light Seat Exeo ST 2013 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Exeo ST, Model: Seat Exeo ST 2013Pages: 327, PDF Size: 5.07 MB

Page 243 of 327

241

Checking and refilling levels

When the coolant is topped up, use a mixture of distilled water and, at

least, 40 % of the G 13 or G 12 plus-plus (TL-VW 774 G) additive (both are

purple) to obtain an optimum anticorrosion protection ⇒

. The mixture of

G 13 with G 12 plus (TL-VW 774 F), G 12 (red) or G 11 (green-blue) engine

coolants will significantly reduce the anticorrosion protection and should,

therefore be avoided ⇒

.

WARNING

If there is not enough anti-freeze in the coolant system, the engine may

fail leading to serious damage. ● Please make sure that the percentage

of additive is correct with respect to the lowest expected ambient tem-

perature in the zone in which the vehicle is to be used. ● When the out-

side temperature is very low, the coolant could freeze and the vehicle

would be immobilised. In this case, the heating would not work either

and inadequately dressed passengers could die of cold.

CAUTION

The original additives should never be mixed with coolants which are not

approved by SEAT. Otherwise, you run the risk of causing severe damage to

the engine and the engine cooling system.

● If the fluid in the expansion tank is not purple but is, for example,

brown, this indicates that the G 13 additive has been mixed with an inade-

quate coolant. The coolant must be changed as soon as possible if this is

the case! This could result in serious faults and engine damage.

For the sake of the environment

Coolants and additives can contaminate the environment. If any fluids are

spilled, they should be collected and correctly disposed of, with respect to

the environment. Checking the coolant level

The coolant level can be checked visually.

Fig. 183 Engine com-

partment: Coolant fluid

deposit

– Switch the ignition off.

– Check the coolant level on coolant fluid expansion tank

⇒ Fig. 183. When the engine is cold, it should be between the

“min” and “max” marks. When the engine is hot, it may be

slightly above the “max” mark.

Its location is shown in the corresponding general overview of the engine

compartment.

The coolant level should be checked with the engine switched off.

The coolant level is monitored by a warning lamp on the instrument panel

display ⇒ page 81. However, we recommend that it should be checked oc-

casionally.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 245 of 327

243

Checking and refilling levels

WARNING

When working in the engine compartment be aware that the radiator fan

may start running suddenly, leading to the risk of injury.

Washer fluid and windscreen wiper blades Windscreen washer system

Plain water is not sufficient for the windscreen washer sys-

tem.

Fig. 184 In the engine

compartment: Cap of

windscreen washer fluid

reservoir

The container for the windscreen washer contains the cleaning fluid for the

windscreen and the headlight washer system*. The container is located in

the engine compartment (front left). The filler cap is marked with the symbol

⇒ Fig. 184. The capacity of the container is listed in ⇒ page 306. Plain water on its own is not enough to clean the glass properly. It is there-

fore advisable to add a suitable washer fluid additive (with wax solvent) to

the water. A washer fluid with freeze-resistant additive should be used in

winter.

CAUTION

● Never put radiator antifreeze or other additives into the windscreen

washer fluid.

● Never use washer fluid which contains paint thinners or solvents as it

can damage the paintwork.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 248 of 327

246Checking and refilling levels

Removing the wiper blade

–Lift the wiper arm away from the glass ⇒ Fig. 187

– Slide the blade adapter in the direction of the arrow and remove

the blade ⇒ Fig. 187.

Fitting the wiper blade

– With one hand, hold the top end of the wiper arm.

– Place the blade as shown in the ⇒ Fig. 188 and slide the adapt-

er along until it engages.

Check the condition of the wiper blade regularly. Change as required.

If the windscreen wiper scrapes, it should be replaced if damaged, or

cleaned if soiled.

If this is not sufficient, refer to a specialised workshop.

WARNING

Do not drive unless you have good visibility through all windows!

● Clean the windscreen wiper blades and all windows regularly.

● The wiper blades should be changed once or twice a year.

CAUTION

● A damaged or dirty window wiper could scratch the rear window.

● Never use fuel, nail varnish remover, paint thinner or similar products to

clean the window.

● Never move the windscreen wiper by hand. This could cause damage. Brake fluid

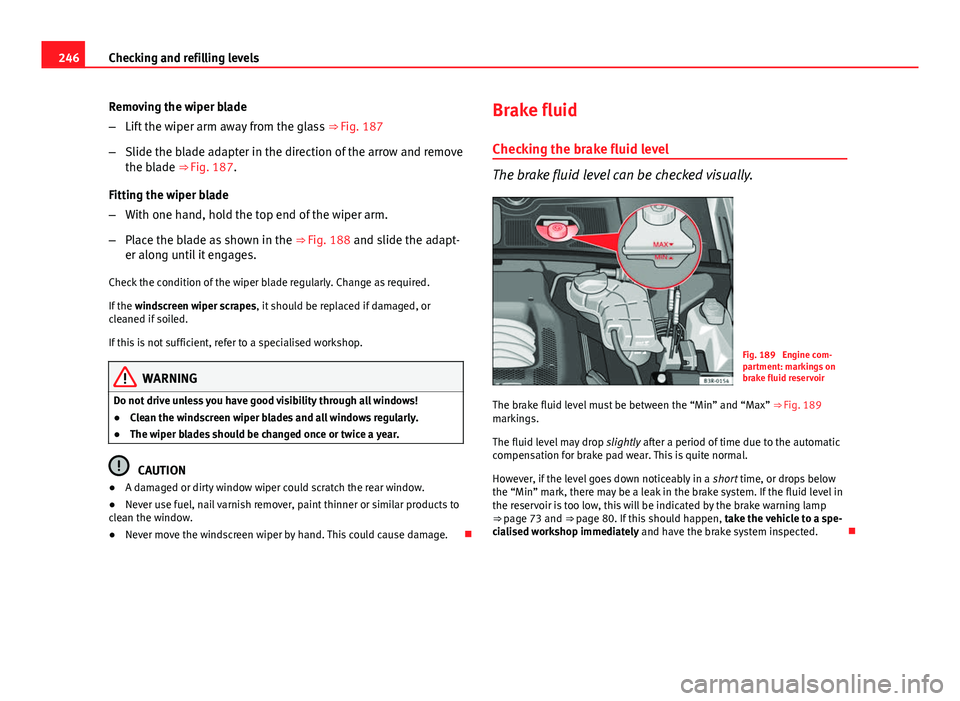

Checking the brake fluid level

The brake fluid level can be checked visually.

Fig. 189 Engine com-

partment: markings on

brake fluid reservoir

The brake fluid level must be between the “Min” and “Max” ⇒ Fig. 189

markings.

The fluid level may drop slightly after a period of time due to the automatic

compensation for brake pad wear. This is quite normal.

However, if the level goes down noticeably in a short time, or drops below

the “Min” mark, there may be a leak in the brake system. If the fluid level in

the reservoir is too low, this will be indicated by the brake warning lamp

⇒ page 73 and

⇒ page 80. If this should happen,

take the vehicle to a spe-

cialised workshop immediately and have the brake system inspected.

Page 251 of 327

249

Checking and refilling levels

A highly explosive mixture of gases is released when the bat-

tery is under charge.

Keep children away from acid and batteries!

WARNING

Always be aware of the danger of injury and chemical burns as well as

the risk of accident or fire when working on the battery and the electrical

system:

● Wear eye protection. Protect your eyes, skin and clothing from acid

and particles containing lead.

● Battery acid is extremely corrosive. Wear protective gloves and eye

protection. Do not tilt the batteries. This could spill acid through the

vents. Rinse battery acid from eyes immediately for several minutes with

clear water. Then seek medical care immediately. Neutralise any acid

splashes on the skin or clothing with a soapy solution, and rinse off with

plenty of water. If acid is swallowed by mistake, consult a doctor immedi-

ately.

● Fires, sparks, open flames and smoking are prohibited. When han-

dling cables and electrical equipment, avoid causing sparks and electro-

static charge. Never short the battery terminals. High-energy sparks can

cause injury.

● A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.

● Keep children away from acid and batteries.

● Before working on the electrical system, you must switch off the en-

gine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bulb is changed, you need only

switch off the light.

WARNING (Continued)

● Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alarm will otherwise be triggered.

● When disconnecting the battery from the vehicle on-board network,

disconnect first the negative cable and then the positive cable.

● Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never re-

verse the polarity of the connections. This could cause an electrical fire.

● Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can freeze at temperatures around 0 °C.

● Ensure that the vent hose is always connected to the battery.

● Never use a defective battery. This could cause an explosion. Replace

a damaged battery immediately.

CAUTION

● Never disconnect the battery if the ignition is switched on or if the en-

gine is running. This could damage the electrical system or electronic com-

ponents.

● Do not expose the battery to direct sunlight over a long period of time,

as the intense ultraviolet radiation can damage the battery housing.

● If the vehicle is left standing in cold conditions for a long period, protect

the battery from freezing. If it freezes it will be damaged.

Charging the battery

A fully-charged battery is important for reliable starting. – Note the warnings ⇒

in Important safety warnings for han-

dling a vehicle battery on page 249 and ⇒ .

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 254 of 327

252Wheels and tyres

2. The tyre pressures should only be checked when the tyres are

cold. The slightly raised pressures of warm tyres must not be re-

duced.

3. Adjust the tyre pressure to the load you are carrying.

Tyre pressure

The correct tyre pressure is especially important at high speeds. The pres-

sure should therefore be checked at least once a month and before starting

a journey.

The sticker with the tyre pressure values can be found on the inside of the

fuel tank flap. The tyre pressure values given are for cold tyres. Do not re-

duce the slightly raised pressures of warm tyres ⇒

.

WARNING

● Check the tyre pressure at least once per month. Checking the tyre

pressure is very important. If the tyre pressure is too high or too low,

there is an increased danger of accidents - particularly at high speeds.

● A tyre can easily burst if the pressure is too low, causing an accident!

● At continuously high speeds, a tyre with insufficient pressure flexes

more. In this way it becomes too hot, and this can cause tread separation

and tyre blow-out. Always observe the recommended tyre pressures.

● If the tyre pressure is too low or too high, the tyres will wear prema-

turely and the vehicle will not handle well. Risk of accident!

For the sake of the environment

Under-inflated tyres will increase fuel consumption. Tyre pressure monitoring*

The tyre pressure monitoring system constantly checks the

pressure of the tyres.

The system warns the driver in the event of a loss of pressure by means of

symbols and messages in the instrument panel display.

Note that tyre pressure also depends on tyre temperature. Tyre pressure in-

creases about 0.1 bar for each 10 °C in tyre temperature increase. The tyre

heats up while the vehicle is being driven and the tyre pressure will rise ac-

cordingly. For this reason, you should only adjust the tyre pressures when

they are cold (i.e. approximately at ambient temperature).

To ensure that the tyre pressure monitoring system works reliably, you

should check and, if necessary, adjust the tyre pressures at regular intervals

and store the correct pressures (reference values) in the system.

A tyre pressure information label is attached to the inside of the fuel tank

flap.

WARNING

● Never adjust tyre pressure when the tyres are hot. This may damage

or even burst the tyres. Risk of accident!

● An insufficiently inflated tyre flexes a lot more at high speeds and

causes significant heating of the tyre. Under these conditions, the tyre

bead may be released or the tyre may burst. Risk of accident!

For the sake of the environment

Under-inflated tyres lead to increased fuel consumption and tyre wear.

Page 255 of 327

253

Wheels and tyres

Significant tyre pressure loss

The tyre symbol is displayed and indicates that the tyre pressure

of at least one tyre is insufficient.

– Stop the vehicle.

– Switch the ignition off.

– Check the tyre(s).

– Change the wheel if necessary.

Tyre pressure monitoring (RKA+)*

The tyre pressure monitor display on the instrument panel

indicates if the pressure is too low.

Fig. 190 Detailed view of

the centre console: But-

ton for the tyre pressure

monitoring system The tyre pressure monitoring system makes use of the ABS sensors to com-

pare the rolling circumference and the frequency characteristics of the

wheels. If the rolling circumference or frequency characteristic changes on

one or more wheels, the tyre pressure warning lamp will light up. The

fault will also be indicated by a warning buzzer. The position of the affected

tyre will also be shown (if only one tyre is affected) on the centre display of

the instrument panel.

The rolling circumference and frequency characteristics can change if:

●

the tyre pressure is too low.

● the tyre has suffered structural damage.

● the wheels or the inflation pressures have been changed without initial-

ising the system (see Adjusting the tyre pressure settings).

● there is a greater load on the wheels of one axle (e.g. if you are carrying

more passengers or luggage).

● the road surface under the left wheels is different to the road surface un-

der the right wheels for a long period.

● when driving with snow chains.

Adjusting the tyre pressure settings (initialising the tyre pressure

monitoring system)

After any incident regarding the wheels of your vehicle, e.g. after modifying

the tyre pressure ⇒ page 255 or after changing or swapping wheels

⇒ page 255 you should - with the vehicle at a standstill and the engine run- ning - press ⇒ Fig. 190. The yellow warning lamp will light up. Hold the

button down for 2 seconds until the warning lamp goes out and an acoustic

warning is given. You can now release the button.

If the wheels are subjected to extreme stress (e.g. heavy load), the tyre

pressure must be increased to the recommended value for the maximum

load (see the adhesive label on the inside of the fuel tank flap) and then

initialise the system.

Safety FirstOperating instructionsPractical TipsTechnical Specifications

Page 256 of 327

254Wheels and tyres

Tyre pressure warning lamp on

When you switch on the ignition, the tyre pressure warning lamp will

light up for about 2 seconds. There is a fault in the system if the indicator

stays on permanently after switching on the ignition. The instrument panel

also display TMPS (Tyre Pressure Monitoring System). Please contact the

nearest specialised workshop as soon as possible.

The tyre pressure warning lamp lights up if the tyre pressure on one or

more wheels is significantly lower than the tyre pressure setting which was

confirmed by the driver ⇒

.

WARNING

● If the tyre pressure warning lamp lights up you must slow down

immediately and avoid any severe braking or steering manoeuvres. Stop

the vehicle as soon as possible and check the tyres and their pressure.

● The driver is responsible for maintaining correct tyre pressures.

Therefore, the tyre pressure must be regularly checked.

● Under certain conditions (e.g. driving at high speeds, on ice and snow

or on poor road surfaces) the tyre pressure warning lamp may not light

up immediately or not at all.

● Please ask your Technical Service or specialised workshop whether

run-flat tyres can be used on your vehicle. Fitting this type of tyre in an

undue manner could lead to your driving licence being taken away from

you. Furthermore, it may led to damage to the vehicle or, under certain

circumstances, may cause accidents.

● If you change normal tyres for run-flat tyres or vice versa, the control

unit must be reprogrammed by the Technical Service or a specialised

workshop.

Note

If you did not press the button for the tyre pressure monitoring system to

confirm a new tyre pressure setting after making changes to the tyre pres-

sures or changing one or more wheels, the warning lamp may light up

although the tyre pressures are correct. In this case, stop the vehicle as

soon as possible and, after examining the tyres, press the button for the

tyre pressure monitoring system.

Page 266 of 327

264If and when

Changing a wheel

Preparation work

What you must do before changing a wheel.

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible. Choose a location that is as

level as possible.

– All occupants should leave the vehicle. They should wait in a

safe place (e.g. behind the roadside crash barrier).

– Apply the handbrake firmly.

– Engage first gear .

– When towing a trailer: Unhitch the trailer from your vehicle.

– Take the tools and the spare wheel ⇒ page 261 out of the lug-

gage compartment.

WARNING

If you have a puncture in heavy traffic, switch on the hazard warning

lights and place the warning triangle in a visible location. This is for your

own safety and also warns other road users.

CAUTION

If you have to change the tyre on a gradient, block the wheel opposite the

wheel being changed by placing a stone or similar object under it to prevent

the vehicle from rolling away.

Note

Please observe legal requirements when doing so.

Changing a wheel

Change the wheel as described below.

– Remove the wheel cover .

– Loosen the wheel bolts ⇒ page 265.

– Raise the vehicle with the jack ⇒ page 266.

– Take off the wheel with the flat tyre and then put on the spare

wheel ⇒ page 267.

– Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the

box spanner ⇒ page 265.

– Replace the cover.

After changing a wheel

After changing the wheel, there are still tasks to complete. – Place the wheel with the defective tyre in the spare wheel well

and secure it.

– Put the tools and jack back in the luggage compartment.

Page 272 of 327

270If and when

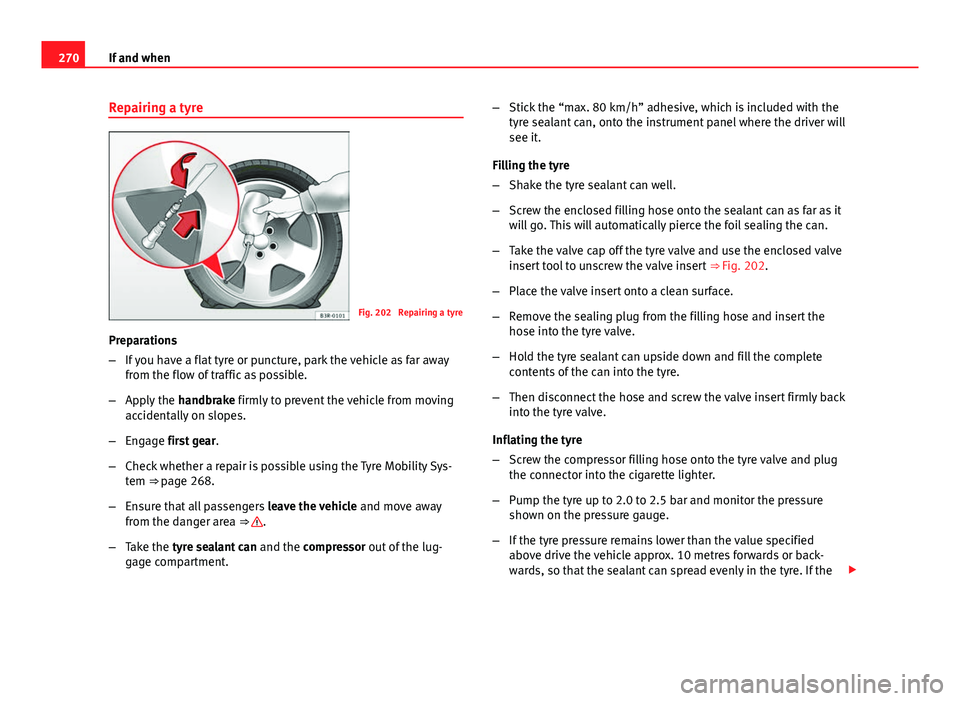

Repairing a tyre

Fig. 202 Repairing a tyre

Preparations

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

– Apply the handbrake firmly to prevent the vehicle from moving

accidentally on slopes.

– Engage first gear .

– Check whether a repair is possible using the Tyre Mobility Sys-

tem ⇒ page 268.

– Ensure that all passengers leave the vehicle and move away

from the danger area ⇒

.

– Take the tyre sealant can and the compressor out of the lug-

gage compartment. –

Stick the “max. 80 km/h” adhesive, which is included with the

tyre sealant can, onto the instrument panel where the driver will

see it.

Filling the tyre

– Shake the tyre sealant can well.

– Screw the enclosed filling hose onto the sealant can as far as it

will go. This will automatically pierce the foil sealing the can.

– Take the valve cap off the tyre valve and use the enclosed valve

insert tool to unscrew the valve insert ⇒ Fig. 202.

– Place the valve insert onto a clean surface.

– Remove the sealing plug from the filling hose and insert the

hose into the tyre valve.

– Hold the tyre sealant can upside down and fill the complete

contents of the can into the tyre.

– Then disconnect the hose and screw the valve insert firmly back

into the tyre valve.

Inflating the tyre

– Screw the compressor filling hose onto the tyre valve and plug

the connector into the cigarette lighter.

– Pump the tyre up to 2.0 to 2.5 bar and monitor the pressure

shown on the pressure gauge.

– If the tyre pressure remains lower than the value specified

above drive the vehicle approx. 10 metres forwards or back-

wards, so that the sealant can spread evenly in the tyre. If the

Page 273 of 327

271

If and when

pressure is still lower than the specification the tyre is too badly

damaged and cannot be repaired using the tyre sealant.

Final check

– After about 10 minutes, stop to check the tyre pressure.

– If tyre pressure is less than 1.3 bar, the tyre is too badly dam-

aged. Do not drive on! You should obtain professional assis-

tance.

WARNING

● If you have a puncture in heavy traffic, switch on the hazard warning

lights and place the warning triangle in a visible location. This is for your

own safety and also warns other road users.

● Make sure your passengers wait in a safe place (for instance behind

the roadside crash barrier).

● Please observe the manufacturer's safety notes on the compressor

and the instructions supplied with the tyre sealant can.

● If it is not possible to build up a tyre pressure of 2.0 bar within 6 mi-

nutes this means that the tyre is too badly damaged. Do not drive on!

● Seek professional assistance if the repair of a tyre puncture is not

possible with the sealing product.

● If tyre pressure is less than 1.3 bar after driving about 10 minutes,

the tyre is too badly damaged. Do not drive on! Obtain technical assis-

tance.

CAUTION

Take special care if you have to repair a tyre on a slope.

Note

● Do not use the compressor for longer than 6 minutes. Otherwise, it

might overheat. When the compressor has cooled down, you can use it

again.

● If tyre sealant should leak out, leave it to dry and then pull it off like foil.

● After carrying out a tyre repair remember to buy a new tyre sealant can at

a specialised workshop. This will ensure that the Tyre Mobility System is op-

erative again.

● Please observe legal requirements when doing so.

Safety FirstOperating instructionsPractical TipsTechnical Specifications