Water Seat Altea XL 2009 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2009, Model line: Altea XL, Model: Seat Altea XL 2009Pages: 297, PDF Size: 9.36 MB

Page 206 of 297

Cleaning and caring for your vehicle205

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Underbody sealant

The vehicle underbody is coated to protect it from chemical

and mechanical damage.The protective coating can be damaged when driving. We recommend you to

ckeck the protective coating under the body and on the running gear, and

reinstated if necessary, before and after the winter season.

We recommend you to go to your Authorised Service Centre to carry out repair

work and additional anti-corrosion work.

WARNING

Do not apply underseal or anti-corrosion coatings to the exhaust pipes,

catalytic converter or the heat shields on the exhaust system. The heat of

the exhaust system or the engine could cause them to ignite! Fire hazard.Cleaning the engine compartment

Take special care when cleaning the engine compartment.Anti-corrosion treatment

The engine compartment and the surface of the power unit are given anti-

corrosion treatment at the factory.

Good corrosion protection is particularly important in winter when the car is

frequently driven on salted roads. To prevent the salt corroding the vehicle,

the entire engine compartment should be thoroughly cleaned before and

after winter.

Your Authorised Service Centre has got the necessary equipment to provide

the correct cleaning and preserving products. For this reason, we recommend

having this work performed by them. The anti-corrosion protection is usually removed if the engine compartment

is cleaned with grease remo

ving solutions, or if you have the engine cleaned.

On commissioning theis work, ensure that all surfaces, seams, joints and

components in the engine compartment are given anti-corrosion treatment.

WARNING

•

When working in the engine compartm ent, always observe the safety

warnings ⇒page 213.

•

Before opening the bonnet, switch the engine off, apply the parking

brake firmly and always remove the key from the ignition.

•

Allow the engine to cool before you clean the engine compartment.

•

Do not clean the vehicle underbody, wheel arches without protecting

your hands and arms. You may cut your self on sharp-edged metal parts.

Failure to comply could result in injury.

•

Moisture, ice and salt on the brakes may affect braking efficiency. Risk

of accident. Directly after washing, avoid sudden and sharp braking.

•

Never touch the radiator fan. It is temperature-controlled and could

start automatically, even when the key is removed from the ignition!For the sake of the environment

Fuel, grease and oil deposits could be removed when the engine is washed.

The polluted water must be cleaned in an oil separator. For this reason,

engine washing should be carried out on ly by a qualified workshop or a petrol

station.

AlteaXL_EN.book Seite 205 M ontag, 2. Februar 2009 12:26 12

Page 207 of 297

Cleaning and caring for your vehicle

206Vehicle interior maintenancePlastic parts and dash panel cleaning– Use a clean, damp cloth to clean plastic parts and the dash

panel.

– If this does not provide satisfactory results, use a special solvent-free plastic cleaning product.

WARNING

Never clean the dash panel and the airbag module surface with cleansers

containing solvents. Solvents cause the surface to become porous. If the

airbag triggered, disintegrating plastic parts could cause substantial inju-

ries.

Caution

Cleaning products which contain solvents will damage the material.Wooden trim cleaning*– Clean the wooden trim with a water-moistened clean cloth.

– If this does not provide satisfactory results, use a gentle soap

solution.

CautionCleaning products which contain solvents will damage the material.

Cloth seat covers and fabric trim cleaningCloth seat covers and fabric trim on the doors, headlining etc. can be cleaned

with a special interior cleanser or with dry foam and a soft brush.Cleaning the radio and climate controlsTo clean the radio and/or climate controls, use a soft damp cloth. For more

resistant dirt, a neutral soap solution may be used.Leather cleaning*Normal cleaning

– Moisten a cotton or woollen cloth with water and wipe over the leather surfaces.

Cleaning stubborn stains

– More stubborn dirt can be removed using a mild soap solution (pure liquid soap; two tablespoons diluted in one litre of water)

and a cloth.

– Do not let the water soak through the leather or soak into the seams.

– Then wipe off with a soft, dry cloth.

Leather maintenance

– The leather should be treated twice a year with a special leather- care product, available in your Authorised Service Centre.

AlteaXL_EN.book Seite 206 M ontag, 2. Februar 2009 12:26 12

Page 221 of 297

Checking and refilling levels

220•

Never pour oil down drains or into the ground.

•

Use a suitable container when draining the used oil. It has to be large

enough to hold all the engine oil

CoolantCoolant specifications

Coolant is a mixture of water and at least 40% coolant addi-

tive.The cooling system must be filled with a mixture of water and at least 40 % of

our coolant additive G 12+ or an addi tive with the specification TT-VW 774 F

(it is dyed purple). This mixture gives the necessary frost protection down to

-25

° C and protects the alloy parts of the cooling system against corrosion. It

also prevents scaling and raises the boiling point of the coolant.

The concentration of coolant must always be at least 40% - even if frost

protection is not required.

If greater frost protection is required in very cold climates, the proportion of

the antifreeze additive G 12+ can be increased. However, the percentage of

coolant additives should not exceed 60%, as this would reduce the frost

protection. It would also reduce th e cooling effect. A mixture with 60%

coolant additive will give frost protection to approx. -40

° C.

WARNING

•

The coolant additive is toxic. There is a toxic risk. Always keep the

coolant additive in the original container which should be stored out of the

reach of children. The same applies to coolant which you have drained off.

•

The coolant additive G 12+ must be added in sufficient quantities to

provide anti-freeze protection at the coldest ambient temperatures that

can be expected. At extremely cold ambient temperatures, the coolant

could freeze, causing the vehicle to breakdown. As the heater would also

not work in this situation, there is a risk of suffering exposure!Caution

•

Other additives may give considerably inferior corrosion protection. The

resulting corrosion in the cooling syst em can lead to a loss of coolant,

causing serious damage to the engine.

•

The coolant additive G 12+ (purple) can be mixed with the additive G 12

(red) or G 11. Never mix G12 (red colour) with G 11.WARNING (continued)

AlteaXL_EN.book Seite 220 M ontag, 2. Februar 2009 12:26 12

Page 222 of 297

Checking and refilling levels221

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Checking the coolant level and topping up

The correct coolant level is important for fault-free func-

tioning of the engine cooling system.Before opening the bonnet, read and observe the warnings ⇒ in

“Safety instructions on working in the engine compartment” on

page 213.

Opening the coolant expansion tank

– Switch off the engine and allow it to cool.

– To prevent scalding, cover the cap on the expansion tank with a thick cloth and carefully unscrew the cap ⇒.

Checking coolant level

– Look into the open coolant expansion tank and read off the coolant level. – If the level is underneath the

“MIN” mark, top up with coolant.

Topping up coolant

–Only use new coolant.

– Do not fill above the “MAX” mark.

Closing the coolant expansion tank

–Screw the cap on again tightly.

The position of the coolant expansion reservoir is shown in the corresponding

engine compartment diagram ⇒page 273.

Make sure that the coolant meets the required specifications ⇒ page 220.

Do not use a different type of additive if coolant additive G 12+ is not avail-

able. In this case use only water and bring the coolant concentration back up

to the correct level as soon as possible by putting in the specified additive

⇒ page 220.

Always top up with new coolant.

Do not fill above the “MAX” mark. Otherwise the excess coolant will be forced

out of the cooling system when the engine is hot.

The coolant additive G 12+ (dyed purple) may be mixed with G 12 (dyed red)

and also with G 11.

WARNING

Any work carried out in the engine compartment or on the engine must be

carried out cautiously.•

When working in the engine compartm ent, always observe the safety

warnings ⇒page 213.

Fig. 161 In the engine

compartment: Coolant

expansion tank cap

AlteaXL_EN.book Seite 221 M ontag, 2. Februar 2009 12:26 12

Page 223 of 297

Checking and refilling levels

222•

When the engine is warm or hot, th e cooling system is pressurised! Do

not unscrew the cap on the expansion t ank when the engine is hot. This is

a burn injury risk.Caution

•

When mixed with other additives the colour of G 12 will change to brown.

If this occurs you should have the coolant changed immediately. Failure to do

so will result in engine damage!

•

If a lot of coolant has been lost, wait for the engine to cool down before

putting in cold coolant. This avoids damaging the engine. Large coolant

losses are an indication of leaks in the cooling system. See a specialised

workshop immediately and have the cooling system checked. Otherwise,

there is a risk of engine damage.

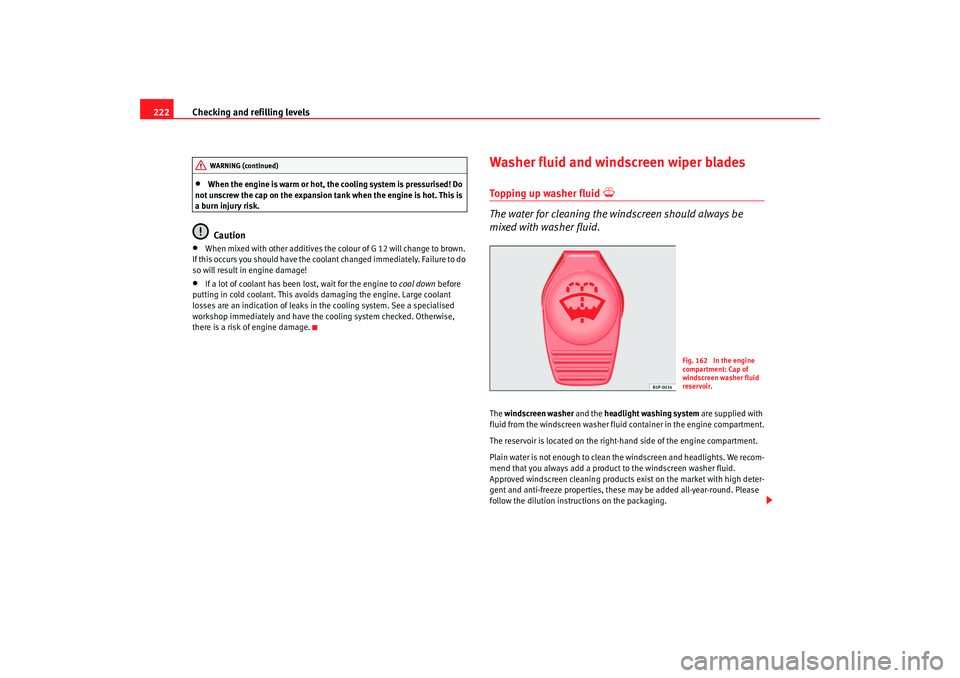

Washer fluid and windscreen wiper bladesTopping up washer fluid

The water for cleaning the windscreen should always be

mixed with washer fluid.The windscreen washer and the headlight washing system are supplied with

fluid from the windscreen washer flui d container in the engine compartment.

The reservoir is located on the right-hand side of the engine compartment.

Plain water is not enough to clean the windscreen and headlights. We recom-

mend that you always add a product to the windscreen washer fluid.

Approved windscreen cleaning products exist on the market with high deter-

gent and anti-freeze properties, these may be added all-year-round. Please

follow the dilution instructions on the packaging.

WARNING (continued)

Fig. 162 In the engine

compartment: Cap of

windscreen washer fluid

reservoir.

AlteaXL_EN.book Seite 222 M ontag, 2. Februar 2009 12:26 12

Page 227 of 297

Checking and refilling levels

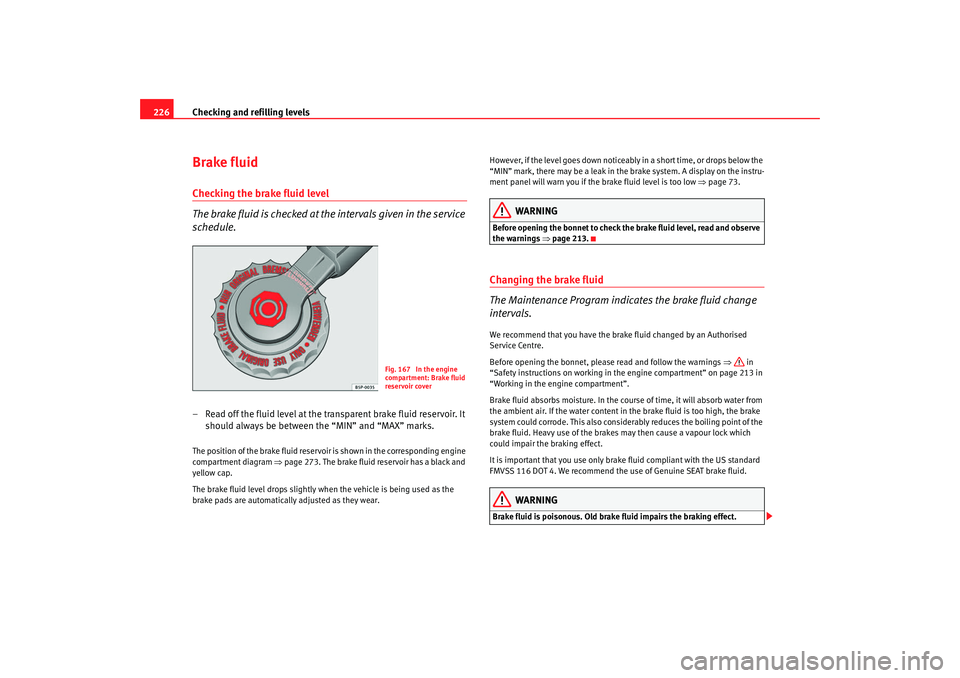

226Brake fluidChecking the brake fluid level

The brake fluid is checked at the intervals given in the service

schedule.– Read off the fluid level at the transparent brake fluid reservoir. It

should always be between the “MIN” and “MAX” marks.The position of the brake fluid reservoir is shown in the corresponding engine

compartment diagram ⇒ page 273. The brake fluid reservoir has a black and

yellow cap.

The brake fluid level drops slightly when the vehicle is being used as the

brake pads are automatically adjusted as they wear. However, if the level goes down noticeab

ly in a short time, or drops below the

“MIN” mark, there may be a leak in the brake system. A display on the instru-

ment panel will warn you if the brake fluid level is too low ⇒page 73.

WARNING

Before opening the bonnet to check the brake fluid level, read and observe

the warnings ⇒page 213.Changing the brake fluid

The Maintenance Program indicates the brake fluid change

intervals.We recommend that you have the brake fluid changed by an Authorised

Service Centre.

Before opening the bonnet, please read and follow the warnings ⇒ in

“Safety instructions on working in the engine compartment” on page 213 in

“Working in the engine compartment”.

Brake fluid absorbs moisture. In the cour se of time, it will absorb water from

the ambient air. If the water content in the brake fluid is too high, the brake

system could corrode. This also consider ably reduces the boiling point of the

brake fluid. Heavy use of the brakes may then cause a vapour lock which

could impair the braking effect.

It is important that you use only brake fluid compliant with the US standard

FMVSS 116 DOT 4. We recommend the use of Genuine SEAT brake fluid.

WARNING

Brake fluid is poisonous. Old brake fluid impairs the braking effect.

Fig. 167 In the engine

compartment: Brake fluid

reservoir cover

AlteaXL_EN.book Seite 226 Montag, 2. Februar 2009 12:26 12

Page 228 of 297

Checking and refilling levels227

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

•

Before opening the bonnet to check the brake fluid level, read and

observe the warnings ⇒page 213.

•

Brake fluid should be stored in the closed original container in a safe

place out of reach of children. There is a toxic risk.

•

Complete the brake fluid change according to the Maintenance

Program. Heavy use of the brakes may cause a vapour lock if the brake fluid

is left in the system for too long. This would seriously affect the efficiency

of the brakes and the safety of the vehicle. This may cause an accident.Caution

Brake fluid could damage the paintwork. Wipe off any brake fluid from the

paintwork immediately.

For the sake of the environment

Brake fluid must be drained and disposed of in the proper manner observing

environmental regulations.

BatteryWarnings on handling the battery

WARNING

Always be aware of the danger of injury and chemical burns as well as the

risk of accident or fire when working on the battery and the electrical

system:•

Wear eye protection. Protect your eyes , skin and clothing from acid and

particles containing lead.

•

Battery acid is very corrosive and caustic. Wear protective gloves and

eye protection. Do not tilt the batter ies. This could spill acid through the

vents. Rinse battery acid from eyes immediately for several minutes with

clear water. Then seek medical care immediately. Neutralize any acid

splashes on the skin or clothing with a soapy solution, and rinse off with

plenty of water. If acid is swallowed by mistake, consult a doctor immedi-

ately.

•

Fires, sparks, naked lights and smoki ng are prohibited. When handling

cables and electrical equipment, avoid causing sparks and electrostatic

WARNING (continued)

Wear eye protection

Battery acid is very corrosive and caustic. Wear protective

gloves and eye protection!

Fires, sparks, naked lights and smoking are prohibited!

A highly explosive mixture of gases is released when the

battery is under charge.

Keep children away from acid and batteries!

AlteaXL_EN.book Seite 227 M ontag, 2. Februar 2009 12:26 12

Page 250 of 297

If and when249

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

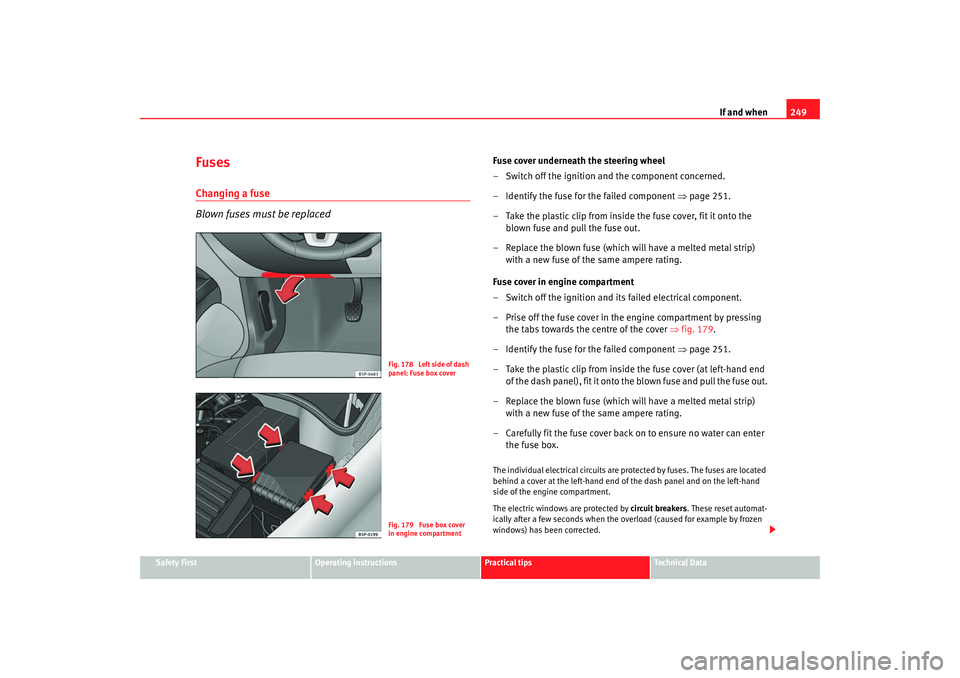

FusesChanging a fuse

Blown fuses must be replaced

Fuse cover underneath the steering wheel

– Switch off the ignition and the component concerned.

– Identify the fuse for the failed component ⇒page 251.

– Take the plastic clip from inside the fuse cover, fit it onto the

blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

Fuse cover in engine compartment

– Switch off the ignition and its failed electrical component.

– Prise off the fuse cover in the engine compartment by pressing the tabs towards the centre of the cover ⇒fig. 179.

– Identify the fuse for the failed component ⇒page 251.

– Take the plastic clip from inside the fuse cover (at left-hand end of the dash panel), fit it onto th e blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip) with a new fuse of the same ampere rating.

– Carefully fit the fuse cover back on to ensure no water can enter the fuse box.The individual electrical circuits are pr otected by fuses. The fuses are located

behind a cover at the left-hand end of the dash panel and on the left-hand

side of the engine compartment.

The electric windows are protected by circuit breakers. These reset automat-

ically after a few seconds when the overload (caused for example by frozen

windows) has been corrected.

Fig. 178 Left side of dash

panel: Fuse box coverFig. 179 Fuse box cover

in engine compartment

AlteaXL_EN.book Seite 249 M ontag, 2. Februar 2009 12:26 12

Page 254 of 297

If and when253

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Bulb changeGeneral notesBefore changing any bulb, first turn off the failed component.

Do not touch the bulb glass. Fingerprints vaporise in the heat, causing a

reduction in the bulb life and conden sation on the mirror surface, thus

reducing efficiency.

A bulb should only be replaced by one of the same type. The type is inscribed

on the bulb, either on the glass part or on the base.

It is highly recommended to keep a box of spare bulbs in the vehicle. At the

very least, the following spare bulbs, which are essential for road safety,

should be kept in the vehicle.

Main headlights

Dipped beam - H7

Main beam - H1

Position - W5W

Indicator - PY21W

Xenon headlights

23) /self-directing

Dipped and full beam - D1S

24)

Daylight - P21W SLL

Position W5W

Indicators PY21W

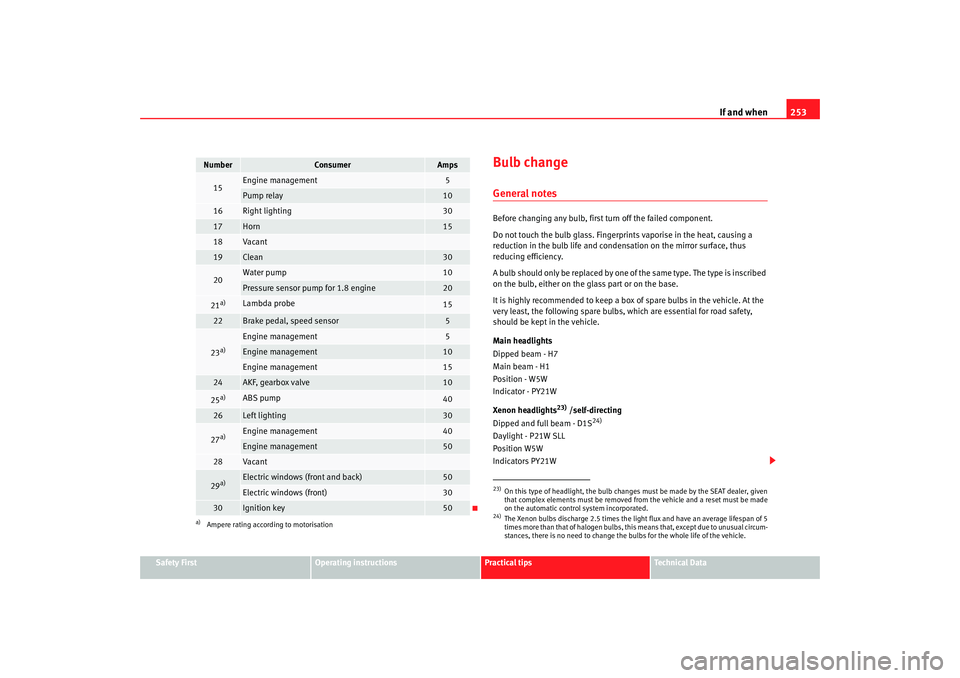

15

Engine management

5

Pump relay

10

16

Right lighting

30

17

Horn

15

18

Vacant

19

Clean

30

20

Water pump

10

Pressure sensor pump for 1.8 engine

20

21a)

Lambda probe

15

22

Brake pedal, speed sensor

5

23a)

Engine management

5

Engine management

10

Engine management

15

24

AKF, gearbox valve

10

25a)

ABS pump

40

26

Left lighting

30

27a)

Engine management

40

Engine management

50

28

Vacant

29a)

Electric windows (front and back)

50

Electric windows (front)

30

30

Ignition key

50

a)Ampere rating according to motorisationNumber

Consumer

Amps

23)On this type of headlight, the bulb changes must be made by the SEAT dealer, given

that complex elements must be removed from the vehicle and a reset must be made

on the automatic control system incorporated.24)The Xenon bulbs discharge 2.5 times the light flux and have an average lifespan of 5

times more than that of halogen bulbs, this means that, except due to unusual circum-

stances, there is no need to change the bulbs for the whole life of the vehicle.

AlteaXL_EN.book Seite 253 M ontag, 2. Februar 2009 12:26 12

Page 295 of 297

Index

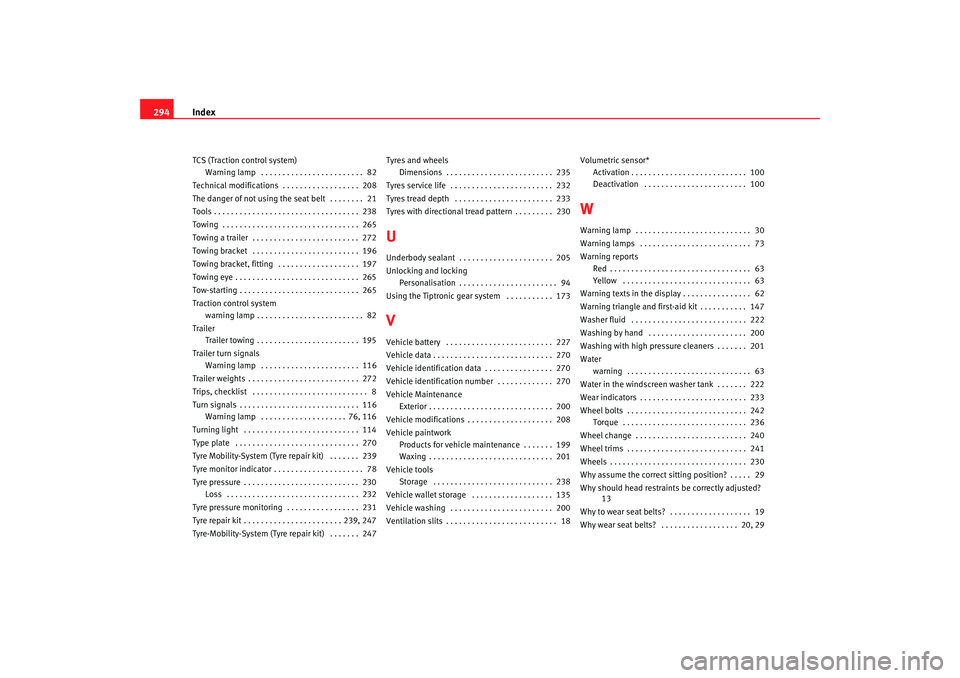

294TCS (Traction control system)

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 82

Technical modifications . . . . . . . . . . . . . . . . . . 208

The danger of not using the seat belt . . . . . . . . 21

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Towing a trailer . . . . . . . . . . . . . . . . . . . . . . . . . 272

Towing bracket . . . . . . . . . . . . . . . . . . . . . . . . . 196

Towing bracket, fitting . . . . . . . . . . . . . . . . . . . 197

Towing eye . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Tow-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Traction control system warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 82

Trailer Trailer towing . . . . . . . . . . . . . . . . . . . . . . . . 195

Trailer turn signals Warning lamp . . . . . . . . . . . . . . . . . . . . . . . 116

Trailer weights . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Trips, checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Turn signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116 Warning lamp . . . . . . . . . . . . . . . . . . . . 76, 116

Turning light . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Tyre Mobility-System (Tyre repair kit) . . . . . . . 239

Tyre monitor indicator . . . . . . . . . . . . . . . . . . . . . 78

Tyre pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 230 Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Tyre pressure monitoring . . . . . . . . . . . . . . . . . 231

Tyre repair kit . . . . . . . . . . . . . . . . . . . . . . . 239, 247

Tyre-Mobility-System (Tyre repair kit) . . . . . . . 247 Tyres and wheels

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 235

Tyres service life . . . . . . . . . . . . . . . . . . . . . . . . 232

Tyres tread depth . . . . . . . . . . . . . . . . . . . . . . . 233

Tyres with directional tread pattern . . . . . . . . . 230

UUnderbody sealant . . . . . . . . . . . . . . . . . . . . . . 205

Unlocking and locking Personalisation . . . . . . . . . . . . . . . . . . . . . . . 94

Using the Tiptronic gear syst em . . . . . . . . . . . 173VVehicle battery . . . . . . . . . . . . . . . . . . . . . . . . . 227

Vehicle data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Vehicle identification data . . . . . . . . . . . . . . . . 270

Vehicle identification number . . . . . . . . . . . . . 270

Vehicle Maintenance

Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Vehicle modifications . . . . . . . . . . . . . . . . . . . . 208

Vehicle paintwork Products for vehicle maintenance . . . . . . . 199

Waxing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Vehicle tools Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Vehicle wallet storage . . . . . . . . . . . . . . . . . . . 135

Vehicle washing . . . . . . . . . . . . . . . . . . . . . . . . 200

Ventilation slits . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Volumetric sensor*

Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Deactivation . . . . . . . . . . . . . . . . . . . . . . . . 100

WWarning lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Warning lamps . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Warning reportsRed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Yellow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Warning texts in the display . . . . . . . . . . . . . . . . 62

Warning triangle and first-aid kit . . . . . . . . . . . 147

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Washing by hand . . . . . . . . . . . . . . . . . . . . . . . 200

Washing with high pressure cleaners . . . . . . . 201

Water warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Water in the windscreen washer tank . . . . . . . 222

Wear indicators . . . . . . . . . . . . . . . . . . . . . . . . . 233

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242 Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Wheel change . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Wheel trims . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Why assume the correct sitting position? . . . . . 29

Why should head restraints be correctly adjusted? 13

Why to wear seat belts? . . . . . . . . . . . . . . . . . . . 19

Why wear seat belts? . . . . . . . . . . . . . . . . . . 20, 29

AlteaXL_EN.book Seite 294 M ontag, 2. Februar 2009 12:26 12