tow Seat Exeo 2012 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Exeo, Model: Seat Exeo 2012Pages: 317, PDF Size: 5.29 MB

Page 195 of 317

193

Intelligent technology

Brake servo

The brake servo assists the driver when braking

The brake servo increases the pressure you apply to the brake pedal. The

brake servo works only when the engine is running.

WARNING

Ensure the vehicle does not move while in neutral, when the engine is

stopped. Failure to do so could result in an accident.

Note

If the brake servo is not working, e.g. because the vehicle has to be towed

or because it is broken, you will have to press the brake pedal considerably

harder to make up for the lack of servo assistance.

Power steering

Power steering makes it easier to turn the steering wheel

when the engine is running. Power steering assists the driver by reducing the force needed to turn the

steering wheel.

Power steering does not work if the engine is off. In this case the steering

wheel requires much more force to turn.

If the steering is held at its turning limit when the vehicle is stationary, this

will place an excessive load on the power steering system. Turning the

steering wheel to its limit places a load on the system, which causes noise.

It will also reduce the idling speed of the engine.

CAUTION

When the engine is running, do not turn the steering wheel to its limit for

more than 15 seconds. Otherwise, there is a risk of damaging the power

steering.

Note

● If the power steering should fail at any time or the engine is switched off

(for instance when being towed), the vehicle can still be steered. However,

more effort will be required to turn the steering wheel.

● If the system is leaking or malfunctioning, please take the vehicle to a

specialised workshop as soon as possible.

● The power steering system requires a special hydraulic fluid. The fluid

reservoir is located at the front of the engine compartment on the left

⇒ page 296. The correct fluid level in the reservoir is important for the pow-

er steering to function properly. The hydraulic fluid level is checked at the

Inspection Service.

Servotronic*

The servotronic system electronically adjusts the power as-

sisted steering.

In vehicles equipped with servotronic power steering the degree of power

assistance ⇒ page 193 is adjusted

electronically according to road speed.

If a fault should occur in the servotronic system, the power steering will still

operate. The degree of power assistance will, however, no longer adapt to

different speeds. If the electronic regulating system is not working properly,

this is most noticeable when turning the steering wheel at low speeds (for

instance when parking), as more effort will be required than usual. The fault

should be corrected by a specialised workshop as soon as possible.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 196 of 317

194Driving and the environment

Driving and the environment

Running-in Running in a new engine

The engine needs to be run in over the first 1500 km.

Up to 1000 kilometres

– Do not drive at speeds of more than 2/3 the maximum speed.

– Do not accelerate hard.

– Avoid high engine revolutions.

– Do not tow a trailer.

From 1000 to 1500 kilometres

– Speeds can be gradually increased to the maximum road speed

or maximum permissible engine speed (rpm).

During its first few hours of running, the internal friction in the engine is

greater than later on, when all the moving parts have bedded in.

For the sake of the environment

If the engine is run in gently, its life will be increased and its oil consump-

tion reduced. Braking capacity and braking distance

The braking capacity and braking distance are influenced by

driving situations and road conditions.

The efficiency of the brakes depends directly on the

brake pad wear. The

rate of wear of the brake pads depends to a great extent on the conditions

under which the vehicle is operated and the way the vehicle is driven. If you

often drive in town traffic, drive short distances or have a sporty driving

style, we recommend that you have the thickness of your brake pads

checked by a Technical Service more frequently than recommended in the

Service Plan.

If you drive with wet brakes, for example, after crossing areas of water, in

heavy rainfall or even after washing the vehicle, the effect of the brakes is

lessened as the brake discs are wet or even frozen (in winter). In this case

the brakes should be dried by pressing the brake pedal several times.

WARNING

Longer braking distances and faults in the brake system increase the risk

of accidents.

● New brake pads must be run in and do not have the correct friction

during the first 200 km. However, the reduced braking capacity may be

compensated by pressing on the brake pedal a little harder. This also ap-

plies when the brake pads have to be changed further on.

● If brakes are wet or frozen, or if you are driving on roads which have

been salted, braking power may be lower than normal.

Page 197 of 317

195

Driving and the environment

WARNING (Continued)

● On steep slopes, if brakes are excessively used, they will overheat.

Before driving down a long steep slope, it is advisable to reduce speed

and change down into a lower gear or range (depending on the type of

transmission). This makes use of engine braking and relieves the brakes.

● Never let the brakes “drag” by applying light pressure. Continuous

braking will cause the brakes to overheat and the braking distance will

increase. Apply and then release the brakes alternately.

● Never let the vehicle run with the engine switched off. The braking

distance is increased considerably when the brake servo is not active.

● If the brake fluid loses its viscosity and is subjected to heavy use, va-

pour bubbles can form in the brake system. This reduces the efficiency of

the brakes.

● Non-standard or damaged front spoilers could restrict the airflow to

the brakes and cause them to overheat. Before purchasing accessories

please observe the relevant instructions ⇒ page 221, Technical modifi-

cations.

● If a brake circuit fails, the braking distance will be increased consider-

ably. Contact a specialised workshop immediately and avoid unnecessa-

ry journeys.

Exhaust gas purification system Catalytic converter*

To maintain the useful life of the catalytic converter

– Use only unleaded petrol with petrol engines, as lead damages

the catalytic converter.

– Do not let the fuel get too low in the tank. –

For engine oil changes, do not replenish with too much engine

oil ⇒ page 230.

– Never tow the vehicle to start it, use jump leads if necessary

⇒ page 285.

If you notice misfiring, uneven running or loss of power when the vehicle is

moving, reduce speed immediately and have the vehicle inspected at the

nearest specialised workshop. In general, the exhaust gas warning lamp

will light up when any of the described symptoms occur ⇒ page 66. If this

happens, unburnt fuel can enter the exhaust system and escape into the en-

vironment. The catalytic converter can also be damaged by overheating.

WARNING

The catalytic converter reaches very high temperatures! There is a risk of

fire.

● Never park where the catalytic converter could come into contact with

dry grass or flammable materials under the vehicle.

● Do not apply additional underseal or anti-corrosion coatings to the

exhaust pipes, catalytic converter or the heat shields on the exhaust sys-

tem. These materials could catch fire when the vehicle is being driven.

CAUTION

Never run the fuel tank completely dry because the irregularity of the fuel

supply may cause ignition problems. This allows unburnt fuel to enter the

exhaust system, which could cause overheating and damage the catalytic

converter.

For the sake of the environment

Even when the emission control system is working perfectly, there may be a

smell of sulphur from the exhaust gas under some conditions. This depends

on the sulphur content of the fuel used. Quite often the problem can be

solved by changing to another brand of fuel.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 201 of 317

199

Trailer towing

Trailer towing Trailer towing

Technical requirements

The towing bracket must meet certain technical require-

ments.

Your vehicle is intended mainly for transporting passengers and luggage.

However, if suitably equipped, it can also be used to tow a trailer or cara-

van.

If your vehicle has been factory-supplied with a towing bracket, all of the

necessary technical and legal aspects for trailing towing have been taking

into account during manufacturing.

Your vehicle is fitted with a 13-pole socket for the electrical connection be-

tween the trailer and the vehicle. If the trailer has a 7-pole connector you

can use an adapter cable. This can be purchased at a Technical Service.

If a towing bracket is to be fitted after the vehicle is purchased, this must be

done according to the instructions of the towing bracket manufacturer

⇒ page 207.

WARNING

If a towing bracket is retrofitted, the installation should be carried out by

a specialised workshop.

● Particularly in high outdoor temperatures, it is not possible to drive

up long steep gradients without a suitable cooling system. The engine

would heat up.

● Incorrect installation can result in a safety risk!

Notes on towing

There are a number of points which need to be checked be-

fore towing a trailer or caravan.

– Observe the maximum permitted trailer weights ⇒ page 296.

Trailer weight

Never exceed the maximum permitted trailer weight.

If you do not load the trailer up to the maximum permitted trailer weight,

you can then climb correspondingly steeper gradients.

The maximum trailer weights listed are only applicable for altitudes up to

1000 m above sea level. With increasing altitude the engine power and

therefore the vehicle's climbing ability are impaired because of the reduced

air density. The maximum trailer weight has to be reduced accordingly. The

weight of the vehicle and trailer must be reduced by about 10% for every

subsequent 1000 m (or part thereof). This figure refers to the combined

weight of the (loaded) vehicle and (loaded) trailer.

The figures for the drawbar load that appear on the identification plate of

the towing bracket are for certification purposes only. The correct figures for

your specific model, which may be lower than these figures for the towing

bracket, are given in the registration documents and on ⇒ page 289. Also

refer to ⇒ page 296.

Distributing the load

Distribute loads in the trailer so that heavy objects are as near to the axle as

possible. Loads carried in the trailer must be secured to prevent them mov-

ing.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 202 of 317

200Trailer towing

Where possible, operate the trailer with the maximum permitted drawbar

load on the ball joint of the towing bracket, but do not exceed the specified

limit.

Tyre pressure

Check the tyre pressures on your vehicle, and adjust for “full load” condi-

tions (refer to the sticker listing the tyre pressures on the door pillar). It may

also be necessary to adjust the tyre pressures on the trailer according to the

recommendations of the trailer manufacturer.

Exterior mirrors

Check whether you can see enough of the road behind the trailer with the

standard mirrors. If this is not the case you should have additional mirrors

fitted. The two exterior mirrors should be fitted on folding arms. Adjust the

mirrors to give sufficient rear vision.

Headlights

Before starting a journey, check the headlight beam settings with the trailer

hitched up. If necessary, alter the height of the headlight beams by means

of the headlight range control. See ⇒ page 119.

Power supply

When you remove the ignition key, the power supply to the trailer is inter-

rupted.

Removable ball joint coupling

Vehicles with a factory-fitted towing bracket are equipped with a removable

ball joint coupling. This is stored in the spare wheel well in the luggage

compartment together with the necessary fitting instructions.

Note

If you frequently tow, we recommend you also have the vehicle serviced be-

tween services. Notes on towing

Towing a trailer involves additional attention by the driver.

Weight distribution

The weight distribution of a loaded trailer with an unladen vehicle is very

unfavourable. However, if this cannot be avoided, drive extra slow to allow

for the unbalanced weight distribution.

Speed

The stability of the vehicle and trailer is reduced with increasing speed.

Therefore, it is advisable not to drive at the maximum permissible speed in

unfavourable road, weather or wind conditions. This especially applies

when driving downhill.

You should always reduce speed immediately if the trailer shows the slight-

est sign of swaying. Never try to stabilise the trailer by accelerating.

Anticipate hazards and brake in good time. If towing a trailer with an inertia

brake, first brake gently and then harder. This will prevent brake tapping by

the trailer wheels when they lock. Select a low gear in due course before go-

ing down a steep downhill. This enables you to use the engine braking to

slow down the vehicle.

Swaying and pitching can be reduced by stabiliser aids. We recommend

having stabiliser aids installed when towing trailers with a high trailer

weight. They can be purchased and installed at a Technical Service.

Reheating

When climbing long hills in hot weather with the engine running fast in low

gear, you should keep an eye on the coolant temperature gauge ⇒ page 60.

Reduce speed immediately if the needle moves to the right end of the scale.

If the temperature warning lamp in the instrument panel should start

flashing, stop the vehicle and let the engine cool down by running it at

idling speed for a few minutes.

Page 203 of 317

201

Trailer towing

Equipment and accessories

Before mounting equipment and accessories (e.g. bicycle

rack) please observe the following notes.

Fig. 153 Load distribu-

tion of equipment and ac-

cessories

The equipment/accessories mounted must not protrude more than 700 mm

from the ball joint 1

.

The total weight (mounted equipment plus the load) must not exceed 75 kg.

The maximum load depends on where the centre of gravity lies.

The maximum weight decreases as the distance between the centre of grav-

ity and the ball joint 1

increases.

The following limits apply:

If the distance is 300 mm, the total weight (incl. the equipment mounted) A

must not exceed 75 kg.

If the distance is 600 mm, the total weight (incl. the equipment mounted) B

must not exceed 35 kg. Only bicycle racks for

a maximum of three bicycles may be used.

Equipment and accessories mounted on the towing bracket

SEAT recommends that you only mount equipment (e.g. bicycle rack) on the

towing bracket which has been officially approved.. If you wish to attach

other equipment please make sure that it has been approved by the manu-

facturer for use on the towing bracket. If you mount unsuitable equipment,

this can cause damage to the towing bracket. In an extreme case, damage

to the towing bracket could cause it to break ⇒

.

WARNING

● If you wish to mount equipment which has not been approved by

SEAT, please ensure that it is suitable for use on SEAT vehicles.

● Use of unsuitable equipment can result in severe damage to the tow-

ing bracket. The towing bracket could then break while pulling a trailer

and cause an accident.

● Never use tools of any kind when fitting and removing the ball joint.

This would damage the locking device, no longer guaranteeing the cor-

rect working order of the bracket. This could lead to an accident.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 204 of 317

202Trailer towing

Removable towing bracket

Introduction

Special care is required when fitting and removing the tow-

ing bracket.

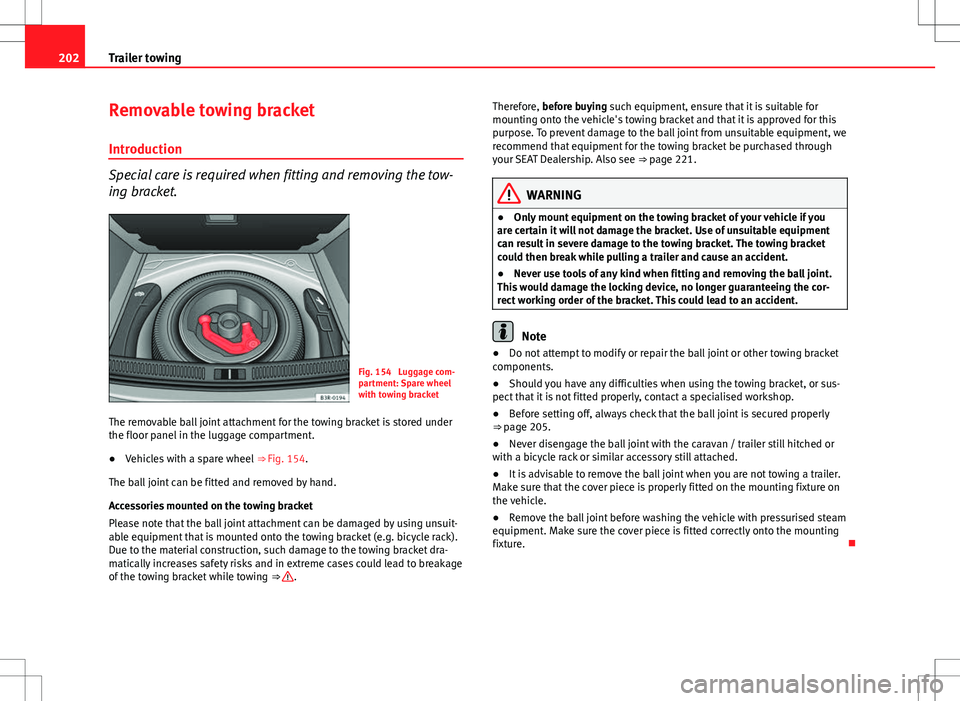

Fig. 154 Luggage com-

partment: Spare wheel

with towing bracket

The removable ball joint attachment for the towing bracket is stored under

the floor panel in the luggage compartment.

● Vehicles with a spare wheel

⇒ Fig. 154.

The ball joint can be fitted and removed by hand.

Accessories mounted on the towing bracket

Please note that the ball joint attachment can be damaged by using unsuit-

able equipment that is mounted onto the towing bracket (e.g. bicycle rack).

Due to the material construction, such damage to the towing bracket dra-

matically increases safety risks and in extreme cases could lead to breakage

of the towing bracket while towing ⇒

. Therefore, before buying such equipment, ensure that it is suitable for

mounting onto the vehicle's towing bracket and that it is approved for this

purpose. To prevent damage to the ball joint from unsuitable equipment, we

recommend that equipment for the towing bracket be purchased through

your SEAT Dealership. Also see

⇒ page 221.

WARNING

● Only mount equipment on the towing bracket of your vehicle if you

are certain it will not damage the bracket. Use of unsuitable equipment

can result in severe damage to the towing bracket. The towing bracket

could then break while pulling a trailer and cause an accident.

● Never use tools of any kind when fitting and removing the ball joint.

This would damage the locking device, no longer guaranteeing the cor-

rect working order of the bracket. This could lead to an accident.

Note

● Do not attempt to modify or repair the ball joint or other towing bracket

components.

● Should you have any difficulties when using the towing bracket, or sus-

pect that it is not fitted properly, contact a specialised workshop.

● Before setting off, always check that the ball joint is secured properly

⇒ page 205.

● Never disengage the ball joint with the caravan / trailer still hitched or

with a bicycle rack or similar accessory still attached.

● It is advisable to remove the ball joint when you are not towing a trailer.

Make sure that the cover piece is properly fitted on the mounting fixture on

the vehicle.

● Remove the ball joint before washing the vehicle with pressurised steam

equipment. Make sure the cover piece is fitted correctly onto the mounting

fixture.

Page 205 of 317

203

Trailer towing

Fitting the ball joint (step 1)

Fig. 155 Rear bumper:

Open the cover piece

– Remove the cover piece 2

⇒ Fig. 155 on the mounting fixture

1 below the bumper as far as it will go. The cover piece is held

automatically in the open position.

– Make sure the mounting fixture is clean. If not, clean it ⇒

.

Cont ⇒ page 203, Fitting the ball joint (step 2).

WARNING

It is important to keep the mounting fixture clean. Otherwise the ball

joint may fail to engage safely and securely. This could lead to an acci-

dent.

Fitting the ball joint (step 2)

Fig. 156 Removable tow-

ing bracket: Ball joint

Fig. 157 Removable tow-

ing bracket: Ball joint

Make sure the ball joint is clean and undamaged

– Check the locking pin A

, release pin B, shaft section C and

knob D ⇒ Fig. 156 on the ball joint to make sure they are clean

and undamaged.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 206 of 317

204Trailer towing

The spring mechanism inside the ball joint must be in the ready

position

–Check that the red marking A

⇒ Fig. 157 on the knob is inside

the black zone marked on the ball joint.

– Check that the locking pin B

is inside the holes in the shaft

section of the ball joint.

– Check that the knob protrudes visibly from the ball joint, so that

there is a clear gap C

between the knob and the ball joint.

The ball joint can only be installed if the internal spring mechanism is in the

ready position.

Cont ⇒ page 204, Fitting the ball joint (step 3).

Fitting the ball joint (step 3)

Fig. 158 Removable tow-

ing bracket: Setting the

spring mechanism to the

"ready" position

Fig. 159 Removable tow-

ing bracket: Inserting the

ball joint

Setting the spring mechanism to the ready position (if required)

– Insert the key 1

⇒ Fig. 158 in the lock on the knob and turn it

towards the red marking.

– Pull out the knob in direction A

, hold and turn in direction Buntil the locking pin 2 engages and the release pin 3 moves

out visibly ⇒ .

Inserting the ball joint

– With the spring mechanism in the ready position, insert the ball

joint into the mounting fixture and push it upwards ⇒ Fig. 159

in the direction indicated (arrow) ⇒

. It should lock into posi-

tion automatically. You should now clearly hear it click into

place.

– Lock the ball joint by turning the key to the green marking.

– Remove the key.

Cont ⇒ page 205, Fitting the ball joint (step 4).

Page 207 of 317

205

Trailer towing

WARNING

● If it is not possible to set the spring mechanism to the ready position

as described above, do not use the ball joint. Please contact a special-

ised workshop.

● To avoid injury, keep your hands away from the knob or cover piece

when inserting the ball joint in the mounting fixture. Otherwise, you

could be injured.

Fitting the ball joint (step 4)

Fig. 160 Removable tow-

ing bracket: Safety check

Fig. 161 Rear bumper:

Pulling down the power

socket

Safety check

– Check that the green marking A

⇒ Fig. 160 on the knob is in-

side the black zone marked on the ball joint.

– Check that the knob is directly against the ball joint, so that

there is no gap between the knob and the ball joint (arrow).

– Check that the ball joint is locked and the key is removed so

that the knob cannot be pulled out ⇒

.

– Check that the ball joint fits tightly in the mounting fixture (try

moving it about to check).

Towing socket

– To plug in the electrical connection for the trailer, pull down the

socket below the bumper ⇒ Fig. 161.

If the safety check is not satisfactory, the ball joint must be fitted again

properly.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications