air condition Seat Exeo 2008 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2008, Model line: Exeo, Model: Seat Exeo 2008Pages: 303, PDF Size: 10.02 MB

Page 184 of 303

Driving and the environment

182your vehicle has automatic transmission). This makes use of engine

braking and relieves the brakes.•

Never let the brakes “slip” by applying light pressure. Continuous

braking will cause the brakes to overheat and the braking distance will

increase. Apply and then release the brakes alternately.

•

Never let the vehicle run with the engine switched off. The braking

distance is increased considerably when the brake servo is not active.

•

Very heavy use of the brakes may cause a vapour lock if the brake fluid

is left in the system for too long. This impairs the braking effect.

•

Non-standard or damaged front spoilers could restrict the airflow to the

brakes and cause them to overheat. Observe the relevant instructions

before purchasing accessories ⇒ page 206, “Technical modifications”.

•

If a brake circuit fails, the braking distance will be increased consider-

ably. Contact a qualified workshop immediately and avoid unnecessary

journeys.

Exhaust gas purification systemCatalytic converter*To conserve the useful life of the catalytic converter

– Always use unleaded petrol.

– Do not let the fuel get too low in the tank.

– For engine oil changes, do not replenish with too much engine oil ⇒page 215. – Never tow the vehicle to start it, use jump leads if necessary

⇒page 271.

If you notice misfiring, uneven running or loss of power when the vehicle is

moving, reduce speed immediately and have the vehicle inspected at the

nearest qualified workshop. In general, the exhaust warning lamp will light

up when any of the described symptoms occur ⇒page 66. If this happens,

unburnt fuel can enter the exhaust system and escape into the environment.

The catalytic converter can also be damaged by overheating.

WARNING

The catalytic converter reaches very high temperatures! Fire hazard!•

Never park where the catalytic convert er could come into contact with

dry grass or inflammable materials under the vehicle.

•

Do not apply additional underseal or anti-corrosion coatings to the

exhaust pipes, catalytic converter or the heat shields on the exhaust

system. These materials could catch fire when the vehicle is being driven.Caution

Never fully drain the fuel tank because the irregularity of the fuel supply may

cause ignition problems. This allows unburnt fuel to enter the exhaust

system, which could cause overheating and damage the catalytic converter.

For the sake of the environment

Even when the emission control system is working perfectly, there may be a

smell of sulphur from the exhaust under some conditions. This depends on

the sulphur content of the fuel used. Quite often the problem can be solved

by changing to another fuel brand.

WARNING (continued)

Exeo_EN.book Seite 182 Freitag, 17. Oktober 2008 11:24 11

Page 186 of 303

Driving and the environment

184Periodic maintenance

Periodic maintenance work guarantees that, before beginning a journey, you

will not consume more than the required amount of fuel. A well-serviced

engine gives you the benefit of improved fuel efficiency as well as maximum

reliability and an enhanced resale value.

A badly serviced engine can consume up to 10% more fuel than necessary.

Avoid short journeys

To reduce the consumption and emission of polluting gases, the engine and

the exhaust filtration systems should reach the optimum service tempera-

ture .

With the engine cold, fuel consumption is proportionally higher. The engine

does not warm up and fuel consumptio n does not regularise until having

driven some four kilometres. This is the reas on why we recommend avoiding

short trips wherever possible.

Maintain the correct tyre pressures

Bear in mind that keeping the tyres at an adequate pressure saves fuel. If the

tyre pressures are just 1 bar too low, this can put the fuel consumption up by

as much as 5 %. Due to the greater rolling resistance, under-inflation also

increases tyre wear and impairs handling.

The tyre pressures should always be checked when the tyres are cold.

Do not use winter tyres all through the year: they will increase fuel consump-

tion by up to 10 %.

Avoid unnecessary weight

Every kilo of extra weight will put up the fuel consumption, so it is worth

checking the luggage compartment occasionally to make sure that no unnec-

essary loads are being transported.

A roof carrier is often left in place for the sake of convenience, even when it is

no longer needed. At a speed of 100-120 km/h your car will use about 12%

more fuel as a result of the extra wind resistance caused by the roof carrier

even when it is not in use. Saving electrical energy

The engine activates the alternator, which produces electricity. With the need

for electricity, fuel consumption is al

so increased. Because of this, always

turn off electrical equipment when you do not need them. Examples of equip-

ment that use a lot of electricity are: the fan at high speeds, the rear window

heating or the seat heaters*.

Environmental friendlinessEnvironmental protection is a top priority in the design, choice of materials

and production of your new Seat.

Design measures for economical recycling•

Joints and connections designed for ease of dismantling

•

Modular construction to facilitate dismantling

•

Increased use of single-grade materials

•

Plastic parts and elastomers are labelled in accordance with ISO 1043,

ISO 11469 and ISO 1629

Choice of materials

•

Nearly all materials used can be recycled

•

Similar types of plastics grouped together for easy recycling

•

Recycled materials used in manufacture

•

Reduction of volatile compounds in plastics

•

CFC-free refrigerant in air conditioning

Compliance with prohibited materials laws: cadmium, asbestos, lead,

mercury, chrome VI.

Manufacturing methods

•

Use of recycled material for manufacturing plastic parts

•

Solvent-free cavity sealing

Exeo_EN.book Seite 184 Freitag, 17. Oktober 2008 11:24 11

Page 207 of 303

Your vehicle maintenance and cleaning205

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

Seat belts cleaning

A dirty belt may not work properly.Check all seat belts regularly and keep them clean.

Seat belts cleaning

– Pull the dirty seat belt right out and unroll it.

– Clean dirty seat belts with a gentle soap solution.

– Allow it to dry.

– Do not roll the seat belt up until it is dry.If large stains form on the belts, it wi ll not retract correctly into the automatic

belt retractor.

WARNING

•

Do not use chemical cleaning agents on the seat belts, as this can

impair the strength of the webbing. Ensure that belts do not come into

contact with corrosive fluids.

•

Check all seat belts condition at regular intervals. If you notice that the

belt webbing, fittings, retractor mechanism or buckle of any of the belts is

damaged, the belt must be replaced by a specialist workshop.

•

Do not attempt to repair a damaged seat belt yourself. The seat belts

must not be removed or modified in any way.Caution

After cleaning, allow seat belts to dry completely before rolling them up.

Otherwise, the belt retractors could become damaged.

Exeo_EN.book Seite 205 Freitag, 17. Oktober 2008 11:24 11

Page 234 of 303

Wheels and tyres

232Anti-puncture tyres*

Anti-puncture tyres allow you to continue driving even with a

punctured tyre, in the majority of cases.Vehicles equipped with anti-puncture

4) tyres from the factory indi-

cate the loss of tyre pressure on the instrument panel.

Driving with anti-puncture tyres (emergency gear)

– Leave the ESP/TCS (electronic stabilisation programme) switched on, or switch on ⇒page 68.

– Continue driving carefully and slowly (80 km/h maximum).

– Avoid sudden manoeuvres and sharp turns.

– Avoid driving over obstacles (for example kerbs) or potholes.

– Look out for the ESP/TCS intervening often, smoke coming from the tyres or the smell of rubber, the vehicle vibrating or a clat-

tering noise. If any of these occur, stop the vehicle.

The anti-puncture tyres have a tag on the side of the tyre, with the description:

“DSST”, “Eufonia”, “RFT”, “ROF”, “RSC”, “SSR” or “ZP”.

The sides of this type of tyre are reinforced. When the tyres lose air they are

supported on the sides (emergency driving).

The loss of pressure in the tyre is shown on the instrument panel. You can

then drive a maximum of 80 km and if the circumstances are favourable (for

example, low load), even more.

The damaged tyre should be changed as soon as possible. The rim should be

checked in a specialist workshop to detect possible damage and replace it if necessary. We recommend you contact Technical Service. If more than one

tyre is being used under emergency conditions, this reduces the distance

which can be travelled.

Starting driving in emergency conditions

At the moment the loss of tyre pressure is indicated on the instrument panel,

at least one of the tyres is running in an emergency state

⇒.

End of emergency operation

Do not drive on if:

•

smoke is coming from one of the tyres,

•

there is a smell of rubber,

•

the vehicle vibrates,

•

there is a rattling noise.

When is it no longer possible to co ntinue driving even using anti-puncture

tyres?

•

If the Electronic Stabilisation Program (ESP) is out of operation.

•

If the tyre pressure monitoring system is out of operation.

•

If one of the tyres has been severely damaged in an accident, etc. If a tyre

has been badly damaged there is a risk that parts of the tread can be thrown

off and cause damage to the fuel lines, brake pipes or fuel filler.

•

It is also advisable to stop driving if severe vibrations occur, or if the wheel

starts overheating and gives off smoke.

WARNING

When driving in emergency conditions, the driving quality of the vehicle is

considerably impaired.•

The maximum permitted speed of 80 km/h is subject to road and

weather conditions. Please observe legal requirements when doing so.

•

Avoid sharp turns and rapid manoeuvres, and brake earlier than usual.

4)Depending upon version and country.

Exeo_EN.book Seite 232 Freitag, 17. Oktober 2008 11:24 11

Page 235 of 303

Wheels and tyres233

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

•

Avoid driving over obstacles (for example kerbs) or potholes.

•

If one or more tyres is being driven in emergency conditions, the driving

quality of the vehicle is impaired and there is a risk of accident.Note

•

The anti-puncture tyres do not “deflate” on losing pressure because they

are supported on the reinforced sides. Therefore defects in the tyre can not be

detected with a visual inspection.

•

Snow chains must not be used on front tyres used in emergency

conditions.

New tyres and wheels

New tyres and wheels have to be run-in.The tyres and wheel rims are an essential part of the vehicle's design. The

tyres and rims approved by SEAT are specially matched to the characteristics

of the vehicle and make a major contribution to good road holding and safe

handling ⇒.

Tyres should be replaced at least in pairs and not individually (i.e. both front

tyres or both rear tyres together). A knowledge of tyre designations makes it

easier to choose the correct tyres. Radial tyres have the tyre designations

marked on the sidewall, for example: 195/65 R15 91T

This contains the following information:

195 Tyre width in mm

65 Height/width ratio in %

R Tyre construction: Radial 15 Rim diameter in inches

91 Load rating code

T Speed rating

The tyres could also have the following information:

•

A direction of rotation symbol

•

“Reinforced” denotes heavy-duty tyres.

The manufacturing date is also indicate d on the tyre sidewall (possibly only

on the inner side of the wheel).

“DOT ... 1103...” means, for example, that the tyre was produced in the 11th

week of 2003.

We recommend that work on tyres and wh eels is carried out by an Authorised

Service Centre. They are familiar with the procedure and have the necessary

special tools and spare parts as well as the proper facilities for disposing of

the old tyres.

Any Authorised Service Centre has full information on the technical require-

ments when installing or changing tyres, wheels or wheel trims.

WARNING

•

We recommend that you use only wh eels and tyres which have been

approved by SEAT for your model. Failure to do so could impair vehicle

handling. Risk of accident.

•

Avoid running the vehicle on tyres th at are more than six years old. If

you have no alternative, you should drive slowly and with extra care at all

times.

•

Never use old tyres or those with an unknown “history of use”.

•

If wheel trims are retrofitted, you must ensure that the flow of air to the

brakes is not restricted. This could cause them to overheat.

•

All four wheels must be fitted with radial tyres of the same type, size

(rolling circumference) and the same tread pattern.

WARNING (continued)

Exeo_EN.book Seite 233 Freitag, 17. Oktober 2008 11:24 11

Page 250 of 303

If and when

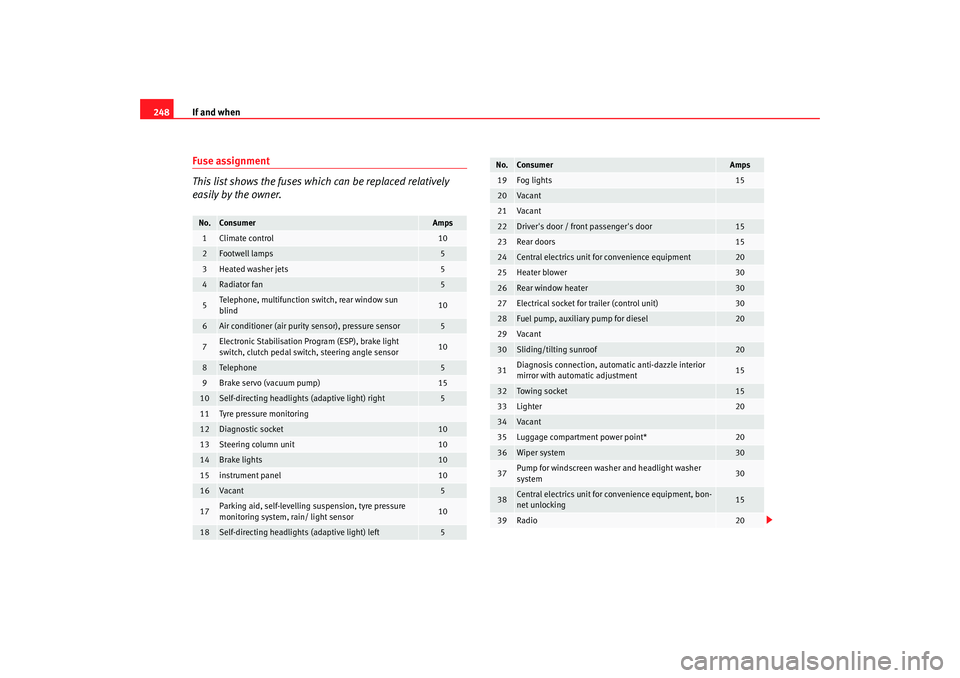

248Fuse assignment

This list shows the fuses which can be replaced relatively

easily by the owner.No.

Consumer

Amps

1

Climate control

10

2

Footwell lamps

5

3

Heated washer jets

5

4

Radiator fan

5

5

Telephone, multifunction switch, rear window sun

blind

10

6

Air conditioner (air purity sensor), pressure sensor

5

7

Electronic Stabilisation Pro gram (ESP), brake light

switch, clutch pedal switch, steering angle sensor

10

8

Telephone

5

9

Brake servo (vacuum pump)

15

10

Self-directing headlights (adaptive light) right

5

11

Tyre pressure monitoring

12

Diagnostic socket

10

13

Steering column unit

10

14

Brake lights

10

15

instrument panel

10

16

Vacant

5

17

Parking aid, self-levelling suspension, tyre pressure

monitoring system, rain/ light sensor

10

18

Self-directing headlights (adaptive light) left

5

19

Fog lights

15

20

Vacant

21

Vacant

22

Driver's door / front passenger's door

15

23

Rear doors

15

24

Central electrics unit for convenience equipment

20

25

Heater blower

30

26

Rear window heater

30

27

Electrical socket for trailer (control unit)

30

28

Fuel pump, auxiliary pump for diesel

20

29

Vacant

30

Sliding/tilting sunroof

20

31

Diagnosis connection, automatic anti-dazzle interior

mirror with automatic adjustment

15

32

Towing socket

15

33

Lighter

20

34

Vacant

35

Luggage compartment power point*

20

36

Wiper system

30

37

Pump for windscreen washer and headlight washer

system

30

38

Central electrics unit for convenience equipment, bon-

net unlocking

15

39

Radio

20

No.

Consumer

Amps

Exeo_EN.book Seite 248 Freitag, 17. Oktober 2008 11:24 11

Page 252 of 303

If and when

250•

Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

•

The high voltage element of gas discharge lamps* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.

•

When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.Caution

•

Remove the ignition key before working on the electric system. If not, a

short circuit could occur.

•

Switch off the lights or parking lights before you change a bulb.For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the proper

manner.

Note

•

Depending on weather conditions (cold or wet), the front lights, the fog

lights, the rear lights and the indicato rs may be temporarily misted. This has

no influence on the life expectancy of the lighting system. By switching on the

lights, the area through which the beam of light is projected will quickly be

demisted. However, the edges may continue to be misted.

•

Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning pr operly. This is not only in the interest

of your own safety, but also in that of all other road users.

•

Before changing a bulb, make sure you have the correct new bulb.

•

Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will vaporise as a result of the heat generated by the bulb, be deposited on the

reflector and impair its surface.

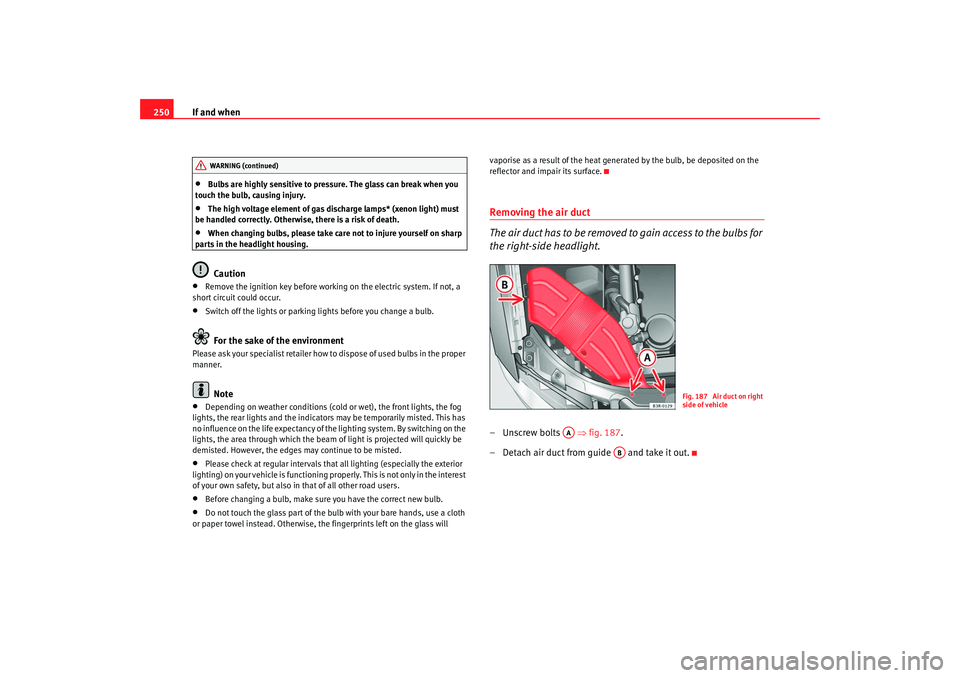

Removing the air duct

The air duct has to be removed to gain access to the bulbs for

the right-side headlight.–Unscrew bolts ⇒

fig. 187.

– Detach air duct from guide and take it out.

WARNING (continued)

Fig. 187 Air duct on right

side of vehicle

AA

AB

Exeo_EN.book Seite 250 Freitag, 17. Oktober 2008 11:24 11

Page 259 of 303

If and when257

Safety First

Operating instructions

Practical tips

Te c h n i c a l D a t a

WARNING

•

Take particular care when working on components in the engine

compartment if the engine is warm - risk of burns!

•

Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

•

The high voltage element of gas discharge lamps* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.

•

When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.Caution

•

Remove the ignition key before workin g on the electric system. If not, a

short circuit could occur.

•

Switch off the lights or parking lights before you change a bulb.For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the proper

manner.

Note

•

Depending on the weather conditions (cold, humidity), the front head-

lights and front lights, the rear pilots and the indicators could steam up. This phenomenon has no influence on the life

expectancy of the vehicle lights. If

headlamps are switched on, the area where the light shaft is projected, is

demisted in little time. However, the edges may be steamed up on the inte-

rior.

•

Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning pr operly. This is not only in the interest

of your own safety, but also in that of all other road users.

•

Before changing a bulb, make sure you have the correct new bulb.

•

Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will

vaporise as a result of the heat generated by the bulb, be deposited on the

reflector and impair its surface.

Removing the air duct

The air duct has to be removed to gain access to the bulbs for

the right-side headlight.

Bulb

Typ e

Xenon bulbs

12 V/35 W (D1S)

DRL (day light)

12 V/21 W (P21W SLL)

Indicator light

12 V/21 W (PY21W)

Side lights

12 V/5 W (W5W blue LL)

Fig. 199 Air duct on right

side of vehicle

Exeo_EN.book Seite 257 Freitag, 17. Oktober 2008 11:24 11

Page 293 of 303

Index291

Index

AAccessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Air conditioner 2C-Climatronic . . . . . . . . . . . . . . . . . . . . . . . 152

Defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Solar-powered blower/solar roof . . . . . . . . 161

Air duct Fitting . . . . . . . . . . . . . . . . . . . . . . . . . 251, 258

Removing . . . . . . . . . . . . . . . . . . . . . . 250, 257

Air purity sensor . . . . . . . . . . . . . . . . . . . . . . . . . 157

Airbag Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 66

Airbag covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Curtain airbags . . . . . . . . . . . . . . . . . . . . . . . 41

Front airbags . . . . . . . . . . . . . . . . . . . . . . . . . 32

Side airbags . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 29

Alternator Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 69

Ambient temperature display . . . . . . . . . . . . . . . 72

Anti-freeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Anti-lock brake system How it works . . . . . . . . . . . . . . . . . . . . . . . . . 176

Anti-puncture tyres . . . . . . . . . . . . . . . . . . . . . . 232 Anti-theft alarm system . . . . . . . . . . . . . . . . . . . 104

Interior monitoring . . . . . . . . . . . . . . . . . . . 105

Aquaplaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Armrest Storage compartment in front armrest . . . . 138

Armrests Adjusting the front armrest . . . . . . . . . . . . . 138

Ashtray Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Athermic windscreen . . . . . . . . . . . . . . . . . . . . . 207

Auto-check system . . . . . . . . . . . . . . . . . . . . . . . 75

Automatic car wash tunnel . . . . . . . . . . . . . . . . 198

Automatic gearbox Safety interlock for ignition key . . . . . . . . . 163

Automatic headlight control . . . . . . . . . . . . . . . 112

BBackground lighting . . . . . . . . . . . . . . . . . . . . . 121

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223 Battery voltage . . . . . . . . . . . . . . . . . . . . . . . . 80

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Disconnection . . . . . . . . . . . . . . . . . . . . . . . 223

Long periods of non-use . . . . . . . . . . . . . . . 223

Replacing . . . . . . . . . . . . . . . . . . . . . . 223, 224

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Winter operations . . . . . . . . . . . . . . . 223, 224 Belt tension device

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 29

Belt tension devices . . . . . . . . . . . . . . . . . . . . . . 26

Bicycle rack Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Biodiesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Biodiesel fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212 Closing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Releasing . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Brake pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Brake servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Brake system Brake servo . . . . . . . . . . . . . . . . . . . . . . . . . 178

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181 Brake assist system . . . . . . . . . . . . . . . . . . 176

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Worn brake pads . . . . . . . . . . . . . . . . . . . . . . 80

Braking distance . . . . . . . . . . . . . . . . . . . . . . . . 181

Bulb change general notes . . . . . . . . . . . . . . . . . . . . . . . . 249

CCar keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Exeo_EN.book Seite 291 Freitag, 17. Oktober 2008 11:24 11

Page 300 of 303

Index

298Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Tow starting

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186, 274 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 188

Notes on towing . . . . . . . . . . . . . . . . . 186, 187

Removable towing bracket . . . . . . . . . . . . . 189

Technical requirements . . . . . . . . . . . . . . . 186

Towing a trailer . . . . . . . . . . . . . . . . . . . . . . . . . 280

Towing bracket, fitting . . . . . . . . . . . . . . . . . . . 195

Towing eye . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Towing eyes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Tow-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Traction control system How the system works . . . . . . . . . . . . . . . . 178

Trailer weights . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Trip recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Type plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Tyre Mobility System . . . . . . . . . . . . . . . . . . . . . 243

Tyre mobility system . . . . . . . . . . . . . . . . . . . . . 237

Tyre pressure . . . . . . . . . . . . . . . . . . . . 66, 89, 227 Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Tyre pressure monitoring . . . . . . . . . . . . . . . . . 228

Tyre pressure monitoring system . . . . . . . . . . . . 88

Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Tyre repair kit Tyre Mobility System . . . . . . . . . . . . . . . . . . 243

Tyres and wheels Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 233

Tyres service life . . . . . . . . . . . . . . . . . . . . . . . . 230 Tyres tread depth . . . . . . . . . . . . . . . . . . . . . . . 231

Tyres with directional tread pattern . . . . . . . . . 227

UUnderbody maintenance . . . . . . . . . . . . . . . . . 202VVehicle data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Vehicle identification data . . . . . . . . . . . . . . . . 278

Vehicle identification number . . . . . . . . . . . . . 278

Vehicle Maintenance

Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Vehicle modifications . . . . . . . . . . . . . . . . . . . . 206

Vehicle paintwork Products for vehicle maintenance . . . . . . . 197

Waxing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Vehicle washing . . . . . . . . . . . . . . . . . . . . . . . . 198

Ventilation slits . . . . . . . . . . . . . . . . . . . . . . . . . . 17WWarning lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Warning lamps Airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Anti-lock brake system . . . . . . . . . . . . . . . . . 67

Electronic differential lock . . . . . . . . . . . . . . 67

Electronic stabilisation programme . . . . . . . 68

Engine management (EPC) . . . . . . . . . . . . . . 69

Exhaust emission control system . . . . . . . . 66 Handbrake . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Red symbols in central display . . . . . . . . . . 76

Seat belt warning lamp . . . . . . . . . . . . . . . . . 68

Yellow symbols in central display . . . . . . . . 78

Warning lamps - overview . . . . . . . . . . . . . . . . . 65

Washer fluid level . . . . . . . . . . . . . . . . . . . . . . . . 80

Washing by hand . . . . . . . . . . . . . . . . . . . . . . . 198

Washing with high pressure cleaners . . . . . . . 199

Wear indicators . . . . . . . . . . . . . . . . . . . . . . . . . 231

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 281 Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227, 280 Changing a wheel . . . . . . . . . . . . . . . . . . . . 238

Why assume the correct sitting position? . . . . . 28

Why should head restraints be correctly adjusted? 13

Why wear seat belts? . . . . . . . . . . . . . . . . . . 19, 28

Why wear seatbelts? . . . . . . . . . . . . . . . . . . . . . . 18

Windows Defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Windscreen washer system . . . . . . . . . . . . . . . 220

Windscreen wiper blades Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Windscreen wipers . . . . . . . . . . . . . . . . . . . . . . 125 Changing blades . . . . . . . . . . . . . . . . . . . . . 221

Rain sensor . . . . . . . . . . . . . . . . . . . . . . . . . 125

Washer jets . . . . . . . . . . . . . . . . . . . . . . . . . 125

Winter Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Winter conditions Defrost function . . . . . . . . . . . . . . . . . . . . . 156

Exeo_EN.book Seite 298 Freitag, 17. Oktober 2008 11:24 11