lock Seat Ibiza 2017 Edition 11.17 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2017, Model line: Ibiza, Model: Seat Ibiza 2017Pages: 312, PDF Size: 6.51 MB

Page 45 of 312

The essentials

● Vehicle

s

with Easy Connect : Press the button and the function button SETTINGS >

Driver assistance > ACC > Dis-

tance .

The w arnin

g limit

can be set from 30 to

210 km/h (18 to 150 mph) ›››

page 209.

The adjustment is made at 10 km/h (6 mph)

intervals. Note

● Ple a

se bear in mind that, even with the

speed warning function, it is still important

to keep an eye on the vehicle speed with the

speedometer and to observe the legal speed

limits.

● The speed limit warning function in the ver-

sion for some c

ountries warns you at a speed

of 120 km/h (75 mph). This is a factory-set

speed limit. Service intervals

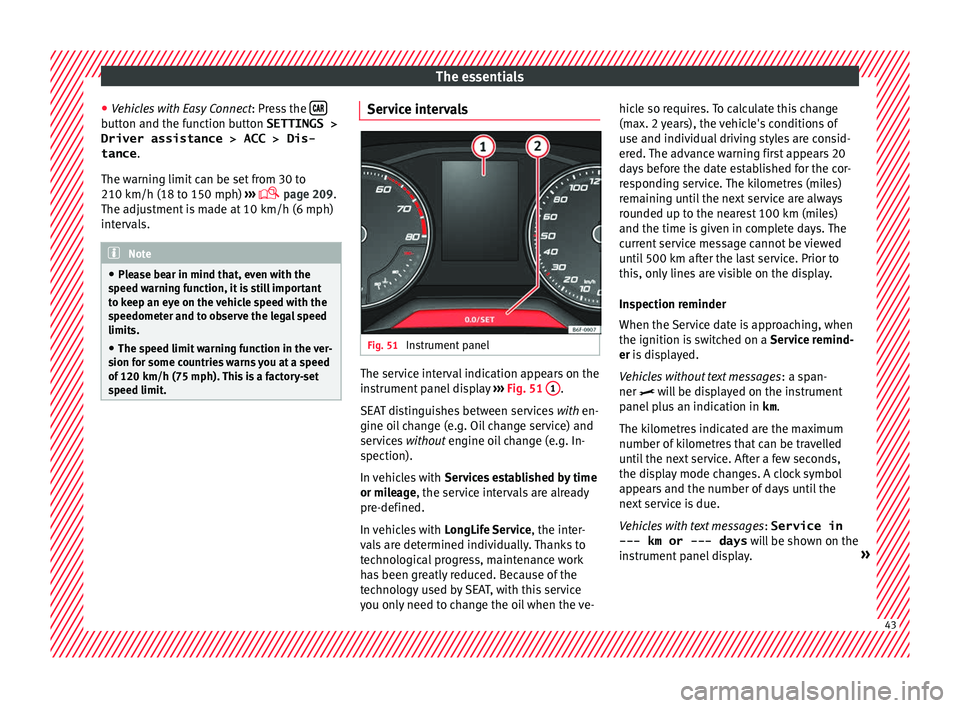

Fig. 51

Instrument panel The service interval indication appears on the

in

s

trument

panel display ››› Fig. 51 1 .

S EA

T di

stinguishes between services with en-

gine oil change (e.g. Oil change service) and

services without engine oil change (e.g. In-

spection).

In vehicles with Services established by time

or mileage, the service intervals are already

pre-defined.

In vehicles with LongLife Service , the inter-

vals are determined individually. Thanks to

technological progress, maintenance work

has been greatly reduced. Because of the

technology used by SEAT, with this service

you only need to change the oil when the ve- hicle so requires. To calculate this change

(max. 2 y

ears), the vehicle's conditions of

use and individual driving styles are consid-

ered. The advance warning first appears 20

days before the date established for the cor-

responding service. The kilometres (miles)

remaining until the next service are always

rounded up to the nearest 100 km (miles)

and the time is given in complete days. The

current service message cannot be viewed

until 500 km after the last service. Prior to

this, only lines are visible on the display.

Inspection reminder

When the Service date is approaching, when

the ignition is switched on a Service remind-

er is displayed.

Vehicles without text messages : a span-

ner will be displayed on the instrument

panel plus an indication in km.

The kilometres indicated are the maximum

number of kilometres that can be travelled

until the next service. After a few seconds,

the display mode changes. A clock symbol

appears and the number of days until the

next service is due.

Vehicles with text messages : Service in

--- km or --- days will be shown on the

instrument panel display. » 43

Page 50 of 312

The essentials

Yellow warning lamps Central warning lamp: additional

information on the instrument

panel display–

Front brake pads worn.›››

page

181

it lights up:

Fault in the ESC, or

disconnection caused by the sys-

tem.

››› page

183

flashes: ESC or ASR activated.

it lights up:

fault in the ASR or

disconnection caused by the sys-

tem.

››› page

184

flashes: ASR working.

ASR manually deactivated.

Or else

: ESC in Sport mode.››› page

183

ABS faulty or does not work.›››

page

187

Rear fog light switched on.›››

page 31

lights up or flashes:

fault in the

emission control system.››› page

203

it lights up:

pre-heating of diesel

engine.

››› page

203

flashes: fault in the diesel engine

management.

fault in the petrol engine man-

agement.›››

page

203

lights up or flashes:

fault in the

steering system.››› page

198

Tyre pressure too low, or fault in

the tyre pressure monitoring sys-

tem.›››

page

278

Fuel tank almost empty.›››

page

121

Fault in airbag system and seat

belt tensioners.›››

page

91 Other warning lamps

Left or right turn signal.›››

page 32

Hazard warning lights on.››› page 32

››› page

150

Trailer turn signals›››

page

243

it lights up green:

Press the brake

pedal!

It blinks in green: the selector lev-

er locking button has not engag-

ed.

››› page

190

it lights up green:

cruise control

activated or speed limiter switch-

ed on and active.

››› page 45

››› page

209

it blinks in green: the speed set

by the speed limiter has been ex-

ceeded.

Main beam on or flasher on.›››

page 32

Natural gas operating mode›››

page

121

››› in Warning symbols on page 122

›››

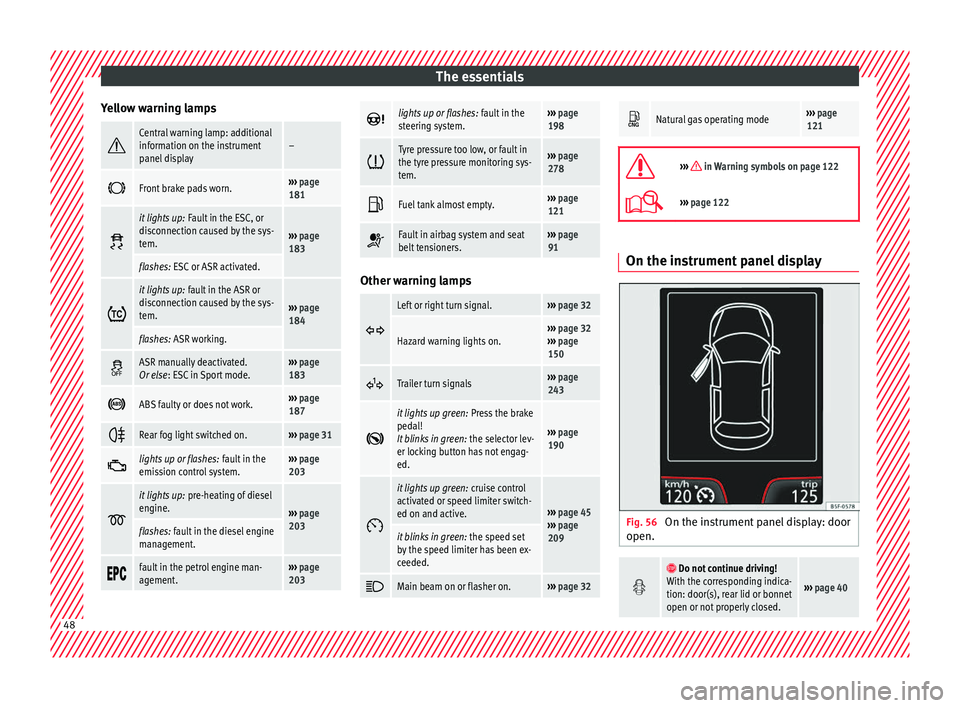

page 122 On the instrument panel display

Fig. 56

On the instrument panel display: door

open.

Do not continue driving!

With the corresponding indica-

tion: door(s), rear lid or bonnet

open or not properly closed.

››› page 40 48

Page 51 of 312

The essentials

Ignition: Do not carry on

driving! Engine coolant level

too low, coolant temperature

too high

››› page

269

Flashing: Fault in the engine

coolant system.

Do not continue driving!

Engine oil pressure too low.››› page

267

Fault in the battery.›››

page

272

Driving light totally or partially

faulty.›››

page

106

Fault in the cornering light sys-

tem.››› page

149

particulate filter blocked.›››

page

202

Flashing: Fault in the oil level

detection. Control manually.

›››

page

267

Ignition: Insufficient engine

oil.

Fault in the gearbox.›››

page

196

Immobiliser active.›››

page

177

Service interval display›››

page 43

Mobile telephone is connected

via Bluetooth to the original

telephone device.›››

page

124

››› page

129

››› Booklet

Audio or

navigation

system

Mobile telephone battery

charge meter. Available only

for devices pre-installed in fac-

tory.

Freezing warning. The outside

temperature is lower than

+4°C (+39°F).›››

page 41

Start-Stop system activated.›››

page

204

Start-Stop system unavailable.

Low consumption driving sta-

tus›››

page

225

›››

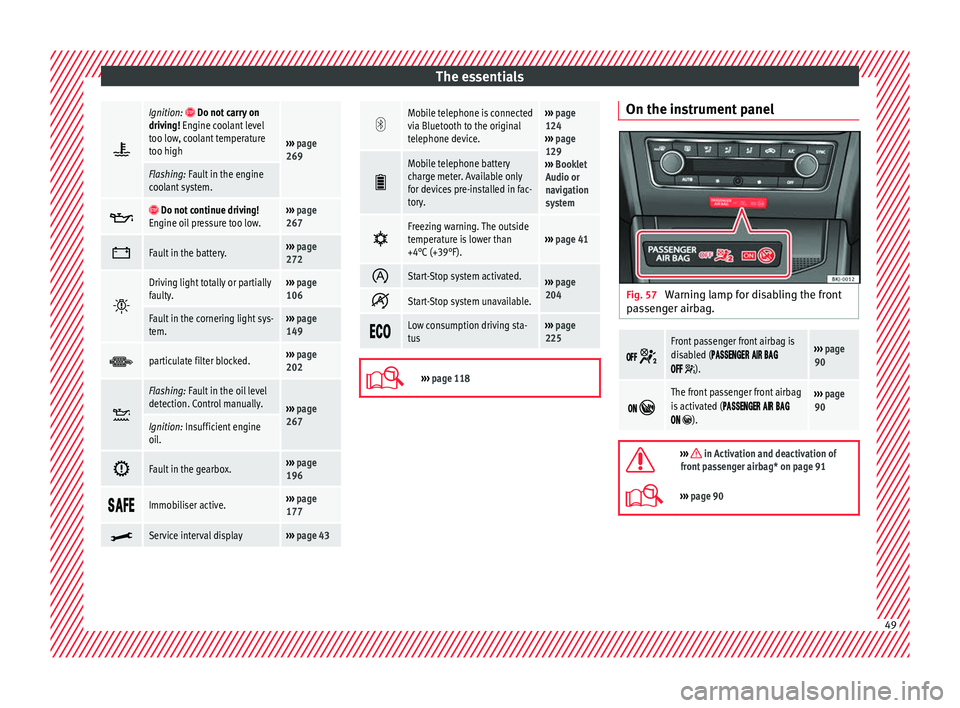

page 118 On the instrument panel

Fig. 57

Warning lamp for disabling the front

p a

s

senger airbag.

Front passenger front airbag is

disabled (

).

››› page

90

The front passenger front airbag

is activated (

).

››› page

90

››› in Activation and deactivation of

front passenger airbag* on page 91

››› page 90 49

Page 52 of 312

The essentials

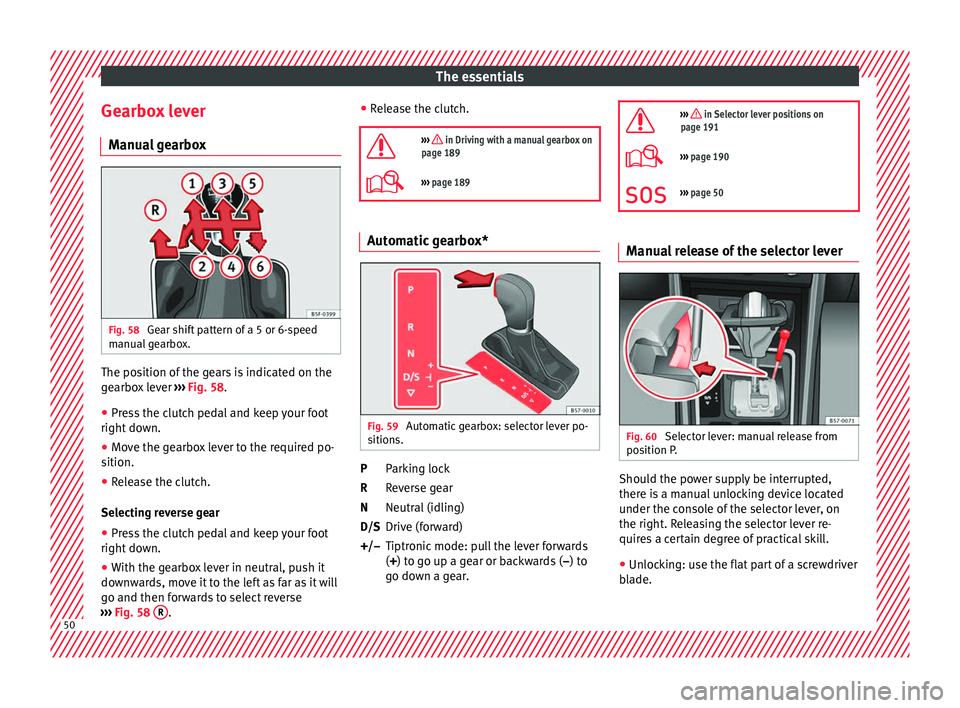

Gearbox lever M anua

l

gearbox Fig. 58

Gear shift pattern of a 5 or 6-speed

m anual

g

earbox. The position of the gears is indicated on the

g

e

arbo

x lever ››› Fig. 58.

● Press the clutch pedal and keep your foot

right down.

● Mo

ve the gearbox lever to the required po-

sition.

● Rel

ease the clutch.

Selecting r

everse gear

● Press the clutch pedal and keep your foot

right down.

● W

ith the gearbox lever in neutral, push it

downw

ards, move it to the left as far as it will

go and then forwards to select reverse

››› Fig. 58 R . ●

Rel

e

ase the clutch.

››› in Driving with a manual gearbox on

page 189

››› page 189 Automatic gearbox*

Fig. 59

Automatic gearbox: selector lever po-

s ition

s. Parking lock

R

ev

er

se gear

Neutral (idling)

Drive (forward)

Tiptronic mode: pull the lever forwards

(+) to go up a gear or backwards ( –) to

go down a gear.

P

R

N

D/S

+/–

››› in Selector lever positions on

page 191

››› page 190

››› page 50 Manual release of the selector lever

Fig. 60

Selector lever: manual release from

po s

ition P

. Should the power supply be interrupted,

ther

e i

s

a manual unlocking device located

under the console of the selector lever, on

the right. Releasing the selector lever re-

quires a certain degree of practical skill.

● Unlocking: use the flat part of a screwdriver

bla

de. 50

Page 53 of 312

The essentials

Removing the cover from the selector lever

● Apply the handbrake › ›

› to ensure that

the c ar doe

s

not move.

● Carefully pull the corners of the selector

lever boot

and twist it upwards above the lev-

er handle.

Releasing the selector lever

● Using a screwdriver, press and hold the yel-

low un

locking tab sideways ››› Fig. 60.

● Press the interlock button on the selector

lever and mo

ve the selector lever to posi-

tion N.

● After carrying out the manual release, at-

tach the sel

ector lever boot on the gearbox

console again. If the power supply should ever fail (e.g. dis-

char

ged battery) and the vehicle has to be

pushed or towed, the selector lever must first

be moved to position N, after operating the

manual release mechanism. WARNING

The selector lever may be moved out of posi-

tion P only when the h

andbrake is firmly ap-

plied. If this does not work, secure the vehi-

cle with the brake pedal. On a slope the vehi-

cle could otherwise start to move inadver-

tently after shifting the selector lever out of

position P - accident risk! Air conditioning

R el

at

ed video Fig. 61

Air conditioning 51

Page 59 of 312

The essentials

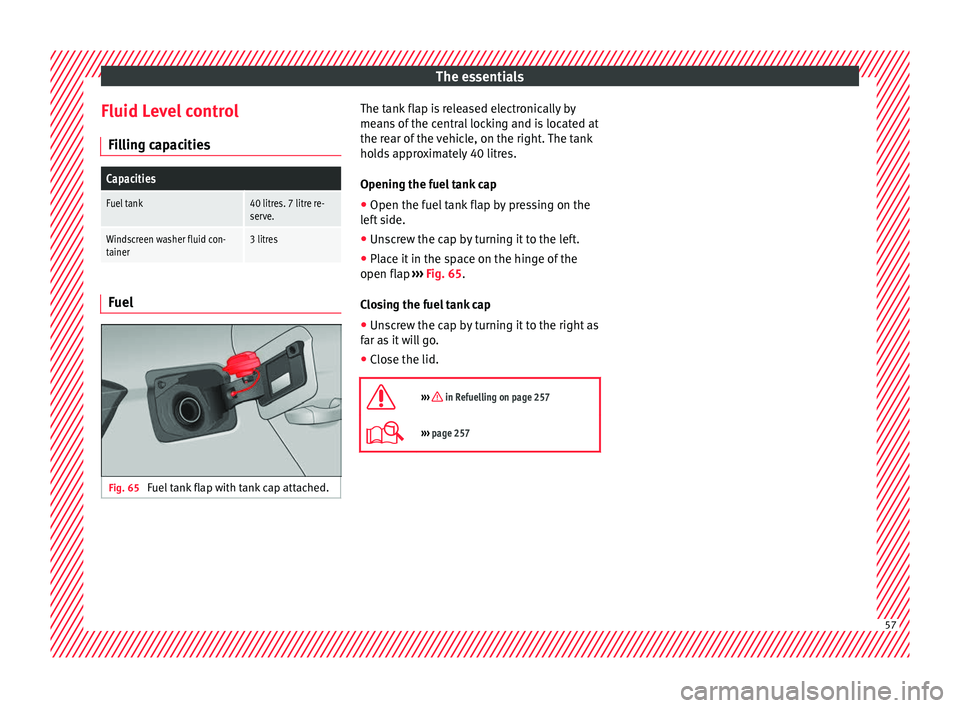

Fluid Level control Fi l

lin

g capacities

Capacities

Fuel tank40 litres. 7 litre re-

serve.

Windscreen washer fluid con-

tainer3 litres Fuel

Fig. 65

Fuel tank flap with tank cap attached. The tank flap is released electronically by

me

an

s

of the central locking and is located at

the rear of the vehicle, on the right. The tank

holds approximately 40 litres.

Opening the fuel tank cap

● Open the fuel tank flap by pressing on the

left

side.

● Unscrew the cap by turning it to the left.

● Place it in the space on the hinge of the

open flap ››

› Fig. 65.

Closing the fuel tank cap

● Unscrew the cap by turning it to the right as

far as

it will go.

● Close the lid.

››› in Refuelling on page 257

››› page 257 57

Page 64 of 312

The essentials

Emergencies F u

se

s

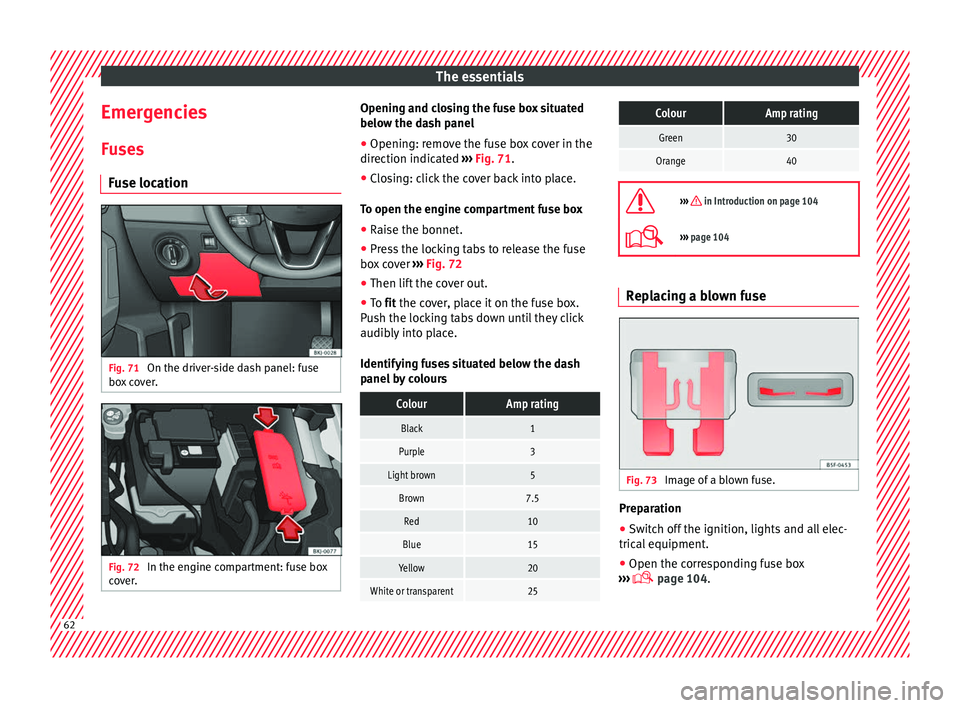

Fuse location Fig. 71

On the driver-side dash panel: fuse

bo x

c

over. Fig. 72

In the engine compartment: fuse box

c o

v

er. Opening and closing the fuse box situated

belo

w the d a

sh panel

● Opening: remove the fuse box cover in the

direction indicat

ed ››› Fig. 71.

● Closing: click the cover back into place.

To open the engine c

ompartment fuse box

● Raise the bonnet.

● Press the locking tabs to release the fuse

box c

over ››› Fig. 72

● Then lift the cover out.

● To fit the cover, place it on the fuse box.

Pu

sh the locking tabs down until they click

audibly into place.

Identifying fuses situated below the dash

panel by colours

ColourAmp rating

Black1

Purple3

Light brown5

Brown7.5

Red10

Blue15

Yellow20

White or transparent25

ColourAmp rating

Green30

Orange40

››› in Introduction on page 104

›››

page 104 Replacing a blown fuse

Fig. 73

Image of a blown fuse. Preparation

●

Switch off the ignition, lights and all elec-

tric al

equipment

.

● Open the corresponding fuse box

›››

page 104.62

Page 66 of 312

The essentials

● Al

l

occupants should leave the vehicle and

wait in a safe place (for instance behind the

roadside crash barrier). WARNING

● Alw a

ys observe the above steps and pro-

tect yourself and other road users.

● If you change the wheel on a slope, block

the wheel on the oppo

site side of the car with

a stone or similar to prevent the vehicle from

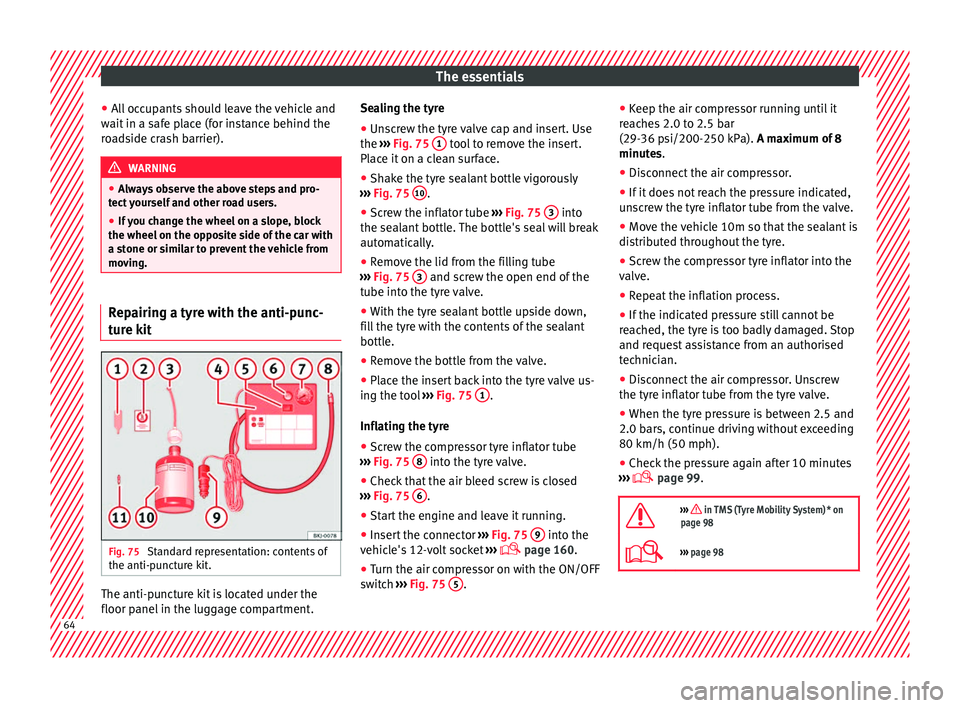

moving. Repairing a tyre with the anti-punc-

t

ur

e k

it Fig. 75

Standard representation: contents of

the anti-p u

nct

ure kit. The anti-puncture kit is located under the

floor p

anel

in the lug

gage compartment. Sealing the tyre

● Unscrew the tyre valve cap and insert. Use

the ›››

Fig. 75 1 tool to remove the insert.

Pl ac

e it

on a clean surface.

● Shake the tyre sealant bottle vigorously

›››

Fig. 75 10 .

● Screw the inflator tube ››

›

Fig. 75 3 into

the se al

ant

bottle. The bottle's seal will break

automatically.

● Remove the lid from the filling tube

›››

Fig. 75 3 and screw the open end of the

t ube int

o the ty

re valve.

● With the tyre sealant bottle upside down,

fill

the tyre with the contents of the sealant

bottle.

● Remove the bottle from the valve.

● Place the insert back into the tyre valve us-

ing the too

l ››› Fig. 75 1 .

Infl atin

g the ty

re

● Screw the compressor tyre inflator tube

›››

Fig. 75 8 into the tyre valve.

● Check that the air bleed screw is closed

› ›

›

Fig. 75 6 .

● Start the engine and leave it running.

● Insert the connector ››

›

Fig. 75 9 into the

v ehic

l

e's 12-volt socket ›››

page 160.

● Turn the air compressor on with the ON/OFF

swit c

h ››› Fig. 75 5 .●

Keep the air c

ompr

essor running until it

reaches 2.0 to 2.5 bar

(29-36 psi/200-250 kPa). A maximum of 8

minutes.

● Disconnect the air compressor.

● If it does not reach the pressure indicated,

uns

crew the tyre inflator tube from the valve.

● Move the vehicle 10m so that the sealant is

distrib

uted throughout the tyre.

● Screw the compressor tyre inflator into the

valve.

● R

epeat the inflation process.

● If the indicated pressure still cannot be

reac

hed, the tyre is too badly damaged. Stop

and request assistance from an authorised

technician.

● Disconnect the air compressor. Unscrew

the tyre infl

ator tube from the tyre valve.

● When the tyre pressure is between 2.5 and

2.0 bars, c

ontinue driving without exceeding

80 km/h (50 mph).

● Check the pressure again after 10 minutes

›››

page 99.

››› in TMS (Tyre Mobility System)* on

page 98

››› page 98 64

Page 67 of 312

The essentials

Changing a wheel R el

at

ed video Fig. 76

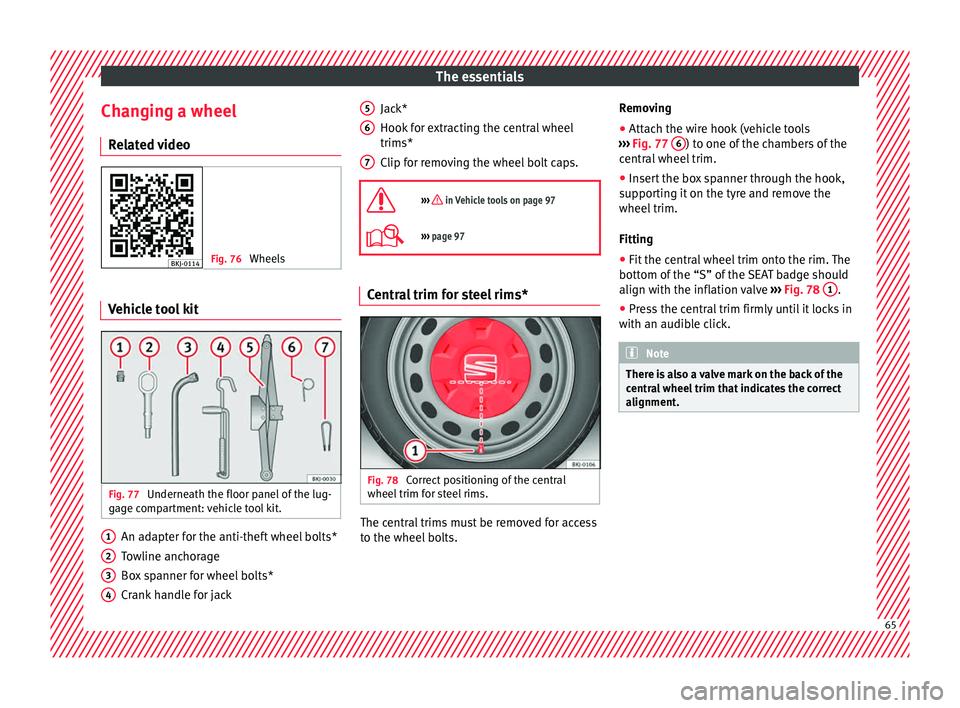

Wheels Vehicle tool kit

Fig. 77

Underneath the floor panel of the lug-

g ag

e c

ompartment: vehicle tool kit. An adapter for the anti-theft wheel bolts*

T

o

wline anc

horage

Box spanner for wheel bolts*

Crank handle for jack

1 2

3

4 Jack*

Hook

f

or e

xtracting the central wheel

trims*

Clip for removing the wheel bolt caps.

››› in Vehicle tools on page 97

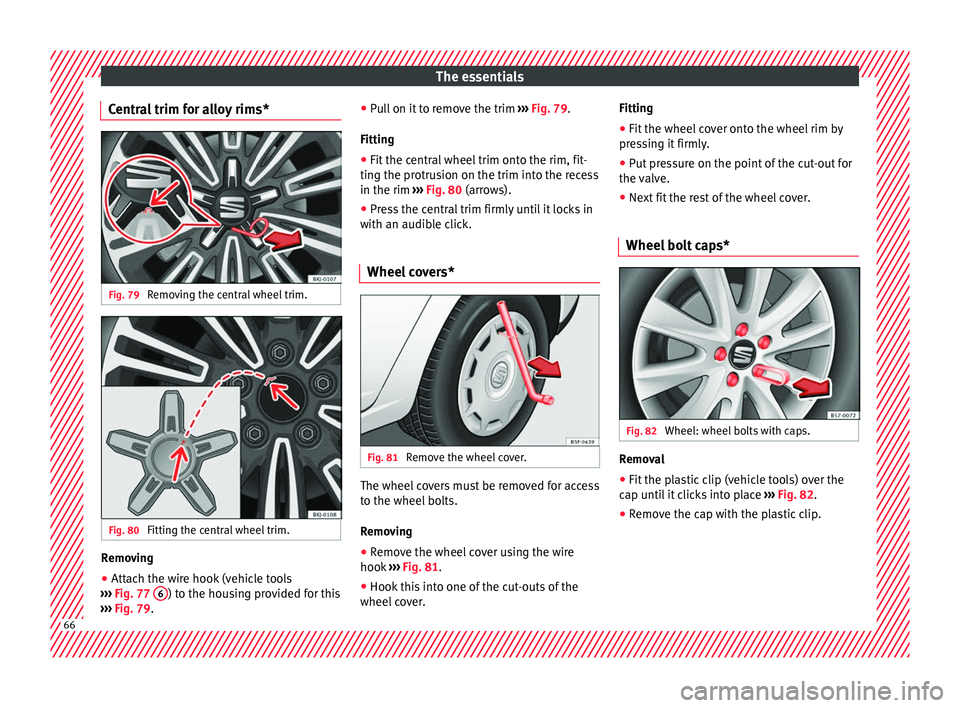

››› page 97 Central trim for steel rims*

Fig. 78

Correct positioning of the central

wheel trim f

or s

teel rims. The central trims must be removed for access

t

o the wheel

bo

lts.

5 6

7 Removing

●

Attach the wire hook (vehicle tools

› ›

›

Fig. 77 6 ) to one of the chambers of the

c entr

al

wheel trim.

● Insert the box spanner through the hook,

suppor

ting it on the tyre and remove the

wheel trim.

Fitting

● Fit the central wheel trim onto the rim. The

bottom of the

“S” of the SEAT badge should

align with the inflation valve ››› Fig. 78 1 .

● Press the central trim firmly until it locks in

w ith an audib

l

e click. Note

There is also a valve mark on the back of the

centr a

l wheel trim that indicates the correct

alignment. 65

Page 68 of 312

The essentials

Central trim for alloy rims* Fig. 79

Removing the central wheel trim. Fig. 80

Fitting the central wheel trim. Removing

● Attach the wire hook (vehicle tools

› ››

Fig. 77 6 ) to the housing provided for this

› ›

›

Fig. 79. ●

Pul

l on it to remove the trim ››› Fig. 79.

Fitting

● Fit the central wheel trim onto the rim, fit-

ting the protru

sion on the trim into the recess

in the rim ››› Fig. 80 (arrows).

● Press the central trim firmly until it locks in

with an audibl

e click.

Wheel covers* Fig. 81

Remove the wheel cover. The wheel covers must be removed for access

t

o the wheel

bo

lts.

Removing ● Remove the wheel cover using the wire

hook ››

› Fig. 81.

● Hook this into one of the cut-outs of the

wheel co

ver. Fitting

●

Fit the wheel cover onto the wheel rim by

pres

sing it firmly.

● Put pressure on the point of the cut-out for

the valv

e.

● Next fit the rest of the wheel cover.

Wheel bolt caps* Fig. 82

Wheel: wheel bolts with caps. Removal

● Fit the plastic clip (vehicle tools) over the

c ap u

nti

l it clicks into place ››› Fig. 82.

● Remove the cap with the plastic clip. 66