brake light Seat Exeo 2013 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Exeo, Model: Seat Exeo 2013Pages: 319, PDF Size: 4.81 MB

Page 218 of 319

216Vehicle maintenance and cleaning

Cleaning the engine compartment

Take special care when cleaning the engine compartment.

Anti-corrosion treatment

The engine compartment and the surface of the power unit are given anti-

corrosion treatment at the factory.

Good corrosion protection is particularly important in winter when the vehi-

cle is frequently driven on salted roads. To prevent the salt corroding the ve-

hicle, the entire engine compartment should be thoroughly cleaned before

and after winter.

Your Technical Services have got the necessary workshop equipment to pro-

vide the correct cleaning and preserving products. For this reason, we rec-

ommend having this work performed by them.

The anti-corrosion protection is usually removed if the engine compartment

is cleaned with grease removing solutions, or if you have the engine

cleaned. On commissioning this work, ensure that all surfaces, seams,

joints and components in the engine compartment are given anti-corrosion

treatment.

WARNING

● When working in the engine compartment, always observe the safety

warnings ⇒ page 227.

● Before opening the bonnet, switch the engine off, apply the hand-

brake firmly and always remove the key from the ignition.

● Allow the engine to cool before you clean the engine compartment.

● Do not clean the vehicle underbody, wheel arches or wheel trims

without protecting your hands and arms. You may cut yourself on sharp-

edged metal parts. Failure to comply could result in injury.

WARNING (Continued)

● Moisture, ice and salt on the brake system may affect braking effec-

tiveness. Risk of accident. Directly after washing, avoid sudden and

sharp braking.

● Never touch the radiator fan. It is temperature-controlled and could

start automatically, even when the key is removed from the ignition!

For the sake of the environment

Fuel, grease and oil deposits could be removed when the engine is washed.

The polluted water must be cleaned in an oil separator. For this reason, en-

gine washing should be carried out only by a specialised workshop or a pet-

rol station.

Vehicle interior maintenance Introduction

The dye used in many modern garments, for example dark jeans, is not al-

ways sufficiently colour-fast. Seat upholstery (material and leather), espe-

cially when light-coloured, may visibly discolour if the dye comes out of

clothing (even when used correctly). This is not an upholstery defect but in-

dicates that the dye in the item of clothing is not sufficiently colour-fast.

The longer stains or dirt remain on the vehicle surfaces, especially the fab-

rics covering the padded upholstery, the more difficult it becomes to clean

and maintain them. If stains and dirt are left for a long time, it may be that

they are impossible to remove.

Page 239 of 319

237

Checking and refilling levels

WARNING

Do not drive unless you have good visibility through all windows!

● The ignition must not be switched on while the front wiper arms are

in a raised position. The wipers would return to their park position and

damage the paintwork on the bonnet.

● To prevent smearing on the windscreen, the wiper blades should be

cleaned regularly using a window cleaner solution. If the wiper blades

are very dirty (e.g. insects etc.), they should be cleaned using a sponge

or cloth. Failure to do so could result in an accident.

● For safety reasons, the wiper blades should be changed once or twice

a year.

CAUTION

● Damaged or dirty windscreen wipers could scratch the windscreen.

● Never use fuel, nail varnish remover, paint thinner or similar products to

clean the windows. This could damage the windscreen wiper blades.

● Never move the windscreen wiper or windscreen wiper arm manually.

This could cause damage.

● Do not pull the windscreen wipers forward unless they are in the service

position. Otherwise the bonnet could be damaged. Brake fluid

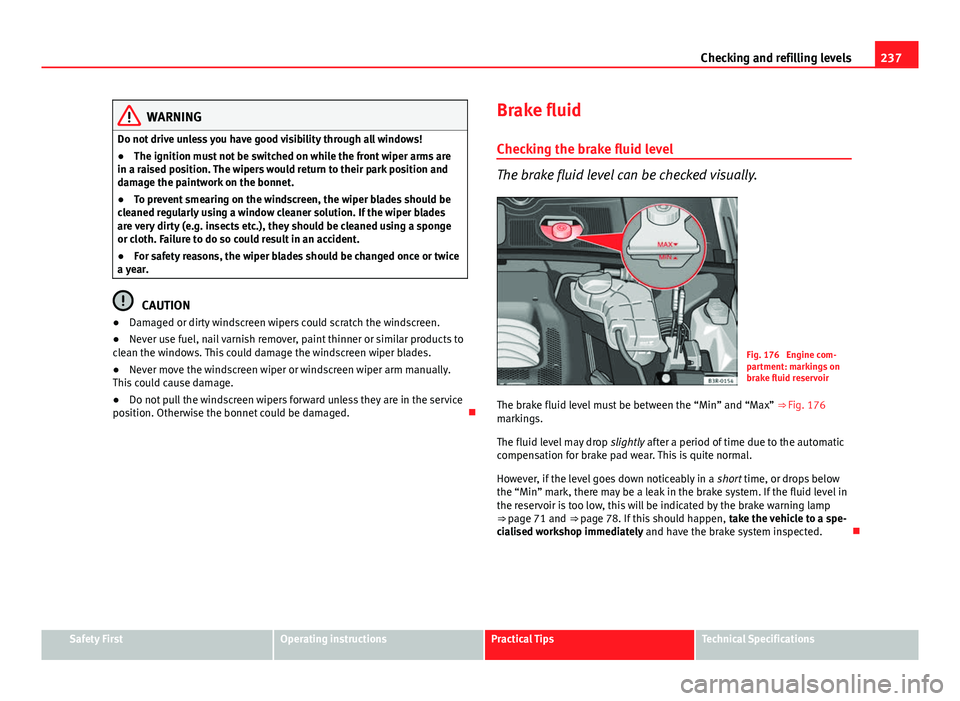

Checking the brake fluid level

The brake fluid level can be checked visually.

Fig. 176 Engine com-

partment: markings on

brake fluid reservoir

The brake fluid level must be between the “Min” and “Max” ⇒ Fig. 176

markings.

The fluid level may drop slightly after a period of time due to the automatic

compensation for brake pad wear. This is quite normal.

However, if the level goes down noticeably in a short time, or drops below

the “Min” mark, there may be a leak in the brake system. If the fluid level in

the reservoir is too low, this will be indicated by the brake warning lamp

⇒ page 71 and

⇒ page 78. If this should happen,

take the vehicle to a spe-

cialised workshop immediately and have the brake system inspected.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 256 of 319

254If and when

wheels fitted on the vehicle because of the wheel/tyre dimensions, rubber

composition, tread pattern, etc. Therefore, note the following restrictions:

● The spare steel wheel is designed only for your vehicle model. Do not

attempt to mount the wheel on any vehicle but your own.

● Your vehicle will have different driving characteristics when the spare

steel rim wheel is mounted ⇒

.

● The spare wheel is only intended for temporary use after having a flat

tyre. Replace the spare wheel with a normal wheel that has the proper tyre

dimensions as soon as possible.

● If the size of the spare steel rim wheel is different to that of the other

wheels, it is unlikely that snow chains suitable for the other wheels will fit it.

WARNING

● After mounting the spare steel rim wheel, the tyre pressure must be

checked and corrected as soon as possible. The tyre pressure must corre-

spond to the vehicle load (consult the table containing the inflation pres-

sures). Otherwise there is danger of causing an accident. Use the highest

tyre pressure as indicated in the table.

● Do not drive faster than 80 km/h, as higher speeds can cause an acci-

dent.

● Avoid heavy acceleration, hard braking and fast cornering, as this

could cause an accident.

Changing a wheel

Preparation work

What you must do before changing a wheel. – If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible. Choose a location that is as

level as possible.

– All occupants should leave the vehicle. They should wait in a

safe place (e.g. behind the roadside crash barrier).

– Apply the handbrake firmly.

– Engage first gear .

– When towing a trailer: Unhitch the trailer from your vehicle.

– Take the tools and the spare wheel ⇒ page 252 out of the lug-

gage compartment.

WARNING

If you have a puncture in heavy traffic, switch on the hazard warning

lights and place the warning triangle in a visible location. This is for your

own safety and also warns other road users.

CAUTION

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Page 263 of 319

261

If and when

Repairing a tyre

Fig. 188 Repairing a tyre

Preparations

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

– Apply the handbrake firmly to prevent the vehicle from moving

accidentally on slopes.

– Engage first gear .

– Check whether a repair is possible using the Tyre Mobility Sys-

tem ⇒ page 259.

– Ensure that all passengers leave the vehicle and move away

from the danger area ⇒

.

– Take the tyre sealant can and the compressor out of the lug-

gage compartment. –

Stick the “max. 80 km/h” adhesive, which is included with the

tyre sealant can, onto the instrument panel where the driver will

see it.

Filling the tyre

– Shake the tyre sealant can well.

– Screw the enclosed filling hose onto the sealant can as far as it

will go. This will automatically pierce the foil sealing the can.

– Take the valve cap off the tyre valve and use the enclosed valve

insert tool to unscrew the valve insert ⇒ Fig. 188.

– Place the valve insert onto a clean surface.

– Remove the sealing plug from the filling hose and insert the

hose into the tyre valve.

– Hold the tyre sealant can upside down and fill the complete

contents of the can into the tyre.

– Then disconnect the hose and screw the valve insert firmly back

into the tyre valve.

Inflating the tyre

– Screw the compressor filling hose onto the tyre valve and plug

the connector into the cigarette lighter.

– Pump the tyre up to 2.0 to 2.5 bar and monitor the pressure

shown on the pressure gauge.

– If the tyre pressure remains lower than the value specified

above drive the vehicle approx. 10 metres forwards or back-

wards, so that the sealant can spread evenly in the tyre. If the

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 278 of 319

276If and when

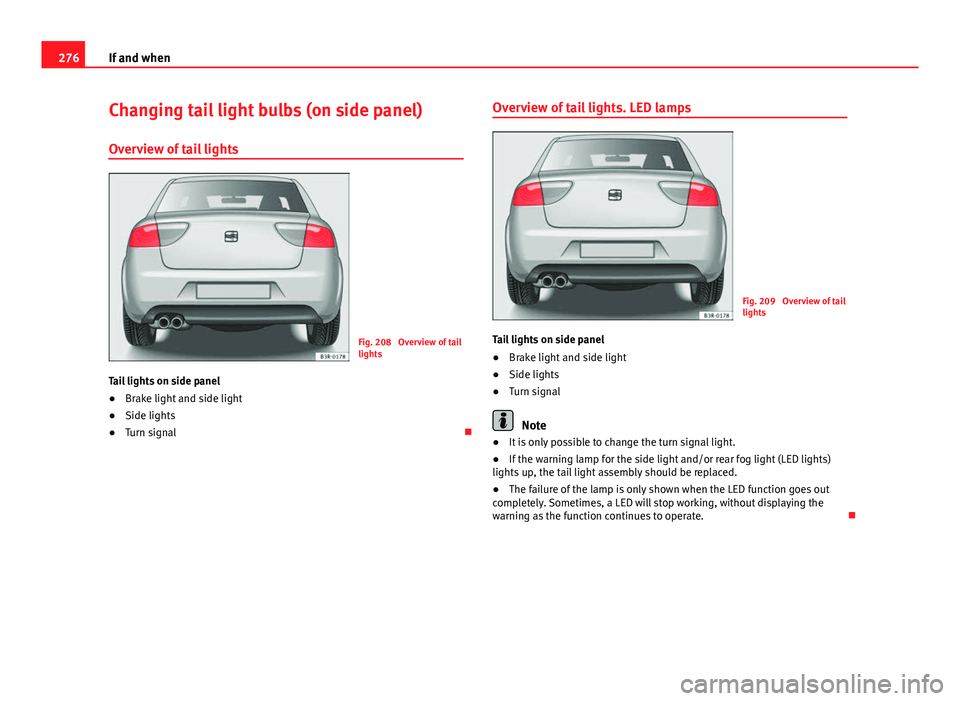

Changing tail light bulbs (on side panel)

Overview of tail lights

Fig. 208 Overview of tail

lights

Tail lights on side panel

● Brake light and side light

● Side lights

● Turn signal Overview of tail lights. LED lamps

Fig. 209 Overview of tail

lights

Tail lights on side panel

● Brake light and side light

● Side lights

● Turn signal

Note

● It is only possible to change the turn signal light.

● If the warning lamp for the side light and/or rear fog light (LED lights)

lights up, the tail light assembly should be replaced.

● The failure of the lamp is only shown when the LED function goes out

completely. Sometimes, a LED will stop working, without displaying the

warning as the function continues to operate.

Page 281 of 319

279

If and when

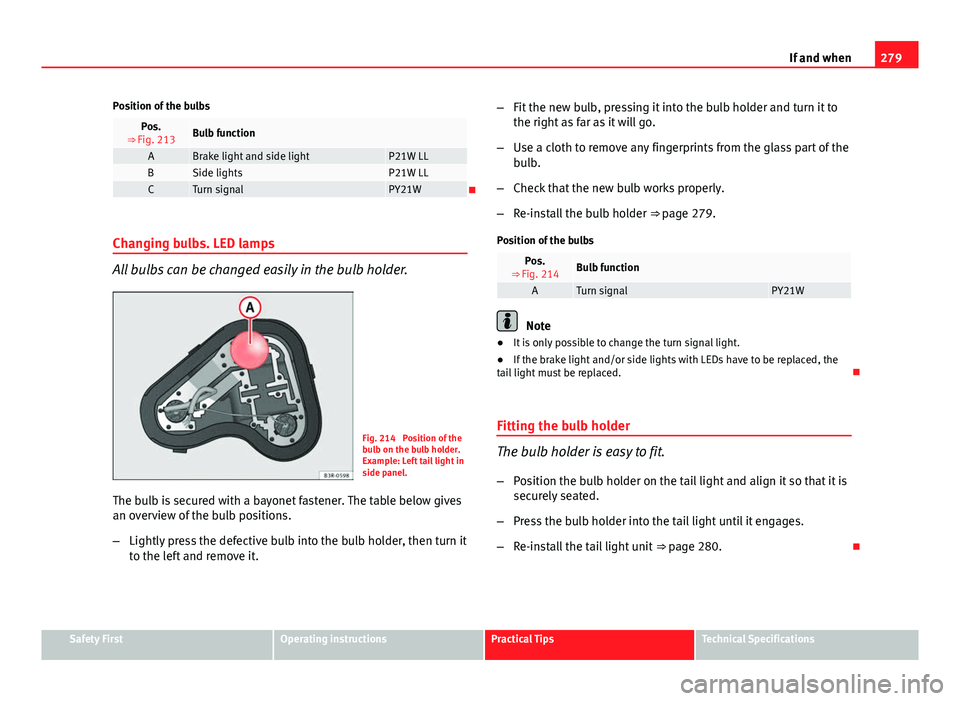

Position of the bulbs

Pos.

⇒ Fig. 213Bulb function

ABrake light and side lightP21W LLBSide lightsP21W LLCTurn signalPY21W

Changing bulbs. LED lamps

All bulbs can be changed easily in the bulb holder.

Fig. 214 Position of the

bulb on the bulb holder.

Example: Left tail light in

side panel.

The bulb is secured with a bayonet fastener. The table below gives

an overview of the bulb positions.

– Lightly press the defective bulb into the bulb holder, then turn it

to the left and remove it. –

Fit the new bulb, pressing it into the bulb holder and turn it to

the right as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the

bulb.

– Check that the new bulb works properly.

– Re-install the bulb holder ⇒ page 279.

Position of the bulbs

Pos.

⇒ Fig. 214Bulb function

ATurn signalPY21W

Note

● It is only possible to change the turn signal light.

● If the brake light and/or side lights with LEDs have to be replaced, the

tail light must be replaced.

Fitting the bulb holder

The bulb holder is easy to fit. – Position the bulb holder on the tail light and align it so that it is

securely seated.

– Press the bulb holder into the tail light until it engages.

– Re-install the tail light unit ⇒ page 280.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 290 of 319

288If and when

–Connect one end of the red jump lead to the positive +

termi-

nal of the vehicle with the flat battery A ⇒ Fig. 231.

– Connect the other end of the red jump lead to the positive ter-

minal +

in the vehicle providing assistance B.

– Connect one end of the black jump lead X

to a suitable ground

terminal, a solid piece of metal in the engine block, or to the en-

gine block ⇒ Fig. 231.

– Connect the other end of the black jump lead X

to a solid met-

al component bolted to the engine block or to the engine block

itself of the vehicle with the flat battery. However, connect it to

a point as far as possible from the battery A

.

4. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

5. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

6. Start the engine of the vehicle with the flat battery and wait two or three minutes until the engine is “running”.

Removing the jump leads

7. Before you remove the jump leads, switch off the dipped beam headlights (if they are switched on).

8. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

9. When the engine is running, disconnect the leads in reverse or- der to the details given above. Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 227.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not lean on the batteries. This could result in chemical burns.

Page 292 of 319

290If and when

Towing and tow-starting

Tow-starting

The use of jump leads is preferable to tow-starting.

We recommend that you do not tow-start your vehicle. Jump-start-

ing is preferable ⇒ page 286.

However, if your vehicle has to be tow-started:

– Engage the 2nd or the 3rd gear.

– Keep the clutch pressed down.

– Switch the ignition on.

– Once both vehicles are moving, release the clutch.

– As soon as the engine starts, press the clutch and move the

gear lever into neutral. This helps to prevent driving into the

towing vehicle.

WARNING

The risk of accidents is high when tow-starting. The vehicle being towed

can easily collide with the towing vehicle.

CAUTION

When tow-starting, fuel could enter the catalytic converter and damage it. General notes

Please observe the following points if you use a tow rope:

Notes for the driver of the towing vehicle

–

Drive slowly at first until the tow rope is taut. Then accelerate

gradually.

– Begin and change gears cautiously. If you are driving an auto-

matic vehicle, accelerate gently.

– Remember that the brake servo and power steering are not

working in the vehicle you are towing. Brake sooner than nor-

mal and pressing the pedal gently.

Notes for the driver of the towed vehicle

– Ensure that the tow rope remains taut at all times when towing.

Tow rope or tow bar

It is easier and safer to tow a vehicle with a tow bar. You should only use a

tow rope if you do not have a tow bar.

A tow rope should be slightly elastic to reduce the loading on both vehicles.

It is advisable to use a tow rope made of synthetic fibre or similarly elastic

material.

Attach the tow rope or the tow bar only to the towline anchorages provided

or a towing bracket.

Driving style

Towing requires some experience, especially when using a tow rope. Both

drivers should be familiar with the technique required for towing. Inexper-

ienced drivers should not attempt to tow.

Page 293 of 319

291

If and when

Do not pull too hard with the towing vehicle and take care to avoid jerking

the tow rope. When towing on an unpaved road, there is always a risk of

overloading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the turn signals,

horn, windscreen wipers and washers.

As the brake servo does not work if the engine is not running, you must ap-

ply considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running,

you will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

● Put the selector lever into position “N”.

● Do not drive faster than 50 km/h (30 mph).

● Do not tow further than 50 km.

● If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.

Note

● Observe legal requirements when towing or tow-starting.

● Switch on the hazard warning lights of both vehicles. However, observe

any regulations to the contrary.

● For technical reasons, vehicles with an automatic gearbox must not be

tow-started.

● If damage to your vehicle means that there is no lubricant in the gear-

box, you must raise the driven wheels while the vehicle is being towed.

● If the vehicle has to be towed more than 50 km (30 miles), the front

wheels should be raised during towing, and towing should be carried out by

a qualified person. ●

The steering wheel is locked when the vehicle has no electrical power.

The vehicle must then be towed with the front wheels raised. Towing should

be carried out by a qualified person.

● The towline anchorage should always be kept in the vehicle. Please refer

to the notes ⇒ page 290, Tow-starting.

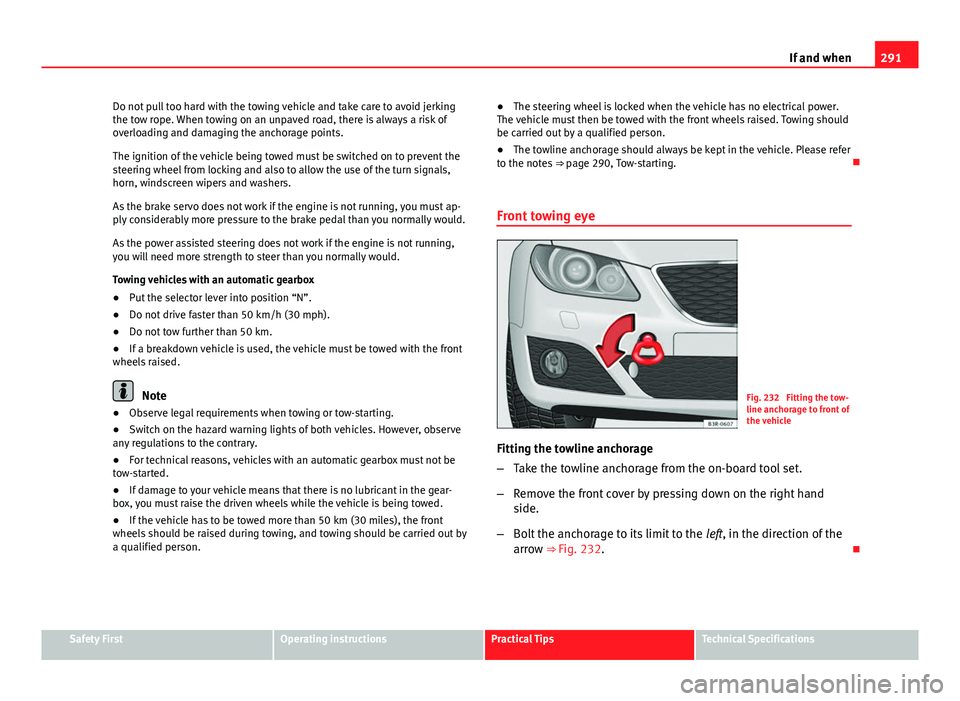

Front towing eyeFig. 232 Fitting the tow-

line anchorage to front of

the vehicle

Fitting the towline anchorage

– Take the towline anchorage from the on-board tool set.

– Remove the front cover by pressing down on the right hand

side.

– Bolt the anchorage to its limit to the left, in the direction of the

arrow ⇒ Fig. 232.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 300 of 319

298Technical specifications

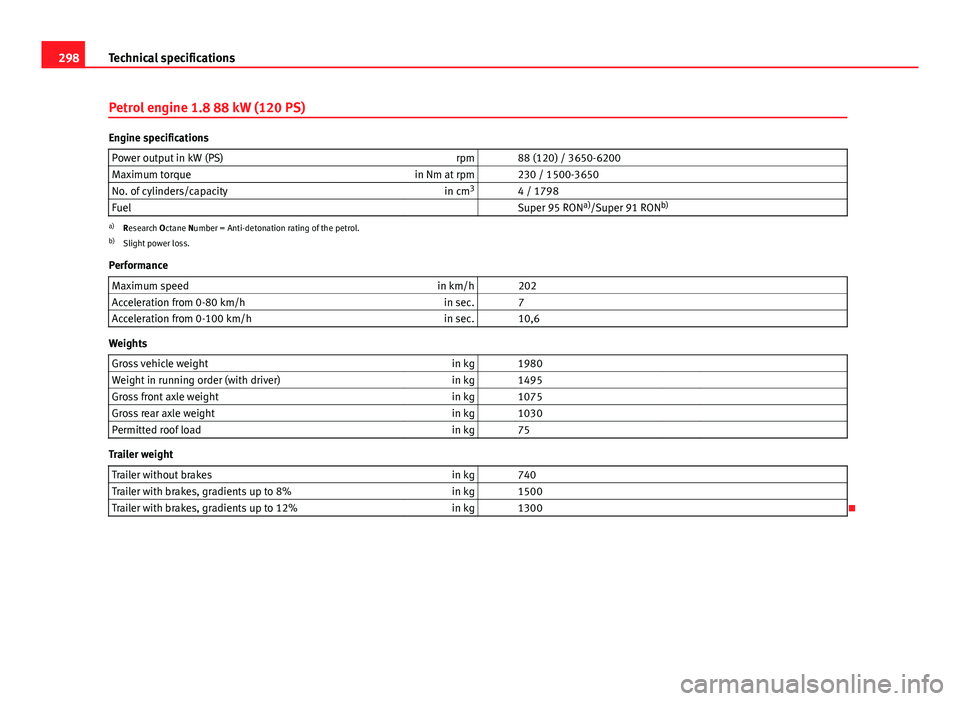

Petrol engine 1.8 88 kW (120 PS)

Engine specifications

Power output in kW (PS) rpm 88 (120) / 3650-6200

Maximum torque in Nm at rpm 230 / 1500-3650

No. of cylinders/capacity in cm3

4 / 1798

Fuel Super 95 RON a)

/Super 91 RON b)

a)

Research Octane Number = Anti-detonation rating of the petrol.

b) Slight power loss.

Performance Maximum speed in km/h 202

Acceleration from 0-80 km/h in sec. 7

Acceleration from 0-100 km/h in sec. 10,6

Weights

Gross vehicle weight in kg 1980

Weight in running order (with driver) in kg 1495

Gross front axle weight in kg 1075

Gross rear axle weight in kg 1030

Permitted roof load in kg 75

Trailer weight

Trailer without brakes in kg 740

Trailer with brakes, gradients up to 8% in kg 1500

Trailer with brakes, gradients up to 12% in kg 1300