bonnet Seat Exeo 2009 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2009, Model line: Exeo, Model: Seat Exeo 2009Pages: 310, PDF Size: 8.54 MB

Page 180 of 310

Driving

178To move the selector lever to position R, press in the interlock button and at

the same time press the brake pedal. Depending on the model, one or two

reversing lights will come on in selector lever position R (when ignition is

switched on).

N - Neutral (idling)

In this position the gearbox is in neutral ⇒.

D - Drive (forwards)

In this position, the gearbox selects the optimal transmission ratio

depending on the engine load, speed and the dynamic gear regulation

program (DRP).

Press the brake pedal when moving the selector lever from N to D if the

vehicle is stationary or at speeds below 5 km/h ⇒.

Under certain circumstances (e.g. when driving in mountains or towing a

trailer or caravan) it can be advantageous to switch temporarily to Tiptronic

mode ⇒page 181, so that the gear ratios can be selected manually to suit

the driving conditions.

S - Sport position

To drive in sports mode, select the position S. The engine power reserve is

used to its maximum. When accelerating the gear shifts will be noticeable.

Press the brake pedal when moving the selector lever from N to S if the

vehicle is stationary or at speeds below 5 km/h ⇒.

WARNING

•Never move the selector lever to R or P when driving. Failure to do so

could result in an accident.•In selector position D or S the vehicle must always be held with the foot

brake when the engine is running. This is because an automatic gearbox

still transmits power even at idling speed, and the vehicle tends to “creep”.

The throttle must on no account be opened inadvertently (for instance by hand from the engine compartment) when a gear is engaged with the

vehicle stationary. The vehicle could otherwise start moving immediately

(in some cases even if the parking brake is engaged) and possibly cause an

accident.

•To avoid accidents, apply the parking brake and put the selector lever

in position P before opening the bonnet and working on the vehicle with

the engine running. Please observe the important safety warnings

⇒ page 221, “Work in the engine compartment”.Note

•Applies to vehicles with tiptronic gearbox:•If the lever is moved accidentally to N when driving, release the acceler-

ator and let the engine speed drop to idling before selecting D or S again.•For the sake of fuel economy (and the environment), the gearbox ratios on

some models are designed so that maximum speed is only obtained when

the selector lever is at position S.WARNING (continued)

Exeo_EN.book Seite 178 Freitag, 28. August 2009 10:14 10

Page 211 of 310

Your vehicle maintenance and cleaning209

Safety First

Controls and equipment

Practical tips

Technical Data

to the windscreen washer fluid prevents wiper blades from juddering. Wax

deposits are not removed.

Caution

•Never use warm or hot water to remove snow and ice from windows and

mirrors. This could cause the glass to crack!•The heating element for the rear window is located on the inner side of the

window. To prevent damage, do not put stickers on the heating elements

inside the window.Cleaning windscreen wiper bladesClean wiper blades are essent ial to provide clear vision.

1. Use a soft cloth to remove dust and dirt from the windscreen wiper blades.

2. Use window cleanser to clean the windscreen wiper blades. Use

a sponge or a cloth to remove stubborn stains.Rubber seals maintenance

If rubber seals are well looked after, they will not freeze so

quickly.1. Use a soft cloth to remove dust and dirt from the rubber seals.

2. Apply a specialist care product to the rubber seals.

The strips on the doors, windows, bonnet and rear lid will remain pliable and

last longer if they are treated with a suitable care product (for example sili-

cone spray).

Caring for rubber seals will also prevent premature ageing and leaks. The

doors will be easier to open. If rubber seals are well looked after, they will not

freeze so quickly in winter.Door lock cylinders

The door lock cylinders can freeze up in winter.To de-ice the lock cylinders you should only use spray with lubricating and

anti-corrosive properties.Cleaning chrome parts1. Clean chrome parts with a damp cloth.

2. Polish chrome parts with a soft, dry cloth.If this does not provide satisfying results, use a specialist chrome cleaning

product . Chrome cleaning products will remove stains and coatings from the

surface.

Caution

To prevent scratching chrome surfaces:•Never use an abrasive care product on chrome.•Do not clean or polish chrome parts in a sandy or dusty environment.

Exeo_EN.book Seite 209 Freitag, 28. August 2009 10:14 10

Page 213 of 310

Your vehicle maintenance and cleaning211

Safety First

Controls and equipment

Practical tips

Technical Data

Cleaning the engine compartment

Take special care when cleaning the engine compartment.Anti-corrosion treatment

The engine compartment and the surface of the power unit are given anti-

corrosion treatment at the factory.

Good corrosion protection is particularly important in winter when the car is

frequently driven on salted roads. To prevent the salt corroding the vehicle,

the entire engine compartment should be thoroughly cleaned before and

after winter.

Yo u r A u t h o r i s e d S e r v i ce Ce n t re has got the necessary equipment to provide

the correct cleaning and preserving products. For this reason, we recommend

having this work performed by them.

The anti-corrosion protection is usually removed if the engine compartment

is cleaned with grease removing solutions, or if you have the engine cleaned.

On commissioning this work, ensure that all surfaces, seams, joints and

components in the engine compartment are given anti-corrosion treatment.

WARNING

•When working in the engine compartment, always observe the safety

warnings ⇒page 221•Before opening the bonnet, switch the engine off, apply the parking

brake firmly and always remove the key from the ignition.•Allow the engine to cool before you clean the engine compartment.•Do not clean the vehicle underbody, wheel arches without protecting

your hands and arms. You may cut yourself on sharp-edged metal parts.

Failure to comply could result in injury.•Moisture, ice and salt on the brakes may affect braking efficiency. Risk

of accident. Directly after washing, avoid sudden and sharp braking.

•Never touch the radiator fan. It is temperature-controlled and could

start automatically, even when the key is removed from the ignition!For the sake of the environment

Fuel, grease and oil deposits could be removed when the engine is washed.

The polluted water must be cleaned in an oil separator. For this reason,

engine washing should be carried out only by a qualified workshop or a petrol

station.Vehicle interior maintenancePlastic parts and dash panel cleaning– Use a clean, damp cloth to clean plastic parts and the dash panel.

– If this does not provide satisfactory results, use a special solvent-free plastic cleaning product.

WARNING

Never clean the dash panel and the airbag module surface with cleansers

containing solvents. Solvents cause the surface to become porous. If the

airbag triggered, disintegrating plastic parts could cause substantial inju-

ries.

WARNING (continued)

Exeo_EN.book Seite 211 Freitag, 28. August 2009 10:14 10

Page 222 of 310

Checking and refilling levels

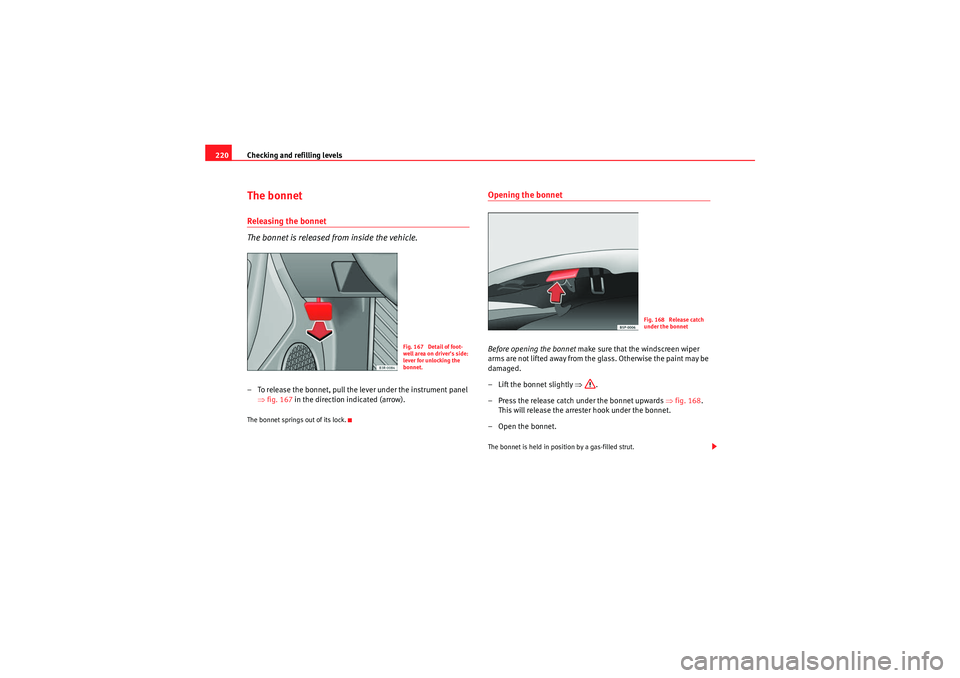

220The bonnetReleasing the bonnet

The bonnet is released from inside the vehicle.– To release the bonnet, pull the lever under the instrument panel

⇒fig. 167 in the direction indicated (arrow).The bonnet springs out of its lock.

Opening the bonnetBefore opening the bonnet make sure that the windscreen wiper

arms are not lifted away from the glass. Otherwise the paint may be

damaged.

– Lift the bonnet slightly ⇒.

– Press the release catch under the bonnet upwards ⇒fig. 168 .

This will release the arrester hook under the bonnet.

– Open the bonnet.The bonnet is held in position by a gas-filled strut.

Fig. 167 Detail of foot-

well area on driver's side:

lever for unlocking the

bonnet.

Fig. 168 Release catch

under the bonnet

Exeo_EN.book Seite 220 Freitag, 28. August 2009 10:14 10

Page 223 of 310

Checking and refilling levels221

Safety First

Controls and equipment

Practical tips

Technical Data

WARNING

Never open the bonnet if you see steam or drips of coolant being released

from t he engine com par t ment . Fail ure to com ply could resul t in burns . Wait

until no steam or coolant can be seen before opening the bonnet.Work in the engine compartment

Extra caution is necessary when working on components in

the engine compartment.Always be aware of the danger of injury and scalding as well as the risk of

accident or even fire when working in the engine compartment (e.g. when

checking and refilling fluids). Therefore, always observe the warnings listed

below and follow all general safety precautions. The engine compartment of

any motor vehicle is a potentially hazardous area ⇒

WARNING

•Switch the engine off.•Remove the ignition key.•Apply handbrake firmly.•If your vehicle is equipped with a manual gearbox, place the gearshift

lever in neutral. If you are driving an automatic vehicle, place the selector

lever in the position P.•Wait for the engine to cool down.•Children should not be allowed to approach the engine compartment•Never spill liquids involved in vehicle operations on the engine

compartment, as these may catch fire (e.g. anti-freeze containing liquid

coolant).

•Take care not to cause short circuits in the electrical system, especially

when working on the battery.•Never touch the radiator fan while the engine is hot, as the fan could

start up suddenly.•Never open the expansion tank when the engine is hot. The cooling

system is under pressure.•Protect face, hands and arms from any hot steam or hot liquid coolant

released by covering the cap with a large, thick rag when opening the

expansion tank.•If any tests have to be performed with the engine running, there is an

extra safety risk from the rotating parts, such as the drive belts, alternator

and radiator fan, etc., and from the high-voltage ignition system.•Observe the following additional warnings if work on the fuel system or

the electrical system is necessary:

−Always disconnect the battery.

− Do not smoke.

− Never work near open flames

− Always keep an approved fire extinguisher immediately available.Caution

When topping up fluids, make sure the correct fluid is put into the correct

filler opening. This can otherwise cause serious malfunctions or engine

damage.

For the sake of the environment

Inspect the ground underneath your vehicle regularly so that any leaks are

detected at an early stage. If you find spots of oil or other fluids, have your

vehicle inspected in the garage.

WARNING (continued)

Exeo_EN.book Seite 221 Freitag, 28. August 2009 10:14 10

Page 224 of 310

Checking and refilling levels

222

NoteOn right-hand drive vehicles some of the containers/ reservoirs mentioned

below are located on the other side of the engine compartment.Closing the bonnet– To close the bonnet, pull it down to overcome the spring pres- sure.

– Leave the bonnet secured in the locking part. Do not tighten

⇒ .

WARNING

•For safety reasons the bonnet must always be completely closed when

the vehicle is moving. After closing it always check that it is properly

secured. The bonnet must be flush with the adjacent body panels.•Should you notice that the bonnet is not safely secured when the

vehicle is moving, stop the vehicle immediately and close the bonnet.

Failure to do so could result in an accident.

Engine oilGeneral notesWe recommend that the oil change should be performed by an Authorised

Service Centre or a qualified workshop, according to the Maintenance

Program. The correct oil specifications for your engine are listed in the

⇒page 223,

“Oil properties”.

Check that the specifications quoted (VW standards) appear on the container

either singly or in combination with other specifications.

Flexible maintenance intervals (Extended Service Intervals*)

Special lubricating oils ⇒page 223 have been developed in the framework

of the SEAT “Extended Service Intervals” ⇒Booklet “Maintenance Program”

This type of oil must be used if you intend to take advantage of the prolonga-

tion of the maintenance intervals in the framework of the “Extended Service

Intervals” program.

•Do not mix the LongLife oil with oil intended for fixed service intervals, as

the requirements for the extended service intervals are then no longer guar-

anteed.•Only in exceptional circumstances, if the engine oil level is too low

⇒ page 224 and LongLife oil is not available, it is permitted to top up (once)

with oil for fixed service intervals ⇒ page 223 (up to a maximum of 0.5

litres).

Fixed service intervals*

If “Extended Service Intervals” are not applied to your vehicle, you can use

oils for fixed service intervals ⇒ page 223. In this case, your vehicle must be

serviced after a fixed interval of 1 year / 15,000 km (10,000 miles) (see the

Maintenance Program).•In exceptional circumstances, if the engine oil level is too low

⇒ page 224 and you cannot obtain the oil specified for your vehicle, you can

put in a small quantity of oil conforming to the specification ACEA A2 or

ACEA A3 (petrol engines) or ACEA B3 or ACEA B4 (diesel engines) (up to 0.5l).

Vehicles with diesel particulate filter*

The Maintenance Program states whether your vehicle is fitted with a diesel

particulate filter.

Exeo_EN.book Seite 222 Freitag, 28. August 2009 10:14 10

Page 231 of 310

Checking and refilling levels229

Safety First

Controls and equipment

Practical tips

Technical Data

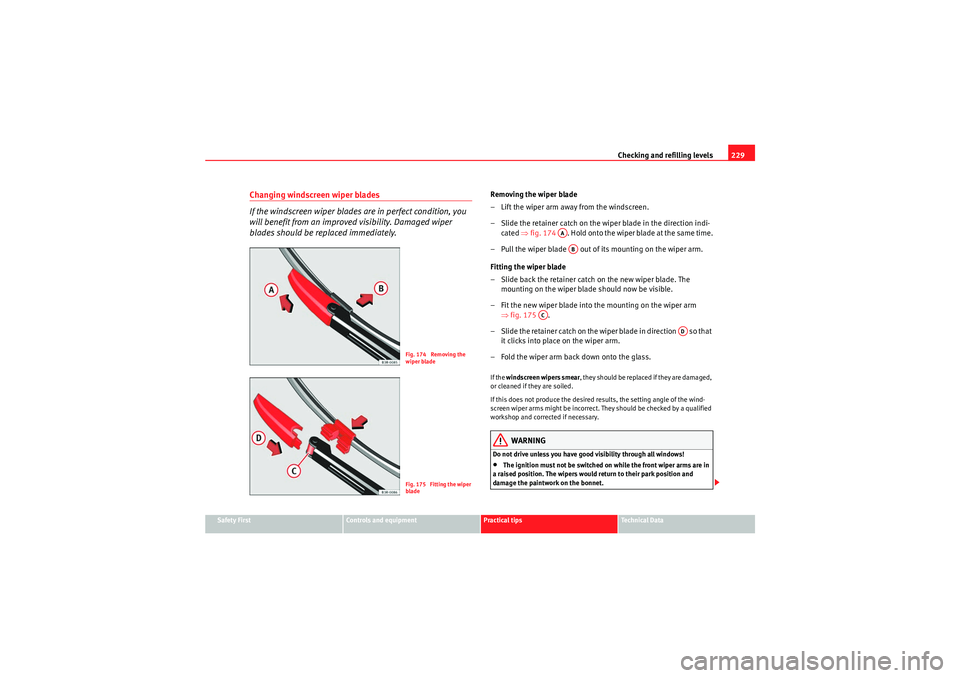

Changing windscreen wiper blades

If the windscreen wiper blades are in perfect condition, you

will benefit from an improved visibility. Damaged wiper

blades should be replaced immediately.

Removing the wiper blade

– Lift the wiper arm away from the windscreen.

– Slide the retainer catch on the wiper blade in the direction indi-

cated ⇒fig. 174 . Hold onto the wiper blade at the same time.

– Pull the wiper blade out of its mounting on the wiper arm.

Fitting the wiper blade

– Slide back the retainer catch on the new wiper blade. The mounting on the wiper blade should now be visible.

– Fit the new wiper blade into the mounting on the wiper arm ⇒fig. 175 .

– Slide the retainer catch on the wiper blade in direction so that it clicks into place on the wiper arm.

– Fold the wiper arm back down onto the glass.If the windscreen wipers smear , t h e y s h o u l d b e r e p la ce d i f t h e y a r e d a m a ge d ,

or cleaned if they are soiled.

If this does not produce the desired results, the setting angle of the wind-

screen wiper arms might be incorrect. They should be checked by a qualified

workshop and corrected if necessary.

WARNING

Do not drive unless you have good visibility through all windows!•The ignition must not be switched on while the front wiper arms are in

a raised position. The wipers would return to their park position and

damage the paintwork on the bonnet.

Fig. 174 Removing the

wiper bladeFig. 175 Fitting the wiper

blade

AAAB

AC

AD

Exeo_EN.book Seite 229 Freitag, 28. August 2009 10:14 10

Page 232 of 310

Checking and refilling levels

230•To prevent smearing on the windscreen, the wiper blades should be

cleaned regularly using a window cleaner solution. If the wiper blades are

very dirty (e.g. insects etc.), they should be cleaned using a sponge or

cloth. Failure to do so could result in an accident.•For safety reasons, the wiper blades should be changed once or twice a

year.Caution

•Damaged or dirty windscreen wipers could scratch the windscreen.•Never use fuel, nail varnish remover, paint thinner or similar products to

clean the windows. This could damage the windscreen wiper blades.•Never move the windscreen wiper or windscreen wiper arm manually. This

could cause damage.•Do not pull the windscreen wipers forward unless they are in the service

position. Otherwise the bonnet could be damaged.

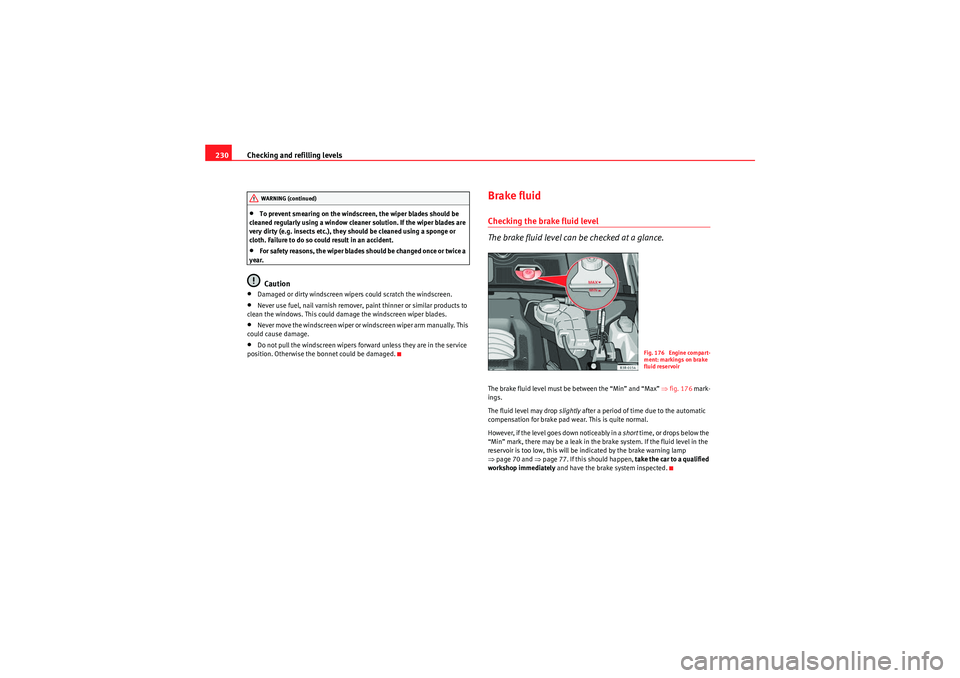

Brake fluidChecking the brake fluid level

The brake fluid level can be checked at a glance.The brake fluid level must be between the “Min” and “Max” ⇒ fig. 176 mark-

ings.

The fluid level may drop slightly after a period of time due to the automatic

compensation for brake pad wear. This is quite normal.

However, if the level goes down noticeably in a short time, or drops below the

“Min” mark, there may be a leak in the brake system. If the fluid level in the

reservoir is too low, this will be indicated by the brake warning lamp

⇒ page 70 and ⇒ page 77. If this should happen, take the car to a qualified

workshop immediately and have the brake system inspected.

WARNING (continued)

Fig. 176 Engine compart-

ment: markings on brake

fluid reservoir

Exeo_EN.book Seite 230 Freitag, 28. August 2009 10:14 10

Page 262 of 310

If and when

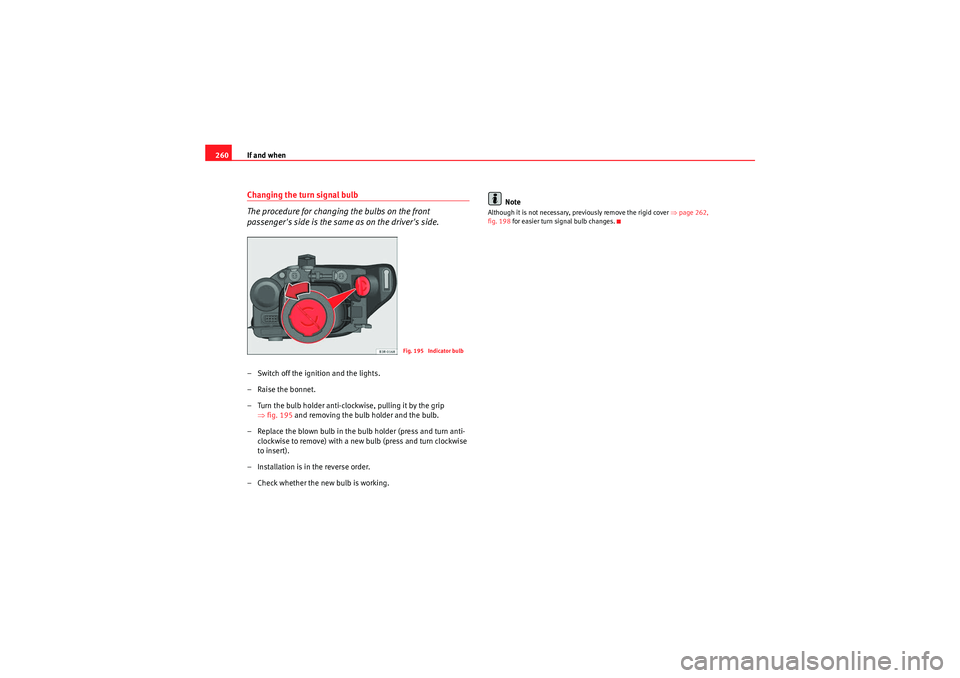

260Changing the turn signal bulb

The procedure for changing the bulbs on the front

passenger's side is the same as on the driver's side.– Switch off the ignition and the lights.

– Raise the bonnet.

– Turn the bulb holder anti-clockwise, pulling it by the grip

⇒fig. 195 and removing the bulb holder and the bulb.

– Replace the blown bulb in the bulb holder (press and turn anti- clockwise to remove) with a new bulb (press and turn clockwise

to insert).

– Installation is in the reverse order.

– Check whether the new bulb is working. Note

Although it is not necessary, previously remove the rigid cover

⇒page 262,

fig. 198 for easier turn signal bulb changes.

Fig. 195 Indicator bulb

Exeo_EN.book Seite 260 Freitag, 28. August 2009 10:14 10

Page 263 of 310

If and when261

Safety First

Controls and equipment

Practical tips

Technical Data

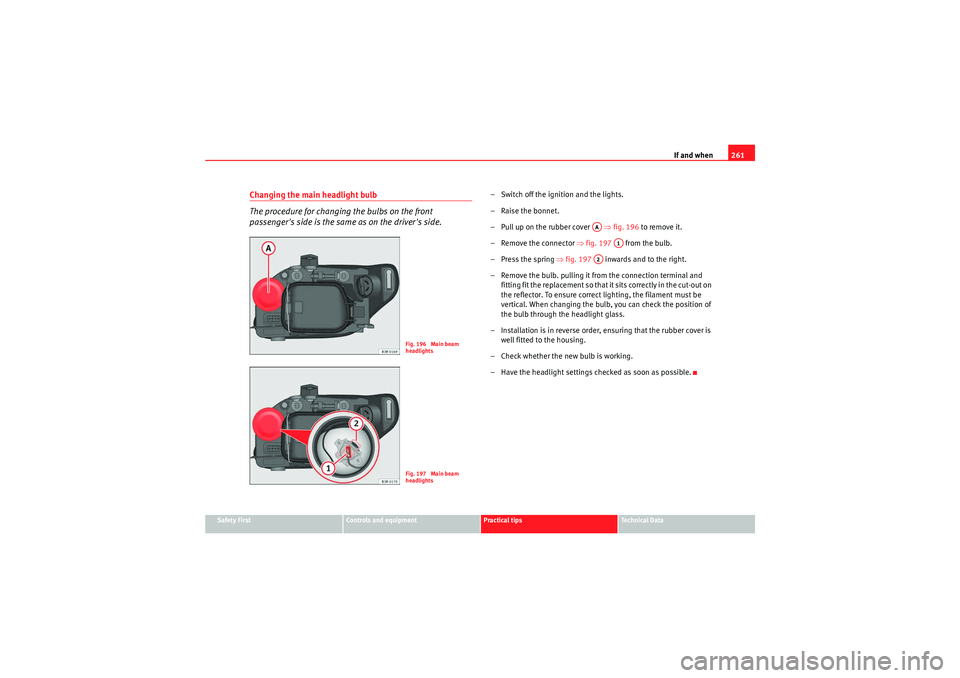

Changing the main headlight bulb

The procedure for changing the bulbs on the front

passenger's side is the same as on the driver's side.

– Switch off the ignition and the lights.

– Raise the bonnet.

– Pull up on the rubber cover ⇒fig. 196 to remove it.

– Remove the connector ⇒fig. 197 from the bulb.

– Press the spring ⇒fig. 197 inwards and to the right.

– Remove the bulb. pulling it from the connection terminal and fitting fit the replacement so that it sits correctly in the cut-out on

the reflector. To ensure correct lighting, the filament must be

vertical. When changing the bulb, you can check the position of

the bulb through the headlight glass.

– Installation is in reverse order, ensuring that the rubber cover is well fitted to the housing.

– Check whether the new bulb is working.

– Have the headlight settings checked as soon as possible.

Fig. 196 Main beam

headlightsFig. 197 Main beam

headlights

AA

A1

A2

Exeo_EN.book Seite 261 Freitag, 28. August 2009 10:14 10