torque Seat Altea Freetrack 2009 Owner's Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2009, Model line: Altea Freetrack, Model: Seat Altea Freetrack 2009Pages: 291, PDF Size: 7.67 MB

Page 188 of 291

Intelligent technology187

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

The TCS should be switched on again afterwards as soon as possible.

WARNING

•

It must be remembered that TCS cannot defy the laws of physics. This

should be kept in mind, particularly on slippery and wet roads and when

towing a trailer.

•

Always adapt your driving style to suit the condition of the roads and

the traffic situation. Do not let the extra safety afforded by TCS tempt you

into taking any risks when driving, this can cause accidents.Caution

•

In order to ensure that TCS function correctly, all four wheels must be

fitted with the same tyres. Any differences in the rolling radius of the tyres can

cause the system to reduce engine power when this is not desired.

•

Modifications to the vehicle (e.g. to the engine, the brake system, running

gear or any components affecting the wheels and tyres) could affect the effi-

ciency of the ABS and TCS.

XDS*

Driveshaft differentialWhen taking a bend, the driveshaft differential mechanism allows the outer

wheel to turn at a higher speed than the inner wheel. In this way, the wheel

which is turning faster (outer wheel) receives less drive torque than the inner

wheel. This may mean that in certain situations the torque provided to the

inner wheel is too high, causing the wheels to spin. On the other hand, the

outer wheel receives a lower drive torque than it could transmit. This causes

an overall loss of lateral grip on the front shaft, resulting in understeering or

“lengthening” of the path. The XDS system is able, using the ESP sensors and signals, to detect and

correct this effect.

The XDS, via the ESP, brakes the inner wheel thus counteracting the excess

drive torque in this wheel. This means that the path requested by the driver

is more precise,

The XDS system operates in combination with the ESP and is always active,

even when the traction control, TCS, is disconnected.

Electronic stabilisation programme (ESP)*General notes

The electronic stabilisation programme increases the

vehicle's stability on the road.The electronic stabilisation programme helps to reduce the danger of skid-

ding.

The electronic stabilisation programme (ESP) consists of

ABS, EDL, TCS and

Steering manoeuvre recommendations.

Electronic Stabilising Program (ESP)*

ESP reduces the danger of skidding by braking the wheels individually.

The system uses the steering wheel angle and road speed to calculate the

changes of direction desired by the driver, and constantly compares them

with the actual behaviour of the vehicle. If the desired course is not being

maintained (for instance, if the car is starting to skid), then the ESP compen-

sates automatically by braking the appropriate wheel.

The forces acting on the braked wheel bring the vehicle back to a stable

condition. If the vehicle tends to oversteer, the system will act on the front

wheel on the outside of the turn.

altea_freetrack_ingles.book Seite 187 Montag, 16. Februar 2009 10:48 10

Page 201 of 291

Trailer towing

200If a towing bracket is to be fitted after the vehicle is purchased, this must be

completed according to the instructions of the towing bracket manufacturer.

The attachment points for the towing bracket are on the lower part of the

vehicle.

The distance between the centre of the ball coupling and the ground should

never be lower than the indicated value, even with a fully loaded vehicle and

including the maximum resting weight.

Elevation values for securing the towing bracket:

65 mm (minimum)

350 mm to 420 mm (fully laden vehicle)

344 mm

531 mm

1,044 mm

1,040 mm

Fitting a towing bracket•

Driving with a trailer involves an extra effort for the vehicle. Therefore,

before fitting a towing bracket, please contact an Authorised Service Centre

to check whether your cooling system needs modification.

•

Submit to the legal requirements in your country (e.g. the fitting of a sepa-

rate warning lamp).

•

Certain vehicle components, e.g. the rear bumper, must be removed and

reinstalled. The towing bracket securing bolts must be tightened using a

torque wrench, and an electrical socket must be connected to the vehicle's

electrical system. The above-mentioned require specialized knowledge and

tools.

•

Figures in the illustration show the elevation value and the attachment

points which must be considered if you are retrofitting a towing bracket.

WARNING

Towing brackets should be fitted by specialists.

•

If the towing bracket is incorrectly installed, there is serious danger of

accident.

•

For your own safety, please observe the instructions provided by the

manufacturer of the towing bracket.Caution

•

If the electrical socket is incorrectly installed, this could cause damage to

the vehicle's electrical system.

AA

ABACADAEAFAG

WARNING (continued)

altea_freetrack_ingles.book Seite 200 Montag, 16. Februar 2009 10:48 10

Page 239 of 291

Wheels and tyres

238wheels or tyres which have not been approved by SEAT for use with your

model may invalidate the vehicle's type approval for use on public roads.•

If the spare tyre is not the same as the tyres that are mounted on the

vehicle - for example with winter tyres - you should only use the spare tyre for

a short period of time and drive with extra care. Refit the normal road wheel

as soon as possible.

Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you may not use wheel bolts from a different car -

even if it is the same model ⇒page 210.

After the wheels have been changed, the tightening torque of the wheel bolts

should be checked as soon as possible with a torque wrench ⇒. The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•

The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.

•

Use only wheel bolts which belong to the wheel.

•

If the torque of the wheel bolts is too low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.

Caution

The prescribed torque for wheel bolts for steel and alloy wheels is 120 Nm.Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.In winter conditions winter tyres will considerably improve the vehicles

handling. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pressures

specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's regis-

tration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

Winter tyres lose their effectiveness when the tread is worn down to a depth

of 4 mm.

The speed rating code ⇒ page 237, “New tyres and wheels” determines the

following speed limits for winter tyres: ⇒

Q max. 160 km/h

S max. 180 km/h

T max. 190 km/h

H max. 210 km/h

In some countries, vehicles which can exceed the speed rating of the fitted

tyre must have an appropriate sticker in the driver's field of view. These

altea_freetrack_ingles.book Seite 238 Montag, 16. Februar 2009 10:48 10

Page 241 of 291

If and when

240If and whenTools, tyre repair kit and spare wheelVehicle Tools

The vehicle onboard tools are located under the floor panel in

the luggage compartment.– Lift the cover of the luggage compartment, by pulling it up with a

finger in the fitting.

– Take the onboard tools out of the vehicle.The tool kit includes:•

Jack*

•

Hook for removing wheel covers* or hub caps*

•

Box spanner for wheel bolts*

•

Reversible screwdriver with handle (including hexagonal interior) for the

wheel bolts. The screwdriver is a combination tool.

•

Towing eye

•

Adapter for the anti-theft wheel bolts*

Some of the items listed are only provided in certain models / model years,

or are optional extras.

WARNING

•

Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts as with this it is not possible to tighten the bolts to the

required torque. Risk of accident.

•

The jack* supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads. Risk of injury.

•

Use the jack* only on firm, level ground.

•

Never start the engine when the vehicle is on the jack. Risk of accident.

•

I f wor k is to be ca r rie d out un de r n ea th the v e hicle , t his mu st b e sec ured

by suitable stands. Otherwise, there is a risk of injury.WARNING (continued)

altea_freetrack_ingles.book Seite 240 Montag, 16. Februar 2009 10:48 10

Page 244 of 291

If and when243

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

After changing a wheel

After changing the wheel there are still tasks to complete.– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart-

ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as possible.

– Have the tightening torque of the wheel bolts checked as soon as possible with a torque wrench. The prescribed torque must be

120 Nm.

Note•

If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt torque

checked.

•

For your safety, drive at moderate speeds until the wheel bolt torque has

been checked.

Wheel trims

The wheel trims must be removed to gain access to the wheel

bolts.Removing

– Insert the extraction hook from the tools into the designated

ring, located in one of the bolt hole covers of the wheel cover

⇒ fig. 170 .

– Pull off the hub cap.

Fig. 170 Changing the

wheel: Removing a hub

cap

altea_freetrack_ingles.book Seite 243 Montag, 16. Februar 2009 10:48 10

Page 272 of 291

General notes on the technical data271

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

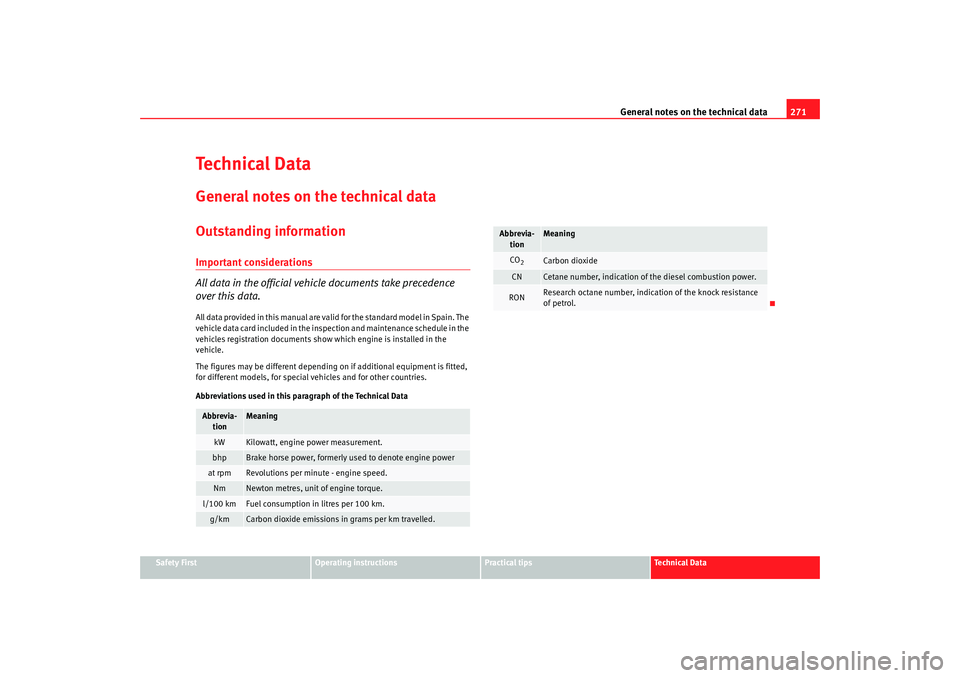

Technical DataGeneral notes on the technical dataOutstanding informationImportant considerations

All data in the official vehicle documents take precedence

over this data.A l l d a t a p r o v i d e d i n t h i s m a n u a l a r e v a l i d f o r t h e s t a n d a r d m o d e l i n S p a i n . T h e

vehicle data card included in the inspection and maintenance schedule in the

vehicles registration documents show which engine is installed in the

vehicle.

The figures may be different depending on if additional equipment is fitted,

for different models, for special vehicles and for other countries.

Abbreviations used in this paragraph of the Technical DataAbbrevia-

tion

Meaning

kW

Kilowatt, engine power measurement.

bhp

Brake horse power, formerly used to denote engine power

at rpm

Revolutions per minute - engine speed.

Nm

Newton metres, unit of engine torque.

l/100 km

Fuel consumption in litres per 100 km.

g/km

Carbon dioxide emissions in grams per km travelled.

CO2

Carbon dioxide

CN

Cetane number, indication of the diesel combustion power.

RON

Research octane number, indication of the knock resistance

of petrol.

Abbrevia-

tion

Meaning

altea_freetrack_ingles.book Seite 271 Montag, 16. Februar 2009 10:48 10

Page 277 of 291

Technical Data

276Diesel engine 2.0l 103 kW (140 bhp). Front-wheel driveGeneral engine data

Performance figures

Weights

Trailer weigh ts Power output in kW (HP)

rpm 103 (140)/ 4000

Maximum torque in Nm at rpm 320/ 1750 - 2500

No. of cylinders, capacity in cm

3

4/ 1968

Compression 18,5 ± 0,5

Fuel Min. 51 CZ

Maximum speed in km/h 196

Acceleration from 0-80 km/h in sec. 7,1

Acceleration from 0-100 km/h in sec. 10,2

Gross vehicle weight in kg 2124

Weight in working order (with driver) in kg 1579

Front gross axle weight in kg 1096

Rear gross axle weight in kg 1041

Permitted roof load in kg 75

Trailer without brakes 750

Trailer with brakes, gradients up to 8% 1650

Trailer with brakes, gradients up to 12% 1400

altea_freetrack_ingles.book Seite 276 Montag, 16. Februar 2009 10:48 10

Page 278 of 291

Technical Data277

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Engine oil capacity

Diesel engine 2.0l 125 kW (170 bhp). four-wheel driveGeneral engine data

Performance figures

Weights

Approximate engine oil capacity with oil filter change

4.5 litres

General engine data

Power output in kW (bhp) rpm 125 (170)/ 4200

Maximum torque in Nm at rpm 350/1750-2500

No. of cylinders, capacity in cm

3

4/ 1968

Compression 18,5 ± 0,5

Fuel Min. 51 CZ

Maximum speed in km/h 204

Acceleration from 0-80 km/h in sec. 5,9

Acceleration from 0-100 km/h in sec. 8,7

Gross vehicle weight in kg 2160

Weight in working order (with driver) in kg 1615

Front gross axle weight in kg 1115

Rear gross axle weight in kg 1086

Permitted roof load in kg 75

altea_freetrack_ingles.book Seite 277 Montag, 16. Februar 2009 10:48 10

Page 289 of 291

Index

288TCS (Traction control system)

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 84

Technical modifications . . . . . . . . . . . . . . . . . . 210

The danger of not using the seat belt . . . . . . . . 22

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Towing a trailer . . . . . . . . . . . . . . . . . . . . . . . . . 274

Towing bracket . . . . . . . . . . . . . . . . . . . . . . . . . 198

Towing bracket, fitting . . . . . . . . . . . . . . . . . . . 199

Towing eye . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Tow-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Traction control system warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 84

Trailer Trailer towing . . . . . . . . . . . . . . . . . . . . . . . . 197

Trailer eyes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Trailer turn signals Warning lamp . . . . . . . . . . . . . . . . . . . . . . . 118

Trailer weights . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Trips, checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Turn signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118 Warning lamp . . . . . . . . . . . . . . . . . . . . 78, 118

Turning light . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Tyre Mobility-System (Tyre repair kit) . . . . . . . 241

Tyre monitor indicator . . . . . . . . . . . . . . . . . . . . . 80

Tyre pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 232 Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Tyre pressure monitoring . . . . . . . . . . . . . . . . . 233

Tyre repair kit . . . . . . . . . . . . . . . . . . . . . . . 241, 249 Tyre-Mobility-System (Tyre repair kit) . . . . . . . 249

Tyres and wheels

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 237

Tyres service life . . . . . . . . . . . . . . . . . . . . . . . . 234

Tyres tread depth . . . . . . . . . . . . . . . . . . . . . . . 235

Tyres with directional tread pattern . . . . . . . . . 232

UUnderbody maintenance . . . . . . . . . . . . . . . . . 207

Unlocking and locking Personalisation . . . . . . . . . . . . . . . . . . . . . . . 96

Using the Tiptronic gear system . . . . . . . . . . . 175VVehicle battery . . . . . . . . . . . . . . . . . . . . . . . . . 229

Vehicle data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Vehicle identification data . . . . . . . . . . . . . . . . 272

Vehicle identification number . . . . . . . . . . . . . 272

Vehicle Maintenance Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Vehicle modifications . . . . . . . . . . . . . . . . . . . . 210

Vehicle paintwork Products for vehicle maintenance . . . . . . . 201

Waxing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Vehicle tools Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Vehicle wallet storage . . . . . . . . . . . . . . . . . . . 137

Vehicle washing . . . . . . . . . . . . . . . . . . . . . . . . 202

Ventilation slits . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Volumetric sensor*

Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Deactivation . . . . . . . . . . . . . . . . . . . . . . . . 102

WWarning lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Warning lamps . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Warning reports

Red . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Warning texts in the display . . . . . . . . . . . . . . . . 64

Warning triangle and first-aid kit . . . . . . . . . . . 149

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Washing by hand . . . . . . . . . . . . . . . . . . . . . . . 202

Washing with high pressure cleaners . . . . . . . 203

Water warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Water in the windscreen washer tank . . . . . . . 224

Wear indicators . . . . . . . . . . . . . . . . . . . . . . . . . 235

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244 Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Wheel change . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Wheel trims . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Why assume the correct sitting position? . . . . . 30

Why should head restraints be correctly adjusted? 13

Why wear seat belts? . . . . . . . . . . . . . . . . . . 21, 30

Why wear seatbelts? . . . . . . . . . . . . . . . . . . . . . . 19

altea_freetrack_ingles.book Seite 288 Montag, 16. Februar 2009 10:48 10