ECU Seat Altea Freetrack 2010 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2010, Model line: Altea Freetrack, Model: Seat Altea Freetrack 2010Pages: 294, PDF Size: 7.71 MB

Page 197 of 294

Trailer towing195

Safety First

Controls and equipment

Practical tips

Technical Data

Trailer towingInstructions to followYour vehicle may be used to tow a trailer when fitted with the correct equip-

ment.

If the car is supplied with a factory-fitted towing bracket it will already have

the necessary technical modifications and meet the statutory requirements

for towing a trailer. For the after-market fitting of a trailer towing bracket see

⇒ page 197.

Connectors

Your vehicle is fitted with a 12-pin connector for the electrical connection

between the trailer and the vehicle.

If the trailer has a 7-pin plug you will need to use an adapter cable. This is

available in any SEAT dealer.

Trailer weight / draw bar loading

Never exceed the authorised towing limit. If you do not load the trailer up to

the maximum permitted trailer weight, you can then climb correspondingly

steeper slopes.

The maximum trailer weights listed are only applicable for altitudes up to

1,000 m above sea level. With increasing altitude the engine power and

therefore the vehicle's climbing ability are impaired because of the reduced

air density. The maximum trailer weight has to be reduced accordingly. The

weight of the vehicle and trailer combination must be reduced by 10% for

every further 1,000 m (or part thereof). The gross combination weight is the

actual weight of the laden vehicle plus the actual weight of the laden trailer.

When possible, operate the trailer with the maximum permitted draw bar

weight on the ball joint of the towing bracket, but do not exceed the specified

limit. The figures for

trailer weights and draw bar weights that are given on the

data plate of the towing bracket are for certification purposes only. The

correct figures for your specific model, which may be lower than these figures

for the towing bracket, are given in the registration documents ⇒Section

“Technical data”.

Distributing the load

Distribute loads in the trailer so that heavy objects are as near to the axle as

possible. Loads carried in the trailer must be secured to prevent them

moving.

Tyre pressure

Set tyre pressure to the maximum permissible pressure shown on the sticker

on the inside of the fuel tank flap. Set the tyre pressure of the trailer tyres in

accordance with the trailer manufacturer's recommendations.

Exterior mirrors

Check whether you can see enough of the road behind the trailer with the

standard mirrors. If this is not the case, you should have additional mirrors

fitted. Both exterior mirrors should be mounted on hinged extension

brackets. Adjust the mirrors to give sufficient vision to the rear.

WARNING

Never transport people in a trailer. This could result in fatal accidents.

Note

•Towing a trailer places additional demands on the vehicle. We recom-

mend additional services between the normal inspection intervals if the

vehicle is used frequently for towing a trailer.

Freetrack_EN.book Seite 195 Donnerstag, 10. September 2009 10:33 10

Page 198 of 294

Trailer towing

196•Find out whether special regulations apply to towing a trailer in your

country.Ball coupling of towing bracket*Depending on the model version, the spherical head on the trailer hook may

be stored in the tool box.

The ball coupling is provided with instructions on fitting and removing the

ball coupling of the towing bracket.

WARNING

The towing bracket ball coupling must be stored securely in the luggage

compartment to prevent them being flung through the vehicle and causing

injury.

Note

•By law, the ball coupling must be re moved if a trailer is not being towed

and it obscures the number plate.Driving tipsDriving with a trailer always requires extra care.Weight distribution

The weight distribution of a loaded trailer with an unladen vehicle is very

unfavourable. However, if this cannot be avoided, drive extra slowly to allow

for the unbalanced weight distribution. Speed

The stability of the vehicle and trailer is reduced with increasing speed. For

this reason, it is advisable not to drive at the maximum permissible speed in

an unfavourable road, weather or wind conditions. This applies especially

when driving downhill.

You should always reduce speed immediately if the trailer shows the slightest

sign of

snaking . Never try to stop the “snaking” by increasing speed.

Always brake in due course. If the trailer has an overrun brake, apply the

brakes gently at first and then, firmly. This will prevent the jerking that can be

caused by the trailer wheels locking. Select a low gear in due course before

going down a steep downhill. This enables you to use the engine braking to

slow down the vehicle.

Reheating

At very high temperatures and during prolonged ascents, driving in a low gear

and high engine speed, always monitor the temperature indicator for the

coolant ⇒page 55.

Electronic Stabilisation Program*

The ESP* system makes it easier to stabilise the trailer in case it skids or

swings.

Freetrack_EN.book Seite 196 Donnerstag, 10. September 2009 10:33 10

Page 200 of 294

Trailer towing

198If a towing bracket is to be fitted after the vehicle is purchased, this must be

completed according to the instructions of the towing bracket manufacturer.

The attachment points for the towing bracket are on the lower part of the

vehicle.

The distance between the centre of the ball coupling and the ground should

never be lower than the indicated value, even with a fully loaded vehicle and

including the maximum resting weight.

Elevation values for securing the towing bracket:

65 mm (minimum)

350 mm to 420 mm (fully laden vehicle)

344 mm

531 mm

1,044 mm

1,040 mm

Fitting a towing bracket•Driving with a trailer involves an extra effort for the vehicle. Therefore,

before fitting a towing bracket, please contact an Authorised Service Centre

to check whether your cooling system needs modification.•Submit to the legal requirements in your country (e.g. the fitting of a sepa-

rate warning lamp).•Certain vehicle components, e.g. the rear bumper, must be removed and

reinstalled. The towing bracket securing bolts must be tightened using a

torque wrench, and an electrical socket must be connected to the vehicle's

electrical system. The above-mentioned require specialized knowledge and

tools.•Figures in the illustration show the elevation value and the attachment

points which must be considered if you are retrofitting a towing bracket.WARNING

Towing brackets should be fitted by specialists.

•If the towing bracket is incorrectly installed, there is serious danger of

accident.•For your own safety, please observe the instructions provided by the

manufacturer of the towing bracket.Caution

•If the electrical socket is incorrectly installed, this could cause damage to

the vehicle's electrical system.

AA

ABACADAEAFAG

WARNING (continued)

Freetrack_EN.book Seite 198 Donnerstag, 10. September 2009 10:33 10

Page 212 of 294

Checking and refilling levels

210Checking and refilling levelsRefuellingThe tank flap is released manually. The tank holds approxi-

mately 55 litres. For four-wheel drive vehicles, the tank

capacity is approximately 60 litres.Unscrewing the tank cap

– Lift the lid.

– Grip the cap and then insert the key into the lock and rotate 180°

to the left.

– Unscrew the cap, turning it anti-clockwise. Closing the tank cap

– Screw the tank cap to the right, until the point of feeling a “click”.

– Turn the key in the lock, without unscrewing the cap, clockwise

through 180°.

– Remove the key and close the flap until it clicks into place. The tank cap is secured with an anti-loss attachment

The tank flap is at the rear of the vehicle on the right.

If the automatic filler nozzle is operated correctly, it will switch itself off as

soon as the tank is “full”. Never attempt to fill beyond this point, as this will

fill the expansion chamber. Fuel may leak out if ambient conditions are warm.

T he co rr ec t fu el g rad e fo r you r v eh icle is giv en on a sti cker o n th e i nsid e of the

fuel tank flap. Further notes on fuel can be found.

WARNING

•Fuel is highly inflammable and can cause serious burns and other inju-

ries.

−Never smoke or use any naked flame when filling the fuel tank of the

vehicle, or a spare fuel canister, with fuel. This is an explosion hazard.

− Follow legal requirements for the use of spare fuel canisters.

− For safety reasons we do not recommend carrying a spare fuel

canister in the vehicle. The canister could be damaged in an accident

and leak.•If, in exceptional circumstances, you have to carry a spare fuel canister,

please observe the following points:

Fig. 154 Tank flap open

Freetrack_EN.book Seite 210 Donnerstag, 10. September 2009 10:33 10

Page 216 of 294

Checking and refilling levels

214

WARNING

All work on the engine or in the engine compartment, e.g. checking and

refilling fluids, involves the danger of injury and scalding as well as the risk

of accident or fire.•Never open the bonnet if you see steam, smoke or coolant escaping

from the engine compartment. Otherwise, there is a risk of sustaining

burns. Wait until no more steam or coolant is emitted, then allow the

engine to cool before carefully opening the bonnet.•Switch off the engine and remove the key from the ignition.•Apply the handbrake and move the gear stick to neutral or selector

lever to position P.•Keep children away from the vehicle.•Never touch hot engine parts. There is a risk of burns.•Never spill liquids on a hot engine or on a hot exhaust gas system. This

is a fire hazard.•Avoid causing short-circuits in the electrical system, particularly at the

points where the jump leads are attached ⇒page 263. The battery could

explode.•Never touch the radiator fan. It is temperature controlled and could

start automatically, even when the engine has been switched off and the

key removed from the ignition!•Do not unscrew the cap on the expansion tank when the engine is hot.

If the coolant is hot, the cooling system will be pressurised!•Protect face, hands and arms by covering the cap with a large, thick

cloth to protect against escaping coolant and steam.•Al wa ys m ake s u re yo u ha ve n o t l e f t a ny o bj e c t s , s u ch as cl e an i n g cl o t h s

and tools, in the engine compartment.•If you have to work underneath the vehicle, you must use suitable

stands additionally to support the vehicle, there is a risk of accident!. A

hydraulic jack is insufficient for securing the vehicle and there is a risk of

injury.

•If any work has to be performed when the engine is started or with the

engine running, there is an additional, potentially fatal, safety risk from the

rotating parts, such as the drive belts, alternator, radiator fan, etc., and

from the high-voltage ignition system. You should also observe the

following points:

−Never touch the electrical wiring of the ignition system.

− Ensure that jewellery, loose clothing and long hair do not get

trapped in rotating engine parts. Danger of death. Before starting any

work remove jewellery, tie back and cover hair, and wear tight-fitting

clothes.

− Always think carefully about pressing the accelerator if a gear is

engaged in either an automatic or manual gearbox. The vehicle could

move, even if the handbrake is applied. Danger of death.•If work has to be carried out on the fuel system or on electrical compo-

nents, you must observe the following safety notes in addition to the above

warnings:

−Always disconnect the battery. The vehicle must be unlocked when

this is done, otherwise the alarm will be triggered.

− Do not smoke.

− Never work near naked flames.

− Always have a fire extinguisher on hand.Caution

When changing or topping up service fluids, make absolutely certain that you

fill the fluids into the correct reservoirs. Failure to observe this point will result

in serious malfunctions and engine damage!

WARNING (continued)

Freetrack_EN.book Seite 214 Donnerstag, 10. September 2009 10:33 10

Page 217 of 294

Checking and refilling levels215

Safety First

Controls and equipment

Practical tips

Technical Data

For the sake of the environment

Service fluids leaks are harmful to the environment. For this reason you

should make regular checks on the ground underneath your vehicle. If you

find spots of oil or other fluids, have your vehicle inspected in a qualified

workshop.Opening the bonnet

The bonnet is released from inside the vehicle.

Before opening the bonnet ensure that the windscreen wipers are in

rest position.

– To release the bonnet, pull the lever under the dashboard

⇒fig. 155 in the direction indicated (arrow). The bonnet will be

released by a spring action ⇒.

– Lift the bonnet using the release lever (arrow) and open the bonnet.

– Release the bonnet stay and secure it in fixture designed for this

in the bonnet.

WARNING

Hot coolant can scald!•Never open the bonnet if you see steam, smoke or coolant escaping

from the engine compartment.

Fig. 155 Detail of foot-

well area on driver's side:

lever for unlocking the

bonnet.

Fig. 156 Arrester hook

for bonnet.

Freetrack_EN.book Seite 215 Donnerstag, 10. September 2009 10:33 10

Page 218 of 294

Checking and refilling levels

216•Wait until no more steam, smoke or coolant is emitted from the bonnet,

then carefully open the bonnet.•When working in the engine compartment, always observe the safety

warnings ⇒page 213.

Closing the bonnet– Raise the bonnet slightly

– Release the bonnet stay and replace it in its support.

– At a height of about 30 cm let it fall so it is locked.If the b onn et d o es n ot clos e , do not p ress d ownwa rds . Op e n it o nce m or e an d

let it fall as before.

WARNING

If the bonnet is not closed properly, it could open while you are driving and

completely obscure your view of the road. Risk of accident.•After closing the bonnet, always check that it is properly secured. The

bonnet must be flush with the surrounding body panels.•If you notice that the bonnet latch is not secured when the vehicle is

moving, stop the vehicle immediately and close the bonnet properly. Risk

of accident.

Engine oilEngine oil specifications

The engine oil used must conf orm with exact specifications.Specifications

The engine comes with a special, high quality, multi grade oil that can be

used in all seasons of the year except for those regions affected by extreme

cold.

As the use of high quality oil is essential for the correct operation of the

engine and its long useful life, when topping up or replacement is necessary

use only those oils that conform to the requirements of the VW standards.

If it is not possible to find oil conforming to the VW standards then oil

conforming to the ACEA or API standards with an appropriate viscosity at

atmospheric temperature should be used instead. The use of this type of oil

may have some repercussions on the performance of the engine for example,

long starting time, increased consumption and a higher emission level.

If a top up is required then different oils may be mixed as long as they all

conform to the VW standards.

The specifications (VW standards) set out in the following page should

appear on the container of the service oil; the container will display together

the different standards for petrol and diesel engines, the oil can be used for

both types of engines.

WARNING (continued)

Freetrack_EN.book Seite 216 Donnerstag, 10. September 2009 10:33 10

Page 238 of 294

Wheels and tyres

236wheels or tyres which have not been approved by SEAT for use with your

model may invalidate the vehicle's type approval for use on public roads.•If the spare tyre is not the same as the tyres that are mounted on the

vehicle - for example with winter tyres - you should only use the spare tyre for

a short period of time and drive with extra care. Refit the normal road wheel

as soon as possible.Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

heads must be used. This ensures that wheels are fitted securely and that the

brake system functions correctly.

In certain circumstances, you may not use wheel bolts from a different car -

even if it is the same model ⇒page 208.

After the wheels have been changed, the tightening torque of the wheel bolts

s ho uld b e che cke d as s o on as p ossible wit h a to rqu e w re nch ⇒. The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.•The wheel bolts must be clean and turn easily. Never apply grease or oil

to them.•Use only wheel bolts which belong to the wheel.•If the torque of the wheel bolts is too low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.

Caution

The prescribed torque for wheel bolts for steel and alloy wheels is 120 Nm.Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.In winter conditions winter tyres will considerably improve the vehicles

handling. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pressures

specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's regis-

tration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

Winter tyres lose their effectiveness when the tread is worn down to a depth

of 4 mm.

The speed rating code ⇒ page 235, “New tyres and wheels” determines the

following speed limits for winter tyres: ⇒

Q max. 160 km/h

S max. 180 km/h

T max. 190 km/h

H max. 210 km/h

In some countries, vehicles which can exceed the speed rating of the fitted

tyre must have an appropriate sticker in the driver's field of view. These

Freetrack_EN.book Seite 236 Donnerstag, 10. September 2009 10:33 10

Page 240 of 294

If and when

238If and whenTools, tyre repair kit and spare wheelVehicle Tools

The vehicle onboard tools are located under the floor panel in

the luggage compartment.– Lift the cover of the luggage compartment, by pulling it up with a

finger in the fitting.

– Take the onboard tools out of the vehicle.The tool kit includes:•Jack*•Hook for removing wheel covers* or hub caps*•Box spanner for wheel bolts*•Reversible screwdriver with handle (including hexagonal interior) for the

wheel bolts. The screwdriver is a combination tool.•Towi ng e ye•Adapter for the anti-theft wheel bolts*

Some of the items listed are only provided in certain models / model years,

or are optional extras.WARNING

•Do not use the hexagonal socket in the screwdriver handle to tighten

the wheel bolts as with this it is not possible to tighten the bolts to the

required torque. Risk of accident.

•The jack* supplied by the factory is only designed for changing wheels

on this model. On no account attempt to use it for lifting heavier vehicles

or other loads. Risk of injury.•Use the jack* only on firm, level ground.•Never start the engine when the vehicle is on the jack. Risk of accident.•If work is to be carried out underneath the vehicle, this must be secured

by suitable stands. Otherwise, there is a risk of injury.WARNING (continued)

Freetrack_EN.book Seite 238 Donnerstag, 10. September 2009 10:33 10

Page 243 of 294

If and when241

Safety First

Controls and equipment

Practical tips

Technical Data

After changing a wheel

After changing the wheel there are still tasks to complete.– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart-

ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as possible.

– Have the tightening torque of th e wheel bolts checked as soon as

possible with a torque wrench. Th e prescribed torque must be

120 Nm.

Note•If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt torque

checked.•For your safety, drive at moderate speeds until the wheel bolt torque has

been checked.

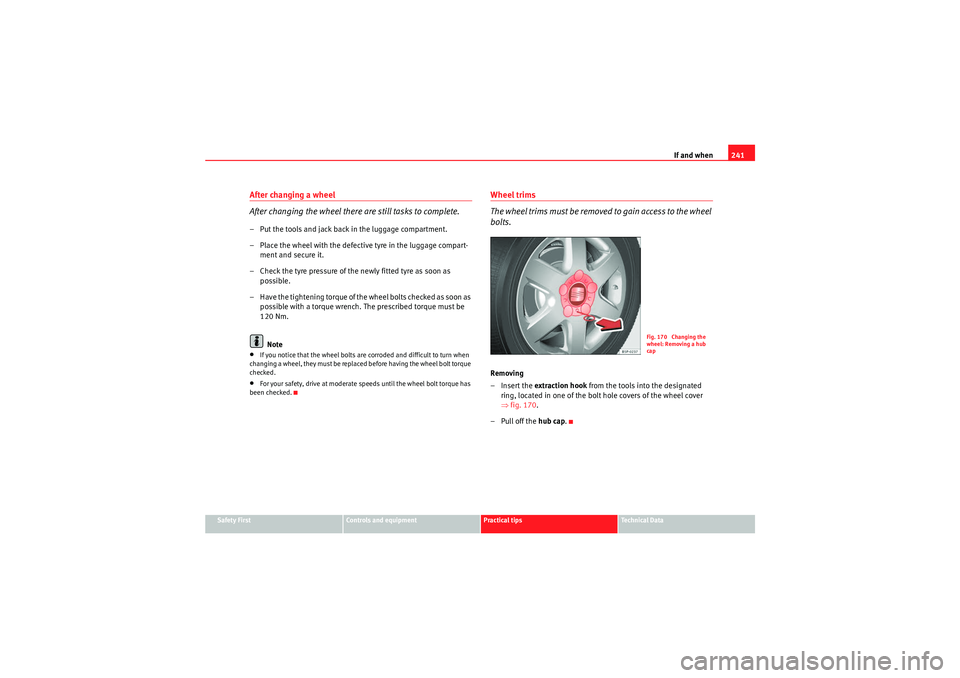

Wheel trims

The wheel trims must be removed to gain access to the wheel

bolts.Removing

– Insert the extraction hook from the tools into the designated

ring, located in one of the bolt hole covers of the wheel cover

⇒ fig. 170 .

–Pull off the hub cap.

Fig. 170 Changing the

wheel: Removing a hub

cap

Freetrack_EN.book Seite 241 Donnerstag, 10. September 2009 10:33 10