wheel Seat Ateca 2016 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2016, Model line: Ateca, Model: Seat Ateca 2016Pages: 328, PDF Size: 6.32 MB

Page 37 of 328

The essentials

If you wish to hide a saving tip immediately

af t

er it appears, press any button on the

windscreen wiper lever*/multifunction steer-

ing wheel*. Note

● If

you hide a saving tip, it will reappear af-

ter you switch the ignition on again.

● The saving tips do not appear in all situa-

tions, b

ut rather with a large separation of

time. Speed warning device

The speed warning device warns the driver

when they

h

ave exceeded the pre-set speed

limit by 3 km/h (2 mph). An audible warning

signal sounds, and the warning lamp and

the driver message Speed limit excee-

ded! will be displayed simultaneously on the

instrument panel. The warning lamp

switches off when reducing speed below the

stored maximum limit.

Speed warning programming is recommen-

ded if you wish to be reminded of a maxi-

mum speed, such as when travelling in a

country with different speed limits or for a

maximum speed for winter tyres.

Setting speed limit warning

You can use the radio or the Easy Connect* to

set, alter or cancel the speed limit warning. ●

Vehicle

s with radio : press the button SETUP > control button

Driver Assistant >

Speed warning .

● Vehicles with Easy Connect : pre

ss the but-

ton Systems or else Vehicle systems >

Driver assistant > Speed warning.

The warning limit can be set from 30 to

240 km/h (20 to 149 mph). The adjustment

is made at 10 km/h (5 mph) intervals. Note

● Ple

ase bear in mind that, even with the

speed warning function, it is still important

to keep an eye on the vehicle speed with the

speedometer and to observe the legal speed

limits.

● The speed limit warning function in the ver-

sion f

or some countries warns you at a speed

of 120 km/h (75 mph). This is a factory-set

speed limit. Service intervals

The service interval indication appears on the

in

s

trument panel display ›››

Fig. 115

3 .

S EA

T distinguishes between services with en-

gine oil change (e.g. Oil change service) and

services without engine oil change (e.g. In-

spection). In vehicles with

Serv

ices established by time

or mileage, the service intervals are already

pre-defined.

In vehicles with LongLife Service , the inter-

vals are determined individually. Thanks to

technological progress, maintenance work

has been greatly reduced. Because of the

technology used by SEAT, with this service

you only need to change the oil when the ve-

hicle so requires. To calculate this change

(max. 2 years), the vehicle's conditions of

use and individual driving styles are consid-

ered. The advance warning first appears 20

days before the date established for the cor-

responding service. The kilometres (miles)

remaining until the next service are always

rounded up to the nearest 100 km (miles)

and the time is given in complete days. The

current service message cannot be viewed

until 500 km after the last service. Prior to

this, only lines are visible on the display.

Inspection reminder

When the Service date is approaching, when

the ignition is switched on a Service remind-

er is displayed.

Vehicles without text messages : a span-

ner will be displayed on the instrument

panel plus an indication in km.

The kilometres indicated are the maximum

number of kilometres that can be travelled

until the next service. After a few seconds, » 35

Page 38 of 328

The essentials

the display mode changes. A clock symbol

ap pe

ars and the number of days until the

next service is due.

Vehicles with text messages : Service in

--- km or --- days will be shown on the

instrument panel display.

Service due

When the service date is due , an audible

warning is given when the ignition is switch-

ed on and the spanner displayed on the

screen flashes for a few seconds .

Vehicles with text messages : Service now

will be shown on the instrument panel dis-

play.

Reading a service notification

With the ignition switched on, the engine off

and the vehicle at a standstill, the current

service notification can be read:

Press and hold the button ›››

Fig. 115

4 for more than 5 seconds to consult the serv-

ic

e me

ssage.

When the service date has passed , a minus

sign is displayed in front of the number of kil-

ometres or days.

Vehicles with text messages : the following

message is displayed: Service --- km

(miles) or --- days ago .The time can also be set via the

key and

Set up function button in the Easy Connect

sy s

tem ›››

page 108.

Resetting service interval display

If the service was not carried out by a SEAT

dealership, the display can be reset as fol-

lows: ● Switch off the ignition, press and hold but-

ton ›

›› Fig. 115

4 .

● Switch ignition back on.

● Release THE 4

› ›

›

Fig. 115 button and

press it again for the next 20 seconds. Note

● The ser v

ice message disappears after a few

seconds, when the engine is started or when OK/RESET is pressed on the windscreen wiper

l ev

er, or OK on the multifunction steering

wheel .

● In

vehicles with the LongLife system in

which the b

attery has been disconnected for

a long period of time, it is not possible to cal-

culate the date of the next service. Therefore

the service interval display may not be cor- rect. In this case, bear in mind the maximum

service intervals permitted in the ››› Book-

let Maintenance Programme.

● If you reset the display manually, the next

serv

ice interval will be indicated as in vehi-

cles with fixed service intervals. For this rea-

son we recommend that the service interval

display be reset by a SEAT authorised Dealer. Cruise control

Oper atin

g the cruise control system

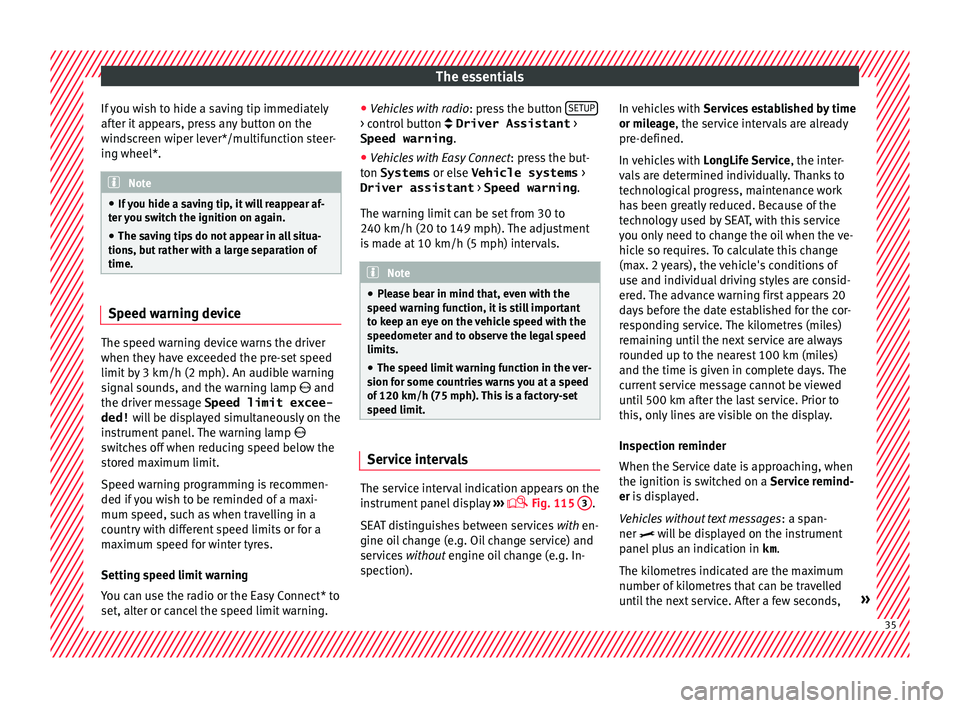

(CCS)* Fig. 47

On the left of the steering column:

sw it

ches and controls for operating the CCS Fig. 48

On the left of the steering column:

thir d l

ever to operate the CCS. 36

Page 50 of 328

The essentials

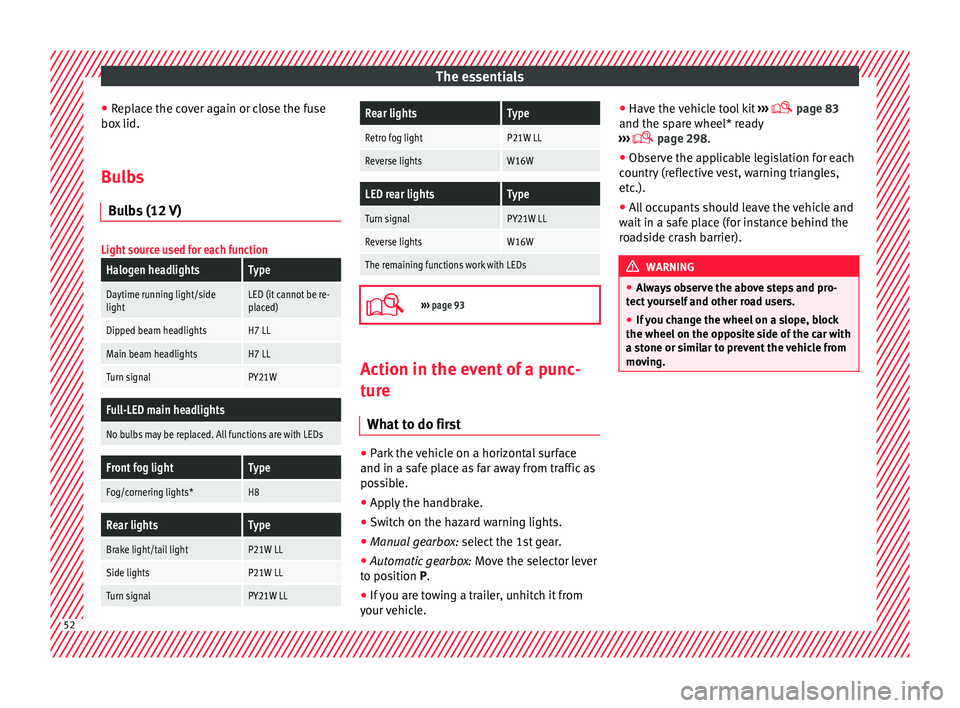

Fluid Level control Fi l

ling capacities

Tank level

Petrol and diesel

engines50 l, of which, approx. 7 l reserve

Four-wheel drive vehicles :

55 l, of which approx. 8.5 l reserve

Capacity of the windscreen washer fluid container

Versions without

headlight washer

systemapprox. 3 litres

Versions with

headlight washer

systemapprox. 5 litres Fuel

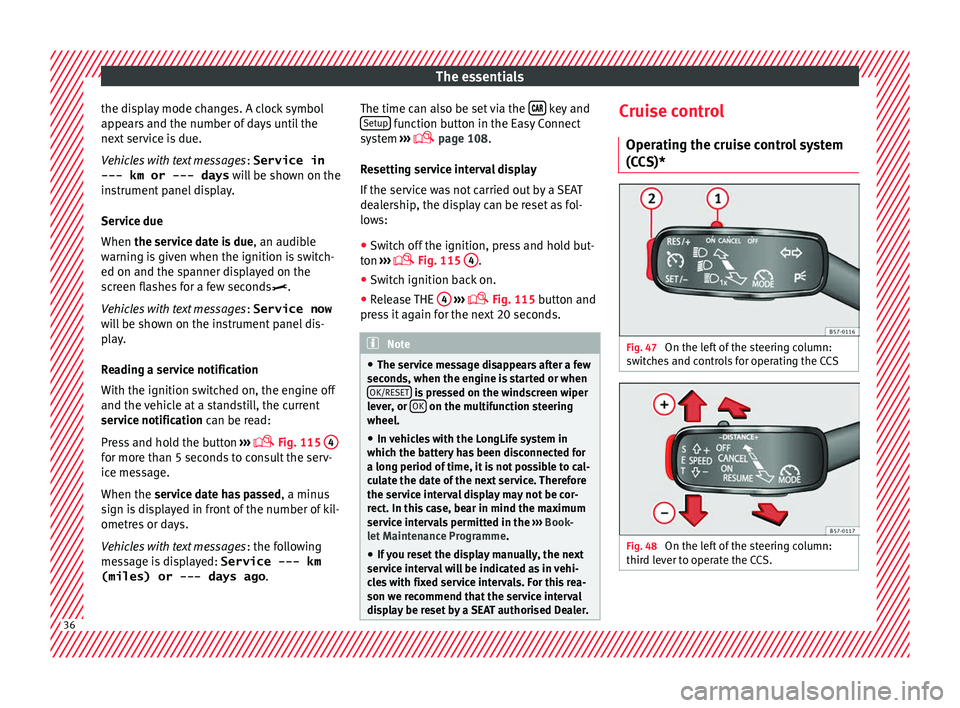

Fig. 58

Fuel tank flap with tank cap attached. The flap that covers the tank cap is unlocked

and loc

k

ed automatically using the central

locking.

Opening the fuel tank cap

● Open the fuel tank flap by pressing on the

lef

t side.

● Unscrew the cap by turning it to the left.

● Place it in the space on the hinge of the

open flap ›

›› Fig. 58.

Closing the fuel tank cap

● Unscrew the cap by turning it to the right as

far a

s it will go.

● Close the lid.

››› in Filling up on page 276

››› page 276 Oil

Fig. 59

Engine oil dipstick. Fig. 60

In the engine compartment: Engine

oi l

filler cap The level is measured using the dipstick loca-

t

ed in the en

gine compartment

››› page 282.

The oil should leave a mark between zones A and

C . It should never exceed zone

A .

● Zone A : Do not add oil.

48

Page 54 of 328

The essentials

● Rep

lace the cover again or close the fuse

box lid.

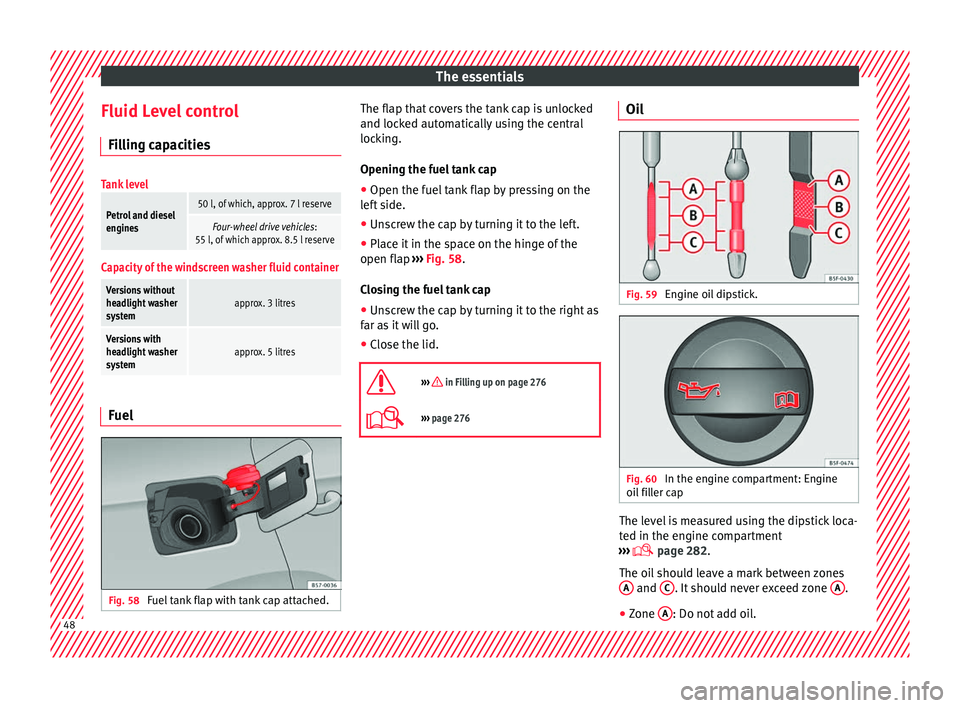

Bulbs Bu

lbs (12 V)

Light source used for each function

Halogen headlightsType

Daytime running light/side

lightLED (it cannot be re-

placed)

Dipped beam headlightsH7 LL

Main beam headlightsH7 LL

Turn signalPY21W

Full-LED main headlights

No bulbs may be replaced. All functions are with LEDs

Front fog lightType

Fog/cornering lights*H8

Rear lightsType

Brake light/tail lightP21W LL

Side lightsP21W LL

Turn signalPY21W LL

Rear lightsType

Retro fog lightP21W LL

Reverse lightsW16W

LED rear lightsType

Turn signalPY21W LL

Reverse lightsW16W

The remaining functions work with LEDs

›››

page 93 Action in the event of a punc-

t

ur

e

What to do first ●

Park the vehicle on a horizontal surface

and in a s af

e place as far away from traffic as

possible.

● Apply the handbrake.

● Switch on the hazard warning lights.

● Manual gearbox: select

the 1st gear.

● Automatic gearbox: Mov

e the selector lever

to position P.

● If you are towing a trailer, unhitch it from

your

vehicle. ●

Have the

vehicle tool kit ›››

page 83

and the spare wheel* ready

››› page 298.

● Observe the applicable legislation for each

cou

ntry (reflective vest, warning triangles,

etc.).

● All occupants should leave the vehicle and

wait

in a safe place (for instance behind the

roadside crash barrier). WARNING

● Alw

ays observe the above steps and pro-

tect yourself and other road users.

● If you change the wheel on a slope, block

the wheel on the op

posite side of the car with

a stone or similar to prevent the vehicle from

moving. 52

Page 56 of 328

The essentials

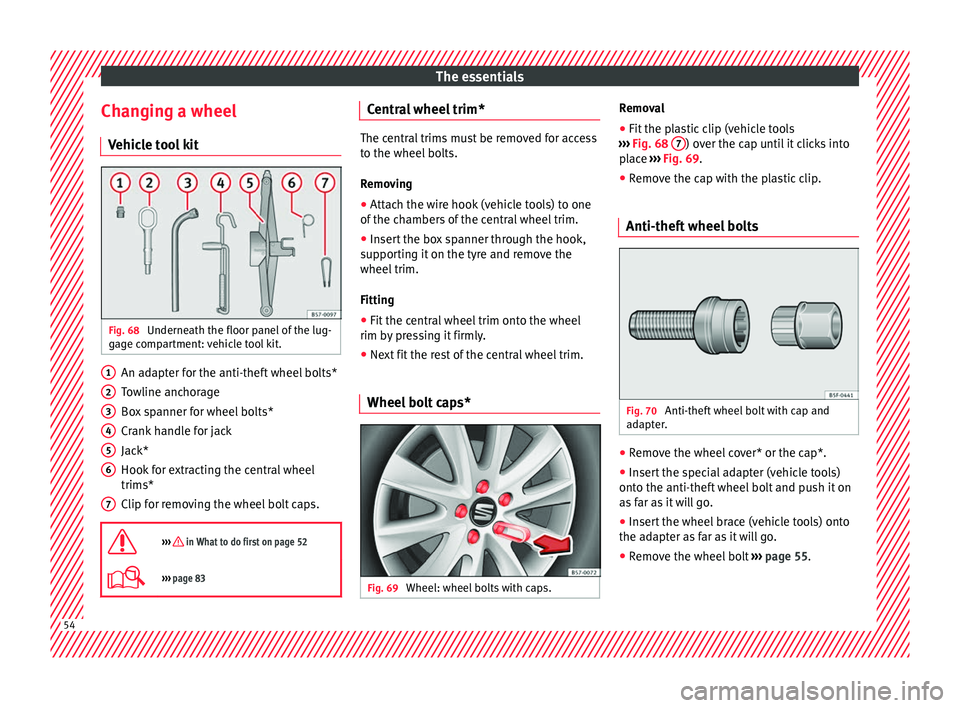

Changing a wheel V ehic

le tool kit Fig. 68

Underneath the floor panel of the lug-

g ag

e compartment: vehicle tool kit. An adapter for the anti-theft wheel bolts*

T

o

wline anchorage

Box spanner for wheel bolts*

Crank handle for jack

Jack*

Hook for extracting the central wheel

trims*

Clip for removing the wheel bolt caps.

››› in What to do first on page 52

››› page 83 1

2

3

4

5

6

7 Central wheel trim*

The central trims must be removed for access

t

o the wheel

bolts.

Removing

● Attach the wire hook (vehicle tools) to one

of the c

hambers of the central wheel trim.

● Insert the box spanner through the hook,

sup

porting it on the tyre and remove the

wheel trim.

Fitting

● Fit the central wheel trim onto the wheel

rim b y

pressing it firmly.

● Next fit the rest of the central wheel trim.

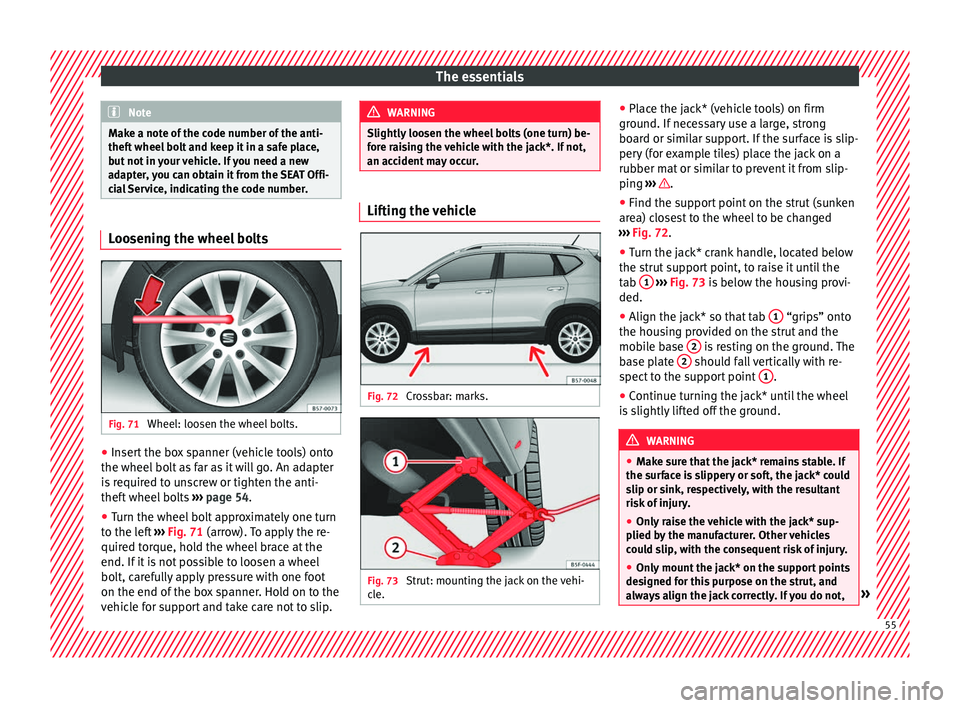

Wheel bolt caps* Fig. 69

Wheel: wheel bolts with caps. Removal

● Fit the plastic clip (vehicle tools

› ›

› Fig. 68 7 ) over the cap until it clicks into

p l

ace ››› Fig. 69.

● Remove the cap with the plastic clip.

Anti-theft wheel bolts Fig. 70

Anti-theft wheel bolt with cap and

a d

apter. ●

Remove the wheel cover* or the cap*.

● Insert the special adapter (vehicle tools)

ont o the anti-thef

t wheel bolt and push it on

as far as it will go.

● Insert the wheel brace (vehicle tools) onto

the ad

apter as far as it will go.

● Remove the wheel bolt ››

› page 55 .54

Page 57 of 328

The essentials

Note

Make a note of the code number of the anti-

thef t

wheel bolt and keep it in a safe place,

but not in your vehicle. If you need a new

adapter, you can obtain it from the SEAT Offi-

cial Service, indicating the code number. Loosening the wheel bolts

Fig. 71

Wheel: loosen the wheel bolts. ●

Insert the box spanner (vehicle tools) onto

the wheel bo

lt as far as it will go. An adapter

is required to unscrew or tighten the anti-

theft wheel bolts ›››

page 54.

● Turn the wheel bolt approximately one turn

to the l

eft ›››

Fig. 71 (arrow). To apply the re-

quired torque, hold the wheel brace at the

end. If it is not possible to loosen a wheel

bolt, carefully apply pressure with one foot

on the end of the box spanner. Hold on to the

vehicle for support and take care not to slip. WARNING

Slightly loosen the wheel bolts (one turn) be-

f or

e raising the vehicle with the jack*. If not,

an accident may occur. Lifting the vehicle

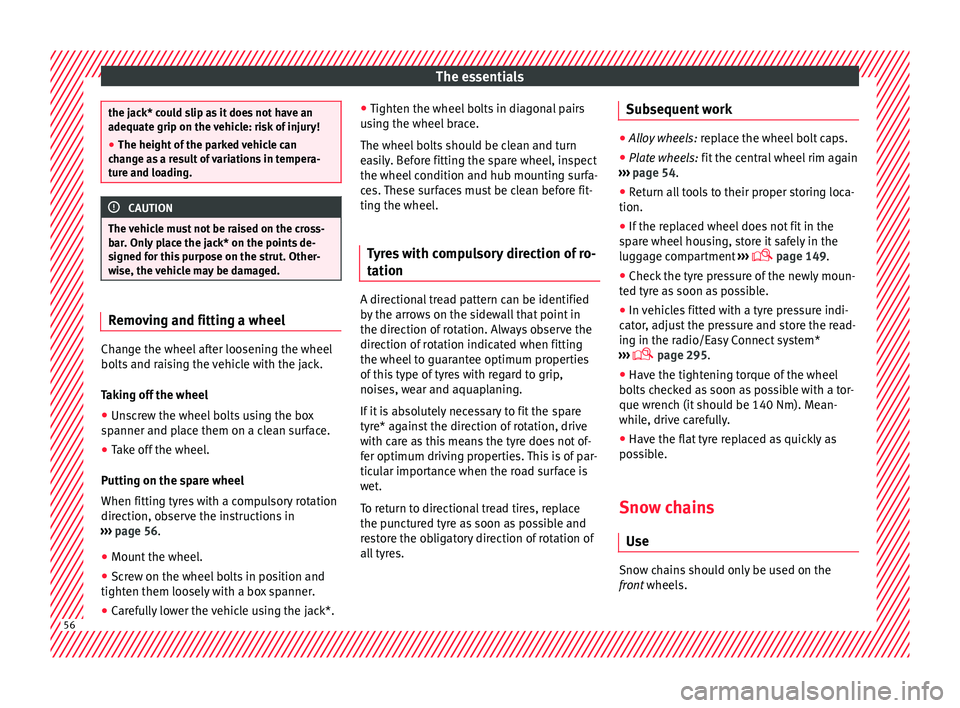

Fig. 72

Crossbar: marks. Fig. 73

Strut: mounting the jack on the vehi-

c l

e. ●

Plac

e the jack* (vehicle tools) on firm

ground. If necessary use a large, strong

board or similar support. If the surface is slip-

pery (for example tiles) place the jack on a

rubber mat or similar to prevent it from slip-

ping ››› .

● Find the support point on the strut (sunken

ar e

a) closest to the wheel to be changed

››› Fig. 72.

● Turn the jack* crank handle, located below

the strut

support point, to raise it until the

tab 1

› ››

Fig. 73

is below the housing provi-

ded.

● Align the jack* so that tab 1 “grips” onto

the hou s

ing provided on the strut and the

mobile base 2 is resting on the ground. The

b a

se plate 2 should fall vertically with re-

s pect

to the support point 1 .

● Continue turning the jack* until the wheel

i s

slightly lifted off the ground. WARNING

● Mak

e sure that the jack* remains stable. If

the surface is slippery or soft, the jack* could

slip or sink, respectively, with the resultant

risk of injury.

● Only raise the vehicle with the jack* sup-

plied b

y the manufacturer. Other vehicles

could slip, with the consequent risk of injury.

● Only mount the jack* on the support points

des

igned for this purpose on the strut, and

always align the jack correctly. If you do not, » 55

Page 58 of 328

The essentials

the jack* could slip as it does not have an

a

dequat

e grip on the vehicle: risk of injury!

● The height of the parked vehicle can

ch

ange as a result of variations in tempera-

ture and loading. CAUTION

The vehicle must not be raised on the cross-

b ar

. Only place the jack* on the points de-

signed for this purpose on the strut. Other-

wise, the vehicle may be damaged. Removing and fitting a wheel

Change the wheel after loosening the wheel

bo

lts

and raising the vehicle with the jack.

Taking off the wheel ● Unscrew the wheel bolts using the box

sp

anner and place them on a clean surface.

● Take off the wheel.

Puttin

g on the spare wheel

When fitting tyres with a compulsory rotation

direction, observe the instructions in

››› page 56.

● Mount the wheel.

● Screw on the wheel bolts in position and

tight en them loo

sely with a box spanner.

● Carefully lower the vehicle using the jack*. ●

Tight en the wheel

bolts in diagonal pairs

using the wheel brace.

The wheel bolts should be clean and turn

easily. Before fitting the spare wheel, inspect

the wheel condition and hub mounting surfa-

ces. These surfaces must be clean before fit-

ting the wheel.

Tyres with compulsory direction of ro-

tation A directional tread pattern can be identified

b

y

the arrows on the sidewall that point in

the direction of rotation. Always observe the

direction of rotation indicated when fitting

the wheel to guarantee optimum properties

of this type of tyres with regard to grip,

noises, wear and aquaplaning.

If it is absolutely necessary to fit the spare

tyre* against the direction of rotation, drive

with care as this means the tyre does not of-

fer optimum driving properties. This is of par-

ticular importance when the road surface is

wet.

To return to directional tread tires, replace

the punctured tyre as soon as possible and

restore the obligatory direction of rotation of

all tyres. Subsequent work ●

Alloy wheels: rep

lace the wheel bolt caps.

● Plate wheels: fit the c

entral wheel rim again

››› page 54.

● Return all tools to their proper storing loca-

tion.

● If the replaced wheel does not fit in the

sp

are wheel housing, store it safely in the

luggage compartment ›››

page 149.

● Check the tyre pressure of the newly moun-

ted ty

re as soon as possible.

● In vehicles fitted with a tyre pressure indi-

c at

or, adjust the pressure and store the read-

ing in the radio/Easy Connect system*

››› page 295.

● Have the tightening torque of the wheel

bolts

checked as soon as possible with a tor-

que wrench (it should be 140 Nm). Mean-

while, drive carefully.

● Have the flat tyre replaced as quickly as

pos

sible.

Snow chains Use Snow chains should only be used on the

fr

on

t wheels.56

Page 59 of 328

The essentials

Check that they are correctly seated after

driv in

g for a few yards; correct the position if

necessary, in accordance with the manufac-

turer's fitting instructions. Keep your speed

below 50 km/h (30 mph).

If there is a danger of being trapped despite

having mounted the chains, it is best to disa-

ble the driving wheels (ASR) in the ESC

››› page 174, Switching on/off the ESC

and ASR.

Snow chains will improve braking ability as

well as traction in winter conditions.

For technical reasons snow chains may only

be used with the following wheel rim/tyre

combination.

215/60 R16Chains with links of maximum 15 mm

215/55 R17Chains with links of maximum 15 mm

215/50 R18Chains with links of maximum 15 mm

Other dimensions do not allow chains Remove any central wheel trims and the rim

rin

g bef

ore fitting snow chains.

Remove the chains when roads are free of

snow. Driving characteristics worsen, and the

wheels become damaged quickly and may

even be rendered unusable. Emergency towing of the vehi-

cl

e

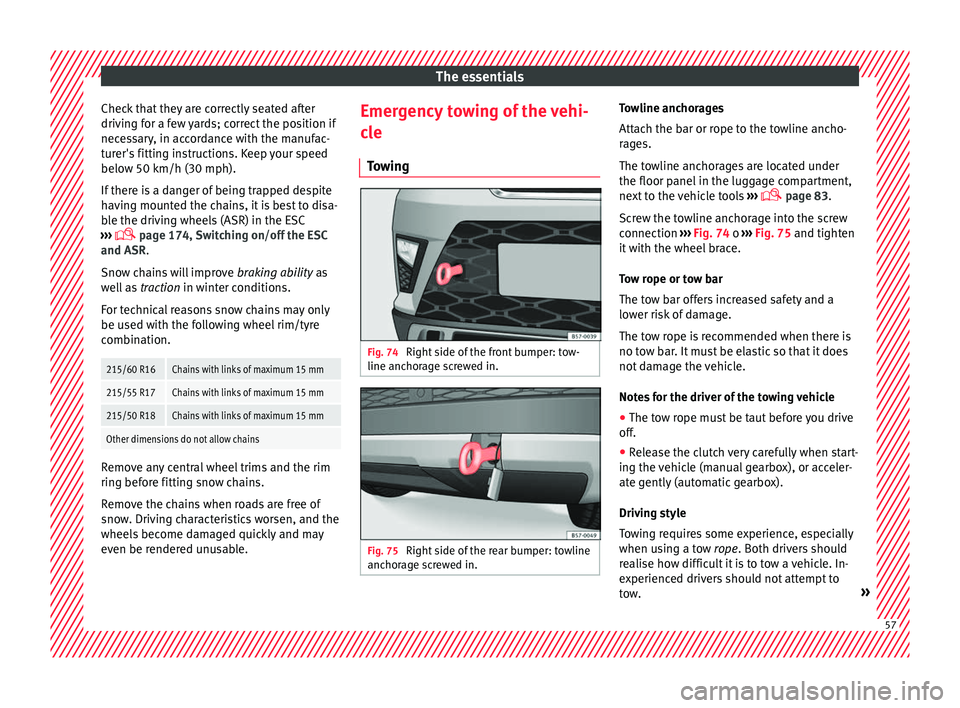

Towing Fig. 74

Right side of the front bumper: tow-

line anc hor

age screwed in. Fig. 75

Right side of the rear bumper: towline

anc hor

age screwed in. Towline anchorages

Att

ac

h the bar or rope to the towline ancho-

rages.

The towline anchorages are located under

the floor panel in the luggage compartment,

next to the vehicle tools ›››

page 83.

Screw the towline anchorage into the screw

connection ››› Fig. 74 o ››› Fig. 75 and tighten

it with the wheel brace.

Tow rope or tow bar

The tow bar offers increased safety and a

lower risk of damage.

The tow rope is recommended when there is

no tow bar. It must be elastic so that it does

not damage the vehicle.

Notes for the driver of the towing vehicle

● The tow rope must be taut before you drive

off.

● R

elease the clutch very carefully when start-

ing the

vehicle (manual gearbox), or acceler-

ate gently (automatic gearbox).

Driving style

Towing requires some experience, especially

when using a tow rope. Both drivers should

realise how difficult it is to tow a vehicle. In-

experienced drivers should not attempt to

tow. » 57

Page 60 of 328

The essentials

Do not pull too hard with the towing vehicle

and t ak

e care to avoid jerking the tow rope.

When towing on an unpaved road, there is al-

ways a risk of overloading and damaging the

anchorage points.

Switch on the ignition so that the turn sig-

nals, windscreen wipers and windscreen

washer can work. Ensure that the steering

wheel is unlocked and moves freely.

Place the gear lever in neutral on vehicles

with a manual gearbox. With an automatic

gearbox, place the lever in N.

To brake, press the brake pedal firmly. The

brake servo does not work when the engine

is switched off.

The power steering only works when the igni-

tion is switched on and the vehicle is moving,

provided that the battery is sufficiently charg-

ed. Otherwise, it will need more force.

Ensure that the tow rope remains taut at all

times.

››› in Introduction on page 86

››› page 86 Tow-starting

If the engine will not start, first try starting it

u

s

ing the battery of another vehicle

››› page 58. You should only attempt to tow-

start a vehicle if charging the battery does

not work. This is done by leveraging wheel

movement.

When tow-starting a vehicle with a petrol en-

gine, do not tow it more than a short dis-

tance, otherwise unburned fuel can enter the

catalytic converter.

● Engage 2nd or 3rd gear before moving off.

● Press the clutch and hold the pedal down.

● Switch the ignition on.

● Once both vehicles are moving, release the

c lut

ch.

● As soon as the engine has started, press

the clut

ch and move the gear lever to neutral.

How to jump start Jump le

ads The jump lead must have a sufficient wire

c

r

oss section.

If the engine fails to start because of a dis-

charged battery, the battery can be connec-

ted to the battery of another vehicle to start

the engine. Jump leads must comply with standard

DIN

72553 (see cab

le manufacturer's instruc-

tions). The wire cross section must be at least

25 mm 2

for petrol engines and at least

35 mm 2

for diesel engines. Note

● The v

ehicles must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected.

● The discharged battery must be properly

connect

ed to the on-board network.58

Page 65 of 328

Safe driving

● Belt

tensioners for the front seats

● Front airbags

● knee airbags,

● Side airbags in the front seat backrests

● Head-protection airbags

● “ISOFIX” anchor points for child seats in

the re

ar side seats with the “ISOFIX” system,

● Height-adjustable front head restraints

● Rear head restraints with in-use position

and non-use po

sition

● Adjustable steering column

The saf

ety equipment mentioned above

works together to provide you and your pas-

sengers with the best possible protection in

the event of an accident. However, these

safety systems can only be effective if you

and your passengers are sitting in a correct

position and use this equipment properly.

Safety is everyone's business! Correct position for passengers

Corr

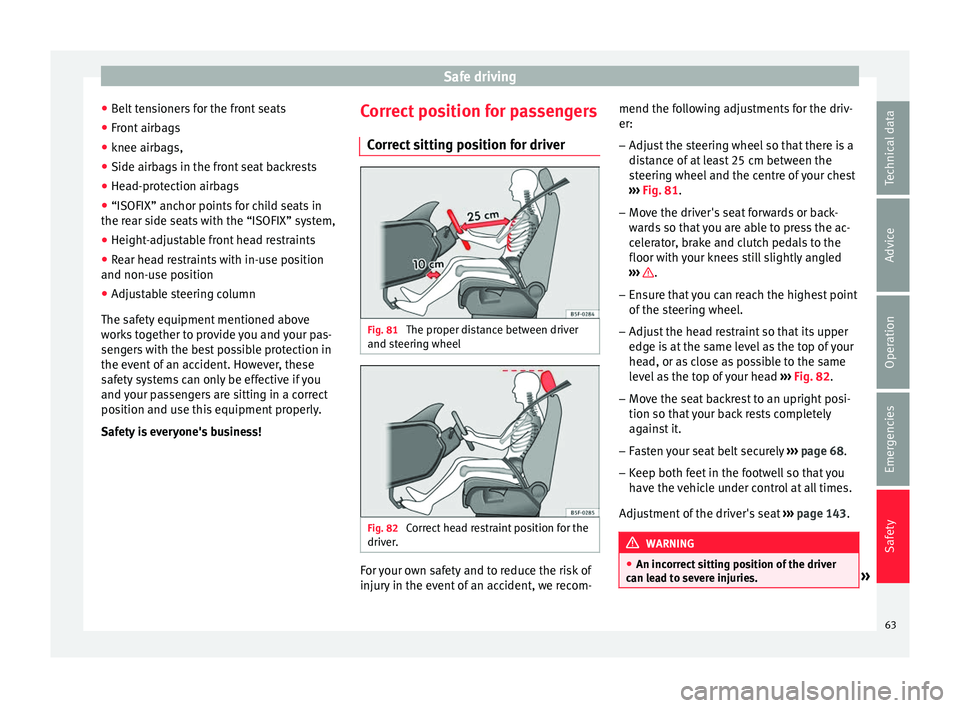

ect sitting position for driver Fig. 81

The proper distance between driver

and s t

eering wheel Fig. 82

Correct head restraint position for the

driv er

. For your own safety and to reduce the risk of

injur

y

in the event of an accident, we recom- mend the following adjustments for the driv-

er:

– Adjust the steering wheel so that there is a

dis

tance of at least 25 cm between the

steering wheel and the centre of your chest

››› Fig. 81.

– Move the driver's seat forwards or back-

war

ds so that you are able to press the ac-

celerator, brake and clutch pedals to the

floor with your knees still slightly angled

››› .

– Ensure that you can reach the highest point

of the s

teering wheel.

– Adjust the head restraint so that its upper

edge i

s at the same level as the top of your

head, or as close as possible to the same

level as the top of your head ››› Fig. 82.

– Move the seat backrest to an upright posi-

tion so that

your back rests completely

against it.

– Fasten your seat belt securely ››

› page 68.

– Keep both feet in the footwell so that you

hav

e the vehicle under control at all times.

Adjustment of the driver's seat ››› page 143. WARNING

● An inc orr

ect sitting position of the driver

can lead to severe injuries. » 63

Technical data

Advice

Operation

Emergencies

Safety