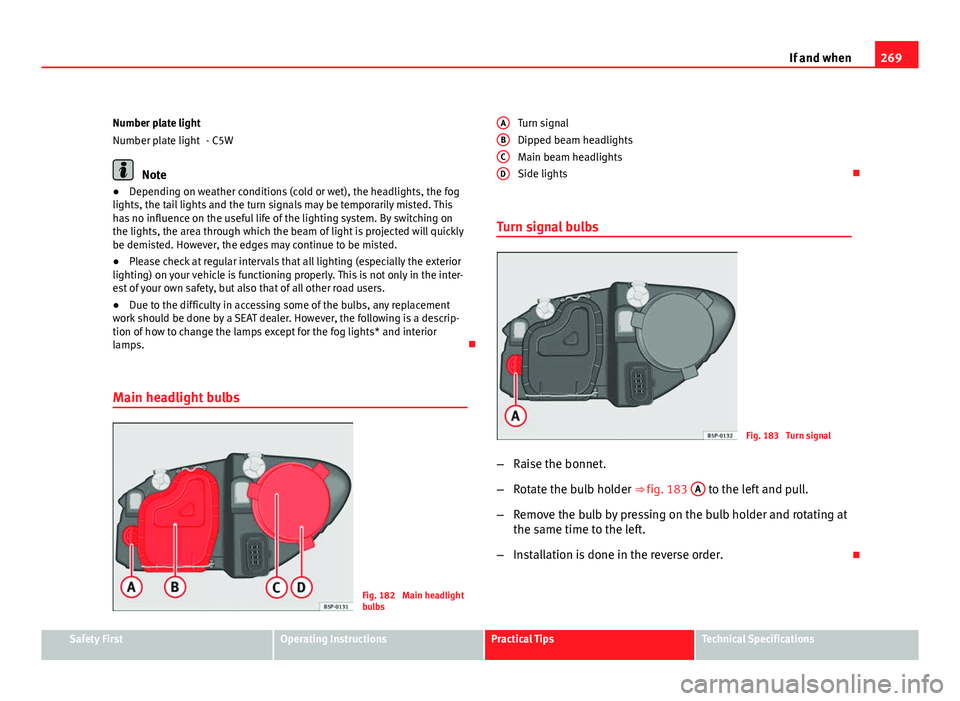

Main headlight bulbs

Fig. 182 Main headlight

bulbs

Number plate light

Turn signal

Dipped beam headlights

Main beam headlights

Side lights

Turn signal bulbs

Fig. 183 Turn signal

– Raise the bonnet.

– Rotate the bulb holder ⇒ fig. 183 A

to the left and pull.

– Remove the bulb by pressing on the bulb holder and rotating at

the same time to the left.

– Installation is done in the reverse order.

A

BCD

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 273 of 313

271

If and when

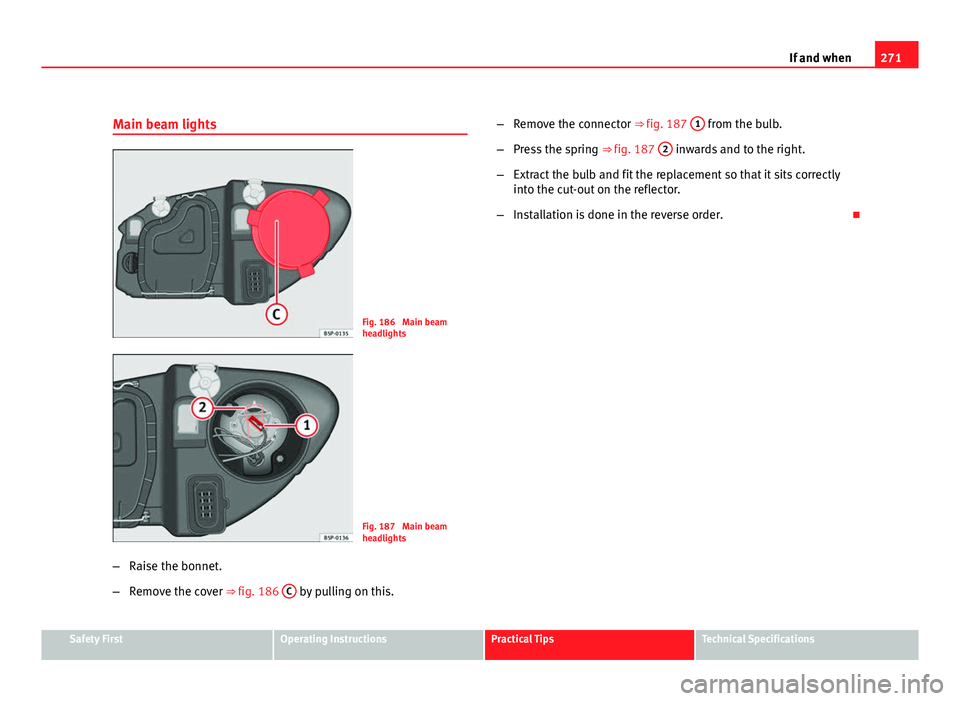

Main beam lights

Fig. 186 Main beam

headlights

Fig. 187 Main beam

headlights

– Raise the bonnet.

– Remove the cover ⇒ fig. 186 C

by pulling on this. –

Remove the connector ⇒ fig. 187 1

from the bulb.

– Press the spring ⇒ fig. 187 2

inwards and to the right.

– Extract the bulb and fit the replacement so that it sits correctly

into the cut-out on the reflector.

– Installation is done in the reverse order.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 275 of 313

273

If and when

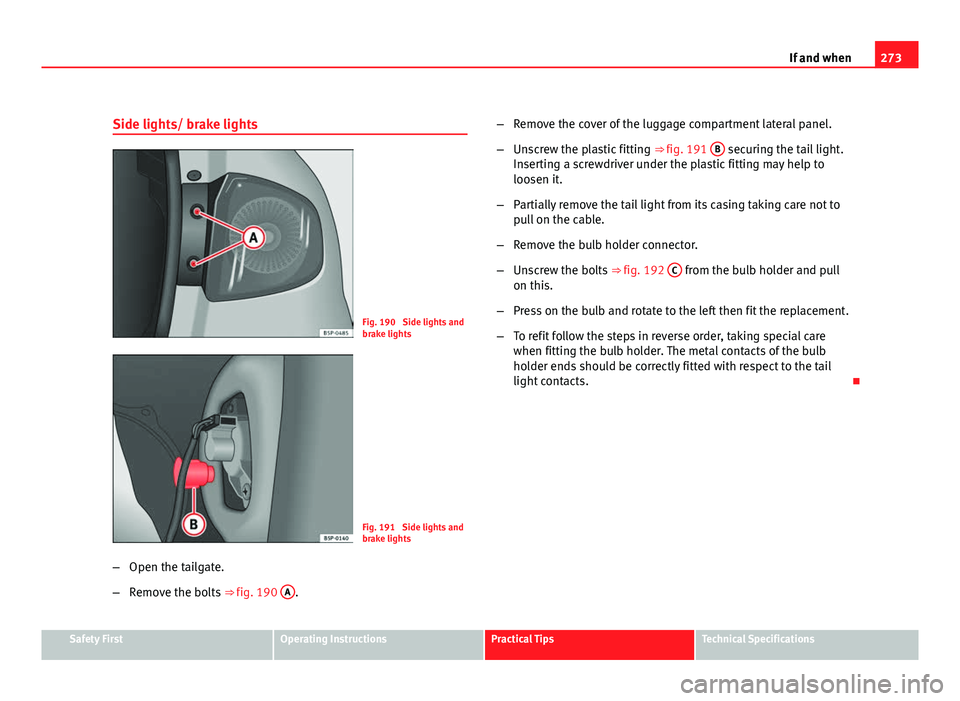

Side lights/ brake lights

Fig. 190 Side lights and

brake lights

Fig. 191 Side lights and

brake lights

– Open the tailgate.

– Remove the bolts ⇒ fig. 190 A

. –

Remove the cover of the luggage compartment lateral panel.

– Unscrew the plastic fitting ⇒ fig. 191 B

securing the tail light.

Inserting a screwdriver under the plastic fitting may help to

loosen it.

– Partially remove the tail light from its casing taking care not to

pull on the cable.

– Remove the bulb holder connector.

– Unscrew the bolts ⇒ fig. 192 C

from the bulb holder and pull

on this.

– Press on the bulb and rotate to the left then fit the replacement.

– To refit follow the steps in reverse order, taking special care

when fitting the bulb holder. The metal contacts of the bulb

holder ends should be correctly fitted with respect to the tail

light contacts.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 277 of 313

275

If and when

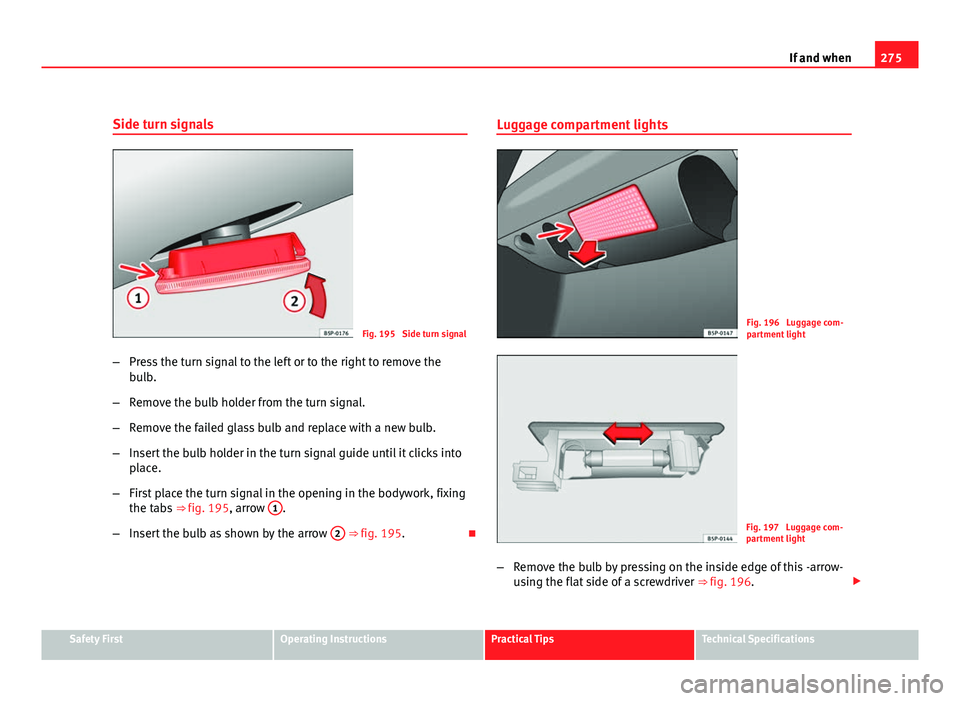

Side turn signals

Fig. 195 Side turn signal

– Press the turn signal to the left or to the right to remove the

bulb.

– Remove the bulb holder from the turn signal.

– Remove the failed glass bulb and replace with a new bulb.

– Insert the bulb holder in the turn signal guide until it clicks into

place.

– First place the turn signal in the opening in the bodywork, fixing

the tabs ⇒ fig. 195, arrow 1

.

– Insert the bulb as shown by the arrow 2

⇒ fig. 195.Luggage compartment lights

Fig. 196 Luggage com-

partment light

Fig. 197 Luggage com-

partment light

– Remove the bulb by pressing on the inside edge of this -arrow-

using the flat side of a screwdriver ⇒ fig. 196.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 279 of 313

277

If and when

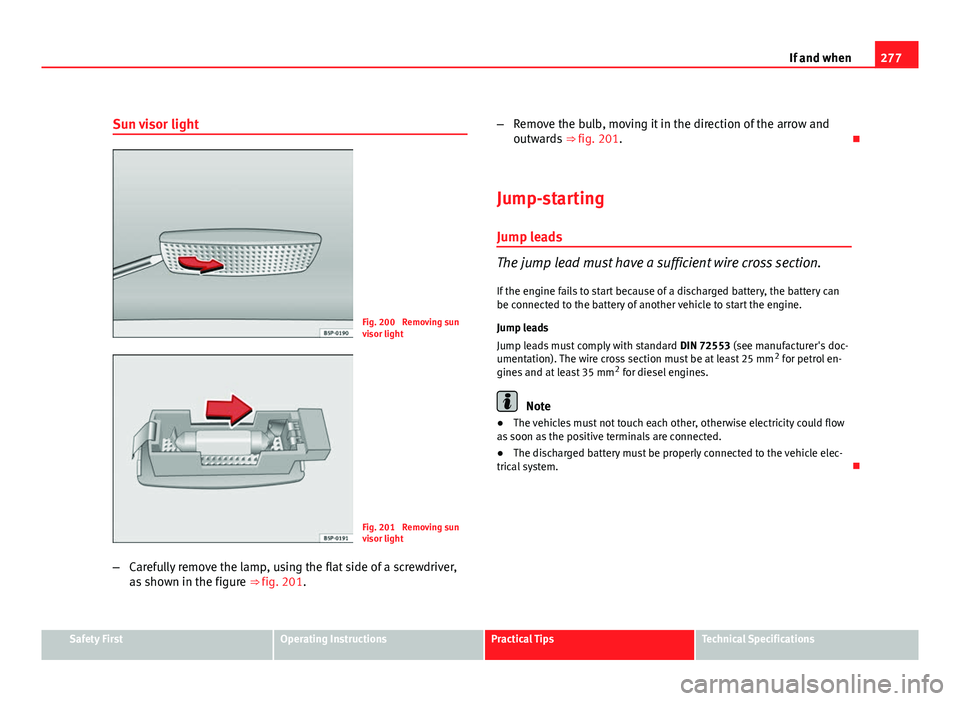

Sun visor light

Fig. 200 Removing sun

visor light

Fig. 201 Removing sun

visor light

– Carefully remove the lamp, using the flat side of a screwdriver,

as shown in the figure ⇒ fig. 201. –

Remove the bulb, moving it in the direction of the arrow and

outwards ⇒ fig. 201.

Jump-starting

Jump leads

The jump lead must have a sufficient wire cross section. If the engine fails to start because of a discharged battery, the battery can

be connected to the battery of another vehicle to start the engine.

Jump leads

Jump leads must comply with standard DIN 72553 (see manufacturer's doc-

umentation). The wire cross section must be at least 25 mm 2

for petrol en-

gines and at least 35 mm 2

for diesel engines.

Note

● The vehicles must not touch each other, otherwise electricity could flow

as soon as the positive terminals are connected.

● The discharged battery must be properly connected to the vehicle elec-

trical system.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 281 of 313

279

If and when

11. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

12. When the engine is running, disconnect the leads in reverse order to the details given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 230, Working in the engine compartment.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

WARNING (Continued)

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not bend over the batteries. This could result in chemical burns.

Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 283 of 313

281

If and when

Do not pull too hard with the towing vehicle and take care to avoid jerking

the tow-rope. When towing on an unpaved road, there is always a risk of

overloading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the turn signals,

horn, windscreen wipers and washers.

As the brake servo does not work if the engine is not running, you must ap-

ply considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running,

you will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

● Put the selector lever into position “N”.

● Do not drive faster than 50 km/h.

● Do not tow further than 50 km.

● If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.

Note

● Observe legal requirements when towing or tow-starting.

● Switch on the hazard warning lights of both vehicles. However, observe

any regulations to the contrary.

● For technical reasons, vehicles with an automatic gearbox must not be

tow-started.

● If damage to your vehicle means that there is no lubricant in the gear-

box, you must raise the drive wheels while the vehicle is being towed.

● If the vehicle has to be towed more than 50 km, the front wheels should

be raised during towing, and towing should be carried out by a qualified

person. ●

The steering wheel is locked when the vehicle has no electrical power.

The vehicle must then be towed with the front wheels raised. Towing should

be carried out by a qualified person.

● The towing eye should always be kept in the vehicle. Please refer to the

notes on ⇒ page 280, Tow-starting.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications