length Seat Altea XL 2014 Owner's Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Altea XL, Model: Seat Altea XL 2014Pages: 321, PDF Size: 4.52 MB

Page 65 of 321

63

Cockpit

Indications for vehicles with LongLife service

Technical progress has made it possible to considerably reduce servicing re-

quirements. With the LongLife System, SEAT ensures that your vehicle only

has an interval service when it is necessary. The length of the Interval Serv-

ices (max. two years) is determined by factors such as conditions under

which the vehicle is used and personal driving style.

The service pre-warning will first appear 20 days before the date on which

the service is due. The distance travelled is rounded off to the nearest

100 km (miles) and the time to full days. The current service message can

only be consulted 500 km (300 miles) after the last service. Until that time,

only dashes are displayed.

Note

● If you reset the display manually, the next service interval will be indica-

ted after 15 000 km (10 000 miles) or one year and will not be calculated

individually.

● Do not reset the display between service intervals as the display will

otherwise be incorrect.

● In LongLife Service vehicles, if the battery is disconnected for a long pe-

riod, the days remaining until the next service cannot be calculated. There-

fore, the service message displays on the instrument panel may be incor-

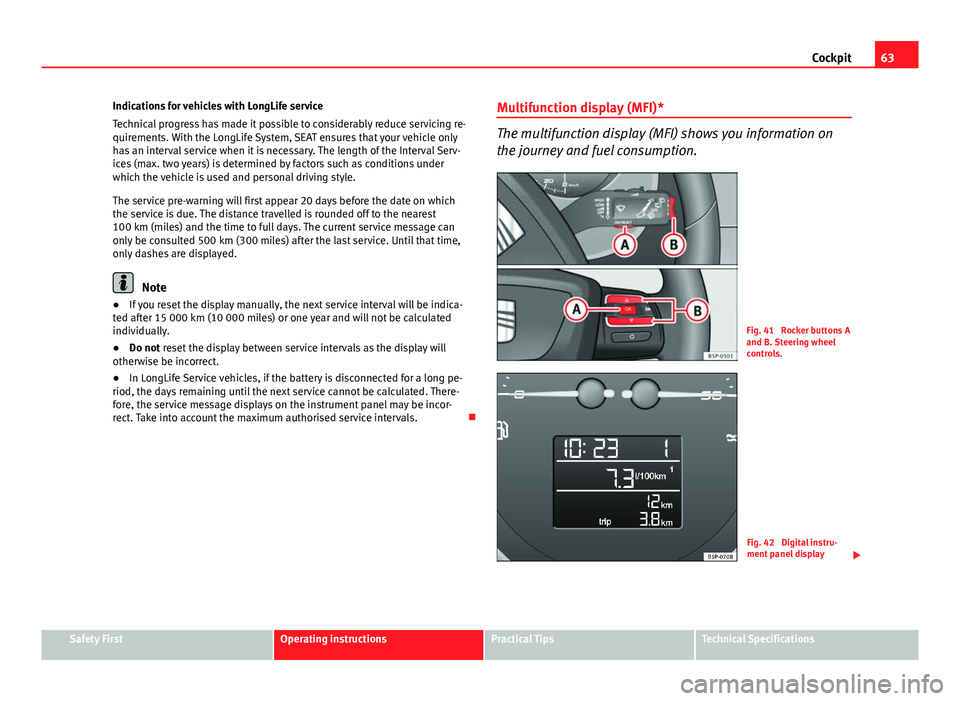

rect. Take into account the maximum authorised service intervals. Multifunction display (MFI)*

The multifunction display (MFI) shows you information on

the journey and fuel consumption.

Fig. 41 Rocker buttons A

and B. Steering wheel

controls.

Fig. 42 Digital instru-

ment panel display

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 129 of 321

127

Lights and visibility

Rear door sun blind*

– Pull out the visor and hook it onto the hooks at the top of the

door frame ⇒ Fig. 82.

Windscreen wipers

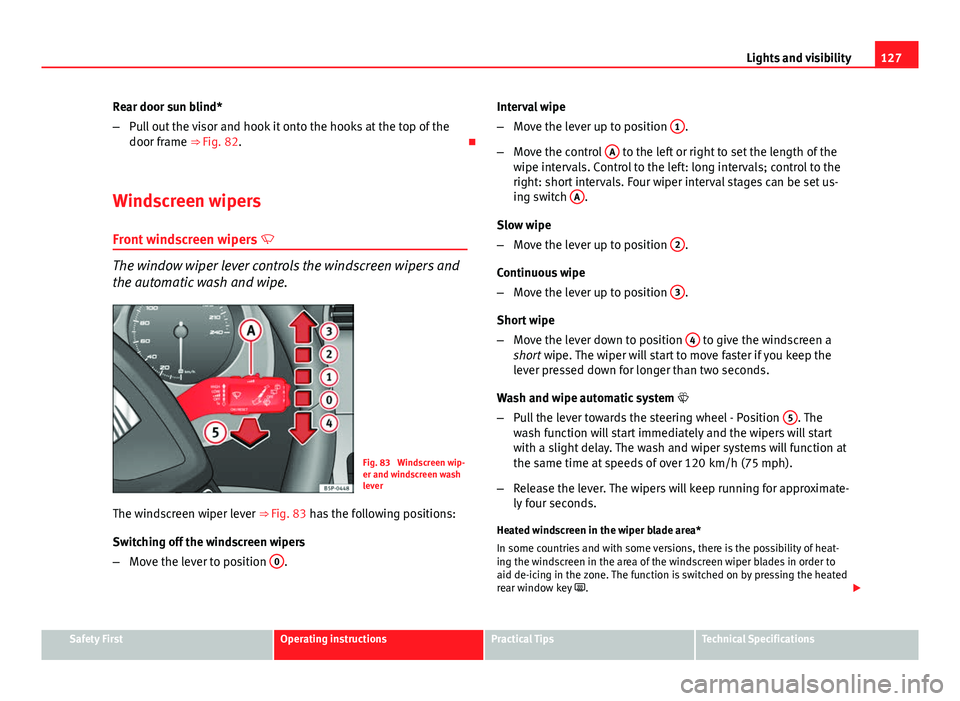

Front windscreen wipers

The window wiper lever controls the windscreen wipers and

the automatic wash and wipe.

Fig. 83 Windscreen wip-

er and windscreen wash

lever

The windscreen wiper lever ⇒ Fig. 83 has the following positions:

Switching off the windscreen wipers

– Move the lever to position 0

. Interval wipe

–

Move the lever up to position 1

.

– Move the control A

to the left or right to set the length of the

wipe intervals. Control to the left: long intervals; control to the

right: short intervals. Four wiper interval stages can be set us-

ing switch A

.

Slow wipe

– Move the lever up to position 2

.

Continuous wipe

– Move the lever up to position 3

.

Short wipe

– Move the lever down to position 4

to give the windscreen a

short wipe. The wiper will start to move faster if you keep the

lever pressed down for longer than two seconds.

Wash and wipe automatic system

– Pull the lever towards the steering wheel - Position 5

. The

wash function will start immediately and the wipers will start

with a slight delay. The wash and wiper systems will function at

the same time at speeds of over 120 km/h (75 mph).

– Release the lever. The wipers will keep running for approximate-

ly four seconds.

Heated windscreen in the wiper blade area*

In some countries and with some versions, there is the possibility of heat-

ing the windscreen in the area of the windscreen wiper blades in order to

aid de-icing in the zone. The function is switched on by pressing the heated

rear window key .

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 160 of 321

158Seats and storage

–Pull the net from underneath between the backrest and the fold-

ing tray and fit it to the slots in the roof, first the right then the

left ⇒ Fig. 127.

– Hook the belts into the front fastening rings to tense the net

⇒ Fig. 128.

Roof rack*

Please observe the following points if you intend to carry loads on the roof:

● For safety reasons, only luggage racks and accessories supplied by SEAT

Official Services are recommended.

● It is essential that you follow the assembly instructions included with

the bars exactly, being especially careful to position the luggage compart-

ment cover bars on the special housings, you must also respect their posi-

tion according to the direction of travel indicated in the assembly manual.

Not following these instructions may cause marks on the bodywork and the

longitudinal bars.

● Pay special attention to the tightening torque of the attachment bolts

and check them following a short journey. If necessary, retighten the bolts

and check them at regular intervals.

● Distribute the load evenly. A maximum load of 40 kg only is permitted

for each roof rack system support bar, the load must be distributed evenly

along the entire length. However, the maximum load permitted for the en-

tire roof (including the support system) of 75 kg must not be exceeded nor

should the total weight of the vehicle be exceeded. See the Technical Data

section.

● When transporting heavy or large objects on the roof, any change in the

normal vehicle behaviour due to a change in the centre of gravity or an in- creased wind resistance must be taken into account. For this reason, a suit-

able speed and driving style must be used.

●

For those vehicles fitted with a sliding/tilting sunroof*, ensure that it

does not interfere with the load on the roof rack system when opened.

Page 200 of 321

198Intelligent technology

The ASR automatically switches on when the engine is started. If necessary,

it may be turned on or off by briefly pushing the button on the centre con-

sole.

When the ASR is switched off, the OFF

warning lamp will light up. The ASR

should normally be left on. Only in exceptional circumstances, when the

slipping of the wheels is required, it will be necessary to have it disconnec-

ted, for example.

● With compact temporary spare wheel.

● When using the snow chains.

● When driving in deep snow or on loose surfaces

● When the vehicle is bogged-down, to free it by rocking.

The ASR should be switched on again as soon as possible.

WARNING

● Remember that not even the ASR can defy the laws of physics. This

should be kept in mind, particularly on slippery and wet roads and when

towing a trailer.

● Always adapt your driving style to suit the condition of the roads and

the traffic situation. The greater safety provided by the ASR should not

encourage you to run any risks.

CAUTION

● To ensure that the ASR works correctly, identical tyres should be fitted

on all four wheels. Any differences in the rolling radius of the tyres can

cause the system to reduce engine power when this is not desired.

● Any modifications made to the vehicle (for example, to the engine,

brake system, running gear or to the combination of wheels and tyres) may

affect the operation of the ABS and ASR. XDS*

Driveshaft differential

When taking a bend, the driveshaft differential mechanism allows the outer

wheel to turn at a higher speed than the inner wheel. In this way, the wheel

that is turning faster (outer wheel) receives less drive torque than the inner

wheel. This may mean that in certain situations the torque delivered to the

inner wheel is too high, causing the wheels to spin. On the other hand, the

outer wheel is receiving a lower drive torque than it could transmit. This

causes an overall loss of lateral grip on the front axle, resulting in under-

steer or “lengthening” of the trajectory.

The XDS system can detect and correct this effect via the sensors and sig-

nals of the ESC.

Via the ESC, the XDS will brake the inside wheel and counter the excess

driving torque of that wheel. This means that the driver's desired trajectory

is much more precise,

The XDS system works in combination with the ESC and is always active,

even when the ASR traction control is disconnected.

Electronic Stability Control (ESC)*

General notes

The Electronic Stability Control increases the vehicle's stabil-

ity on the road. The Electronic Stability Control helps reduce the danger of skidding.

The Electronic Stability Control (ESC) includes the ABS, EDL, ASR and Steer-

ing manoeuvre recommendation systems.

Page 248 of 321

246Checking and refilling levels

To change the blades it is necessary to change the rest position of

the wipers to the service position.

Service position (For changing wiper blades)

–Ensure that the wiper blades are not frozen.

– Turn ignition on and off and then (before approx. 8 seconds

have elapsed), move the windscreen wiper lever to the intermit-

tent wipe position. The windscreen wipers will move to the serv-

ice position.

Changing the windscreen wiper blades

– Lift the wiper arm away from the windscreen.

– Push the side buttons, free the blade and pull in the direction of

the arrow ⇒ Fig. 171

Fitting the wiper blade

– Insert a blade of identical length and design into the wiper arm.

– Slide the blade until it clicks into position.

– Push the wiper arms back against the windscreen.

The windscreen wiper arms return to their original position when the igni-

tion is turned on and the windscreen wiper lever is operated, or when driv-

ing faster than 6 km/h (4 mph).

If the windscreen wipers smear , they should be replaced if they are dam-

aged, or cleaned if they are soiled.

If this does not produce the desired results, the setting angle of the wind-

screen wiper arms might be incorrect. They should be checked by a special-

ised workshop and corrected if necessary.

WARNING

Do not drive unless you have good visibility through all windows!

● Clean the windscreen wiper blades and all windows regularly.

● The wiper blades should be changed once or twice a year.

CAUTION

● Damaged or dirty windscreen wipers could scratch the windscreen.

● Never use fuel, nail varnish remover, paint thinner or similar products to

clean the windows. This could damage the windscreen wiper blades.

● Never move the windscreen wiper or windscreen wiper arm manually.

This could cause damage.

● Do not pull the windscreen wipers forward unless they are in the service

position. Otherwise the bonnet could be damaged.

Note

● The windscreen wiper arms can be moved to the service position only

when the bonnet is properly closed.

Page 261 of 321

259

Wheels and tyres

WARNING

● We recommend that you use only wheels and tyres which have been

approved by SEAT for your model. Failure to do so could impair vehicle

handling. Risk of accident.

● Avoid running the vehicle on tyres that are more than 6 years old. If

you have no alternative, you should drive slowly and with extra care at all

times.

● Never use old tyres or those with an unknown history of use.

● If wheel trims are retrofitted, you must ensure that the flow of air to

the brakes is not restricted. This could cause the brake system to over-

heat.

● All four wheels must be fitted with radial tyres of the same type, size

(rolling circumference) and the same tread pattern.

For the sake of the environment

Old tyres must be disposed of according to the laws in the country con-

cerned.

Note

● For technical reasons, it is not generally possible to use the wheels from

other vehicles. This can also apply to wheels of the same model. The use of

wheels or tyres which have not been approved by SEAT for use with your

model may invalidate the vehicle's type approval for use on public roads.

● If the spare tyre is not the same as the tyres that are mounted on the

vehicle (e.g. winter tyres) you should only use the spare tyre for a short peri-

od of time and drive with extra care. Refit the normal road wheel as soon as

possible. Wheel bolts

Wheel bolts must be tightened to the correct torque.

The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped

bolt heads must be used. This ensures that wheels are fitted securely and

that the brake system functions correctly.

In certain circumstances, you should not use wheel bolts from a different

vehicle, even if it is the same model ⇒ page 226.

After the wheels have been changed, the tightening torque of the wheel

bolts should be checked as soon as possible with a torque wrench ⇒

.

The tightening torque for steel and alloy wheels is 120 Nm.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.

● The wheel bolts must be clean and turn easily. Never apply grease or

oil to them.

● Use only wheel bolts which belong to the wheel.

● If the tightening torque of the wheel bolts is too low, they could loos-

en whilst the vehicle is in motion. Risk of accident! If the tightening tor-

que is too high, the wheel bolts and threads can be damaged.

CAUTION

The prescribed tightening torque for wheel bolts for steel and alloy wheels

is 120 Nm.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 309 of 321

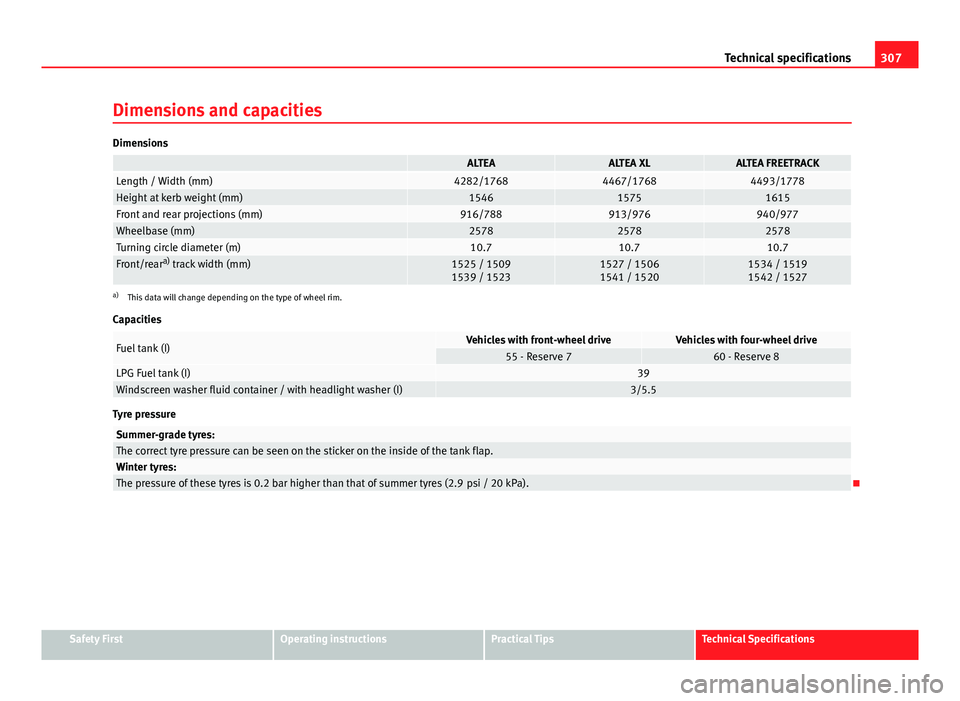

307

Technical specifications

Dimensions and capacities

Dimensions

ALTEAALTEA XLALTEA FREETRACKLength / Width (mm)4282/17684467/17684493/1778Height at kerb weight (mm)154615751615Front and rear projections (mm)916/788913/976940/977Wheelbase (mm)257825782578Turning circle diameter (m)10.710.710.7Front/rear a)

track width (mm)1525 / 1509

1539 / 15231527 / 1506

1541 / 15201534 / 1519

1542 / 1527

a) This data will change depending on the type of wheel rim.

Capacities

Fuel tank (I)Vehicles with front-wheel driveVehicles with four-wheel drive55 - Reserve 760 - Reserve 8LPG Fuel tank (I)39Windscreen washer fluid container / with headlight washer (I)3/5.5

Tyre pressure

Summer-grade tyres:The correct tyre pressure can be seen on the sticker on the inside of the tank flap.Winter tyres:The pressure of these tyres is 0.2 bar higher than that of summer tyres (2.9 psi / 20 kPa).

Safety FirstOperating instructionsPractical TipsTechnical Specifications