warning lights Seat Altea 2012 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Altea, Model: Seat Altea 2012Pages: 313, PDF Size: 4.47 MB

Page 181 of 313

179

Driving

Manual gearbox

Driving with a manual gearbox

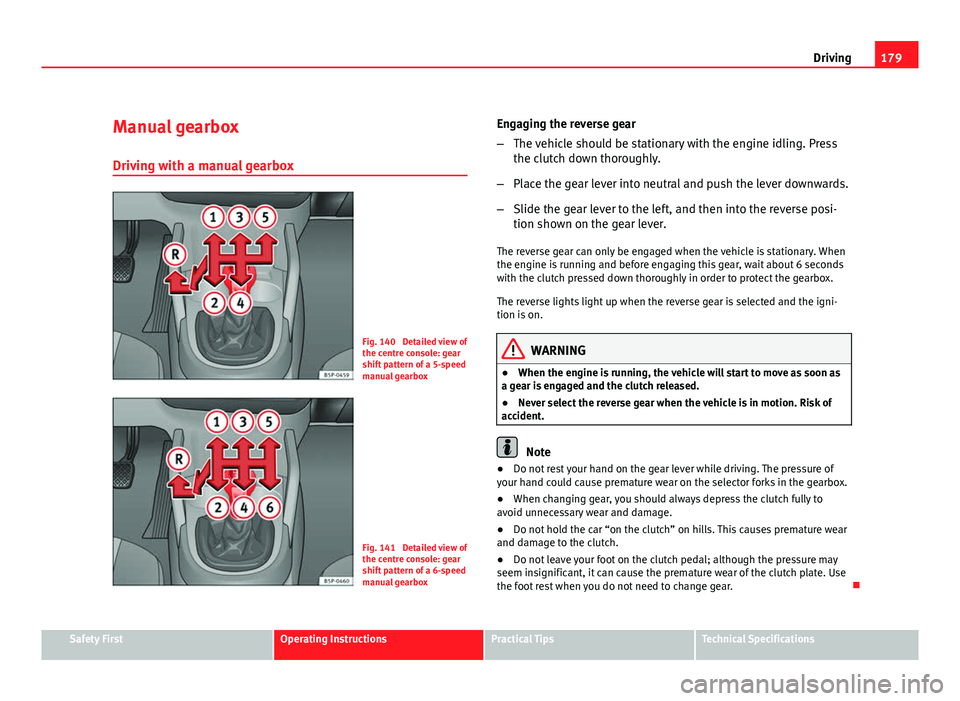

Fig. 140 Detailed view of

the centre console: gear

shift pattern of a 5-speed

manual gearbox

Fig. 141 Detailed view of

the centre console: gear

shift pattern of a 6-speed

manual gearbox Engaging the reverse gear

–

The vehicle should be stationary with the engine idling. Press

the clutch down thoroughly.

– Place the gear lever into neutral and push the lever downwards.

– Slide the gear lever to the left, and then into the reverse posi-

tion shown on the gear lever.

The reverse gear can only be engaged when the vehicle is stationary. When

the engine is running and before engaging this gear, wait about 6 seconds

with the clutch pressed down thoroughly in order to protect the gearbox.

The reverse lights light up when the reverse gear is selected and the igni-

tion is on.

WARNING

● When the engine is running, the vehicle will start to move as soon as

a gear is engaged and the clutch released.

● Never select the reverse gear when the vehicle is in motion. Risk of

accident.

Note

● Do not rest your hand on the gear lever while driving. The pressure of

your hand could cause premature wear on the selector forks in the gearbox.

● When changing gear, you should always depress the clutch fully to

avoid unnecessary wear and damage.

● Do not hold the car “on the clutch” on hills. This causes premature wear

and damage to the clutch.

● Do not leave your foot on the clutch pedal; although the pressure may

seem insignificant, it can cause the premature wear of the clutch plate. Use

the foot rest when you do not need to change gear.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 184 of 313

182Driving

–Press on the button on the selector lever knob (on the left,

⇒ fig. 145.

– Select a gear for driving ( R, D or S).

– Release the button and wait a few seconds for the gear to en-

gage, a light jerk will be felt.

– Release the brake and accelerate.

Short stop

– Hold the vehicle stationary with the brake pressed down (for ex-

ample at traffic lights). The selector lever does not need to be

put into the positions P or N for this.

– Do not press the accelerator.

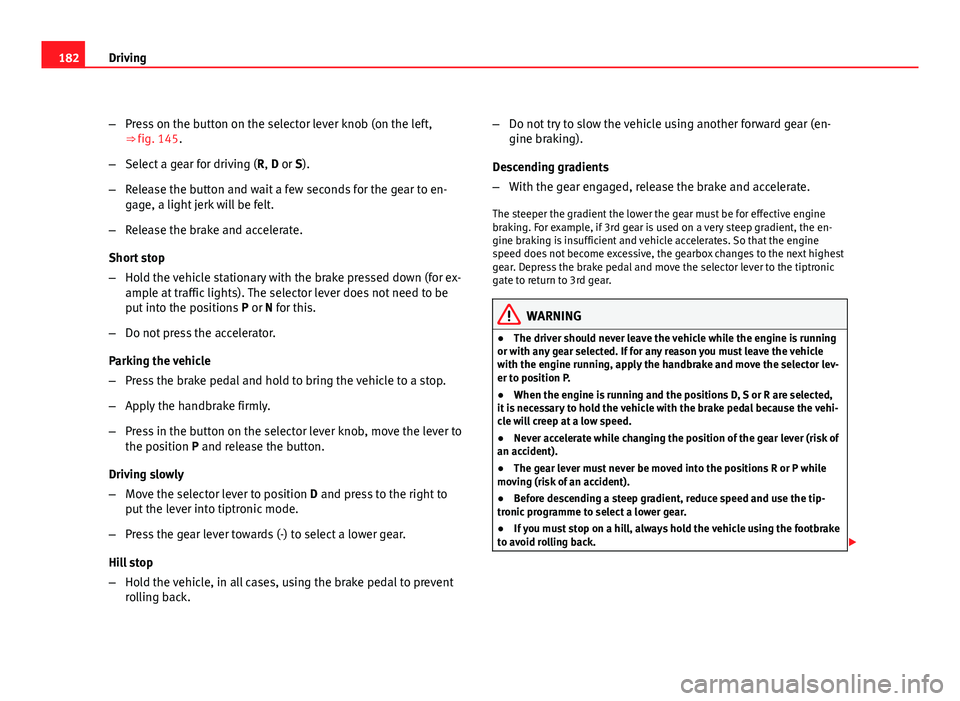

Parking the vehicle

– Press the brake pedal and hold to bring the vehicle to a stop.

– Apply the handbrake firmly.

– Press in the button on the selector lever knob, move the lever to

the position P and release the button.

Driving slowly

– Move the selector lever to position D and press to the right to

put the lever into tiptronic mode.

– Press the gear lever towards (-) to select a lower gear.

Hill stop

– Hold the vehicle, in all cases, using the brake pedal to prevent

rolling back. –

Do not try to slow the vehicle using another forward gear (en-

gine braking).

Descending gradients

– With the gear engaged, release the brake and accelerate.

The steeper the gradient the lower the gear must be for effective engine

braking. For example, if 3rd gear is used on a very steep gradient, the en-

gine braking is insufficient and vehicle accelerates. So that the engine

speed does not become excessive, the gearbox changes to the next highest

gear. Depress the brake pedal and move the selector lever to the tiptronic

gate to return to 3rd gear.

WARNING

● The driver should never leave the vehicle while the engine is running

or with any gear selected. If for any reason you must leave the vehicle

with the engine running, apply the handbrake and move the selector lev-

er to position P.

● When the engine is running and the positions D, S or R are selected,

it is necessary to hold the vehicle with the brake pedal because the vehi-

cle will creep at a low speed.

● Never accelerate while changing the position of the gear lever (risk of

an accident).

● The gear lever must never be moved into the positions R or P while

moving (risk of an accident).

● Before descending a steep gradient, reduce speed and use the tip-

tronic programme to select a lower gear.

● If you must stop on a hill, always hold the vehicle using the footbrake

to avoid rolling back.

Page 187 of 313

185

Driving

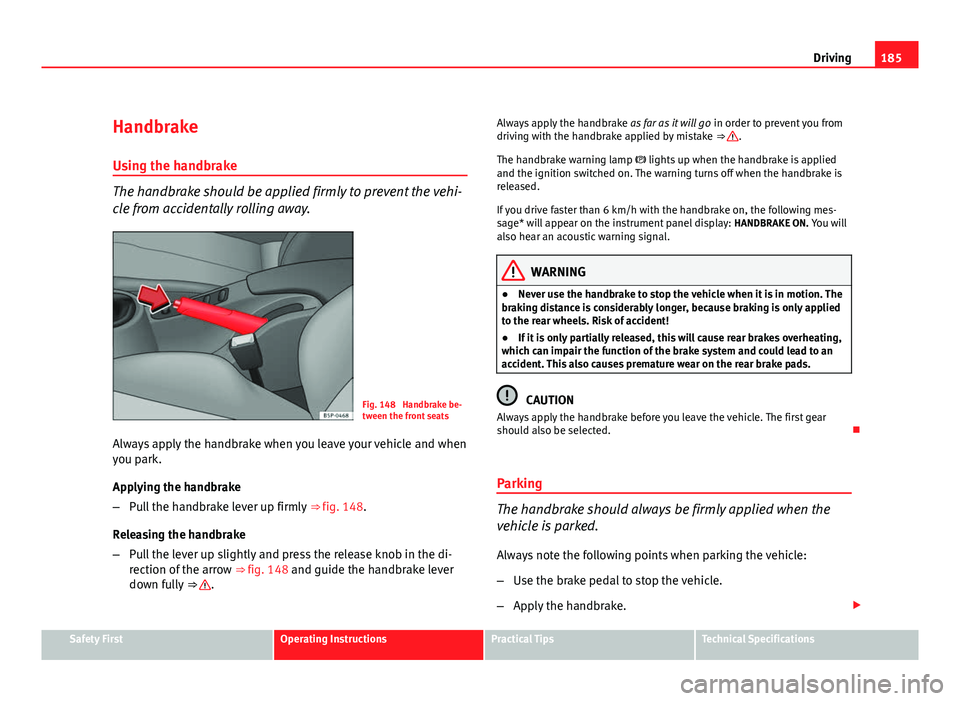

Handbrake Using the handbrake

The handbrake should be applied firmly to prevent the vehi-

cle from accidentally rolling away.

Fig. 148 Handbrake be-

tween the front seats

Always apply the handbrake when you leave your vehicle and when

you park.

Applying the handbrake

– Pull the handbrake lever up firmly ⇒ fig. 148.

Releasing the handbrake

– Pull the lever up slightly and press the release knob in the di-

rection of the arrow ⇒ fig. 148 and guide the handbrake lever

down fully ⇒

. Always apply the handbrake

as far as it will go in order to prevent you from

driving with the handbrake applied by mistake ⇒

.

The handbrake warning lamp lights up when the handbrake is applied

and the ignition switched on. The warning turns off when the handbrake is

released.

If you drive faster than 6 km/h with the handbrake on, the following mes-

sage* will appear on the instrument panel display: HANDBRAKE ON. You will

also hear an acoustic warning signal.

WARNING

● Never use the handbrake to stop the vehicle when it is in motion. The

braking distance is considerably longer, because braking is only applied

to the rear wheels. Risk of accident!

● If it is only partially released, this will cause rear brakes overheating,

which can impair the function of the brake system and could lead to an

accident. This also causes premature wear on the rear brake pads.

CAUTION

Always apply the handbrake before you leave the vehicle. The first gear

should also be selected.

Parking

The handbrake should always be firmly applied when the

vehicle is parked.

Always note the following points when parking the vehicle:

– Use the brake pedal to stop the vehicle.

– Apply the handbrake.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 196 of 313

194Intelligent technology

Practical Tips

Intelligent technology

Brakes Brake servo

The brake servo increases the pressure you apply to the brake pedal. It

works only when the engine is running .

If the brake servo is not functioning due to a malfunction, or if the vehicle

has to be towed, you will have to press the brake pedal considerably harder

to make up for the lack of servo assistance.

WARNING

The braking distance can also be affected by external factors.

● Never let the vehicle coast with the engine switched off. Failure to do

so could result in an accident. The braking distance is increased consid-

erably when the brake servo is not active.

● If the brake servo is not working, for example when the vehicle is be-

ing towed, you will have to press the brake pedal considerably harder

than normal.

Hydraulic Brake Assist (HBA)*

The Hydraulic Brake Assist function (HBA) is only included in

vehicles with ESC (ESP).

In an emergency, most drivers brake in time, but not with maximum force.

This results in unnecessarily long braking distances.

This is when the brake assist system comes into action. When pressing the

brake pedal rapidly, the assistant interprets it as an emergency. It then very

quickly builds up the full brake pressure so that the ABS can be activated

more quickly and efficiently, thus reducing the braking distance.

Do not reduce the pressure on the brake pedal. The brake assist system

switches off automatically as soon as you release the brake.

Emergency braking warning

If the vehicle is braked suddenly and continuously at a speed of more than

80 km/h, the brake light flashes several times per second to warn vehicles

driving behind. If you continue braking, the hazard warning lights will come

on automatically when the vehicle comes to a standstill. They switch off au-

tomatically when the vehicle starts to move again.

Page 198 of 313

196Intelligent technology

The ASR (TCS) is connected automatically when the engine starts. If neces-

sary, it may be turned on or off by briefly pushing the button on the centre

console.

When the ASR (TCS) is disconnected, the warning lamp OFF

lights up. The

TCS should normally be left on. Only in exceptional circumstances, when the

slipping of the wheels is required, it will be necessary to have it disconnec-

ted, for example.

● With compact temporary spare wheel.

● When using the snow chains.

● When driving in deep snow or on loose surfaces

● When the vehicle is bogged-down, to free it by rocking.

The TCS should be switched on again as soon as possible.

WARNING

● Remember that the ASR (TCS) cannot defy the laws of physics. This

should be kept in mind, particularly on slippery and wet roads and when

towing a trailer.

● Always adapt your driving style to suit the condition of the roads and

the traffic situation. Do not let the extra safety afforded by ASR (TCS)

tempt you into taking any risks when driving.

CAUTION

● To ensure that the ASR (TCS) functions correctly, all four wheels must be

fitted with the same tyres. Any differences in the rolling radius of the tyres

can cause the system to reduce engine power when this is not desired.

● Modifications to the vehicle (e.g. to the engine, the brake system, run-

ning gear or any components affecting the wheels and tyres) could affect

the efficiency of the ABS and ASR (TCS). XDS*

Driveshaft differential

When taking a bend, the driveshaft differential mechanism allows the outer

wheel to turn at a higher speed than the inner wheel. In this way, the wheel

that is turning faster (outer wheel) receives less drive torque than the inner

wheel. This may mean that in certain situations the torque delivered to the

inner wheel is too high, causing the wheels to spin. On the other hand, the

outer wheel is receiving a lower drive torque than it could transmit. This

causes an overall loss of lateral grip on the front axle, resulting in under-

steer or “lengthening” of the trajectory.

By using the ESC (ESP) sensors and signals, the XDS system is able to de-

tect and correct this effect.

Through the ESC (ESP), the XDS brakes the inner wheel, thereby counteract-

ing the excess drive torque in this wheel. This means that the driver's de-

sired trajectory is much more precise,

The XDS system operates in combination with the ESC (ESP) and is always

active, even when the traction control ASR (TCS) is disconnected.

Electronic Stability Control ESC (ESP) *

General notes

The Electronic Stability Control increases the vehicle's stabil-

ity on the road. The Electronic Stability Control helps reduce the danger of skidding.

The Electronic Stability Control ESC (ESP) includes the ABS, EDL, ASR (TCS)

and Steering manoeuvre recommendations.

Page 199 of 313

197

Intelligent technology

Electronic Stability Control ESC (ESP) *

The ESC (ESP) reduces the danger of skidding by braking the wheels indi-

vidually.

The system uses the steering wheel angle and road speed to calculate the

changes of direction desired by the driver, and constantly compares them

with the actual behaviour of the vehicle. If the desired course is not being

maintained (for instance, if the vehicle is starting to skid), then the ESC

(ESP) compensates automatically by braking the appropriate wheel.

The forces acting on the braked wheel bring the vehicle back to a stable

condition. If the vehicle tends to oversteer, the system will act on the front

wheel on the outside of the turn.

Steering manoeuvre recommendations

This is a complementary safety function included in the ESC (ESP). This

function aids the driver to better stabilize the vehicle in a critical situation.

For example, in case of sudden braking surface with varied adherence, the

vehicle will tend to destabilise its trajectory to the right or to the left. In this

case the ESC (ESP) recognises the situation and helps the driver with a

counter steering manoeuvre from the power steering.

This function simply provides the driver with a recommended manoeuvre in

critical situations.

The vehicle does not steer itself with this function, the driver has full control

of the vehicle at all times.

WARNING

● Remember that ESC (ESP) cannot defy the laws of physics. This

should be kept in mind, particularly on slippery and wet roads and when

towing a trailer.

● Always adapt your driving style to suit the condition of the roads and

the traffic situation. Do not let the extra safety afforded by ESC (ESP)

tempt you into taking any risks when driving.

CAUTION

● To ensure that the ESC (ESP) functions correctly, all four wheels must be

fitted with the same tyres. Any differences in the rolling radius of the tyres

can cause the system to reduce engine power when this is not desired.

● Modifications to the vehicle (e.g. to the engine, the brake system, run-

ning gear or any components affecting the wheels and tyres) could affect

the efficiency of the ABS, EDL, ESC (ESP) and ASR (TCS).

Anti-lock brake system (ABS)

The anti-lock brake system prevents the wheels locking during braking

⇒ page 195.

Electronic differential lock (EDL)*

The electronic differential lock helps prevent the loss of trac-

tion caused if one of the driven wheels starts spinning.

EDL helps the vehicle to start moving, accelerate and climb a gradient in

slippery conditions where this may otherwise be difficult or even impossi-

ble.

The system will control the revolutions of the drive wheels using the ABS

sensors (in case of an EDL fault the warning lamp for ABS lights up)

⇒ page 84.

At speeds of up to approximately 80 km/h, it is able to balance out differen-

ces in the speed of the driven wheels of approximately 100 rpm caused by a

slippery road surface on one side of the vehicle. It does this by braking the

wheel which has lost traction and distributing more driving force to the oth-

er driven wheel via the differential.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 241 of 313

239

Checking and refilling levels

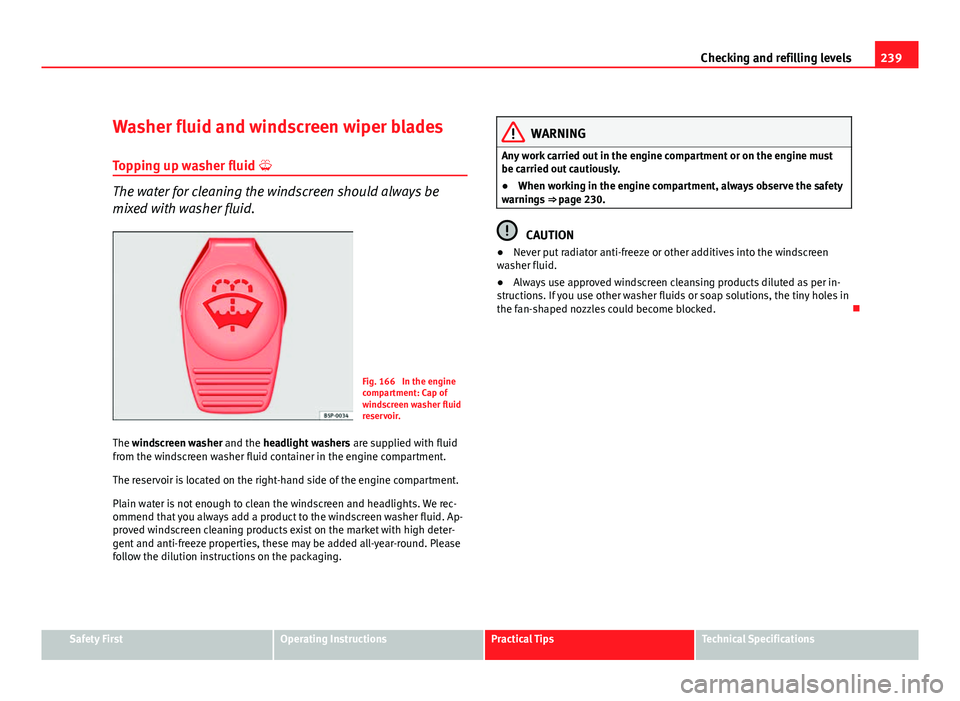

Washer fluid and windscreen wiper blades Topping up washer fluid

The water for cleaning the windscreen should always be

mixed with washer fluid.

Fig. 166 In the engine

compartment: Cap of

windscreen washer fluid

reservoir.

The windscreen washer and the headlight washers are supplied with fluid

from the windscreen washer fluid container in the engine compartment.

The reservoir is located on the right-hand side of the engine compartment.

Plain water is not enough to clean the windscreen and headlights. We rec-

ommend that you always add a product to the windscreen washer fluid. Ap-

proved windscreen cleaning products exist on the market with high deter-

gent and anti-freeze properties, these may be added all-year-round. Please

follow the dilution instructions on the packaging.

WARNING

Any work carried out in the engine compartment or on the engine must

be carried out cautiously.

● When working in the engine compartment, always observe the safety

warnings ⇒ page 230.

CAUTION

● Never put radiator anti-freeze or other additives into the windscreen

washer fluid.

● Always use approved windscreen cleansing products diluted as per in-

structions. If you use other washer fluids or soap solutions, the tiny holes in

the fan-shaped nozzles could become blocked.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 258 of 313

256If and when

How to use the temporary spare wheel

Should you ever have a punctured tyre, the temporary spare wheel is only

intended for temporary use until you can reach a workshop. The standard-

size road wheel should be replaced as soon as possible.

Please note the following restrictions when using the temporary spare

wheel. This spare wheel has been specially designed for your vehicle, thus,

it cannot be changed with the spare wheel from another vehicle.

No other type of tyre (normal summer or winter tyre) may be fitted on the

compact temporary spare wheel rim.

Snow chains

For technical reasons, snow chains must not be used on the compact tem-

porary spare wheel.

If you have a puncture on one of the front wheels when using snow chains,

fit the compact temporary spare in place of one of the rear wheels. You can

then attach the snow chains to the wheel taken from the rear and use this

wheel to replace the punctured front wheel.

WARNING

● The tyre pressures must be checked and corrected as soon as possi-

ble. The emergency tyre pressure for dimensions 125/70R16 125/70R18

135/90R16 is 4.2 bar; for all other tyre dimensions please refer to the la-

bel on the fuel cap. Failure to do so could result in an accident.

● Do not drive faster than 80 km/h. Higher speeds can cause an acci-

dent.

● Avoid heavy acceleration, hard braking and fast cornering. Risk of ac-

cident.

● Never use two or more compact spare tyres at the same time, risk of

accident.

● No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.

Tyre repair kit*

The tyre repair kit (for vehicles not including a spare wheel)

is stored under the floor panel in the luggage compartment.

Your vehicle is equipped with the Tyre Mobility System (tyre repair kit).

The tyre repair kit consists of a container with sealing compound to repair

the puncture and a compressor to generate the required tyre pressure. The

kit will reliably seal punctures up to a size of about 4 mm caused by the

penetration of a foreign body into the tyre.

Note

● Seek professional assistance if the repair of a tyre puncture is not possi-

ble with the sealing compound.

Wheel change Preparation work

What you must do before changing a wheel.

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Switch off the engine. Switch on the hazard warning lights.

– Apply the handbrake firmly.

Page 259 of 313

257

If and when

– Engage the first gear , or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

– Take the vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in posi-

tion. This is for your own safety and also warns other road users.

CAUTION

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.

Changing a wheel

Change the wheel as described below

– Remove the wheel cover . Also refer to ⇒ fig. 175

– Slacken the wheel bolts .

– Raise the vehicle with the jack at the corresponding area

– Remove the wheel and put on the spare one –

Lower the vehicle.

– Tighten the wheel bolts firmly with the box spanner

– Replace the hub cap.

After changing a wheel

After changing the wheel there are still tasks to complete. – Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart-

ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as pos-

sible.

– Have the tightening torque of the wheel bolts checked as soon

as possible with a torque wrench. The prescribed torque must

be 120 Nm.

Note

● If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt tor-

que checked.

● For safety reasons, drive at moderate speeds until the wheel bolt tight-

ening torque has been checked.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 265 of 313

263

If and when

Preparation work

Certain steps must be taken before repairing a tyre.

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

– Apply the handbrake firmly.

– Engage first gear , or put the selector lever to position P.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Check whether a repair is possible using the Tyre Mobility Sys-

tem “General information and safety notes.”

– Unscrew inflation cap from the affected wheel.

– Take the tyre repair kit out of the luggage compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in posi-

tion. This is for your own safety and also warns other road users.

CAUTION

Take special care if you have to repair a tyre on a slope.

Note

Please observe legal requirements when doing so. Tyre repair

The following sections describe the procedures for repairing

a tyre.

Using the sealing compound

– The instructions on the container give detailed information on

how to use the sealing compound.

Inflating the tyre.

– Remove the air compressor and hose from the container.

– Screw the retaining nut onto the valve.

– Plug the compressor cable into a 12 volt power point.

– Turn on compressor and monitor the pressure shown on the

pressure gauge.

Completing the repair

– Remove the compressor hose from the valve.

– Fit the valve cap.

– Unplug the compressor from the socket.

– Return all tools to their proper storing location.

Note

● If the vehicle is equipped with tyre pressure control, enter the new tyre

pressures using the SET button on the centre console.

● The compressor should never be allowed to run for longer than 6 mi-

nutes.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications