turn signal Seat Exeo 2011 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Exeo, Model: Seat Exeo 2011Pages: 313, PDF Size: 5.02 MB

Page 264 of 313

262If and when

Note

Although it is not necessary, previously remove the rigid cover ⇒ fig. 193 for

easier turn signal bulb changes.

Changing the main headlight bulb

The procedure for changing the bulb is the same on both

sides.

Fig. 191 Main beam

headlights

Fig. 192 Main beam

headlights

– Switch off the ignition and the lights.

– Raise the bonnet.

– Pull up on the rubber cover A

⇒ fig. 191 to remove it.

– Remove the connector ⇒ fig. 192 1

from the bulb.

– Press the spring ⇒ fig. 192 2

inwards and to the right.

– Remove the bulb. pulling it from the connection terminal and

fitting fit the replacement so that it sits correctly in the cut-out

on the reflector. To ensure correct lighting, the filament must be

vertical. When changing the bulb, you can check the position of

the bulb through the headlight glass.

– Installation is in reverse order, ensuring that the rubber cover is

well fitted to the housing.

– Check whether the new bulb is working.

– Have the headlight settings checked as soon as possible.

Page 268 of 313

266If and when

● Main headlight lamps: Xenon ⇒

lights.

● Sources of the DRL (daylight) light unit and position.

WARNING

● Take particular care when working on components in the engine com-

partment if the engine is warm - risk of burns!

● Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

● The high voltage element of gas discharge bulbs* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.

● When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.

CAUTION

● Remove the ignition key before working on the electric system. If not, a

short circuit could occur.

● Switch off the lights or parking lights before you change a bulb.

For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the prop-

er manner.

Note

● Depending on weather conditions (cold or wet), the front lights, the fog

lights, the tail lights and the turn signals may be temporarily misted. This

has no influence on the useful life of the lighting system. By switching on

the lights, the area through which the beam of light is projected will quickly

be demisted. However, the edges may continue to be misted.

● Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the inter-

est of your own safety, but also in that of all other road users. ●

Before changing a bulb, make sure you have the correct new bulb.

● Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will va-

porise as a result of the heat generated by the bulb, be deposited on the

reflector and impair its surface.

Removing the air duct

The air duct has to be removed to gain access to the bulbs

for the right-side headlight.

Fig. 199 Air duct on

right side of vehicle

– Unscrew bolts A

⇒ fig. 199.

– Detach air duct from guide B

and take it out.

Page 269 of 313

267

If and when

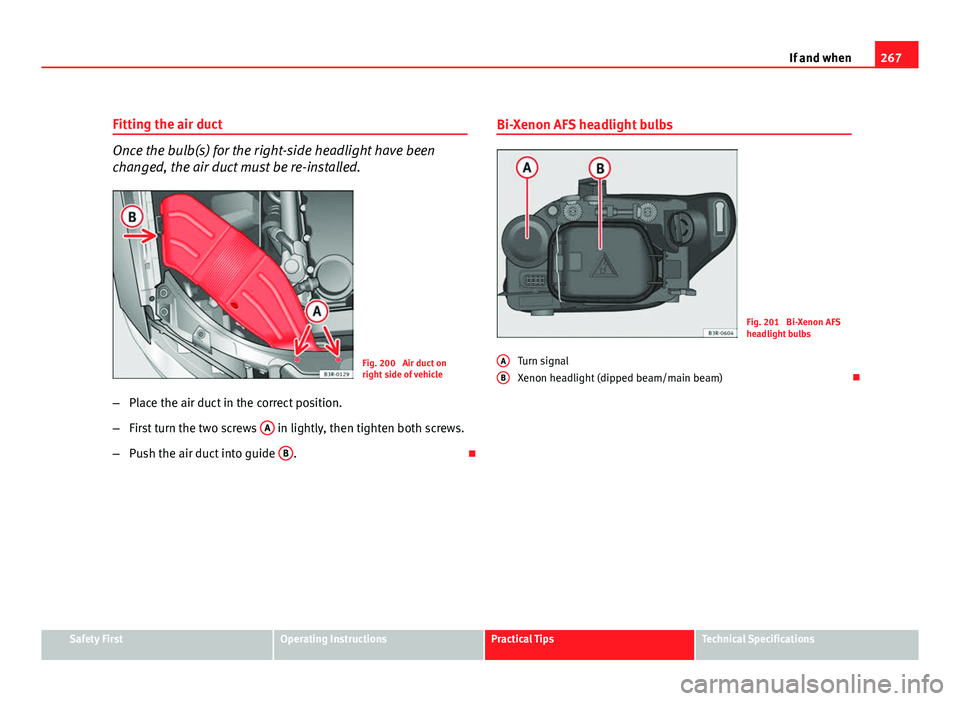

Fitting the air duct

Once the bulb(s) for the right-side headlight have been

changed, the air duct must be re-installed.

Fig. 200 Air duct on

right side of vehicle

– Place the air duct in the correct position.

– First turn the two screws A

in lightly, then tighten both screws.

– Push the air duct into guide B

. Bi-Xenon AFS headlight bulbs

Fig. 201 Bi-Xenon AFS

headlight bulbs

Turn signal

Xenon headlight (dipped beam/main beam)

A

B

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 270 of 313

268If and when

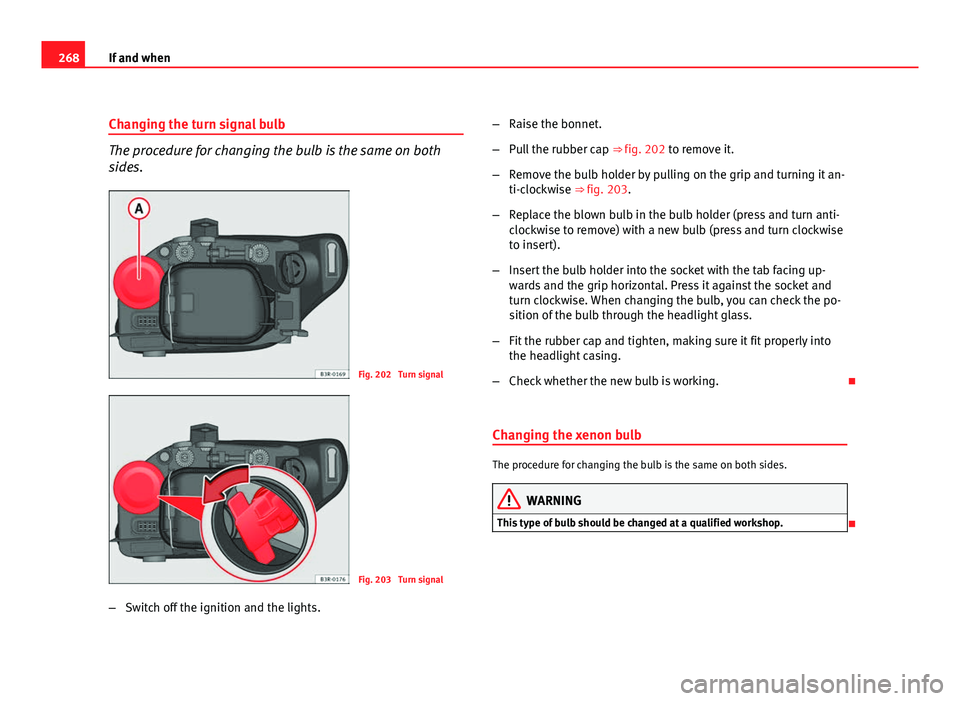

Changing the turn signal bulb

The procedure for changing the bulb is the same on both

sides.

Fig. 202 Turn signal

Fig. 203 Turn signal

– Switch off the ignition and the lights. –

Raise the bonnet.

– Pull the rubber cap ⇒ fig. 202 to remove it.

– Remove the bulb holder by pulling on the grip and turning it an-

ti-clockwise ⇒ fig. 203.

– Replace the blown bulb in the bulb holder (press and turn anti-

clockwise to remove) with a new bulb (press and turn clockwise

to insert).

– Insert the bulb holder into the socket with the tab facing up-

wards and the grip horizontal. Press it against the socket and

turn clockwise. When changing the bulb, you can check the po-

sition of the bulb through the headlight glass.

– Fit the rubber cap and tighten, making sure it fit properly into

the headlight casing.

– Check whether the new bulb is working.

Changing the xenon bulb

The procedure for changing the bulb is the same on both sides.

WARNING

This type of bulb should be changed at a qualified workshop.

Page 271 of 313

269

If and when

Changing tail light bulbs (on side panel)

Overview of tail lights

Fig. 204 Overview of tail

lights

Tail lights on side panel

● Brake light and side light

● Side lights

● Turn signal Overview of tail lights. LED lamps

Fig. 205 Overview of tail

lights

Tail lights on side panel

● Brake light and side light

● Side lights

● Turn signal

Note

● It is only possible to change the turn signal light.

● If the warning lamp for the side light and/or rear fog light (LED lights)

lights up, the tail light assembly should be replaced.

● The failure of the lamp is only shown when the LED function goes out

completely. Sometimes, a LED will stop working, without displaying the

warning as the function continues to operate.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 274 of 313

272If and when

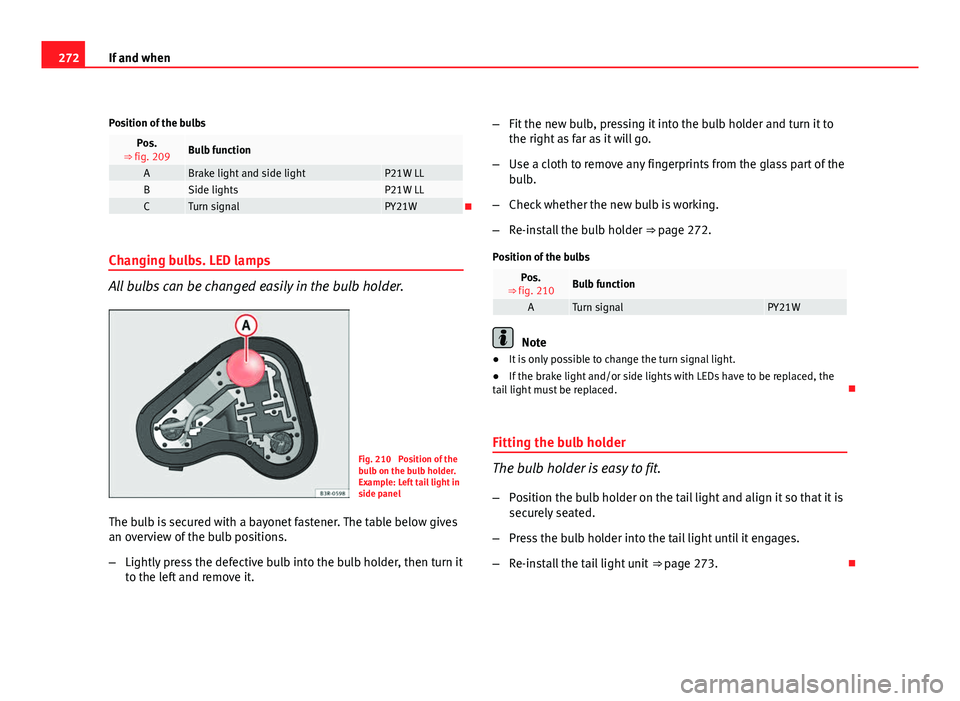

Position of the bulbs

Pos.

⇒ fig. 209Bulb function

ABrake light and side lightP21W LLBSide lightsP21W LLCTurn signalPY21W

Changing bulbs. LED lamps

All bulbs can be changed easily in the bulb holder.

Fig. 210 Position of the

bulb on the bulb holder.

Example: Left tail light in

side panel

The bulb is secured with a bayonet fastener. The table below gives

an overview of the bulb positions.

– Lightly press the defective bulb into the bulb holder, then turn it

to the left and remove it. –

Fit the new bulb, pressing it into the bulb holder and turn it to

the right as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the

bulb.

– Check whether the new bulb is working.

– Re-install the bulb holder ⇒ page 272.

Position of the bulbs

Pos.

⇒ fig. 210Bulb function

ATurn signalPY21W

Note

● It is only possible to change the turn signal light.

● If the brake light and/or side lights with LEDs have to be replaced, the

tail light must be replaced.

Fitting the bulb holder

The bulb holder is easy to fit. – Position the bulb holder on the tail light and align it so that it is

securely seated.

– Press the bulb holder into the tail light until it engages.

– Re-install the tail light unit ⇒ page 273.

Page 279 of 313

277

If and when

Position of the bulbs

Pos.

⇒ fig. 218Bulb function

AReverse lightP21W LL

Fitting the bulb holder

The bulb holder is easy to fit. – Check that the seal is seated correctly on the bulb holder.

– Position the bulb holder on the tail light and align it so that it is

securely seated.

– Press the bulb holder into the tail light until it engages.

– Fit the cover back in the interior trim so that it engages.

– Make sure that all bulbs for the tail lights are working. Side turn signals

Fig. 219 Side turn signal

– Press the turn signal to the left or to the right to remove the

bulb.

– Remove the bulb holder from the turn signal.

– Remove the failed glass bulb and replace with a new bulb.

– Insert the bulb holder in the turn signal guide until it clicks into

place.

– First place the turn signal in the opening in the bodywork, fixing

the tabs ⇒ fig. 219, arrow 1

.

– Insert the bulb as shown by the arrow 2

⇒ fig. 219.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 286 of 313

284If and when

Do not pull too hard with the towing vehicle and take care to avoid jerking

the tow-rope. When towing on an unpaved road, there is always a risk of

overloading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the turn signals,

horn, windscreen wipers and washers.

As the brake servo does not work if the engine is not running, you must ap-

ply considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running,

you will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

● Put the selector lever into position “N”.

● Do not drive faster than 50 km/h.

● Do not tow further than 50 km.

● If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.

Note

● Observe legal requirements when towing or tow-starting.

● Switch on the hazard warning lights of both vehicles. However, observe

any regulations to the contrary.

● For technical reasons, vehicles with an automatic gearbox must not be

tow-started.

● If damage to your vehicle means that there is no lubricant in the gear-

box, you must raise the drive wheels while the vehicle is being towed.

● If the vehicle has to be towed more than 50 km, the front wheels should

be raised during towing, and towing should be carried out by a qualified

person. ●

The steering wheel is locked when the vehicle has no electrical power.

The vehicle must then be towed with the front wheels raised. Towing should

be carried out by a qualified person.

● The towing eye should always be kept in the vehicle. Please refer to the

notes ⇒ page 283, Tow-starting.

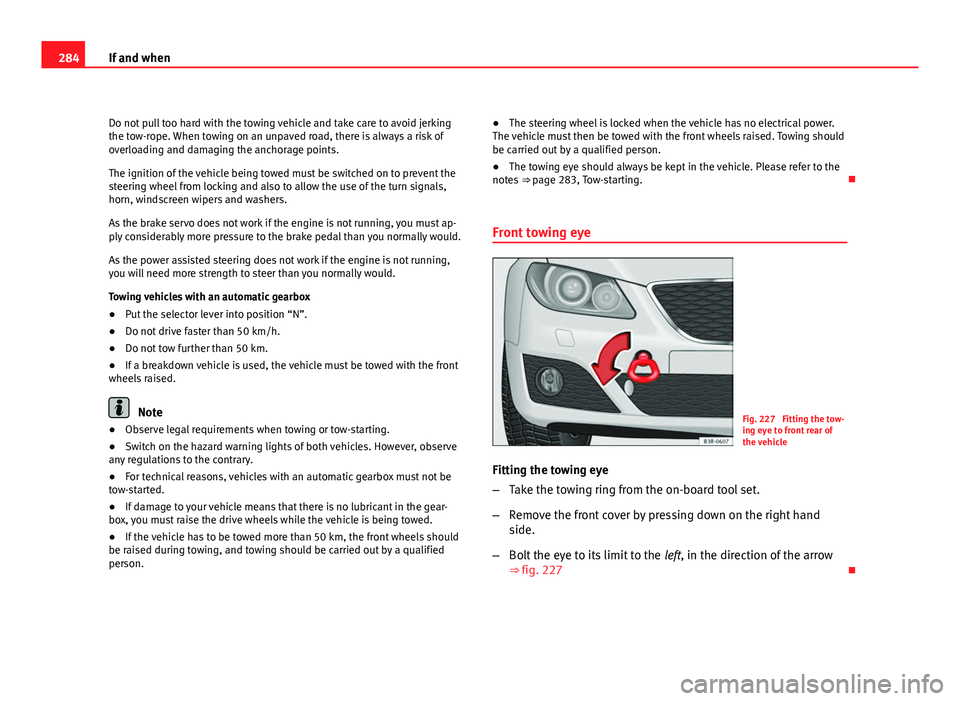

Front towing eyeFig. 227 Fitting the tow-

ing eye to front rear of

the vehicle

Fitting the towing eye

– Take the towing ring from the on-board tool set.

– Remove the front cover by pressing down on the right hand

side.

– Bolt the eye to its limit to the left, in the direction of the arrow

⇒ fig. 227

Page 310 of 313

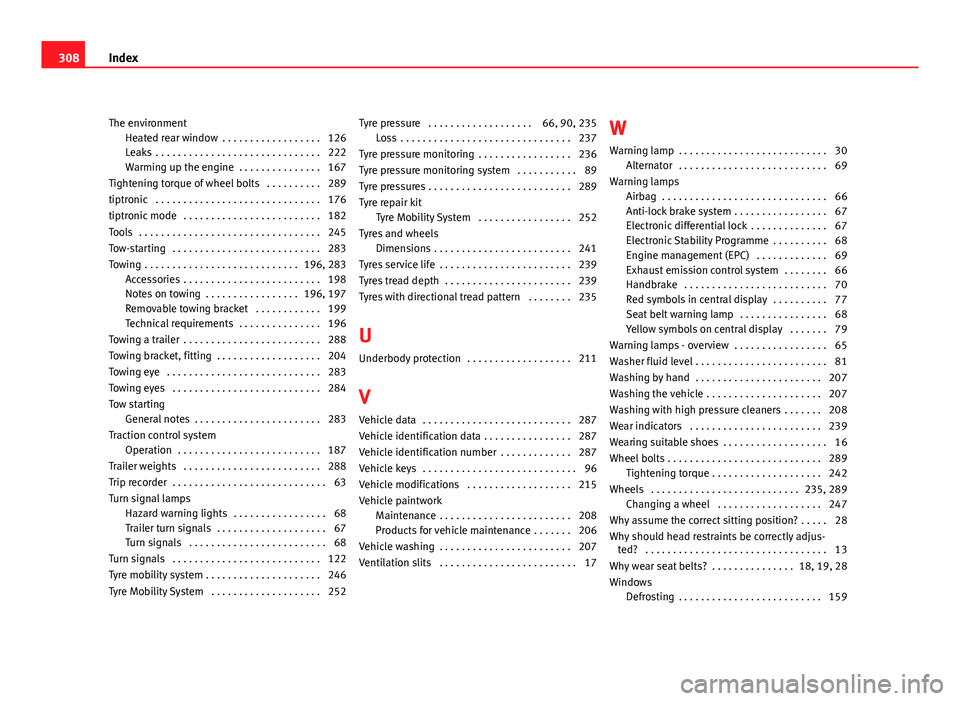

The environmentHeated rear window . . . . . . . . . . . . . . . . . . 126

Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Warming up the engine . . . . . . . . . . . . . . . 167

Tightening torque of wheel bolts . . . . . . . . . . 289

tiptronic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

tiptronic mode . . . . . . . . . . . . . . . . . . . . . . . . . 182

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Tow-starting . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196, 283 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 198

Notes on towing . . . . . . . . . . . . . . . . . 196, 197

Removable towing bracket . . . . . . . . . . . . 199

Technical requirements . . . . . . . . . . . . . . . 196

Towing a trailer . . . . . . . . . . . . . . . . . . . . . . . . . 288

Towing bracket, fitting . . . . . . . . . . . . . . . . . . . 204

Towing eye . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Towing eyes . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Tow starting General notes . . . . . . . . . . . . . . . . . . . . . . . 283

Traction control system Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Trailer weights . . . . . . . . . . . . . . . . . . . . . . . . . 288

Trip recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Turn signal lamps Hazard warning lights . . . . . . . . . . . . . . . . . 68

Trailer turn signals . . . . . . . . . . . . . . . . . . . . 67

Turn signals . . . . . . . . . . . . . . . . . . . . . . . . . 68

Turn signals . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Tyre mobility system . . . . . . . . . . . . . . . . . . . . . 246

Tyre Mobility System . . . . . . . . . . . . . . . . . . . . 252 Tyre pressure . . . . . . . . . . . . . . . . . . . 66, 90, 235

Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Tyre pressure monitoring . . . . . . . . . . . . . . . . . 236

Tyre pressure monitoring system . . . . . . . . . . . 89

Tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Tyre repair kit Tyre Mobility System . . . . . . . . . . . . . . . . . 252

Tyres and wheels Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 241

Tyres service life . . . . . . . . . . . . . . . . . . . . . . . . 239

Tyres tread depth . . . . . . . . . . . . . . . . . . . . . . . 239

Tyres with directional tread pattern . . . . . . . . 235

U Underbody protection . . . . . . . . . . . . . . . . . . . 211

V Vehicle data . . . . . . . . . . . . . . . . . . . . . . . . . . . 287

Vehicle identification data . . . . . . . . . . . . . . . . 287

Vehicle identification number . . . . . . . . . . . . . 287

Vehicle keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Vehicle modifications . . . . . . . . . . . . . . . . . . . 215

Vehicle paintwork Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 208

Products for vehicle maintenance . . . . . . . 206

Vehicle washing . . . . . . . . . . . . . . . . . . . . . . . . 207

Ventilation slits . . . . . . . . . . . . . . . . . . . . . . . . . 17 W

Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Warning lamps Airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Anti-lock brake system . . . . . . . . . . . . . . . . . 67

Electronic differential lock . . . . . . . . . . . . . . 67

Electronic Stability Programme . . . . . . . . . . 68

Engine management (EPC) . . . . . . . . . . . . . 69

Exhaust emission control system . . . . . . . . 66

Handbrake . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Red symbols in central display . . . . . . . . . . 77

Seat belt warning lamp . . . . . . . . . . . . . . . . 68

Yellow symbols on central display . . . . . . . 79

Warning lamps - overview . . . . . . . . . . . . . . . . . 65

Washer fluid level . . . . . . . . . . . . . . . . . . . . . . . . 81

Washing by hand . . . . . . . . . . . . . . . . . . . . . . . 207

Washing the vehicle . . . . . . . . . . . . . . . . . . . . . 207

Washing with high pressure cleaners . . . . . . . 208

Wear indicators . . . . . . . . . . . . . . . . . . . . . . . . 239

Wearing suitable shoes . . . . . . . . . . . . . . . . . . . 16

Wheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289 Tightening torque . . . . . . . . . . . . . . . . . . . . 242

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . 235, 289 Changing a wheel . . . . . . . . . . . . . . . . . . . 247

Why assume the correct sitting position? . . . . . 28

Why should head restraints be correctly adjus- ted? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Why wear seat belts? . . . . . . . . . . . . . . . 18, 19, 28

Windows Defrosting . . . . . . . . . . . . . . . . . . . . . . . . . . 159

308 Index