warning Seat Exeo ST 2011 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Exeo ST, Model: Seat Exeo ST 2011Pages: 319, PDF Size: 5.12 MB

Page 259 of 319

257

If and when

An unstable surface under the jack may cause the vehicle to slip off the

jack. Therefore, the jack must be fitted on solid ground offering good sup-

port. Use a large, stable base if necessary. On a hard, slippery surface (such

as tiles) use a rubber mat or similar to prevent the jack from slipping.

WARNING

● Take all precautions so that the base of the jack does not slip. Failure

to do so could result in an accident.

● The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must

be completed.

After loosening the wheel bolts and raising the vehicle with the

jack, change the wheel as described below:

Removing a wheel

– Unscrew the wheel bolts using the box spanner and place them

on a clean surface.

Fitting a wheel

– Screw on the wheel bolts in position and tighten them loosely

with a box spanner.

The wheel bolts should be clean and easily screwed. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These sur-

faces must be clean before fitting the wheel. If tyres with a specific direction of rotation are fitted, note the direction of

rotation.

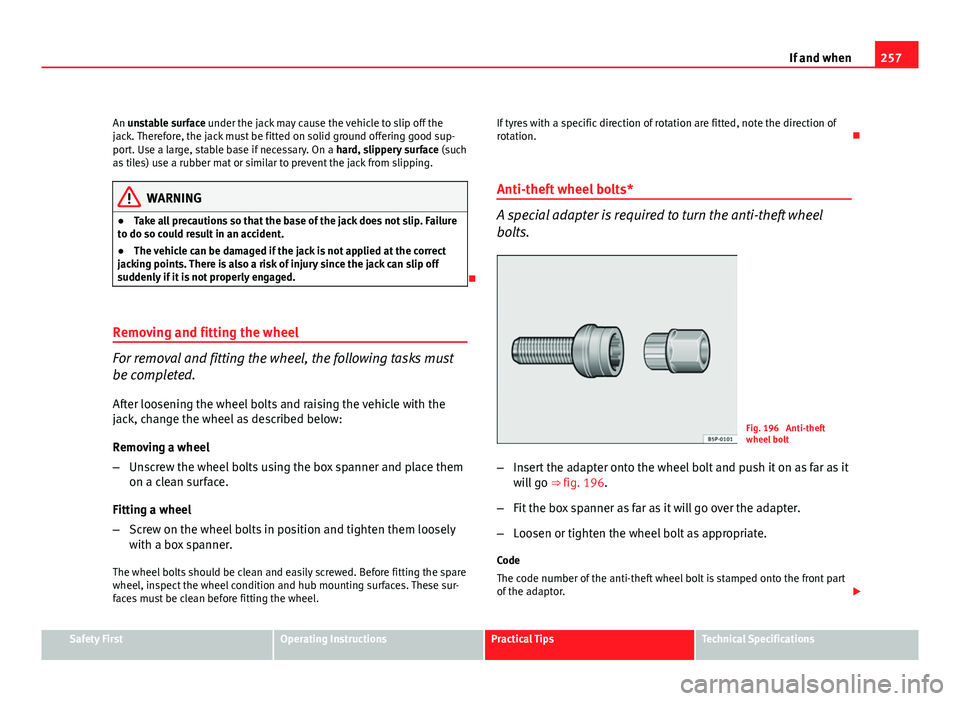

Anti-theft wheel bolts*

A special adapter is required to turn the anti-theft wheel

bolts.

Fig. 196 Anti-theft

wheel bolt

– Insert the adapter onto the wheel bolt and push it on as far as it

will go ⇒ fig. 196.

– Fit the box spanner as far as it will go over the adapter.

– Loosen or tighten the wheel bolt as appropriate.

Code

The code number of the anti-theft wheel bolt is stamped onto the front part

of the adaptor.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 261 of 319

259

If and when

The sealing compound must not be used in the following cases:

● If the cuts and punctures on the tyre are longer than 4 mm ⇒ fig. 197 1

●

If the wheel rim has been damaged 2●

If you have been driving with very low pressure or a completely flat tyre

3

How to use the TMS (tyre mobility system) is described in the section Re-

pairing a tyre ⇒ page 260 and in the instructions supplied with the tyre

sealant can.

The TMS (tyre mobility system) can be used at outside temperatures down

to -20 °C.

WARNING

After repairing a tyre please note the following points:

● Do not drive faster than 80 km/h.

● Avoid heavy acceleration, hard braking and fast cornering.

● Vehicle handling could be impaired.

● Tyres which have been sealed using the Tyre Mobility System are only

suitable for temporary use over a short period.

● After using the tyre sealant the tyre pressure monitoring system* may

malfunction. Therefore, please drive carefully to the next available quali-

fied workshop.

● The Tyre Mobility System must NOT be used:

– If the cuts and punctures on the tyre are longer or wider than

4 mm.

– if the wheel rim has been damaged.

– if you have been driving with very low pressure or a completely flat

tyre.

● Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

WARNING (Continued)

● Do not allow the sealant to come into contact with your eyes, skin or

clothing.

● If you do come into contact with the sealant immediately rinse the

eyes or skin affected with clean water.

● Change clothing immediately if it becomes soiled with the tyre seal-

ant.

● Make sure you do not breathe in the fumes!

● If any of the tyre sealant is accidentally ingested, immediately rinse

the mouth thoroughly and drink lots of water.

–Do not induce vomiting. Seek medical assistance if needed.

● If any allergic reactions should occur get medical help immediately.

● Keep the sealant away from children.

For the sake of the environment

If you have to dispose of a sealant can, go to a specialised waste service or

to a SEAT Technical Service, where the product can be recycled in an appro-

priate waste container.

Note

● If sealant should leak out, leave it to dry. This way you can pull it off like

a piece of foil.

● Observe the expiry date stated on the sealing compound can. Have the

sealing compound exchanged by a specialised workshop.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 263 of 319

261

If and when

pressure is still lower than the specification the tyre is too badly

damaged and cannot be repaired using the tyre sealant.

Final check

– After about 10 minutes, stop to check the tyre pressure.

– If tyre pressure is less than 1.3 bar, the tyre is too badly dam-

aged. Do not drive on! You should obtain professional assis-

tance.

WARNING

● If you have a puncture in heavy traffic, switch on the hazard warning

lights and place the warning triangle in a visible location. This is for your

own safety and also warns other road users.

● Make sure your passengers wait in a safe place (for instance behind

the roadside crash barrier).

● Please observe the manufacturer's safety notes on the compressor

and the instructions supplied with the tyre sealant can.

● If it is not possible to build up a tyre pressure of 2.0 bar within 6 mi-

nutes this means that the tyre is too badly damaged. Do not drive on!

● Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing compound.

● If tyre pressure is less than 1.3 bar after driving about 10 minutes,

the tyre is too badly damaged. Do not drive on! Obtain technical assis-

tance.

CAUTION

Take special care if you have to repair a tyre on a slope.

Note

● Do not use the compressor for longer than 6 minutes. Otherwise, it

might overheat. When the compressor has cooled down, you can use it

again.

● If tyre sealant should leak out, leave it to dry and then pull it off like foil.

● After carrying out a tyre repair remember to buy a new tyre sealant can at

a qualified workshop. This will ensure that the Tyre Mobility System is oper-

ative again.

● Please observe legal requirements when doing so.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 267 of 319

265

If and when

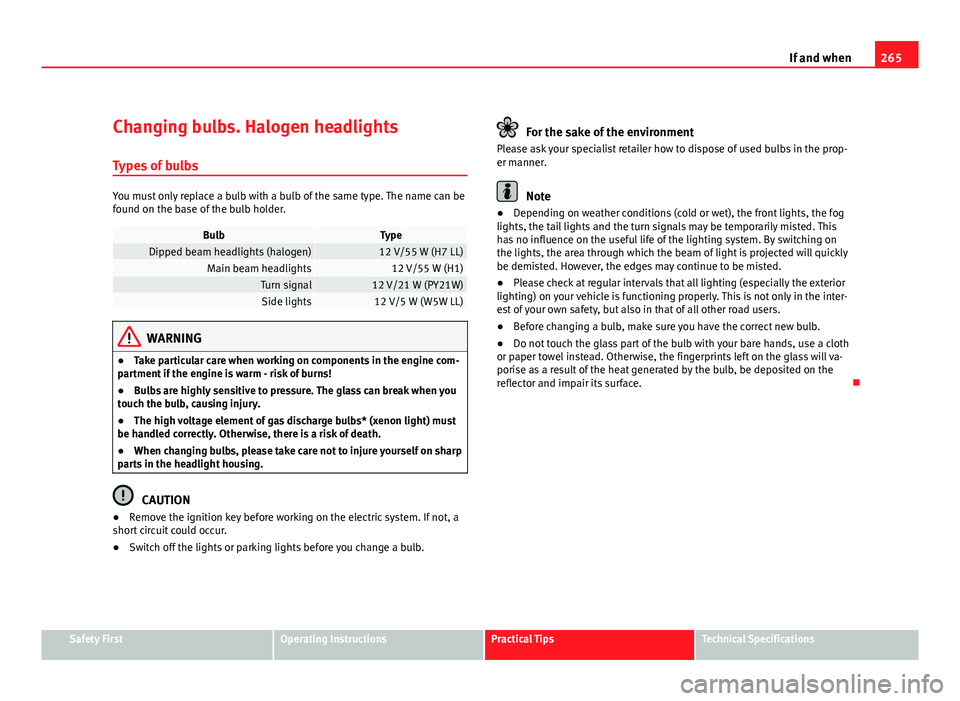

Changing bulbs. Halogen headlights Types of bulbs

You must only replace a bulb with a bulb of the same type. The name can be

found on the base of the bulb holder.

BulbTypeDipped beam headlights (halogen)12 V/55 W (H7 LL)Main beam headlights12 V/55 W (H1)Turn signal12 V/21 W (PY21W)Side lights12 V/5 W (W5W LL)

WARNING

● Take particular care when working on components in the engine com-

partment if the engine is warm - risk of burns!

● Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

● The high voltage element of gas discharge bulbs* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.

● When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.

CAUTION

● Remove the ignition key before working on the electric system. If not, a

short circuit could occur.

● Switch off the lights or parking lights before you change a bulb.

For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the prop-

er manner.

Note

● Depending on weather conditions (cold or wet), the front lights, the fog

lights, the tail lights and the turn signals may be temporarily misted. This

has no influence on the useful life of the lighting system. By switching on

the lights, the area through which the beam of light is projected will quickly

be demisted. However, the edges may continue to be misted.

● Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the inter-

est of your own safety, but also in that of all other road users.

● Before changing a bulb, make sure you have the correct new bulb.

● Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will va-

porise as a result of the heat generated by the bulb, be deposited on the

reflector and impair its surface.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 274 of 319

272If and when

● Main headlight lamps: Xenon ⇒

lights.

● Sources of the DRL (daylight) light unit and position.

WARNING

● Take particular care when working on components in the engine com-

partment if the engine is warm - risk of burns!

● Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

● The high voltage element of gas discharge bulbs* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.

● When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.

CAUTION

● Remove the ignition key before working on the electric system. If not, a

short circuit could occur.

● Switch off the lights or parking lights before you change a bulb.

For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the prop-

er manner.

Note

● Depending on weather conditions (cold or wet), the front lights, the fog

lights, the tail lights and the turn signals may be temporarily misted. This

has no influence on the useful life of the lighting system. By switching on

the lights, the area through which the beam of light is projected will quickly

be demisted. However, the edges may continue to be misted.

● Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the inter-

est of your own safety, but also in that of all other road users. ●

Before changing a bulb, make sure you have the correct new bulb.

● Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will va-

porise as a result of the heat generated by the bulb, be deposited on the

reflector and impair its surface.

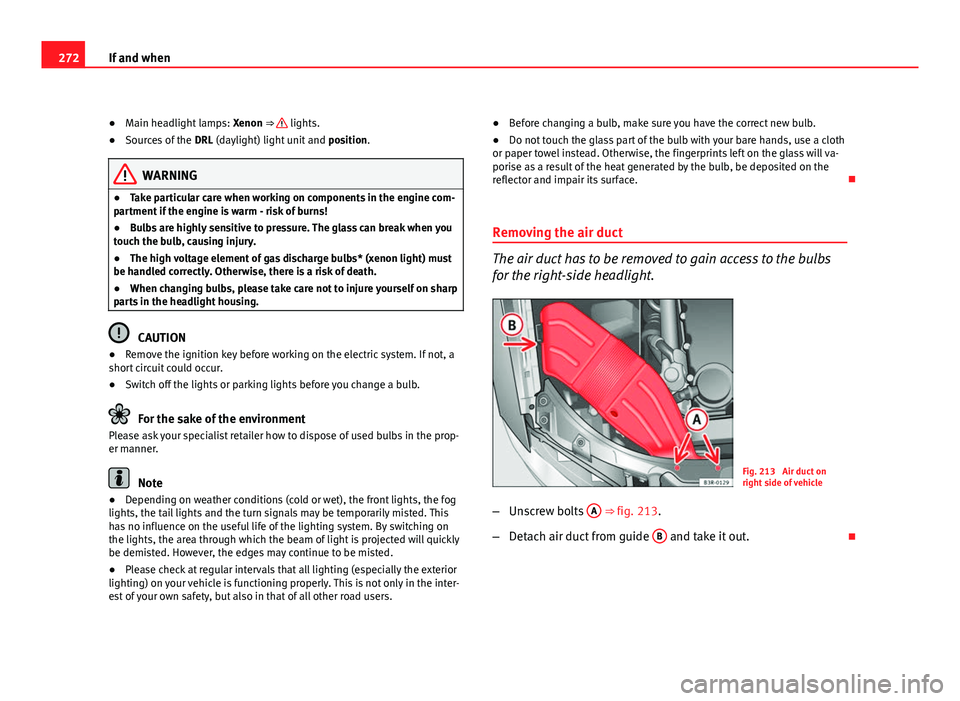

Removing the air duct

The air duct has to be removed to gain access to the bulbs

for the right-side headlight.

Fig. 213 Air duct on

right side of vehicle

– Unscrew bolts A

⇒ fig. 213.

– Detach air duct from guide B

and take it out.

Page 276 of 319

274If and when

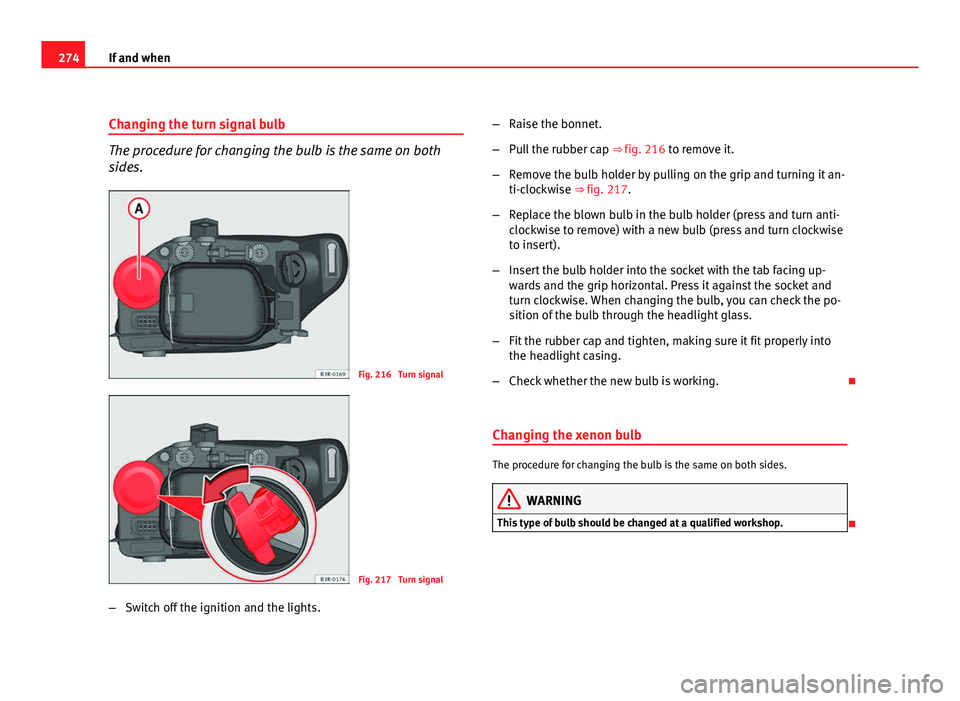

Changing the turn signal bulb

The procedure for changing the bulb is the same on both

sides.

Fig. 216 Turn signal

Fig. 217 Turn signal

– Switch off the ignition and the lights. –

Raise the bonnet.

– Pull the rubber cap ⇒ fig. 216 to remove it.

– Remove the bulb holder by pulling on the grip and turning it an-

ti-clockwise ⇒ fig. 217.

– Replace the blown bulb in the bulb holder (press and turn anti-

clockwise to remove) with a new bulb (press and turn clockwise

to insert).

– Insert the bulb holder into the socket with the tab facing up-

wards and the grip horizontal. Press it against the socket and

turn clockwise. When changing the bulb, you can check the po-

sition of the bulb through the headlight glass.

– Fit the rubber cap and tighten, making sure it fit properly into

the headlight casing.

– Check whether the new bulb is working.

Changing the xenon bulb

The procedure for changing the bulb is the same on both sides.

WARNING

This type of bulb should be changed at a qualified workshop.

Page 277 of 319

275

If and when

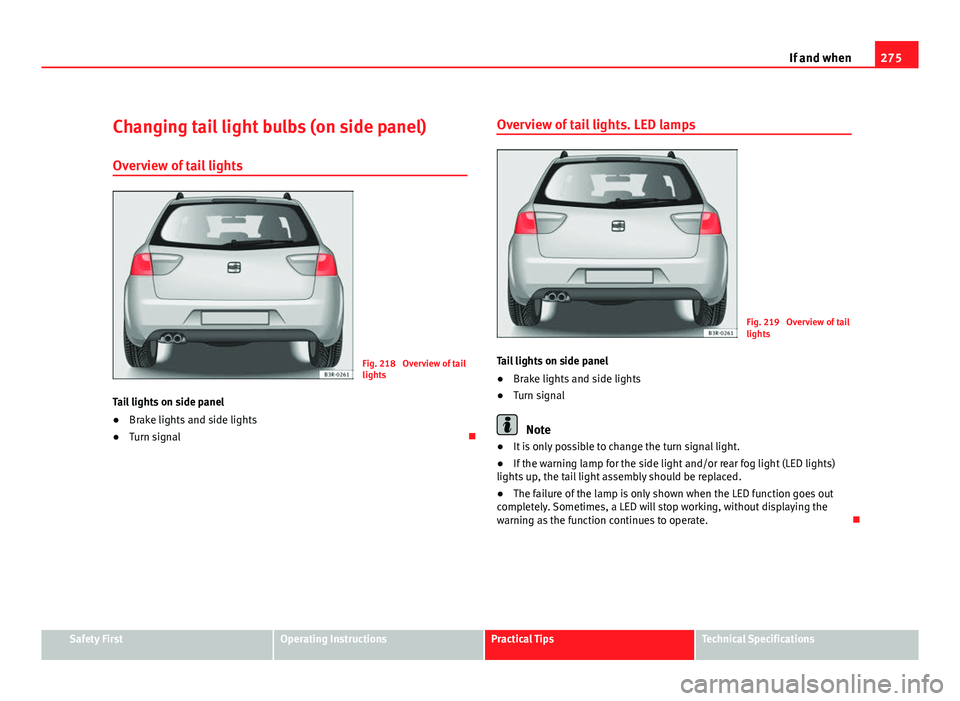

Changing tail light bulbs (on side panel)

Overview of tail lights

Fig. 218 Overview of tail

lights

Tail lights on side panel

● Brake lights and side lights

● Turn signal Overview of tail lights. LED lamps

Fig. 219 Overview of tail

lights

Tail lights on side panel

● Brake lights and side lights

● Turn signal

Note

● It is only possible to change the turn signal light.

● If the warning lamp for the side light and/or rear fog light (LED lights)

lights up, the tail light assembly should be replaced.

● The failure of the lamp is only shown when the LED function goes out

completely. Sometimes, a LED will stop working, without displaying the

warning as the function continues to operate.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 279 of 319

277

If and when

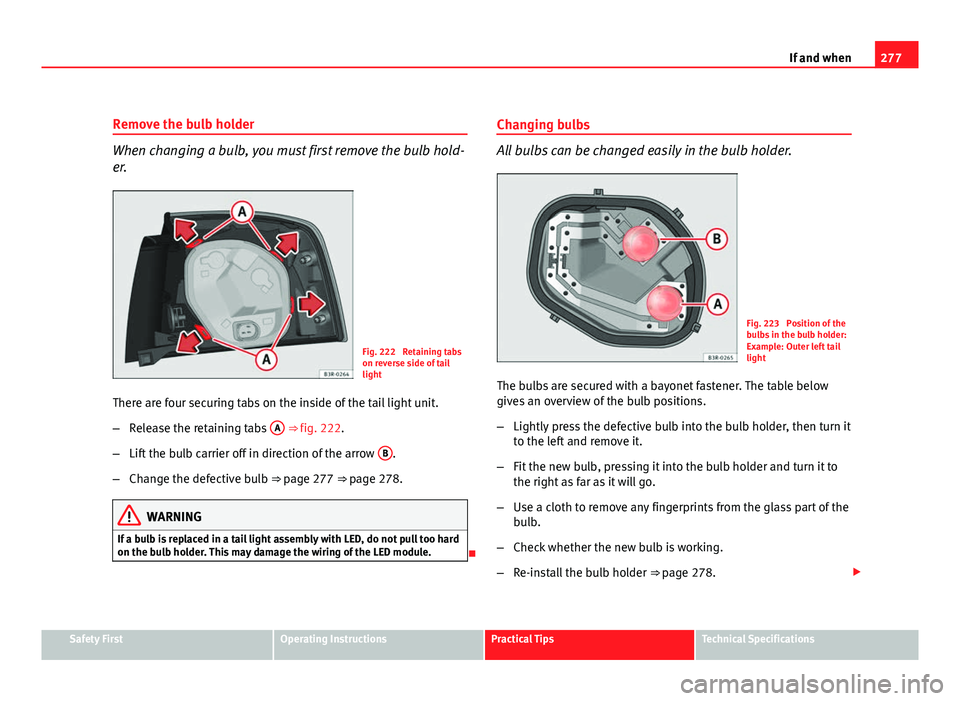

Remove the bulb holder

When changing a bulb, you must first remove the bulb hold-

er.

Fig. 222 Retaining tabs

on reverse side of tail

light

There are four securing tabs on the inside of the tail light unit.

– Release the retaining tabs A

⇒ fig. 222.

– Lift the bulb carrier off in direction of the arrow B

.

– Change the defective bulb ⇒ page 277 ⇒ page 278.

WARNING

If a bulb is replaced in a tail light assembly with LED, do not pull too hard

on the bulb holder. This may damage the wiring of the LED module.

Changing bulbs

All bulbs can be changed easily in the bulb holder.

Fig. 223 Position of the

bulbs in the bulb holder:

Example: Outer left tail

light

The bulbs are secured with a bayonet fastener. The table below

gives an overview of the bulb positions.

– Lightly press the defective bulb into the bulb holder, then turn it

to the left and remove it.

– Fit the new bulb, pressing it into the bulb holder and turn it to

the right as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the

bulb.

– Check whether the new bulb is working.

– Re-install the bulb holder ⇒ page 278.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 282 of 319

280If and when

CAUTION

Take care when fitting the tail light unit to make sure there is no damage to

the paintwork or any of its components.

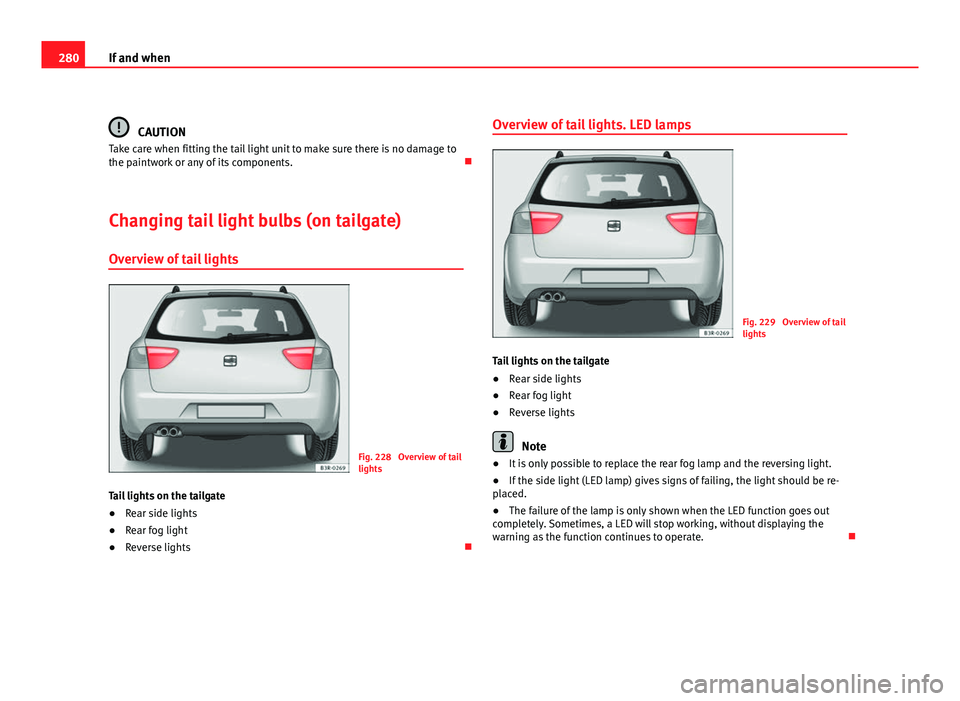

Changing tail light bulbs (on tailgate) Overview of tail lights

Fig. 228 Overview of tail

lights

Tail lights on the tailgate

● Rear side lights

● Rear fog light

● Reverse lights Overview of tail lights. LED lamps

Fig. 229 Overview of tail

lights

Tail lights on the tailgate

● Rear side lights

● Rear fog light

● Reverse lights

Note

● It is only possible to replace the rear fog lamp and the reversing light.

● If the side light (LED lamp) gives signs of failing, the light should be re-

placed.

● The failure of the lamp is only shown when the LED function goes out

completely. Sometimes, a LED will stop working, without displaying the

warning as the function continues to operate.

Page 283 of 319

281

If and when

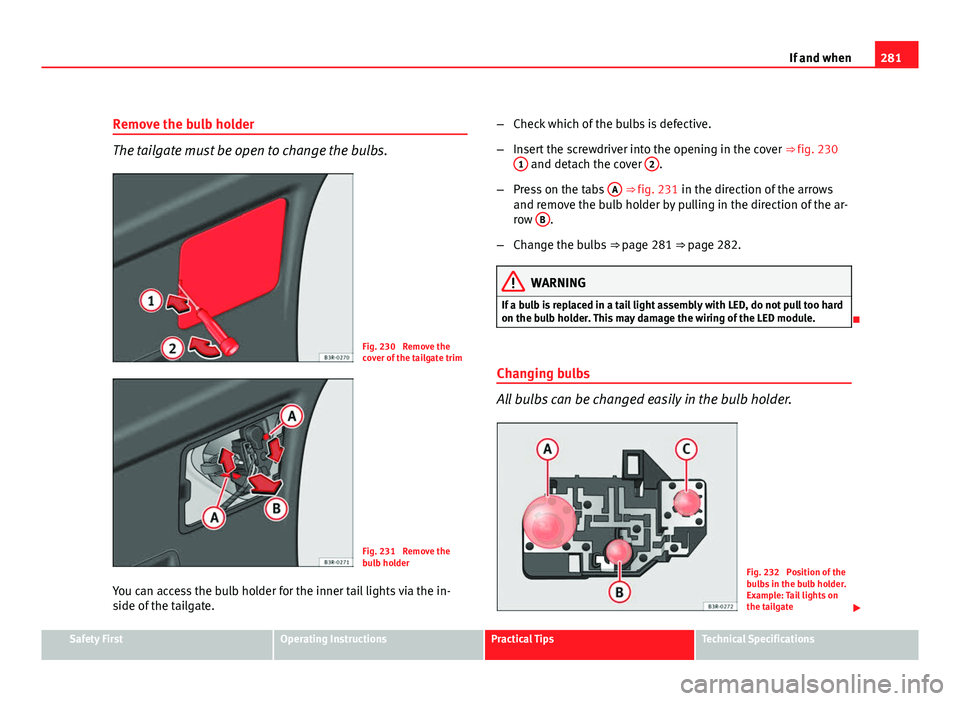

Remove the bulb holder

The tailgate must be open to change the bulbs.

Fig. 230 Remove the

cover of the tailgate trim

Fig. 231 Remove the

bulb holder

You can access the bulb holder for the inner tail lights via the in-

side of the tailgate. –

Check which of the bulbs is defective.

– Insert the screwdriver into the opening in the cover ⇒ fig. 230

1

and detach the cover 2.

– Press on the tabs A

⇒ fig. 231 in the direction of the arrows

and remove the bulb holder by pulling in the direction of the ar-

row B

.

– Change the bulbs ⇒ page 281 ⇒ page 282.

WARNING

If a bulb is replaced in a tail light assembly with LED, do not pull too hard

on the bulb holder. This may damage the wiring of the LED module.

Changing bulbs

All bulbs can be changed easily in the bulb holder.

Fig. 232 Position of the

bulbs in the bulb holder.

Example: Tail lights on

the tailgate

Safety FirstOperating InstructionsPractical TipsTechnical Specifications