warning Seat Exeo 2009 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2009, Model line: Exeo, Model: Seat Exeo 2009Pages: 310, PDF Size: 8.54 MB

Page 259 of 310

If and when257

Safety First

Controls and equipment

Practical tips

Technical Data

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

The electric windows and electric seat adjusters are protected by circuit

breakers

. These reset automatically after a few seconds when the overload

(caused for example by frozen windows) has been corrected.

Note

Please note that the above list contains all data at the time of going to press,

so it is subject to modifications. If discrepancies should occur, please refer to

the sticker on the inside of the fuse cover for the correct information for your

model.BulbsGeneral notesYou can change the following bulbs for exterior lights yourself:•Main headlights: all (except for xenon headlights)•Rear lights: All bulbs•Side indicator bulb

The following bulbs can only be changed by a qualified workshop:

•Main headlights: Xenon* bulb ⇒page 264•Front fog lights: Bulb

As a rule, you require a certain degree of practical skill to change defective

bulbs. This applies in particular to those bulbs which are only accessible from

the engine compartment.

If in doubt, we recommend that you have defective bulbs changed by a qual-

ified workshop or qualified mechanic.

If you do decide to change bulbs in the engine compartment yourself, be

aware of the safety risks involved ⇒page 221 ⇒ in “Types of bulbs”.Changing bulbs Halogen headlightsTypes of bulbsYou must only replace a bulb with a bulb of the same type. The name can be

found on the base of the bulb.

WARNING

•Take particular care when working on components in the engine

compartment if the engine is warm - risk of burns!

41

Va can t

30

42

Electronic stabilisation programme (ESP)

25

43

Engine management

15

44

Seat heating

35

No.

Consumer

Amps

Bulb

Type

Dipped-beam headlights (halogen)

12 V/55 W (H7 LL)

Main beam headlights

12 V/55 W (H1)

Indicator light

12 V/21 W (PY21W)

Side lights

12 V/5 W (W5W LL)

Exeo_EN.book Seite 257 Freitag, 28. August 2009 10:14 10

Page 260 of 310

If and when

258•Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.•The high voltage element of gas discharge lamps* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.•When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.Caution

•Remove the ignition key before working on the electric system. If not, a

short circuit could occur.•Switch off the lights or parking lights before you change a bulb.For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the proper

manner.

Note

•Depending on weather conditions (cold or wet), the front lights, the fog

lights, the rear lights and the indicators may be temporarily misted. This does

not affect the useful life of the lighting system. By switching on the lights, the

area through which the beam of light is projected will quickly be demisted.

However, the edges may continue to be misted.•Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the interest

of your own safety, but also in that of all other road users.•Before changing a bulb, make sure you have the correct new bulb.•Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will vaporise as a result of the heat generated by the bulb, be deposited on the

reflector and impair its surface.

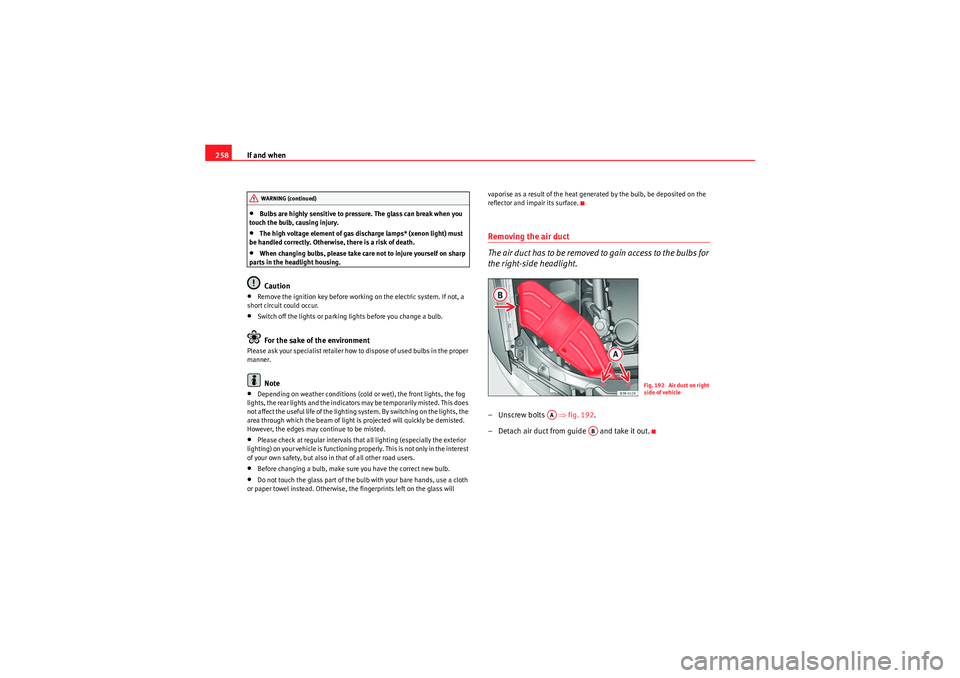

Removing the air duct

The air duct has to be removed to gain access to the bulbs for

the right-side headlight.–Unscrew bolts ⇒

fig. 192.

– Detach air duct from guide and take it out.

WARNING (continued)

Fig. 192 Air duct on right

side of vehicle

AA

AB

Exeo_EN.book Seite 258 Freitag, 28. August 2009 10:14 10

Page 267 of 310

If and when265

Safety First

Controls and equipment

Practical tips

Technical Data

WARNING

•Take particular care when working on components in the engine

compartment if the engine is warm - risk of burns!•Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.•The high voltage element of gas discharge lamps* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.•When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.Caution

•Remove the ignition key before working on the electric system. If not, a

short circuit could occur.•Switch off the lights or parking lights before you change a bulb.For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the proper

manner.

Note

•Depending on weather conditions (cold or wet), the front lights, the fog

lights, the rear lights and the indicators may be temporarily misted. This does not affect the useful life of the lighting system. By switching on the lights, the

area through which the beam of light is projected will quickly be demisted.

However, the edges may continue to be misted.

•Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning pr operly. This is not only in the interest

of your own safety, but also in that of all other road users.•Before changing a bulb, make sure you have the correct new bulb.•Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will

vaporise as a result of the heat generated by the bulb, be deposited on the

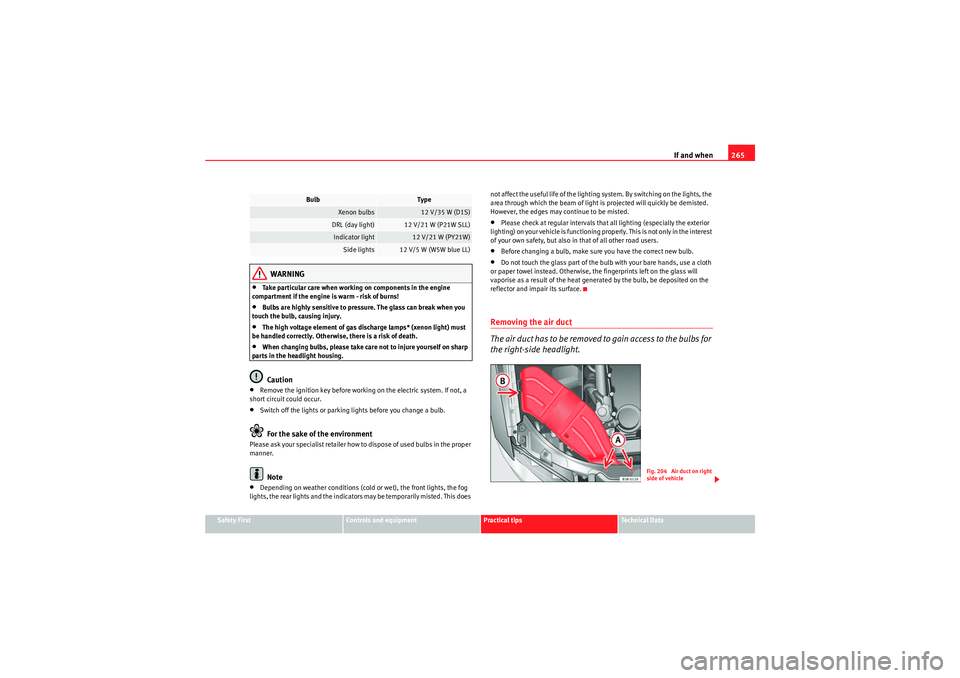

reflector and impair its surface.Removing the air duct

The air duct has to be removed to gain access to the bulbs for

the right-side headlight.

Bulb

Type

Xenon bulbs

12 V/35 W (D1S)

DRL (day light)

12 V/21 W (P21W SLL)

Indicator light

12 V/21 W (PY21W)

Side lights

12 V/5 W (W5W blue LL)

Fig. 204 Air duct on right

side of vehicle

Exeo_EN.book Seite 265 Freitag, 28. August 2009 10:14 10

Page 271 of 310

If and when269

Safety First

Controls and equipment

Practical tips

Technical Data

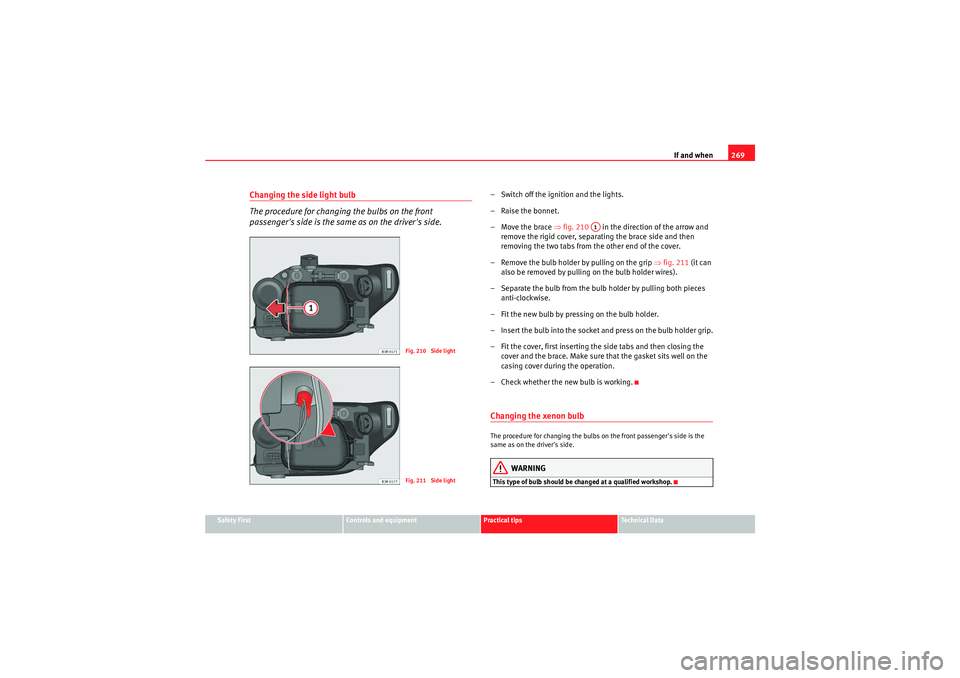

Changing the side light bulb

The procedure for changing the bulbs on the front

passenger's side is the same as on the driver's side.

– Switch off the ignition and the lights.

– Raise the bonnet.

– Move the brace ⇒fig. 210 in the direction of the arrow and

remove the rigid cover, separating the brace side and then

removing the two tabs from the other end of the cover.

– Remove the bulb holder by pulling on the grip ⇒fig. 211 (it can

also be removed by pulling on the bulb holder wires).

– Separate the bulb from the bulb holder by pulling both pieces anti-clockwise.

– Fit the new bulb by pressing on the bulb holder.

– Insert the bulb into the socket and press on the bulb holder grip.

– Fit the cover, first inserting the side tabs and then closing the cover and the brace. Make sure that the gasket sits well on the

casing cover during the operation.

– Check whether the new bulb is working.Changing the xenon bulbThe procedure for changing the bulbs on the front passenger's side is the

same as on the driver's side.

WARNING

This type of bulb should be changed at a qualified workshop.

Fig. 210 Side lightFig. 211 Side light

A1

Exeo_EN.book Seite 269 Freitag, 28. August 2009 10:14 10

Page 283 of 310

If and when281

Safety First

Controls and equipment

Practical tips

Technical Data

WARNING

•Please note the safety warnings referring to working in the engine

compartment ⇒page 221.•The battery providing assistance must have the same voltage as the flat

battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.•Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.•Keep sparks, flames and lighted cigarettes away from batteries, danger

of explosion. Failure to comply could result in an explosion.•Observe the instructions provided by the manufacturer of the jump

leads.•Do not connect the negative cable from the other vehicle directly to the

negative terminal of the flat battery. The gas emitted from the battery could

be ignited by sparks. Danger of explosion.•Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.•The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.•Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.•Do not bend over the batteries. This could result in chemical burns.Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

Exeo_EN.book Seite 281 Freitag, 28. August 2009 10:14 10

Page 284 of 310

If and when

282Towing and tow-startingTo w - s t a r t i n g

The use of jump leads is preferable to tow-starting.We recommend that you do not tow-start your vehicle. Jump-starting

is preferable ⇒ page 279.

However, if your vehicle has to be tow-started:

– Engage the 2

nd or the 3

rd gear.

– Keep the clutch pressed down.

– Switch the ignition on.

– Once both vehicles are moving, release the clutch.

– As soon as the engine starts, press the clutch and move the gear lever into neutral. This helps to prevent driving into the towing

vehicle.

WARNING

The risk of accidents is high when tow-starting. The vehicle being towed

can easily collide with the towing vehicle.

Caution

When tow-starting, fuel could enter the catalytic converter and damage it.

CommentsPlease observe the following points if you use a tow-rope:

Notes for the driver of the towing vehicle

– Drive slowly at first until the tow-rope is taut. Then accelerate gradually.

– Begin and change gears cautiously. If you are driving an auto- matic vehicle, accelerate gently.

– Remember that the brake servo and power steering are not working in the vehicle you are towing. Brake earlier than you

would normally, but with a more gentle pressure on the brake.

Notes for the driver of the towed vehicle

– Ensure that the tow-rope remains taut at all times when towing.Tow-rope or tow-bar

It is easier and safer to tow a vehicle with a tow-bar. You should only use a

tow-rope if you do not have a tow-bar.

A tow-rope should be slightly elastic to reduce the loading on both vehicles.

It is advisable to use a tow-rope made of synthetic fibre or similarly elastic

material.

Attach the tow-rope or the tow-bar only to the towing eyes provided or a

towing bracket.

Driving style

Towing requires some experience, especially when using a tow-rope. Both

drivers should be familiar with the technique required for towing. Inexperi-

enced drivers should not attempt to tow-start or tow away another vehicle.

Exeo_EN.book Seite 282 Freitag, 28. August 2009 10:14 10

Page 285 of 310

If and when283

Safety First

Controls and equipment

Practical tips

Technical Data

Do not pull too hard with the towing vehicle and take care to avoid jerking the

tow-rope. When towing on an unpaved road, there is always a risk of over-

loading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the indicators, horn,

windscreen wipers and washers.

As the brake servo does not work if the engine is not running, you must apply

considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running, you

will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

•Put the selector lever into position “N”.•Do not drive faster than 50 km/h when towing a vehicle.•Do not tow further than 50 km.•If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.Note

•Observe legal requirements when towing or tow-starting.•Switch on the hazard warning lights of both vehicles. However, observe

any regulations to the contrary.•For technical reasons, vehicles with an automatic gearbox must not be

tow-started.•If damage to your vehicle means that there is no lubricant in the gearbox,

you must raise the drive wheels while the vehicle is being towed.•If the vehicle has to be towed more than 50 km, the front wheels must be

raised during towing, and towing should be carried out by a qualified person.•The steering wheel is locked when the vehicle has no electrical power. The

vehicle must then be towed with the front wheels raised. Towing should be

carried out by a qualified person.

•The towing eye should always be kept in the vehicle. Please refer to the

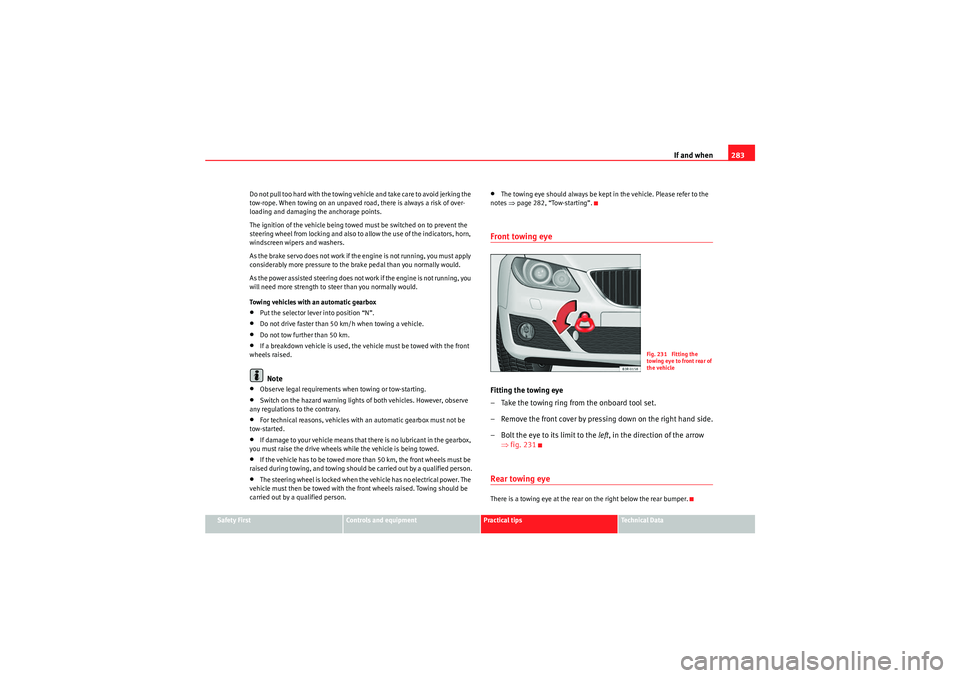

notes ⇒page 282, “Tow-starting”.Front towing eyeFitting the towing eye

– Take the towing ring from the onboard tool set.

– Remove the front cover by pressing down on the right hand side.

– Bolt the eye to its limit to the left, in the direction of the arrow

⇒ fig. 231Rear towing eyeThere is a towing eye at the rear on the right below the rear bumper.

Fig. 231 Fitting the

towing eye to front rear of

the vehicle

Exeo_EN.book Seite 283 Freitag, 28. August 2009 10:14 10

Page 289 of 310

General notes on the technical data287

Safety First

Controls and equipment

Practical tips

Technical Data

Data on fuel consumptionFuel consumption

The consumption and emission details shown on the vehicle

data sticker differ from one vehicle to another.The fuel consumption and CO

2 emissions of the vehicle can be found on the

vehicle data sticker.

The fuel consumption and emissions figures given are based on the vehicle

weight category, which is determined according to the engine/gearbox

combination and the equipment fitted.

The consumption and emission figures are calculated in accordance with the

EC test requirements 1999/100/EC. These test requirements specify a real-

istic test method based on normal everyday driving.

The following test conditions are applied:

Note

•Actual consumption may vary from quoted test values, depending on

personal driving style, road and traffic conditions, the weather and the

vehicle condition.WeightsKerb weight refers to the basic model with a fuel tank filled to 90% capacity

and without optional extras. The figure quoted includes 75 kg to allow for the

weight of the driver.

For special versions and optional equipment fittings or for the addition of

accessories, the weight of the vehicle will increase ⇒.

WARNING

•Please note that the centre of gravity may shift when transporting

heavy objects; this may affect the vehicle's handling and lead to an acci-

dent. Always adjust your speed and driving style to suit road conditions

and requirements.•Never exceed the gross axle weight rating or the gross vehicle weight

rating. If the allowed axle load or the allowed total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

Urban cycle

The urban cycle starts with an engine cold start. City driving

is then simulated.

Extra urban

cycle

In the extra urban cycle simulation the vehicle frequently

accelerates and brakes in all gears, as in normal everyday

driving. The road speed ranges from 0 to 120 km/h.

To ta l co n-

sumption

The average total consumption is calculated with a weighting

of around 37% for the urban cycle and 63% for the extra

urban cycle.

CO2 emis-

sions

The exhaust gases are collected during both driving cycles to

calculate carbon dioxide emissions. The gas composition is

then analysed to evaluate the CO

2 content and other emis-

sions.

Exeo_EN.book Seite 287 Freitag, 28. August 2009 10:14 10

Page 290 of 310

General notes on the technical data

288Towing a trailerTrailer weightsTrailer weights

The trailer weights and drawbar loads approved are selected in intensive

trials according to precisely defined criteria. The approved trailer weights are

valid for vehicles in the EU for maximum speeds of 80 km/h (in certain

circumstances up to 100 km/h). The figures may be different in other coun-

tries. All data in the official vehicle documents take precedence over these

data ⇒ .

Drawbar load

The maximum permitted weight exerted by the trailer drawbar on the ball joint

of the towing bracket must not exceed 75 kg.

In the interest of road safety, we recommend that you always tow

approaching the maximum drawbar load. The response of the trailer on the

road will be poor if the drawbar load is too small.

If the maximum permissible drawbar load cannot be met (e.g. with small,

empty and light-weight single axle trailers o r ta n d e m a x l e t r a i l e r s wi t h a n a x le

base of less than 1 metre), at least 4% of the actual trailer weight is a legal

stipulation for a drawbar load.

WARNING

•For safet y reas ons , d o not excee d the 8 0 k m/h limit . Th is is als o valid in

countries where higher speeds are permitted.•Never exceed the maximum trailer weights or the draw bar loading. If

the permissible axle load or the permissible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

WheelsTyre pressure, snow chains, wheel boltsTyre pressures

The sticker with the tyre pressure values can be found on the inside of the

tank flap. The tyre pressure values given there are for cold tyres. The slightly

raised pressures of warm tyres must not be reduced. ⇒

Snow chains

Snow chains may be fitted only to the front wheels.

Consult the chapter “wheels” of this manual.

Wheel bolts

After the wheels have been changed, the tightening torque of the wheel bolts

s ho uld b e che cke d as s o on as p ossible wit h a to rqu e w re nch ⇒ . The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

•Check the tyre pressure at least once per month. Checking tyre pressure

value is very important. If the tyre pressure is too high or too low, there is

an increased danger of accidents, particularly at high speeds.•If the torque of the wheel bolts is too low, they could loosen while the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads can be damaged.Note

We recommend that you ask your Authorised Service Centre for information

about appropriate wheel, tyre and snow chain size.

Exeo_EN.book Seite 288 Freitag, 28. August 2009 10:14 10

Page 301 of 310

Index299

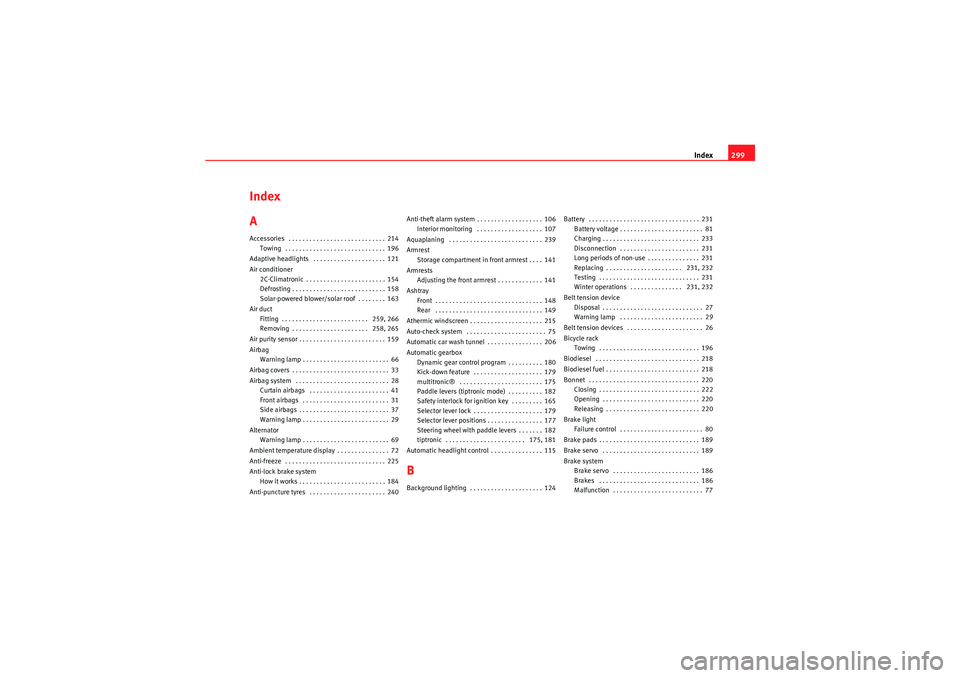

Index

AAccessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Adaptive headlights . . . . . . . . . . . . . . . . . . . . . 121

Air conditioner 2C-Climatronic . . . . . . . . . . . . . . . . . . . . . . . 154

Defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Solar-powered blower/solar roof . . . . . . . . 163

Air duct Fitting . . . . . . . . . . . . . . . . . . . . . . . . . 259, 266

Removing . . . . . . . . . . . . . . . . . . . . . . 258, 265

Air purity sensor . . . . . . . . . . . . . . . . . . . . . . . . . 159

Airbag Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 66

Airbag covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Curtain airbags . . . . . . . . . . . . . . . . . . . . . . . 41

Front airbags . . . . . . . . . . . . . . . . . . . . . . . . . 31

Side airbags . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 29

Alternator Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . 69

Ambient temperature display . . . . . . . . . . . . . . . 72

Anti-freeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Anti-lock brake system How it works . . . . . . . . . . . . . . . . . . . . . . . . . 184

Anti-puncture tyres . . . . . . . . . . . . . . . . . . . . . . 240 Anti-theft alarm system . . . . . . . . . . . . . . . . . . . 106

Interior monitoring . . . . . . . . . . . . . . . . . . . 107

Aquaplaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Armrest Storage compartment in front armrest . . . . 141

Armrests Adjusting the front armrest . . . . . . . . . . . . . 141

Ashtray Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Athermic windscreen . . . . . . . . . . . . . . . . . . . . . 215

Auto-check system . . . . . . . . . . . . . . . . . . . . . . . 75

Automatic car wash tunnel . . . . . . . . . . . . . . . . 206

Automatic gearbox Dynamic gear control program . . . . . . . . . . 180

Kick-down feature . . . . . . . . . . . . . . . . . . . . 179

multitronic® . . . . . . . . . . . . . . . . . . . . . . . . 175

Paddle levers (tiptronic mode) . . . . . . . . . . 182

Safety interlock for ignition key . . . . . . . . . 165

Selector lever lock . . . . . . . . . . . . . . . . . . . . 179

Selector lever positions . . . . . . . . . . . . . . . . 177

Steering wheel with paddle levers . . . . . . . 182

tiptronic . . . . . . . . . . . . . . . . . . . . . . . 175, 181

Automatic headlight control . . . . . . . . . . . . . . . 115

BBackground lighting . . . . . . . . . . . . . . . . . . . . . 124 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Battery voltage . . . . . . . . . . . . . . . . . . . . . . . . 81

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Disconnection . . . . . . . . . . . . . . . . . . . . . . . 231

Long periods of non-use . . . . . . . . . . . . . . . 231

Replacing . . . . . . . . . . . . . . . . . . . . . . 231, 232

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Winter operations . . . . . . . . . . . . . . . 231, 232

Belt tension device Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 29

Belt tension devices . . . . . . . . . . . . . . . . . . . . . . 26

Bicycle rack Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Biodiesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Biodiesel fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220 Closing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Opening . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Releasing . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Brake light Failure control . . . . . . . . . . . . . . . . . . . . . . . . 80

Brake pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Brake servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Brake system Brake servo . . . . . . . . . . . . . . . . . . . . . . . . . 186

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Exeo_EN.book Seite 299 Freitag, 28. August 2009 10:14 10