ECU Seat Exeo 2013 Service Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Exeo, Model: Seat Exeo 2013Pages: 319, PDF Size: 4.81 MB

Page 241 of 319

239

Checking and refilling levels

Disconnecting the battery

If the battery is disconnected, some of the vehicle's functions will become

inoperative (e.g. electric windows). These functions will require resetting af-

ter the battery is reconnected. For this reason, the battery should only be

disconnected from the vehicle's electrical system when absolutely necessa-

ry.

Long periods of non-use

The battery will gradually lose its charge because certain electrical equip-

ment continues to draw current even when the ignition is off. If you park the

vehicle for long periods of time in winter you should take the battery out of

the vehicle and store it in a place protected from frost. This way it will not

freeze and become damaged. At warm outside temperatures it is sufficient

to disconnect the negative terminal of the battery. Even when the battery is

not connected you should charge it from time to time.

Winter operation

The battery is drained more in cold weather, which means that the starting

power is reduced. For this reason, have the battery checked and charged if

necessary before the start of winter.

Replacing the battery

A replacement battery must have the same capacity, voltage and current rat-

ing. It must also have the same dimensions as the original, factory-fitted

battery and have sealed caps. The SEAT batteries which have been specially

developed fulfil the maintenance, performance and safety specifications for

your vehicle.

We recommend you use maintenance-free batteries.

WARNING

● All work on batteries requires specialist knowledge. If work is re-

quired on the battery, this should be performed by a Technical Service or

specialised workshop. Danger of caustic burns and explosion!

● The battery must not be opened. Never try to change the battery's liq-

uid level. Explosive gas is released from the battery that could cause an

explosion.

CAUTION

● The battery holder and clamps must always be correctly secured.

● Before starting any work on the battery, always observe the warnings

listed under ⇒

.

For the sake of the environment

Batteries contain toxic substances including sulphuric acid and lead.

Therefore, they must be disposed of in line with environmental regulations

and must not be disposed of with ordinary household waste. Make sure dis-

connected batteries cannot tip over. Sulphuric acid could be spilt!

Important safety warnings for handling a vehicle battery

The battery is located at the back of the engine compartment ⇒ page 297.

Wear eye protection

Battery acid is extremely corrosive. Wear protective gloves

and eye protection!

Fires, sparks, open flames and smoking are prohibited!

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 252 of 319

250Wheels and tyres

Wheel bolts

Wheel bolts must be tightened to the correct torque.

The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped

bolt heads must be used. This ensures that wheels are fitted securely and

that the brake system functions correctly.

In certain circumstances, you should not use wheel bolts from a different

vehicle, even if it is the same model ⇒ page 222.

After the wheels have been changed, the tightening torque of the wheel

bolts should be checked as soon as possible with a torque wrench. ⇒

The tightening torque for steel and alloy wheels is 120 Nm.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.

● The wheel bolts must be clean and turn easily. Never apply grease or

oil to them.

● Use only wheel bolts which belong to the wheel.

● If the tightening torque of the wheel bolts is too low, they could loos-

en whilst the vehicle is in motion. Risk of accident! If the tightening tor-

que is too high, the wheel bolts and threads can be damaged.

CAUTION

The prescribed tightening torque for wheel bolts for steel and alloy wheels

is 120 Nm. Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.

In winter conditions winter tyres will considerably improve the vehicle's han-

dling. The design of summer tyres (width, rubber compound, tread pattern)

gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pres-

sures specified for summer tyres (see sticker on fuel tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's reg-

istration documentation. Use only radial winter tyres. All tyre sizes listed in

the vehicle documentation also apply to winter tyres.

Winter tyres lose their effectiveness when the tread is worn down to a depth

of 4 mm.

The speed rating code ⇒ page 248, New tyres and wheels determines the

following speed limits for winter tyres: ⇒

max. 160 km/h (100 mph)

max. 180 km/h (110 mph)

max. 190 km/h (118 mph)

max. 210 km/h (130 mph)

In some countries, vehicles which can exceed the speed rating of the fitted

tyre must have an appropriate sticker in the driver's field of view. These

stickers are available from your Technical Service. The legal requirements of

each country must be followed.

Do not have winter tyres fitted for unnecessarily long periods. Vehicles with

summer tyres handle better when the roads are free of snow and ice.

Q

S

T

H

Page 255 of 319

253

If and when

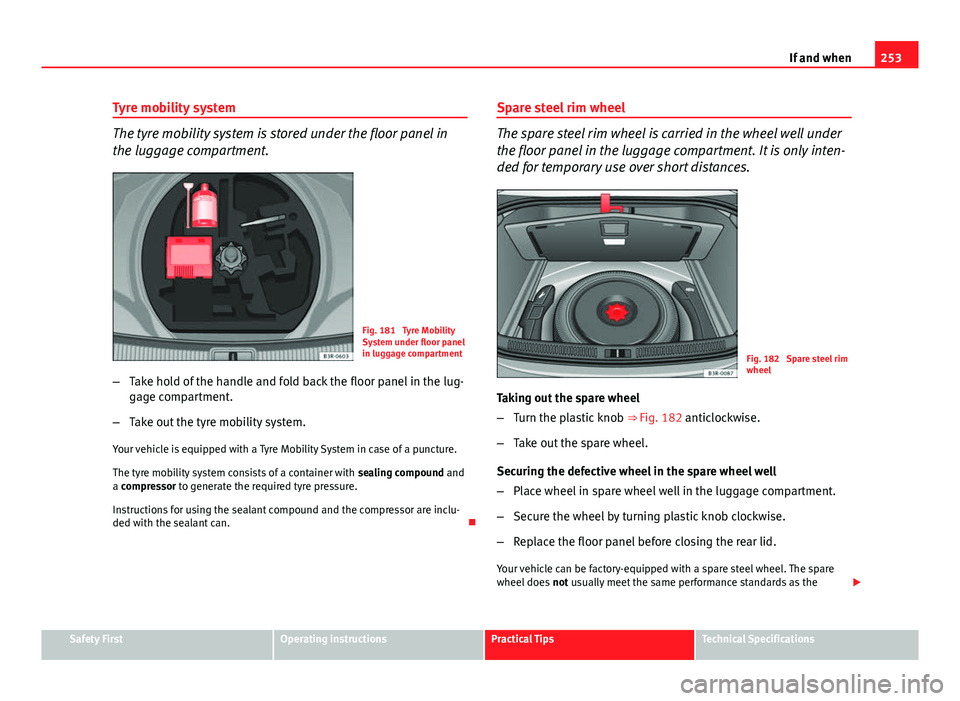

Tyre mobility system

The tyre mobility system is stored under the floor panel in

the luggage compartment.

Fig. 181 Tyre Mobility

System under floor panel

in luggage compartment

– Take hold of the handle and fold back the floor panel in the lug-

gage compartment.

– Take out the tyre mobility system.

Your vehicle is equipped with a Tyre Mobility System in case of a puncture.

The tyre mobility system consists of a container with sealing compound and

a compressor to generate the required tyre pressure.

Instructions for using the sealant compound and the compressor are inclu-

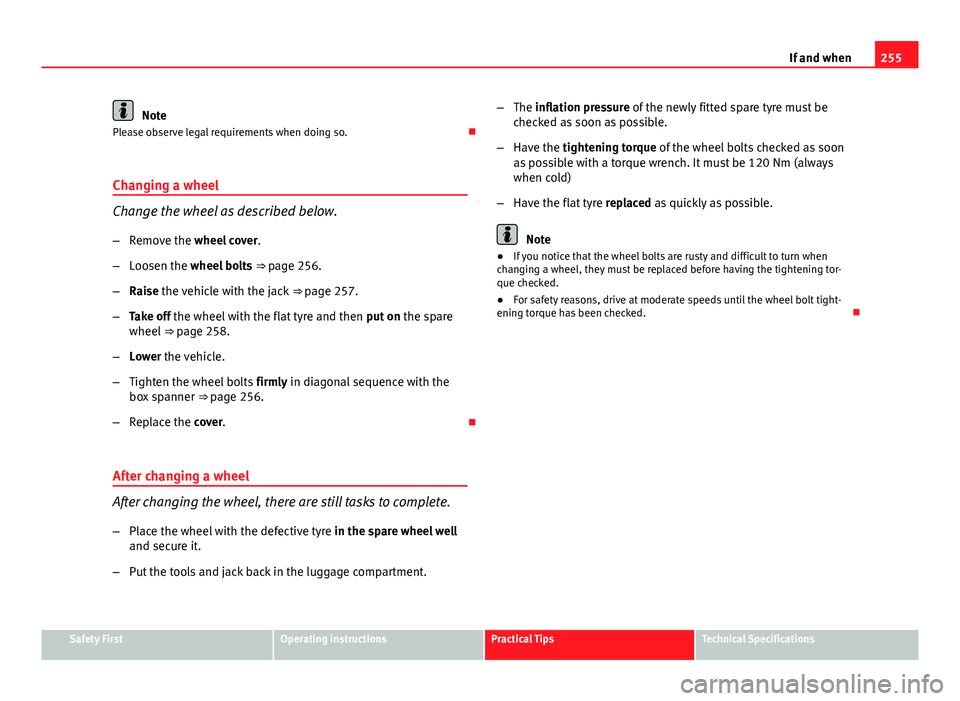

ded with the sealant can. Spare steel rim wheel

The spare steel rim wheel is carried in the wheel well under

the floor panel in the luggage compartment. It is only inten-

ded for temporary use over short distances.

Fig. 182 Spare steel rim

wheel

Taking out the spare wheel

– Turn the plastic knob ⇒ Fig. 182 anticlockwise.

– Take out the spare wheel.

Securing the defective wheel in the spare wheel well

– Place wheel in spare wheel well in the luggage compartment.

– Secure the wheel by turning plastic knob clockwise.

– Replace the floor panel before closing the rear lid.

Your vehicle can be factory-equipped with a spare steel wheel. The spare

wheel does not usually meet the same performance standards as the

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 257 of 319

255

If and when

Note

Please observe legal requirements when doing so.

Changing a wheel

Change the wheel as described below.

– Remove the wheel cover .

– Loosen the wheel bolts ⇒ page 256.

– Raise the vehicle with the jack ⇒ page 257.

– Take off the wheel with the flat tyre and then put on the spare

wheel ⇒ page 258.

– Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the

box spanner ⇒ page 256.

– Replace the cover.

After changing a wheel

After changing the wheel, there are still tasks to complete. – Place the wheel with the defective tyre in the spare wheel well

and secure it.

– Put the tools and jack back in the luggage compartment. –

The inflation pressure of the newly fitted spare tyre must be

checked as soon as possible.

– Have the tightening torque of the wheel bolts checked as soon

as possible with a torque wrench. It must be 120 Nm (always

when cold)

– Have the flat tyre replaced as quickly as possible.

Note

● If you notice that the wheel bolts are rusty and difficult to turn when

changing a wheel, they must be replaced before having the tightening tor-

que checked.

● For safety reasons, drive at moderate speeds until the wheel bolt tight-

ening torque has been checked.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 279 of 319

277

If and when

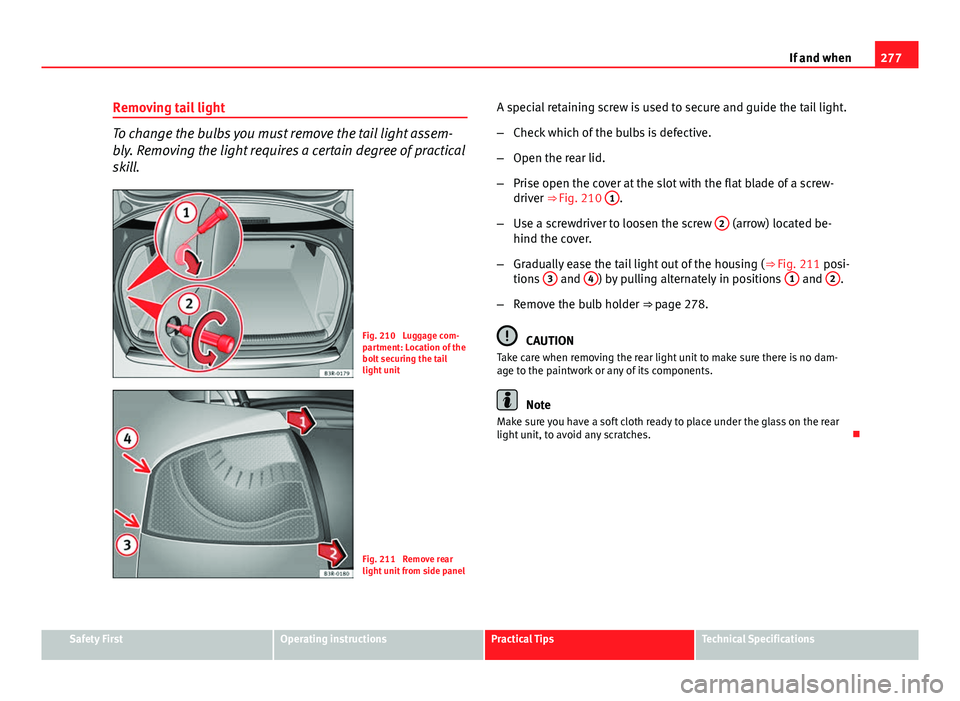

Removing tail light

To change the bulbs you must remove the tail light assem-

bly. Removing the light requires a certain degree of practical

skill.

Fig. 210 Luggage com-

partment: Location of the

bolt securing the tail

light unit

Fig. 211 Remove rear

light unit from side panel A special retaining screw is used to secure and guide the tail light.

–

Check which of the bulbs is defective.

– Open the rear lid.

– Prise open the cover at the slot with the flat blade of a screw-

driver ⇒ Fig. 210 1

.

– Use a screwdriver to loosen the screw 2

(arrow) located be-

hind the cover.

– Gradually ease the tail light out of the housing ( ⇒ Fig. 211 posi-

tions 3

and 4) by pulling alternately in positions 1 and 2.

– Remove the bulb holder ⇒ page 278.

CAUTION

Take care when removing the rear light unit to make sure there is no dam-

age to the paintwork or any of its components.

Note

Make sure you have a soft cloth ready to place under the glass on the rear

light unit, to avoid any scratches.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 280 of 319

278If and when

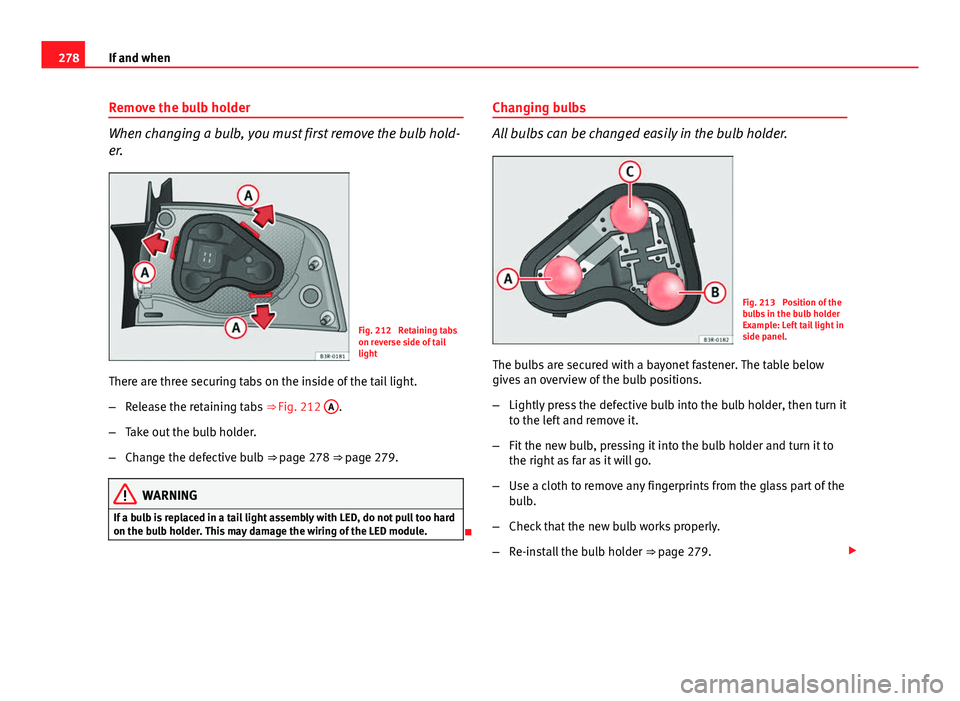

Remove the bulb holder

When changing a bulb, you must first remove the bulb hold-

er.

Fig. 212 Retaining tabs

on reverse side of tail

light

There are three securing tabs on the inside of the tail light.

– Release the retaining tabs ⇒ Fig. 212 A

.

– Take out the bulb holder.

– Change the defective bulb ⇒ page 278 ⇒ page 279.

WARNING

If a bulb is replaced in a tail light assembly with LED, do not pull too hard

on the bulb holder. This may damage the wiring of the LED module.

Changing bulbs

All bulbs can be changed easily in the bulb holder.

Fig. 213 Position of the

bulbs in the bulb holder

Example: Left tail light in

side panel.

The bulbs are secured with a bayonet fastener. The table below

gives an overview of the bulb positions.

– Lightly press the defective bulb into the bulb holder, then turn it

to the left and remove it.

– Fit the new bulb, pressing it into the bulb holder and turn it to

the right as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the

bulb.

– Check that the new bulb works properly.

– Re-install the bulb holder ⇒ page 279.

Page 281 of 319

279

If and when

Position of the bulbs

Pos.

⇒ Fig. 213Bulb function

ABrake light and side lightP21W LLBSide lightsP21W LLCTurn signalPY21W

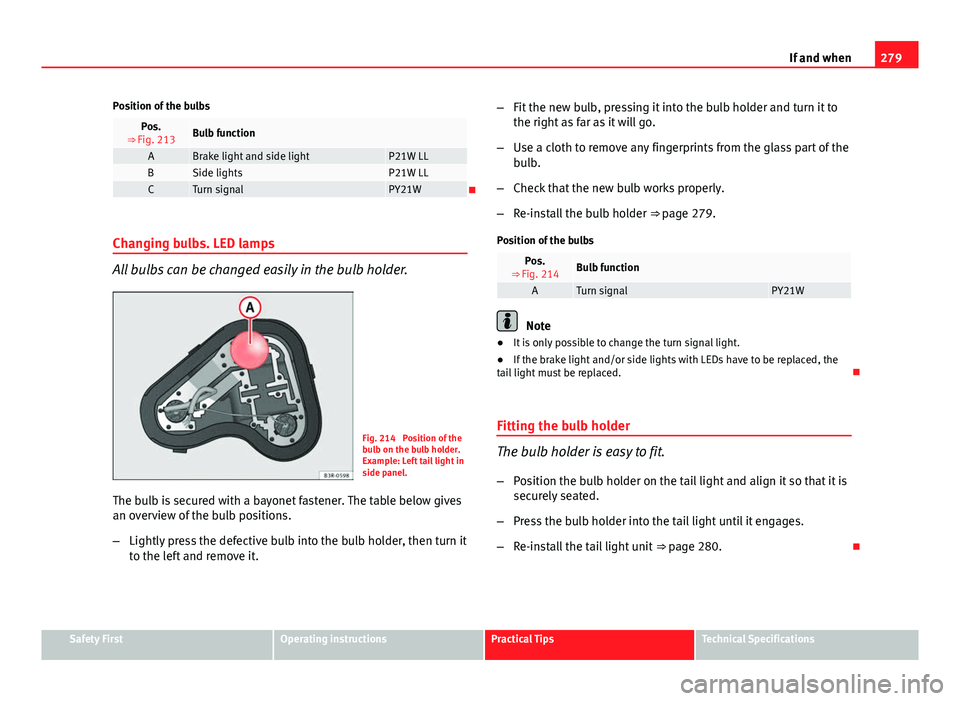

Changing bulbs. LED lamps

All bulbs can be changed easily in the bulb holder.

Fig. 214 Position of the

bulb on the bulb holder.

Example: Left tail light in

side panel.

The bulb is secured with a bayonet fastener. The table below gives

an overview of the bulb positions.

– Lightly press the defective bulb into the bulb holder, then turn it

to the left and remove it. –

Fit the new bulb, pressing it into the bulb holder and turn it to

the right as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the

bulb.

– Check that the new bulb works properly.

– Re-install the bulb holder ⇒ page 279.

Position of the bulbs

Pos.

⇒ Fig. 214Bulb function

ATurn signalPY21W

Note

● It is only possible to change the turn signal light.

● If the brake light and/or side lights with LEDs have to be replaced, the

tail light must be replaced.

Fitting the bulb holder

The bulb holder is easy to fit. – Position the bulb holder on the tail light and align it so that it is

securely seated.

– Press the bulb holder into the tail light until it engages.

– Re-install the tail light unit ⇒ page 280.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 282 of 319

280If and when

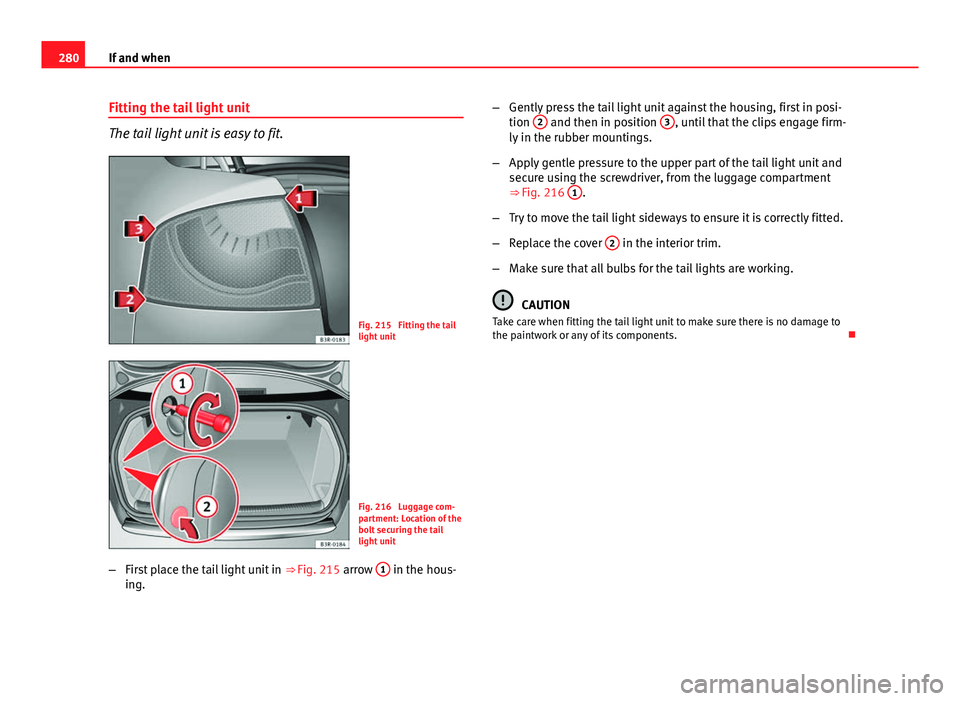

Fitting the tail light unit

The tail light unit is easy to fit.

Fig. 215 Fitting the tail

light unit

Fig. 216 Luggage com-

partment: Location of the

bolt securing the tail

light unit

– First place the tail light unit in ⇒ Fig. 215 arrow 1

in the hous-

ing. –

Gently press the tail light unit against the housing, first in posi-

tion 2

and then in position 3, until that the clips engage firm-

ly in the rubber mountings.

– Apply gentle pressure to the upper part of the tail light unit and

secure using the screwdriver, from the luggage compartment

⇒ Fig. 216 1

.

– Try to move the tail light sideways to ensure it is correctly fitted.

– Replace the cover 2

in the interior trim.

– Make sure that all bulbs for the tail lights are working.

CAUTION

Take care when fitting the tail light unit to make sure there is no damage to

the paintwork or any of its components.

Page 285 of 319

283

If and when

The bulbs are secured with a bayonet fastener. The table below

gives an overview of the bulb positions.

– Lightly press the defective bulb into the bulb holder, then turn it

to the left and remove it.

– Fit the new bulb, pressing it into the bulb holder and turn it to

the right as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the

bulb.

– Check that the new bulb works properly.

– Re-install the bulb holder ⇒ page 284.

Position of the bulbs

Pos.

⇒ Fig. 221Bulb function

AReverse lightP21W LL

BSide light and

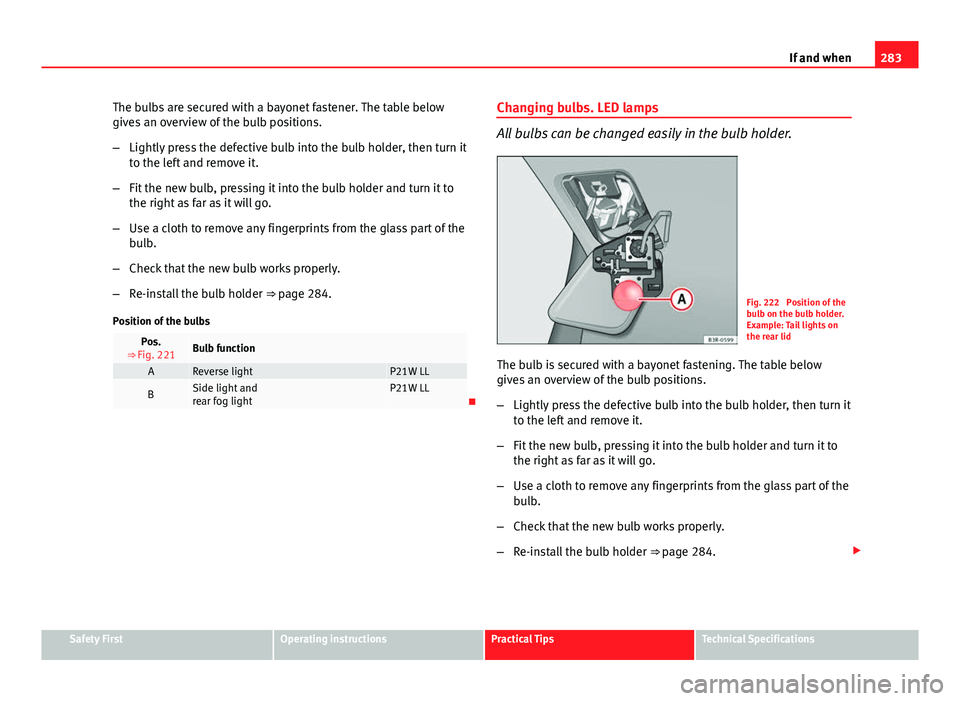

rear fog lightP21W LL Changing bulbs. LED lamps

All bulbs can be changed easily in the bulb holder.

Fig. 222 Position of the

bulb on the bulb holder.

Example: Tail lights on

the rear lid

The bulb is secured with a bayonet fastening. The table below

gives an overview of the bulb positions.

– Lightly press the defective bulb into the bulb holder, then turn it

to the left and remove it.

– Fit the new bulb, pressing it into the bulb holder and turn it to

the right as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the

bulb.

– Check that the new bulb works properly.

– Re-install the bulb holder ⇒ page 284.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 286 of 319

284If and when

Position of the bulbs

Pos.

⇒ Fig. 222Bulb function

AReverse lightP21W LL

Fitting the bulb holder

The bulb holder is easy to fit. – Check that the seal is seated correctly on the bulb holder.

– Position the bulb holder on the tail light and align it so that it is

securely seated.

– Press the bulb holder into the tail light until it engages.

– Fit the cover back in the interior trim so that it engages.

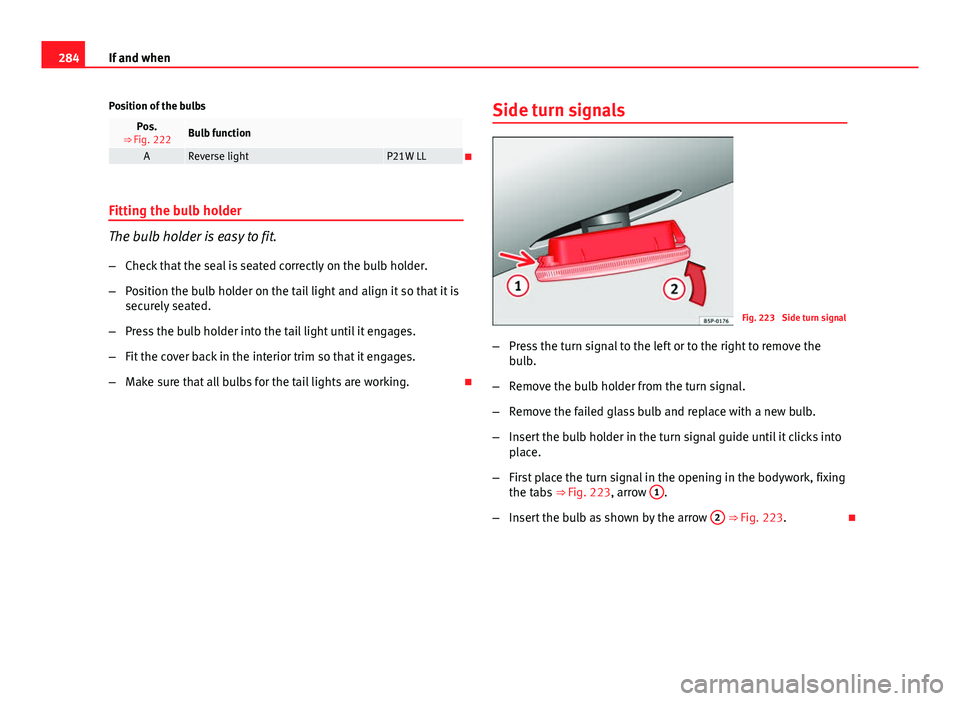

– Make sure that all bulbs for the tail lights are working. Side turn signals

Fig. 223 Side turn signal

– Press the turn signal to the left or to the right to remove the

bulb.

– Remove the bulb holder from the turn signal.

– Remove the failed glass bulb and replace with a new bulb.

– Insert the bulb holder in the turn signal guide until it clicks into

place.

– First place the turn signal in the opening in the bodywork, fixing

the tabs ⇒ Fig. 223, arrow 1

.

– Insert the bulb as shown by the arrow 2

⇒ Fig. 223.