wheel Seat Ibiza 5D 2006 Workshop Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2006, Model line: Ibiza 5D, Model: Seat Ibiza 5D 2006Pages: 268, PDF Size: 8.14 MB

Page 206 of 268

If and when

204

WARNING

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack, loosening the wheel bolts more than one turn can result in an acci-

dent.

Note

•

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.

•

If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

Raising the vehicle

The vehicle must be raised with a jack to remove the wheel.

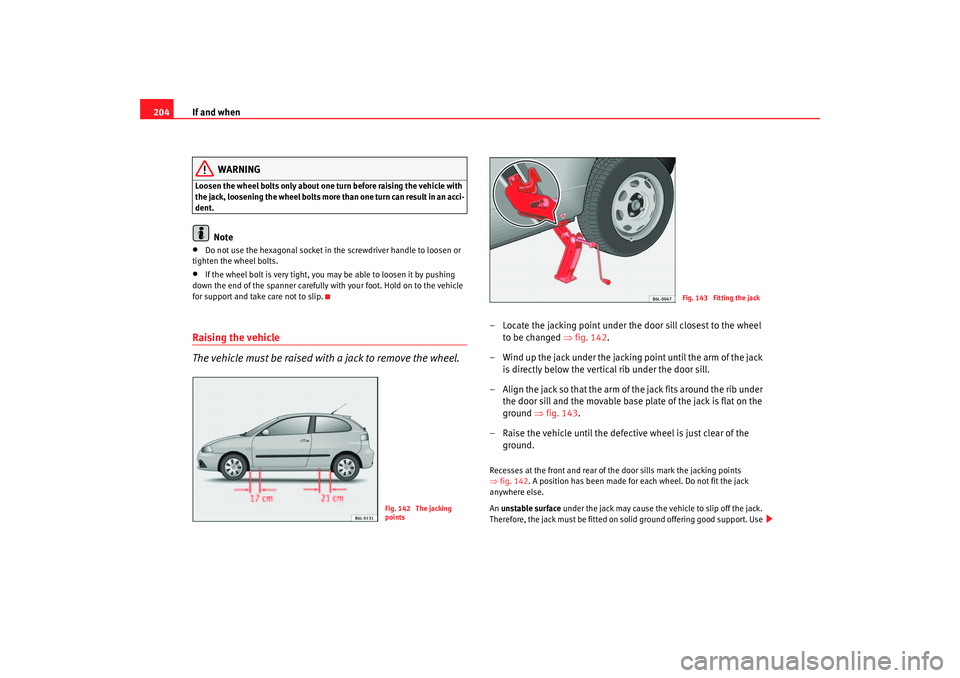

– Locate the jacking point under the door sill closest to the wheel to be changed ⇒fig. 142.

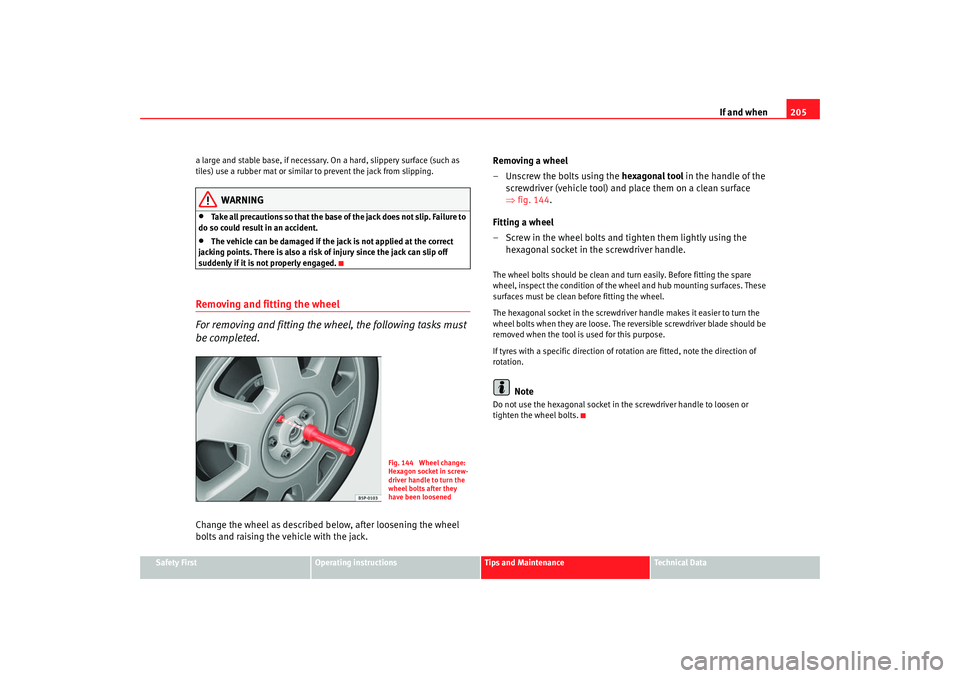

– Wind up the jack under the jacking point until the arm of the jack is directly below the vertical rib under the door sill.

– Align the jack so that the arm of the jack fits around the rib under the door sill and the movable base plate of the jack is flat on the

ground ⇒fig. 143.

– Raise the vehicle until the defective wheel is just clear of the ground.Recesses at the front and rear of the door sills mark the jacking points

⇒fig. 142. A position has been made for each wheel. Do not fit the jack

anywhere else.

An unstable surface under the jack may cause the vehicle to slip off the jack.

Therefore, the jack must be fitted on solid ground offering good support. Use

Fig. 142 The jacking

points

Fig. 143 Fitting the jack

ibiza_angles_0706_DEF Seite 204 Freitag, 1. September 2006 1:18 13

Page 207 of 268

If and when205

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

a large and stable base, if necessary. On a hard, slippery surface (such as

tiles) use a rubber mat or similar to prevent the jack from slipping.

WARNING

•

Take all precautions so that the base of the jack does not slip. Failure to

do so could result in an accident.

•

The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

Removing and fitting the wheel

For removing and fitting the wheel, the following tasks must

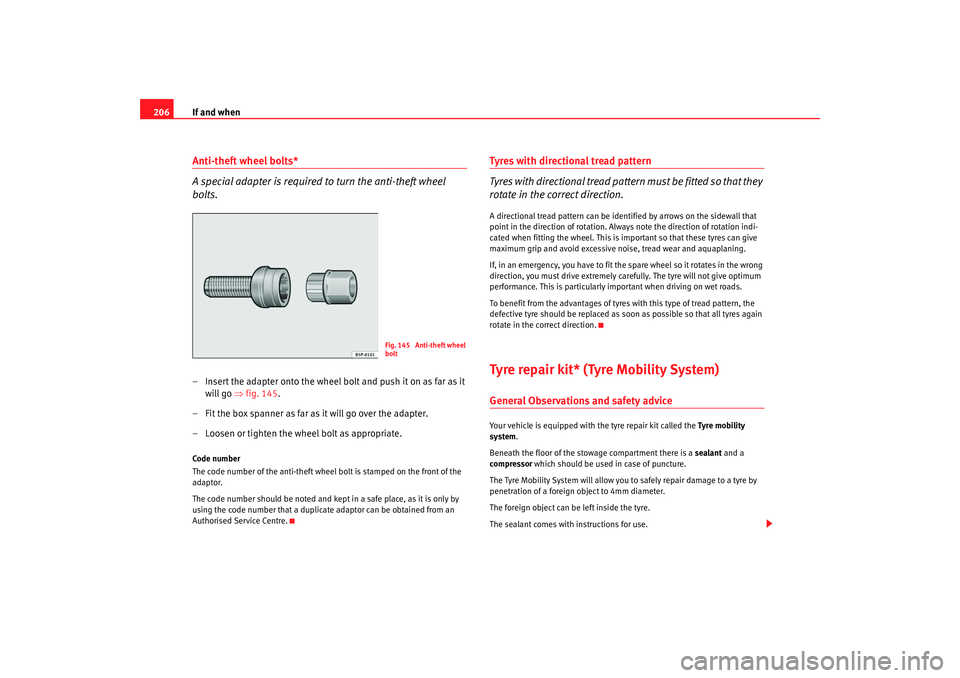

be completed.Change the wheel as described below, after loosening the wheel

bolts and raising the vehicle with the jack. Removing a wheel

– Unscrew the bolts using the

hexagonal tool in the handle of the

screwdriver (vehicle tool) and place them on a clean surface

⇒ fig. 144.

Fitting a wheel

– Screw in the wheel bolts and tighten them lightly using the hexagonal socket in the screwdriver handle.

The wheel bolts should be clean and turn easily. Before fitting the spare

wheel, inspect the condition of the wheel and hub mounting surfaces. These

surfaces must be clean before fitting the wheel.

The hexagonal socket in the screwdriver handle makes it easier to turn the

wheel bolts when they are loose. The reversible screwdriver blade should be

removed when the tool is used for this purpose.

If tyres with a specific direction of ro tation are fitted, note the direction of

rotation.

Note

Do not use the hexagonal socket in the screwdriver handle to loosen or

tighten the wheel bolts.

Fig. 144 Wheel change:

Hexagon socket in screw-

driver handle to turn the

wheel bolts after they

have been loosened

ibiza_angles_0706_DEF Seite 205 Freitag, 1. September 2006 1:18 13

Page 208 of 268

If and when

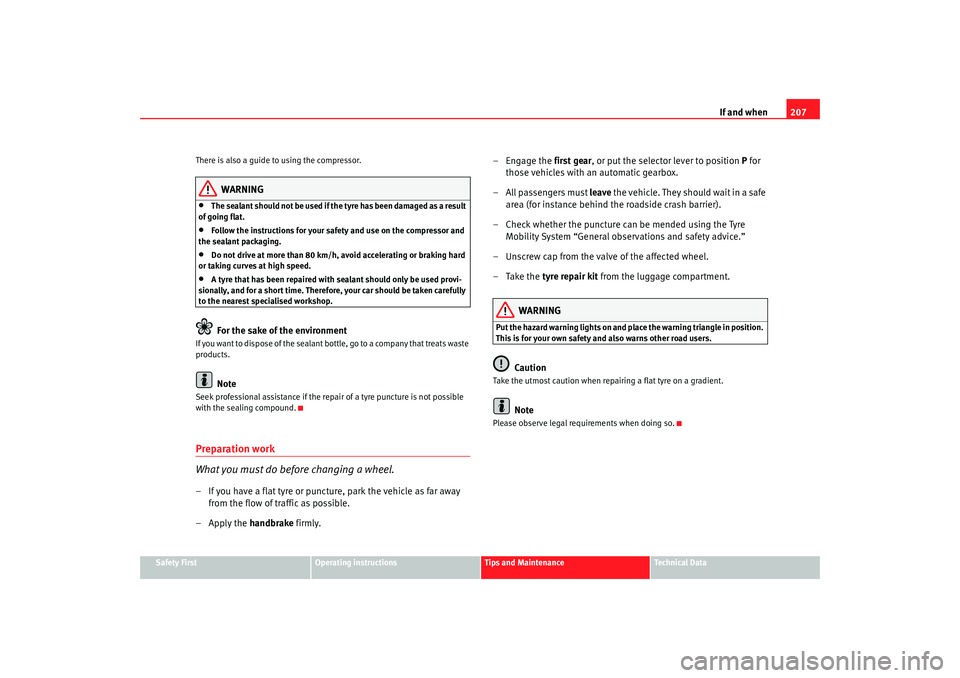

206Anti-theft wheel bolts*

A special adapter is required to turn the anti-theft wheel

bolts.– Insert the adapter onto the wheel bolt and push it on as far as it

will go ⇒fig. 145 .

– Fit the box spanner as far as it will go over the adapter.

– Loosen or tighten the wheel bolt as appropriate.Code number

The code number of the anti-theft wheel bolt is stamped on the front of the

adaptor.

The code number should be noted and kept in a safe place, as it is only by

using the code number that a duplicate adaptor can be obtained from an

Authorised Service Centre.

Tyres with directional tread pattern

Tyres with directional tread pattern must be fi tted s o tha t they

rotate in the correct direction.A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always note the direction of rotation indi-

cated when fitting the wheel. This is important so that these tyres can give

maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, in an emergency, you have to fit the spare wheel so it rotates in the wrong

direction, you must drive extremely care fully. The tyre will not give optimum

performance. This is particularly im portant when driving on wet roads.

To benefit from the advantages of tyres with this type of tread pattern, the

defective tyre should be replaced as soon as possible so that all tyres again

rotate in the correct direction.Tyre repair kit* (Tyre Mobility System)General Observations and safety adviceYour vehicle is equipped with the tyre repair kit called the Tyre mobility

system.

Beneath the floor of the stowage compartment there is a sealant and a

compressor which should be used in case of puncture.

The Tyre Mobility System will allow you to safely repair damage to a tyre by

penetration of a foreign object to 4mm diameter.

The foreign object can be left inside the tyre.

The sealant comes with instructions for use.

Fig. 145 Anti-theft wheel

bolt

ibiza_angles_0706_DEF Seite 206 Freitag, 1. September 2006 1:18 13

Page 209 of 268

If and when207

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

There is also a guide to using the compressor.

WARNING

•

The sealant should not be used if th

e tyre has been damaged as a result

of going flat.

•

Follow the instructions for your safety and use on the compressor and

the sealant packaging.

•

Do not drive at more than 80 km/h, avoid accelerating or braking hard

or taking curves at high speed.

•

A tyre that has been repaired with sealant should only be used provi-

sionally, and for a short time. Therefore, your car should be taken carefully

to the nearest specialised workshop.For the sake of the environment

If you want to dispose of the sealant bottle, go to a company that treats waste

products.

Note

Seek professional assistance if the repair of a tyre puncture is not possible

with the sealing compound.Preparation work

What you must do before changing a wheel.– If you have a flat tyre or puncture, park the vehicle as far away from the flow of traffic as possible.

–Apply the handbrake firmly. – Engage the first gear

, or put the selector lever to position P for

those vehicles with an automatic gearbox.

– All passengers must leave the vehicle. They should wait in a safe

area (for instance behind the roadside crash barrier).

– Check whether the puncture can be mended using the Tyre Mobility System “General observations and safety advice.”

– Unscrew cap from the valve of the affected wheel.

– Take the tyre repair kit from the luggage compartment.

WARNING

Put the hazard warning lights on and place the warning triangle in position.

This is for your own safety and also warns other road users.

Caution

Take the utmost caution when repairing a flat tyre on a gradient.

Note

Please observe legal requirements when doing so.

ibiza_angles_0706_DEF Seite 207 Freitag, 1. September 2006 1:18 13

Page 211 of 268

If and when209

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

steering wheel on the right the fuses are

on the right-hand side of the instru-

ment panel, behind a cover.

The electric windows are protected by circuit breakers. These reset automat-

ically after a few seconds when the overload (caused for example by frozen

windows) has been corrected.

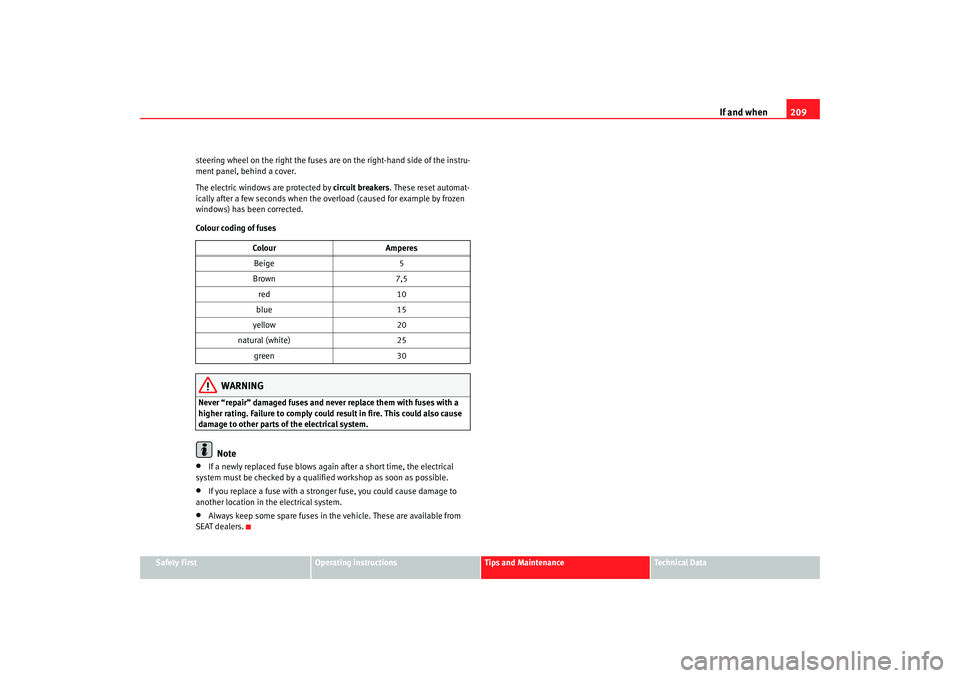

Colour coding of fuses

WARNING

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could result in fire. This could also cause

damage to other parts of the electrical system.

Note

•

If a newly replaced fuse blows again after a short time, the electrical

system must be checked by a qualified workshop as soon as possible.

•

If you replace a fuse with a stronger fuse, you could cause damage to

another location in the electrical system.

•

Always keep some spare fuses in the vehicle. These are available from

SEAT dealers. Colour

Amperes

Beige 5

Brown 7,5

red 10

blue 15

yellow 20

natural (white) 25

green 30

ibiza_angles_0706_DEF Seite 209 Freitag, 1. September 2006 1:18 13

Page 214 of 268

If and when

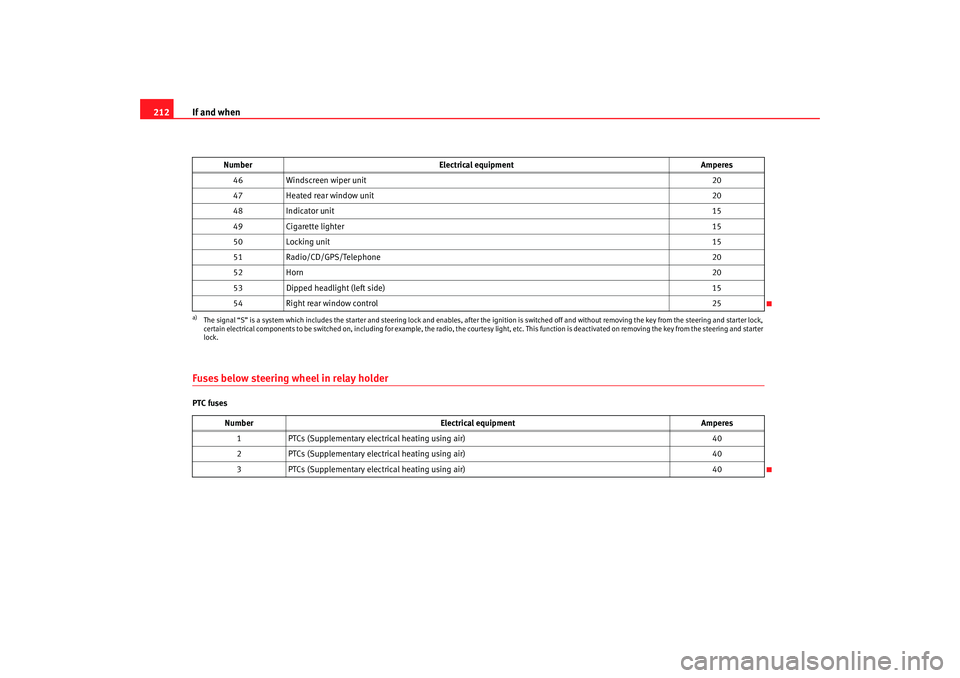

212Fuses below steering wheel in relay holderPTC fuses 46

Windscreen wiper unit 20

47 Heated rear window unit 20

48 Indicator unit 15

49 Cigarette lighter 15

50 Locking unit 15

51 Radio/CD/GPS/Telephone 20

52 Horn 20

53 Dipped headlight (left side) 15

54 Right rear window control 25a)The signal “S” is a system which includes the starter and steering lock and enables, after the ignition is switched off and wit hout removing the key from the steering and starter lock,

certain electrical components to be switched on, including for example, the radio, the courtesy light, etc. This function is de activated on removing the key from the steering and starter

lock.

Number Electrical equipment Amperes

1 PTCs (Supplementary electrical heating using air) 40

2 PTCs (Supplementary electrical heating using air) 40

3 PTCs (Supplementary electrical heating using air) 40

Number

Electrical equipment Amperes

ibiza_angles_0706_DEF Seite 212 Freitag, 1. September 2006 1:18 13

Page 231 of 268

If and when229

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Fitting the front towing eye

– First remove the right hand co ver from the lower part of the

bumper.

– Remove the bolt ⇒page 228, fig. 171 .

– Take the towing ring from the onboard tools.

– Rotate the towing ring to the left until it is completely tightened into position.

– To remove the ring, rotate it to the right.Tow-rope or tow-bar

It is easier and safer to tow a vehicle with a tow-bar. You should only use a

tow-rope if you do not have a tow-bar.

A tow-rope should be slight ly elastic to reduce the loading on both vehicles.

It is advisable to use a tow-rope made of synthetic fibre or similarly elastic

material.

Attach the tow-rope or the tow-bar only to the towing eyes provided or a

towing bracket.

Driving style

Towing requires some experience, espec ially when using a tow-rope. Both

drivers should be famili ar with the technique required for towing. Inexperi-

enced drivers should not attempt to tow-start or tow away another vehicle.

Do not pull too hard with the towing vehi cle and take care to avoid jerking the

tow-rope. When towing on an unpaved road, there is always a risk of over-

loading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the turn signals,

horn, windscreen wipers and washers. As the brake servo does not work if th

e engine is not running, you must apply

considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running, you

will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

•

Put the selector lever into position “N”.

•

Do not drive faster than 50 km/h when towing a vehicle.

•

Do not tow further than 50 km.

•

If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.Note

•

Observe legal requirements when towing or tow-starting.

•

Switch on the hazard warning lights of both vehicles. However, observe

any regulations to the contrary.

•

For technical reasons, vehicles with an automatic gearbox must not be

tow-started.

•

If damage to your vehicle means that there is no lubricant in the gearbox,

you must raise the drive wheels while the vehicle is being towed.

•

If the vehicle has to be towed more than 50 km, the front wheels must be

raised during towing, and towing should be carried out by a qualified person.

•

The steering wheel is locked when the vehicle has no electrical power. The

vehicle must then be towed with the front wheels raised. Towing should be

carried out by a qualified person.

•

The towing eye should always be kept in the vehicle. Please refer to the

notes on ⇒page 228.

AA

ibiza_angles_0706_DEF Seite 229 Freitag, 1. September 2006 1:18 13

Page 236 of 268

General notes on the technical data

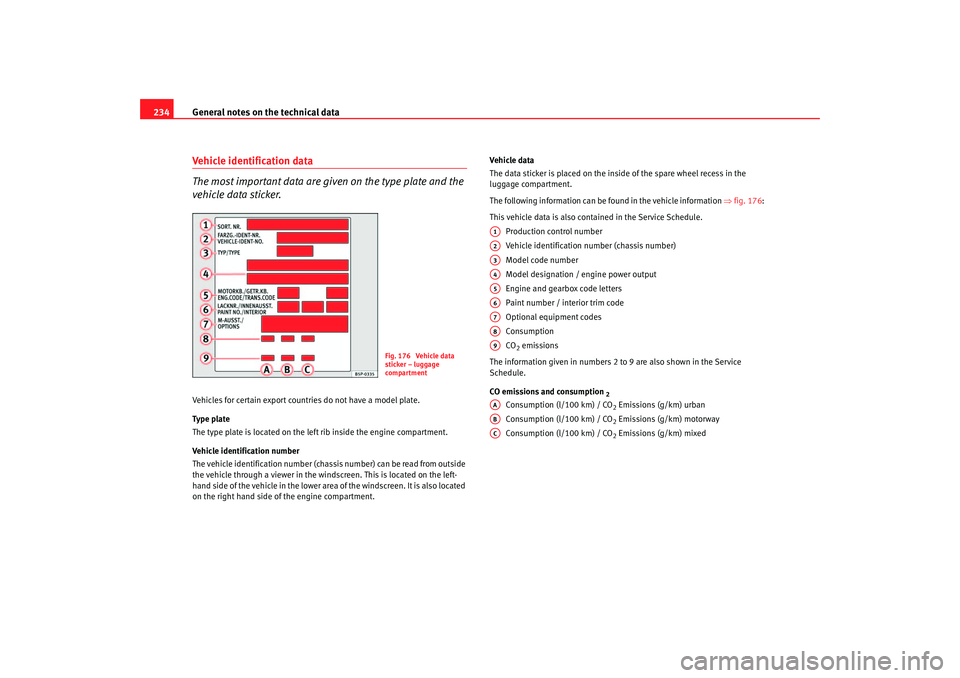

234Vehicle identification data

The most important data are given on the type plate and the

vehicle data sticker.Vehicles for certain export countries do not have a model plate.

Type plate

The type plate is located on the left rib inside the engine compartment.

Vehicle identification number

The vehicle identification number (chass is number) can be read from outside

the vehicle through a viewer in the windscreen. This is located on the left-

hand side of the vehicle in the lower area of the windscreen. It is also located

on the right hand side of the engine compartment. Vehicle data

The data sticker is placed on the inside of the spare wheel recess in the

luggage compartment.

The following information can be found in the vehicle information

⇒fig. 176 :

This vehicle data is also contained in the Service Schedule. Production control number

Vehicle identification number (chassis number)

Model code number

Model designation / engine power output

Engine and gearbox code letters

Paint number / interior trim code

Optional equipment codes

Consumption

CO2 emissions

The information given in numbers 2 to 9 are also shown in the Service

Schedule.

CO emissions and consumption

2

Consumption (l/100 km) / CO

2 Emissions (g/km) urban

Con

sumption (l/100 km) / CO

2 Emissions (g/km) motorway

Consumption (l/100 km) / CO2 Emissions (g/km) mixed

Fig. 176 Vehicle data

sticker – luggage

compartment

A1A2A3A4A5A6A7A8A9AAABAC

ibiza_angles_0706_DEF Seite 234 Freitag, 1. September 2006 1:18 13

Page 238 of 268

General notes on the technical data

236WeightsKerb weight refers to the basic model with a fuel tank filled to 90% capacity

and without optional extras. The figure quoted includes 75 kg to allow for the

weight of the driver.

For special versions and optional equipment fittings or for the addition of

accessories, the weight of the vehicle will increase ⇒.

WARNING

•

Please note that the centre of gravity may shift when transporting

heavy objects; this may affect the vehi cle's handling and lead to an acci-

dent. Always adjust your speed and dr iving style to suit road conditions

and requirements.

•

Never exceed the gross axle weight rating or the gross vehicle weight

rating. If the allowed axle load or the allowed total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

To w i n g a t r a i l e rTrailer weightsTrailer weights

The trailer weights and drawbar loads approved are selected in intensive

trials according to precisely defined criteria. The approved trailer weights are

valid for vehicles in EU for maximum speeds of 80 km/h (in certain circum-

stances up to 100 km/h). The figures may be different in other countries. All

data in the official vehicle documents take precedence over these data ⇒. Drawbar load

The

maximum permitted weight exerted by the trailer drawbar on the ball joint

of the towing bracket must not exceed 75 kg.

In the interest of road safety, we recommend that you always tow

approaching the maximum drawbar load. The response of the trailer on the

road will be poor if th e drawbar load is too small.

If the maximum permissible drawbar load cannot be met (e.g. with small,

empty and light-weight single axle trailers or tandem axle trailers with an axle

base of less than 1 metre), at least 4% of the actual trailer weight is a legal

stipulation for a drawbar load.

WARNING

•

For safety reasons, you should not drive at speeds above 80 km/h when

towing a trailer. This also applies to countries where higher speeds are

permitted.

•

Never exceed the maximum trailer weights or the draw bar loading. If

the permissible axle load or the perm issible total weight is exceeded, the

driving characteristics of the vehicle may change, leading to accidents,

injuries and damage to the vehicle.

WheelsTyre pressure, snow chains, wheel boltsTyre pressures

The sticker with the tyre pressure values can be found on the inside of the

tank flap. The tyre pressure values given there are for cold tyres. The slightly

raised pressures of warm tyres must not be reduced ⇒.

ibiza_angles_0706_DEF Seite 236 Freitag, 1. September 2006 1:18 13

Page 239 of 268

General notes on the technical data 237

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Snow chains

Snow chains are only permitted on the front wheels and only for tyres 155/80

R13; 165/70 R14 and 185/80 R14. Snow ch

ains must have fine-pitch links

which do not protrude more than 15 mm, including tension device.

Remaining tyres can be fitted with chains no thicker than 9 mm.

Wheel bolts

After the wheels have been changed, the tightening torque of the wheel bolts

should be checked as soon as possible with a torque wrench ⇒. The tight-

ening torque for steel and alloy wheels is 120 Nm.

WARNING

•

Check the tyre pressure at least once per month. Correct tyre pressure

is very important. If the tyre pressure is too high or too low, there is an

increased danger of accidents, particularly at high speeds.

•

If the torque of the wheel bolts is too low, they could loosen whilst the

vehicle is in motion. Risk of accident! If the tightening torque is too high,

the wheel bolts and threads could be damaged.Note

We recommend that you ask your Authorised Service Centre for information

about appropriate wheel, tyre and snow chain size.

ibiza_angles_0706_DEF Seite 237 Freitag, 1. September 2006 1:18 13