warning Seat Altea Freetrack 2013 Owner's Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Altea Freetrack, Model: Seat Altea Freetrack 2013Pages: 301, PDF Size: 4.45 MB

Page 255 of 301

253

If and when

WARNING

Loosen the wheel bolts only about one turn before raising the vehicle

with the jack, otherwise there is a risk of accident.

Note

● If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

Raising the vehicle

In order to remove the wheel, the vehicle must be raised

with a jack.

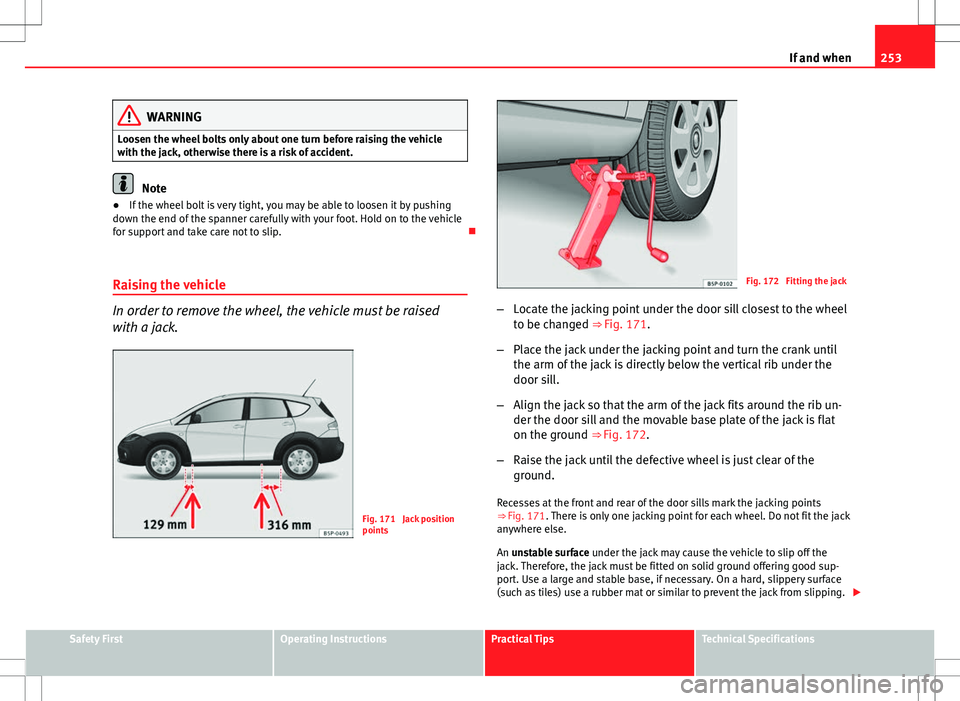

Fig. 171 Jack position

points

Fig. 172 Fitting the jack

– Locate the jacking point under the door sill closest to the wheel

to be changed ⇒ Fig. 171.

– Place the jack under the jacking point and turn the crank until

the arm of the jack is directly below the vertical rib under the

door sill.

– Align the jack so that the arm of the jack fits around the rib un-

der the door sill and the movable base plate of the jack is flat

on the ground ⇒ Fig. 172.

– Raise the jack until the defective wheel is just clear of the

ground.

Recesses at the front and rear of the door sills mark the jacking points

⇒ Fig. 171. There is only one jacking point for each wheel. Do not fit the jack

anywhere else.

An unstable surface under the jack may cause the vehicle to slip off the

jack. Therefore, the jack must be fitted on solid ground offering good sup-

port. Use a large and stable base, if necessary. On a hard, slippery surface

(such as tiles) use a rubber mat or similar to prevent the jack from slipping.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 256 of 301

254If and when

WARNING

● Take all precautions so that the base of the jack does not slip. Failure

to do so could result in an accident.

● The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

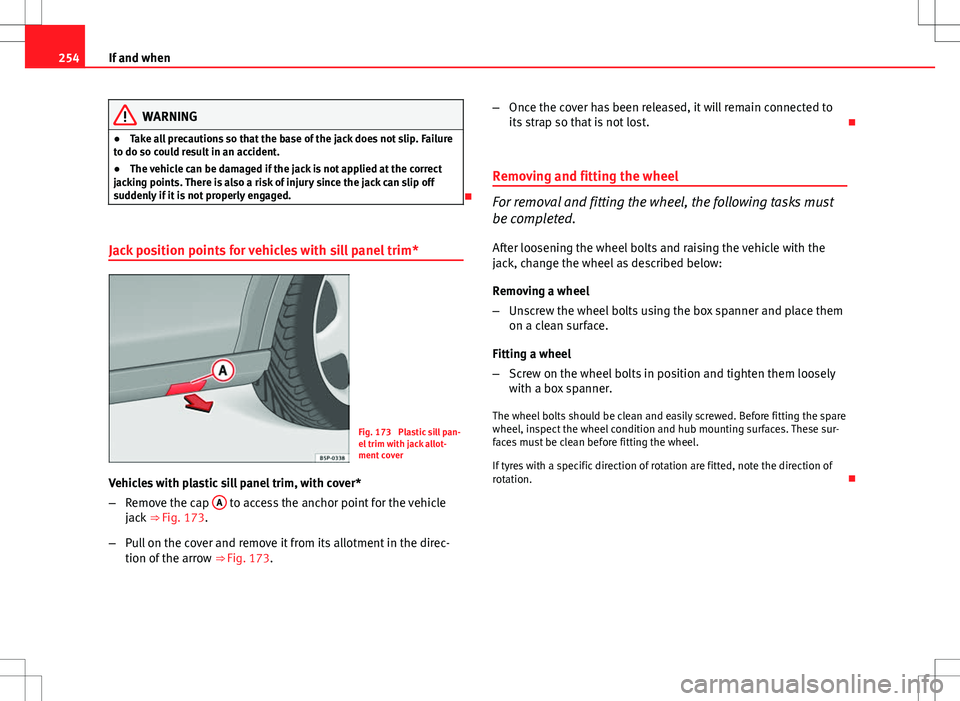

Jack position points for vehicles with sill panel trim*

Fig. 173 Plastic sill pan-

el trim with jack allot-

ment cover

Vehicles with plastic sill panel trim, with cover*

– Remove the cap A

to access the anchor point for the vehicle

jack ⇒

Fig. 173.

– Pull on the cover and remove it from its allotment in the direc-

tion of the arrow ⇒

Fig. 173. –

Once the cover has been released, it will remain connected to

its strap so that is not lost.

Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must

be completed.

After loosening the wheel bolts and raising the vehicle with the

jack, change the wheel as described below:

Removing a wheel

– Unscrew the wheel bolts using the box spanner and place them

on a clean surface.

Fitting a wheel

– Screw on the wheel bolts in position and tighten them loosely

with a box spanner.

The wheel bolts should be clean and easily screwed. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These sur-

faces must be clean before fitting the wheel.

If tyres with a specific direction of rotation are fitted, note the direction of

rotation.

Page 258 of 301

256If and when

You will also find instructions for operating the compressor.

WARNING

● Do not attempt to repair a puncture with the sealing product if the

tyre has been damaged by driving the vehicle after the tyre has lost its

air.

● Always observe warnings and follow instructions concerning com-

pressor and sealing compound carefully.

● Do not drive faster than 80 km/h (50 mph), avoid heavy acceleration,

hard braking and fast cornering.

● Tyres which have been repaired with sealing compound are only suit-

able for temporary use over a short period. Therefore, please drive care-

fully to the next available specialised workshop.

For the sake of the environment

If you have to dispose of a sealant can, go to a specialised waste service or

to a SEAT Technical Service, where the product can be recycled in an appro-

priate waste container.

Note

● If sealing product should leak out, leave it to dry. This way you can pull it

off like a piece of foil.

● Observe the expiry date stated on the sealing compound can. Have the

sealing compound exchanged by a specialised workshop.

● Seek professional assistance if the repair of a tyre puncture is not possi-

ble with the sealing product. Preparation work

Certain steps must be taken before repairing a tyre.

–

If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

– Apply the handbrake firmly.

– Engage first gear , or put the selector lever to position P.

– All occupants should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Check whether a repair is possible using the Tyre Mobility Sys-

tem “General information and safety notes.”

– Unscrew inflation cap from the affected wheel.

– Take the tyre repair kit out of the luggage compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in posi-

tion. This is for your own safety and also warns other road users.

CAUTION

Take special care if you have to repair a tyre on a slope.

Note

Please observe legal requirements when doing so.

Page 261 of 301

259

If and when

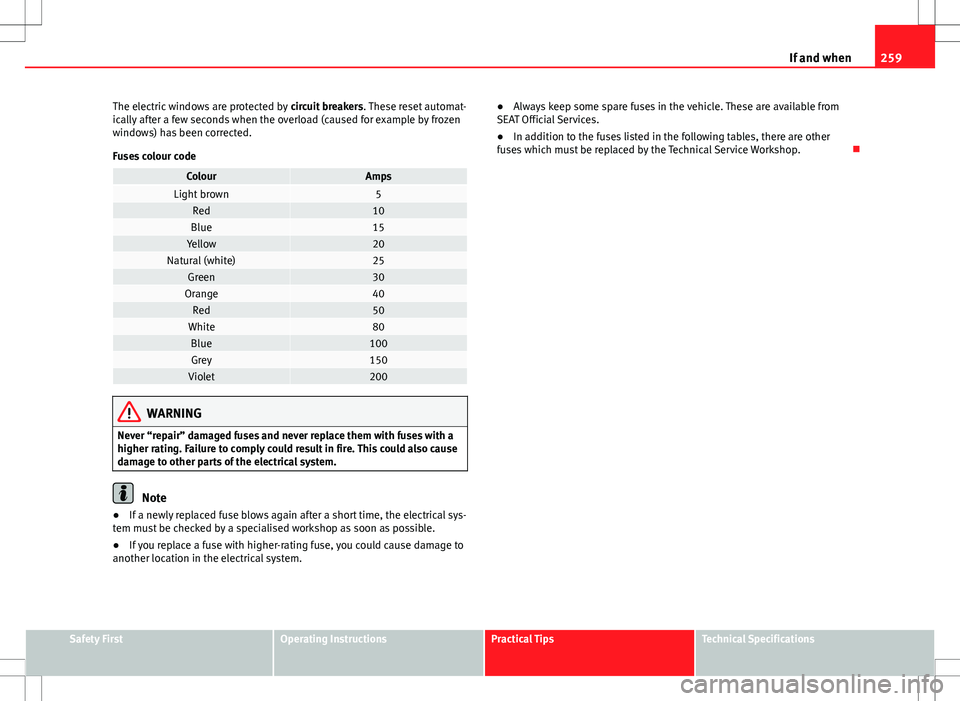

The electric windows are protected by circuit breakers. These reset automat-

ically after a few seconds when the overload (caused for example by frozen

windows) has been corrected.

Fuses colour code

ColourAmpsLight brown5Red10Blue15Yellow20Natural (white)25Green30Orange40Red50White80Blue100Grey150Violet200

WARNING

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could result in fire. This could also cause

damage to other parts of the electrical system.

Note

● If a newly replaced fuse blows again after a short time, the electrical sys-

tem must be checked by a specialised workshop as soon as possible.

● If you replace a fuse with higher-rating fuse, you could cause damage to

another location in the electrical system. ●

Always keep some spare fuses in the vehicle. These are available from

SEAT Official Services.

● In addition to the fuses listed in the following tables, there are other

fuses which must be replaced by the Technical Service Workshop.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 275 of 301

273

If and when

Starting

5. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

6. Start the engine of the vehicle with the flat battery and wait two or three minutes until the engine is “running”.

Removing the jump leads

7. Before you remove the jump leads, switch off the dipped beam headlights (if they are switched on).

8. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

9. When the engine is running, disconnect the leads in reverse or- der to the details given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 222, Working in the engine compartment.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

WARNING (Continued)

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not lean on the batteries. This could result in chemical burns.

Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 276 of 301

274If and when

Towing and tow-starting

Tow-starting

The use of jump leads is preferable to tow-starting.

We recommend that you do not tow-start your vehicle. Jump-start-

ing is preferable ⇒ page 271.

However, if your vehicle has to be tow-started:

– Engage the 2nd or the 3rd gear.

– Keep the clutch pressed down.

– Switch the ignition on.

– Once both vehicles are moving, release the clutch.

– As soon as the engine starts, press the clutch and move the

gear lever into neutral. This helps to prevent driving into the

towing vehicle.

WARNING

The risk of accidents is high when tow-starting. The vehicle being towed

can easily collide with the towing vehicle.

CAUTION

When tow-starting, fuel could enter the catalytic converter and damage it. General notes

Please observe the following points if you use a tow rope:

Notes for the driver of the towing vehicle

–

Drive slowly at first until the tow rope is taut. Then accelerate

gradually.

– Begin and change gears cautiously. If you are driving an auto-

matic vehicle, accelerate gently.

– Remember that the brake servo and power steering are not

working in the vehicle you are towing. Brake sooner than nor-

mal and pressing the pedal gently.

Notes for the driver of the towed vehicle

– Ensure that the tow rope remains taut at all times when towing.

Tow rope or tow bar

It is easier and safer to tow a vehicle with a tow bar. You should only use a

tow rope if you do not have a tow bar.

A tow rope should be slightly elastic to reduce the loading on both vehicles.

It is advisable to use a tow rope made of synthetic fibre or similarly elastic

material.

Attach the tow rope or the tow bar only to the towline anchorages provided

or a towing bracket.

Driving style

Towing requires some experience, especially when using a tow rope. Both

drivers should be familiar with the technique required for towing. Inexper-

ienced drivers should not attempt to tow.

Page 277 of 301

275

If and when

Do not pull too hard with the towing vehicle and take care to avoid jerking

the tow rope. When towing on an unpaved road, there is always a risk of

overloading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the turn signals,

horn, windscreen wipers and washers.

As the brake servo does not work if the engine is not running, you must ap-

ply considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running,

you will need more strength to steer than you normally would.

● The vehicle must not be towed faster than 50 km/h (30 mph).

● The vehicle must not be towed faster than 50 km/h (30 mph).

Towing vehicles with an automatic gearbox

● Put the selector lever into position “N”.

● Do not drive faster than 50 km/h (30 mph).

● Do not tow further than 50 km.

● If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.

Note

● Observe legal requirements when towing or tow-starting.

● Switch on the hazard warning lights of both vehicles. However, observe

any regulations to the contrary.

● For technical reasons, vehicles with an automatic gearbox must not be

tow-started.

● If damage to your vehicle means that there is no lubricant in the gear-

box, you must raise the driven wheels while the vehicle is being towed.

● If the vehicle has to be towed more than 50 km (30 miles), the front

wheels should be raised during towing, and towing should be carried out by

a qualified person. ●

The steering wheel is locked when the vehicle has no electrical power.

The vehicle must then be towed with the front wheels raised. Towing should

be carried out by a qualified person.

● The towline anchorage should always be kept in the vehicle. Please refer

to the notes on ⇒ page 274, Tow-starting.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 281 of 301

279

Description of specifications

Information on fuel consumption

Fuel consumption

The consumption and emission details shown on the vehicle

data sticker differ from one vehicle to another. The vehicle fuel consumption and CO 2 emissions can be consulted on the

vehicle data sticker in the spare wheel well, inside the luggage compart-

ment and on the rear cover of the Maintenance Programme.

The fuel consumption and CO 2 emission values refer to the weight category

assigned to your vehicle according to the engine and gearbox combination,

as well as the specific equipment fitted, and is only used to compare be-

tween the different models.

The fuel consumption and CO 2 emissions do not depend only on the per-

formance of the vehicle, they can also differ from the established values de-

pending on other factors such as driving style, road conditions, traffic con-

ditions, environmental conditions, load and number of passengers.

Calculation of fuel consumption

The consumption values have been calculated based on measurements per-

formed or supervised by certified CE laboratories according to the latest ver-

sion of directives 715/2007/EC and 80/1268/CEE (for more information

consult the European Union Publications Office at EUR-Lex: © European Un-

ion, http://eur-lex.europa.eu/en/index.htm) and are valid for the kerb

weight indicated for the vehicle.

Note

In practice, and considering all the factors mentioned here, consumption

values can differ from those calculated in the current European regulations. Weights

Kerb weight refers to the basic model with a fuel tank filled to 90% capacity

and without optional extras. The figure quoted includes 75 kg to allow for

the weight of the driver.

For special versions and optional equipment fittings or for the addition of

accessories, the weight of the vehicle will increase

⇒

.

WARNING

● Please note that the centre of gravity may shift when transporting

heavy objects; this may affect vehicle handling and lead to an accident.

Always adjust your speed and driving style to suit road conditions and re-

quirements.

● Never exceed the gross axle weight rating or the gross vehicle weight

rating. If the allowed axle load or the allowed total weight is exceeded,

the driving characteristics of the vehicle may change, leading to acci-

dents, injuries and damage to the vehicle.

Towing a trailer Trailer weights

Trailer weight

The trailer weights and drawbar loads approved are selected in intensive tri-

als according to precisely defined criteria. The approved trailer weights are

valid for vehicles in the EU for maximum speeds of 80 km/h (50 mph) (in

certain circumstances up to 100 km/h (60 mph)). The figures may be differ-

ent in other countries. All data in the official vehicle documentation takes

precedence over these data at all times ⇒

.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 282 of 301

280Description of specifications

Drawbar loads

The maximum permitted drawbar load on the ball joint of the towing bracket

must not exceed 75 kg.

In the interest of road safety, we recommend that you always tow approach-

ing the maximum drawbar load. The response of the trailer on the road will

be poor if the drawbar load is too small.

If the maximum permissible drawbar load cannot be met (e.g. with small,

empty and light-weight single axle trailers or tandem axle trailers with a

wheelbase of less than 1 metre), a minimum of 4% of the actual trailer

weight is legally required for the drawbar load.

WARNING

● For safety reasons, do not exceed the 80 km/h (50 mph) limit. This is

also valid in countries where higher speeds are permitted.

● Never exceed the maximum trailer weights or the drawbar load. If the

permissible axle load or the permissible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

Page 291 of 301

Index

A

ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188Control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 82

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Acoustic warning . . . . . . . . . . . . . . . . . . . . . . . 168

Adaptive headlights . . . . . . . . . . . . . . . . . . . . . 117

Adjusting the seat belt height . . . . . . . . . . . . . . 28

AFS (cornering lights) . . . . . . . . . . . . . . . . . . . 118

Airbag covers . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 32

Curtain airbags . . . . . . . . . . . . . . . . . . . . . . . 41

Front airbags . . . . . . . . . . . . . . . . . . . . . . . . 34

Side airbags . . . . . . . . . . . . . . . . . . . . . . . . . 38

Air conditioner General notes . . . . . . . . . . . . . . . . . . . . . . . 164

Air conditioner automatic mode 2C-Climatronic . . . . . . . . . . . . . . . . . . . . . . 161

Air Conditioner* 2C-Climatronic* . . . . . . . . . . . . . . . . . . . . . 159

Air conditioning* . . . . . . . . . . . . . . . . . . . . . . . 156

Air recirculation mode 2C-Climatronic . . . . . . . . . . . . . . . . . . . . . . 163

Manual air conditioner . . . . . . . . . . . . . . . . 158

Alarm system Switching off . . . . . . . . . . . . . . . . . . . . . . . . 104

Alcantara . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

All-wheel drive . . . . . . . . . . . . . . . . . . . . . . . . . 191 Alternator

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 83

Anti-lock brake system . . . . . . . . . . . . . . . . . . . 188 Control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 82

Anti-theft alarm system . . . . . . . . . . . . . . . . . . 104 Switching off . . . . . . . . . . . . . . . . . . . . . . . . 104

Anti-theft wheel bolts . . . . . . . . . . . . . . . . . . . 252

Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Aquaplaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Ashtray* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Aspects to note before setting off . . . . . . . . . . . . 8

ASR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188 Warning light . . . . . . . . . . . . . . . . . . . . . . . . 87

Audible warning . . . . . . . . . . . . . . . . . . . . . . . . . 20

Automatic anti-dazzle interior mirror Deactivating the anti-dazzle function . . . . 128

Automatic anti-dazzle interior mirror* Activating the anti-dazzle function . . . . . . 128

Automatic car wash tunnel . . . . . . . . . . . . . . . 206

Automatic gearbox Kick-down feature . . . . . . . . . . . . . . . . . . . . 179

Automatic gearbox / DSG automatic gearbox 175

Automatic lighting . . . . . . . . . . . . . . . . . . . . . . 114

Automatic windscreen wiper/washer . . . . . . . 124

Auxiliary audio connection: AUX-IN . . . . . . . . 148

B

Ball coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . 202 Battery

Changing . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Winter conditions . . . . . . . . . . . . . . . . . . . . 236

Before setting off . . . . . . . . . . . . . . . . . . . . . . . . . 8

Biodiesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Biodiesel fuel . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234 Changing . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 65

Brake pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Brake pedal control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 88

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195 Worn brake pads . . . . . . . . . . . . . . . . . . . . . 83

Brake servo . . . . . . . . . . . . . . . . . . . . . . . . 187, 195

Brake system . . . . . . . . . . . . . . . . . . . . . . . . . . 234 Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Brake servo . . . . . . . . . . . . . . . . . . . . . . . . . 192

warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 84

Braking distance . . . . . . . . . . . . . . . . . . . . . . . 195

Bulb changes General notes . . . . . . . . . . . . . . . . . . . . . . . 262

Bulb defect control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 84

Buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120, 168

289

Index