technical specifications Seat Ibiza 5D 2011 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Ibiza 5D, Model: Seat Ibiza 5D 2011Pages: 278, PDF Size: 3.83 MB

Page 223 of 278

221

If and when

An unstable surface under the jack may cause the vehicle to slip off the

jack. Therefore, the jack must be fitted on solid ground offering good sup-

port. Use a large and stable base, if necessary. On a hard, slippery surface

(such as tiles) use a rubber mat or similar to prevent the jack from slipping.

WARNING

● Take all precautions so that the base of the jack does not slip. Failure

to do so could result in an accident.

● The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must

be completed.

Change the wheel as described below after loosening the wheel

bolts and raising the vehicle with the jack.

Removing a wheel

– Unscrew the wheel bolts using the box spanner and place them

on a clean surface.

Fitting a wheel

– Screw on the wheel bolts in position and tighten them loosely

with a box spanner.

The wheel bolts should be clean and easily screwed. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These sur-

faces must be clean before fitting the wheel. If tyres with a specific direction of rotation are fitted, note the direction of

rotation.

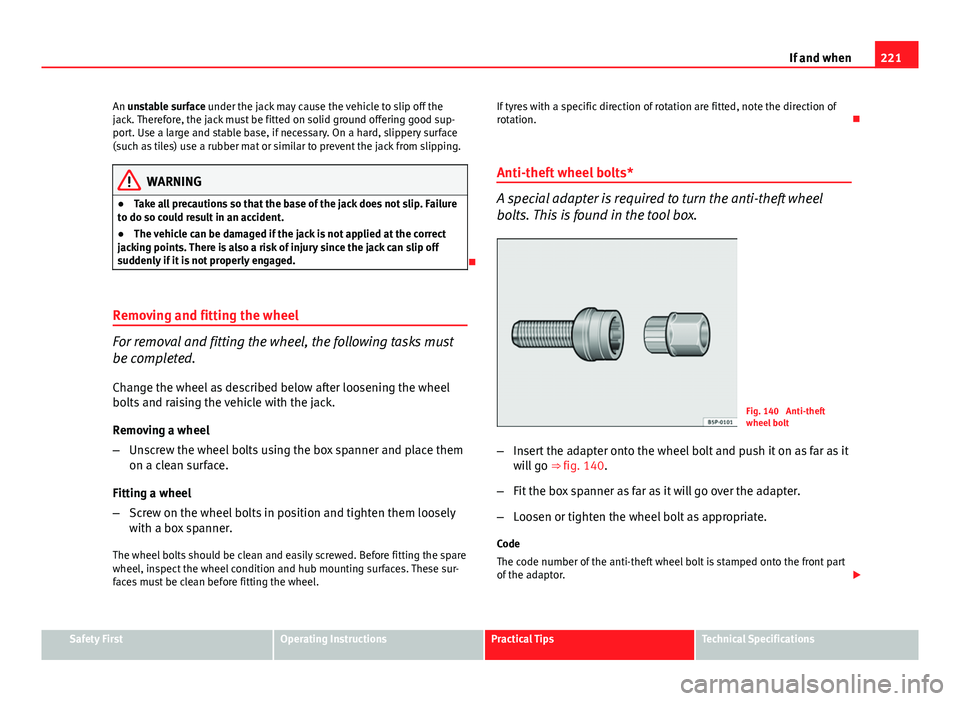

Anti-theft wheel bolts*

A special adapter is required to turn the anti-theft wheel

bolts. This is found in the tool box.

Fig. 140 Anti-theft

wheel bolt

– Insert the adapter onto the wheel bolt and push it on as far as it

will go ⇒ fig. 140.

– Fit the box spanner as far as it will go over the adapter.

– Loosen or tighten the wheel bolt as appropriate.

Code

The code number of the anti-theft wheel bolt is stamped onto the front part

of the adaptor.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 225 of 278

223

If and when

Note

● If sealant should leak out, leave it to dry. This way you can pull it off like

a piece of foil.

● Observe the expiry date stated on the sealing compound can. Have the

sealing compound exchanged by a specialised workshop.

● Seek professional assistance if the repair of a tyre puncture is not possi-

ble with the sealing compound.

What to do first

Certain steps must be taken before repairing a tyre.

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

– Apply the handbrake firmly.

– Engage first gear , or put the selector lever to position P.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Check whether a repair is possible using the Tyre Mobility Sys-

tem “General information and safety notes.”

– Unscrew inflation cap from the affected wheel.

– Take the tyre repair kit out of the luggage compartment.

WARNING

Switch on the hazard warning lights and place the warning triangles in

position. This is for your own safety and also warns other road users.

CAUTION

Take special care if you have to repair a tyre on a slope.

Note

● Please observe legal requirements when doing so.

● Remember to replace the sealing compound as soon as possible.

Tyre repair

The following sections describe the procedures for repairing

a tyre.

Using the sealing compound

– The instructions on the container give detailed information on

how to use the sealing compound.

Inflating the tyre.

– Remove the air compressor and hose from the container.

– Screw the retaining nut onto the valve.

– Plug the compressor cable into a 12 volt power point.

– Turn on compressor and monitor the pressure shown on the

pressure gauge.

Completing the repair

– Remove the compressor hose from the valve.

– Fit the valve cap.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 227 of 278

225

If and when

Note

● If a newly replaced fuse blows again after a short time, the electrical sys-

tem must be checked by a specialised workshop as soon as possible.

● If you replace a fuse with higher-rating fuse, you could cause damage to

another location in the electrical system.

● Always keep some spare fuses in the vehicle. These are available from

SEAT dealers.

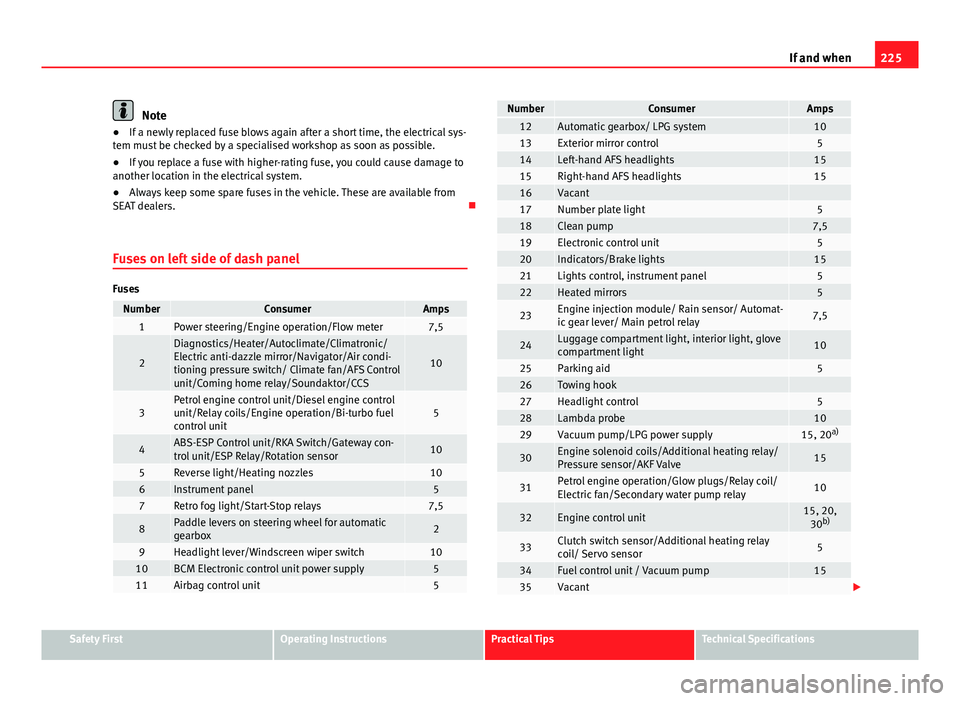

Fuses on left side of dash panel

Fuses

NumberConsumerAmps1Power steering/Engine operation/Flow meter7,5

2

Diagnostics/Heater/Autoclimate/Climatronic/

Electric anti-dazzle mirror/Navigator/Air condi-

tioning pressure switch/ Climate fan/AFS Control

unit/Coming home relay/Soundaktor/CCS

10

3Petrol engine control unit/Diesel engine control

unit/Relay coils/Engine operation/Bi-turbo fuel

control unit5

4ABS-ESP Control unit/RKA Switch/Gateway con-

trol unit/ESP Relay/Rotation sensor10

5Reverse light/Heating nozzles106Instrument panel57Retro fog light/Start-Stop relays7,5

8Paddle levers on steering wheel for automatic

gearbox2

9Headlight lever/Windscreen wiper switch1010BCM Electronic control unit power supply511Airbag control unit5

NumberConsumerAmps12Automatic gearbox/ LPG system1013Exterior mirror control514Left-hand AFS headlights1515Right-hand AFS headlights1516Vacant 17Number plate light518Clean pump7,519Electronic control unit520Indicators/Brake lights1521Lights control, instrument panel522Heated mirrors5

23Engine injection module/ Rain sensor/ Automat-

ic gear lever/ Main petrol relay7,5

24Luggage compartment light, interior light, glove

compartment light10

25Parking aid526Towing hook 27Headlight control528Lambda probe1029Vacuum pump/LPG power supply15, 20 a)

30Engine solenoid coils/Additional heating relay/

Pressure sensor/AKF Valve15

31Petrol engine operation/Glow plugs/Relay coil/

Electric fan/Secondary water pump relay10

32Engine control unit15, 20,

30 b)

33Clutch switch sensor/Additional heating relay

coil/ Servo sensor5

34Fuel control unit / Vacuum pump1535Vacant

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 229 of 278

227

If and when

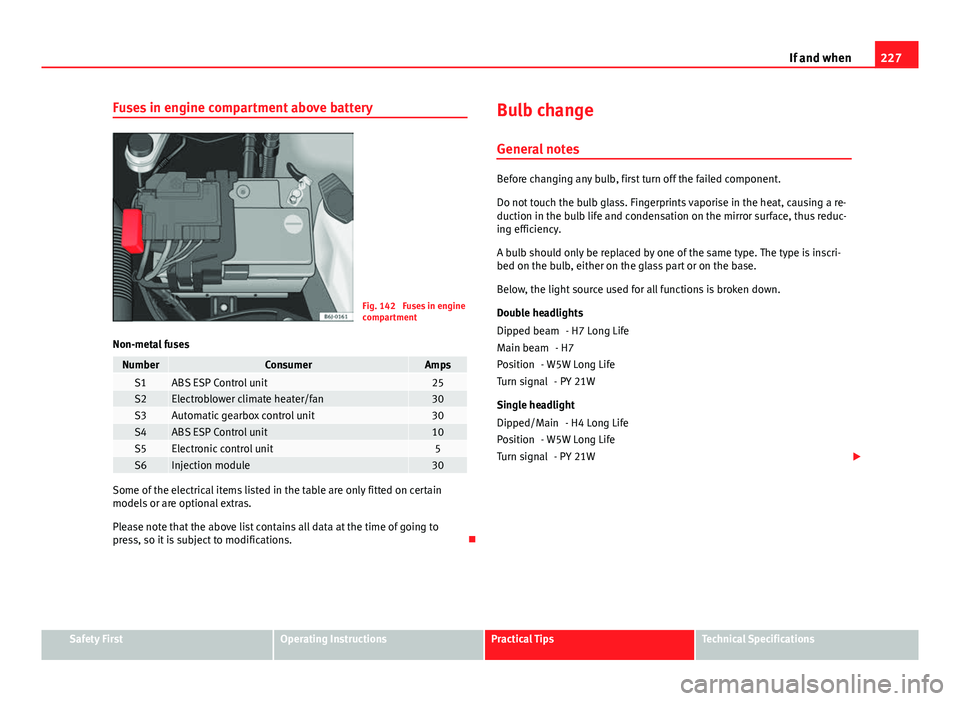

Fuses in engine compartment above battery

Fig. 142 Fuses in engine

compartment

Non-metal fuses

NumberConsumerAmpsS1ABS ESP Control unit25S2Electroblower climate heater/fan30S3Automatic gearbox control unit30S4ABS ESP Control unit10S5Electronic control unit5S6Injection module30

Some of the electrical items listed in the table are only fitted on certain

models or are optional extras.

Please note that the above list contains all data at the time of going to

press, so it is subject to modifications. Bulb change

General notes

Before changing any bulb, first turn off the failed component.

Do not touch the bulb glass. Fingerprints vaporise in the heat, causing a re-

duction in the bulb life and condensation on the mirror surface, thus reduc-

ing efficiency.

A bulb should only be replaced by one of the same type. The type is inscri-

bed on the bulb, either on the glass part or on the base.

Below, the light source used for all functions is broken down.

Double headlights - H7 Long Life

- H7

- W5W Long Life - PY 21W

Single headlight - H4 Long Life

- W5W Long Life - PY 21W

Dipped beam

Main beam

Position

Turn signal

Dipped/Main

Position

Turn signal

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 231 of 278

229

If and when

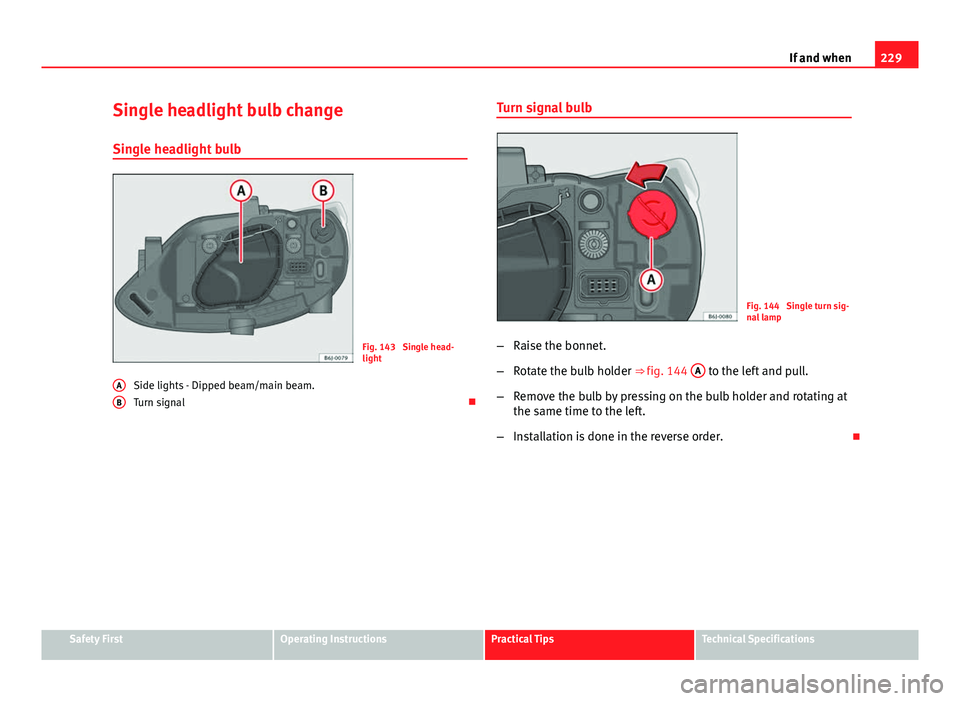

Single headlight bulb change

Single headlight bulb

Fig. 143 Single head-

light

Side lights - Dipped beam/main beam.

Turn signal

A

B

Turn signal bulb

Fig. 144 Single turn sig-

nal lamp

– Raise the bonnet.

– Rotate the bulb holder ⇒ fig. 144 A

to the left and pull.

– Remove the bulb by pressing on the bulb holder and rotating at

the same time to the left.

– Installation is done in the reverse order.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 233 of 278

231

If and when

– Move the loop ⇒ fig. 145 1

in the direction of the arrow and

remove the cover.

– Remove the bulb holder 4

⇒ fig. 147 outwards.

– Replace the bulb by pulling it out and inserting the replace-

ment.

– Installation is done in the reverse order.

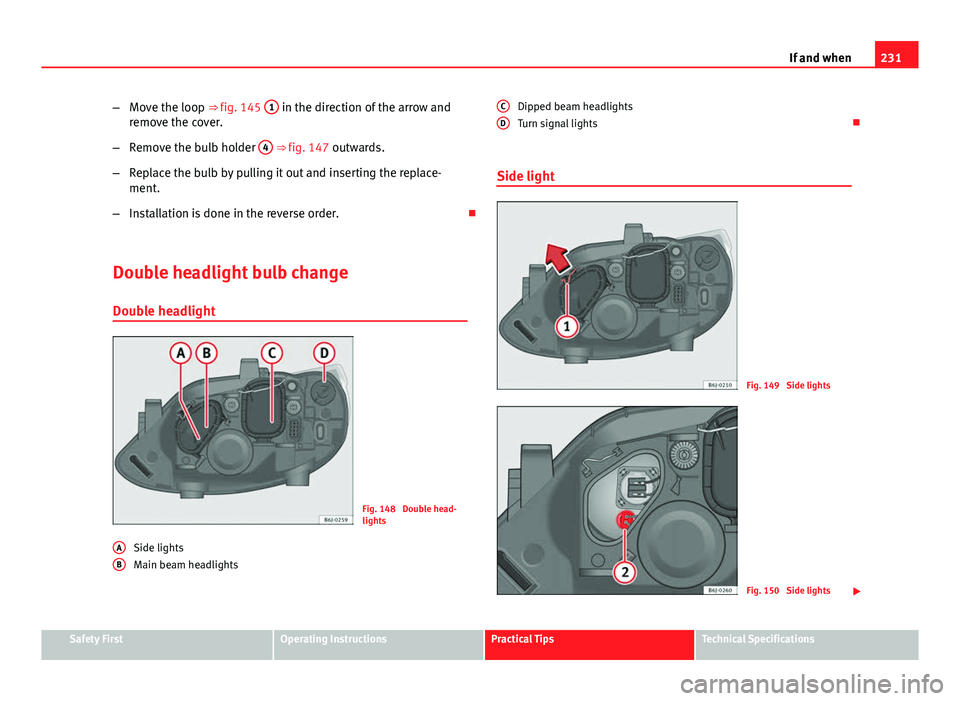

Double headlight bulb change Double headlight

Fig. 148 Double head-

lights

Side lights

Main beam headlights

A

B

Dipped beam headlights

Turn signal lights

Side light

Fig. 149 Side lights

Fig. 150 Side lights

C

D

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 235 of 278

233

If and when

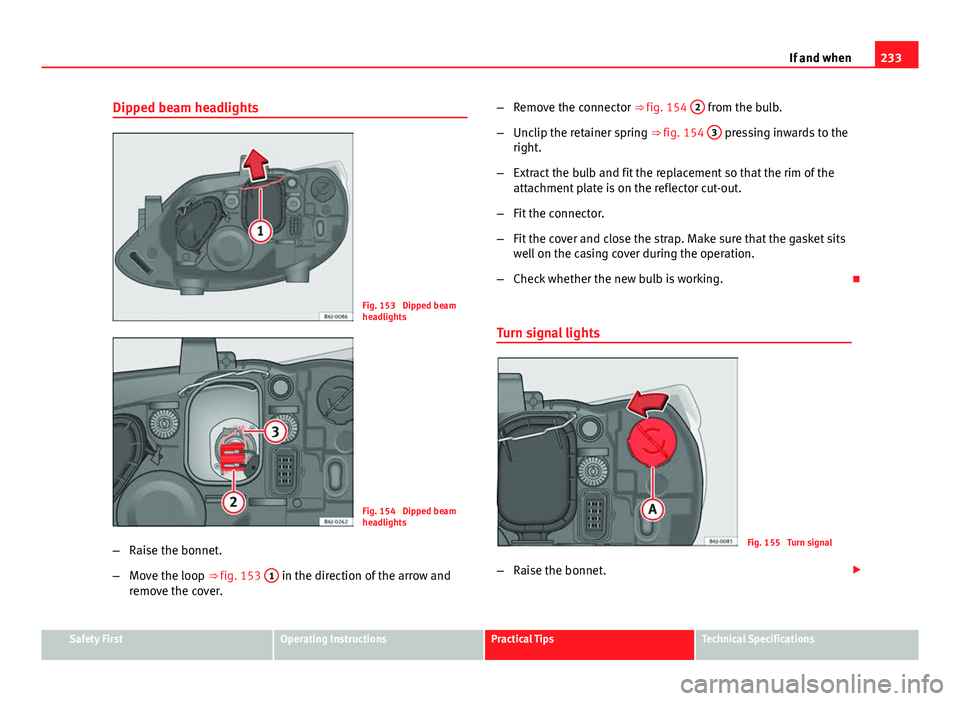

Dipped beam headlights

Fig. 153 Dipped beam

headlights

Fig. 154 Dipped beam

headlights

– Raise the bonnet.

– Move the loop ⇒ fig. 153 1

in the direction of the arrow and

remove the cover. –

Remove the connector ⇒ fig. 154 2

from the bulb.

– Unclip the retainer spring ⇒ fig. 154 3

pressing inwards to the

right.

– Extract the bulb and fit the replacement so that the rim of the

attachment plate is on the reflector cut-out.

– Fit the connector.

– Fit the cover and close the strap. Make sure that the gasket sits

well on the casing cover during the operation.

– Check whether the new bulb is working.

Turn signal lights

Fig. 155 Turn signal

– Raise the bonnet.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 237 of 278

235

If and when

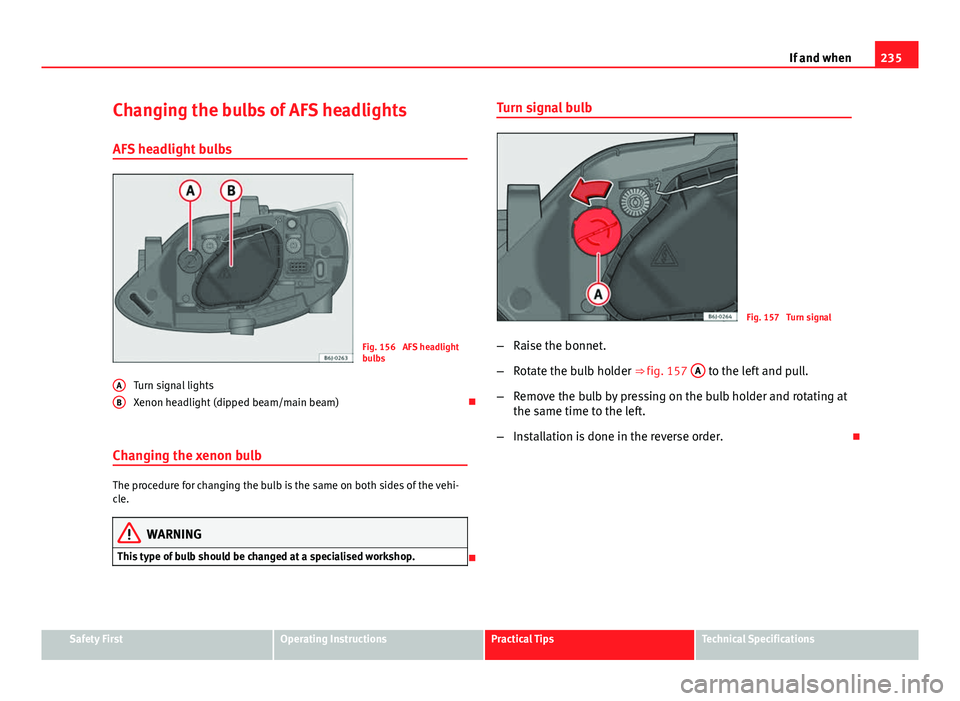

Changing the bulbs of AFS headlights

AFS headlight bulbs

Fig. 156 AFS headlight

bulbs

Turn signal lights

Xenon headlight (dipped beam/main beam)

Changing the xenon bulb

The procedure for changing the bulb is the same on both sides of the vehi-

cle.

WARNING

This type of bulb should be changed at a specialised workshop.

A

B

Turn signal bulb

Fig. 157 Turn signal

– Raise the bonnet.

– Rotate the bulb holder ⇒ fig. 157 A

to the left and pull.

– Remove the bulb by pressing on the bulb holder and rotating at

the same time to the left.

– Installation is done in the reverse order.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 239 of 278

237

If and when

– Installation is done in the reverse order.

– Check that the bulb functions.

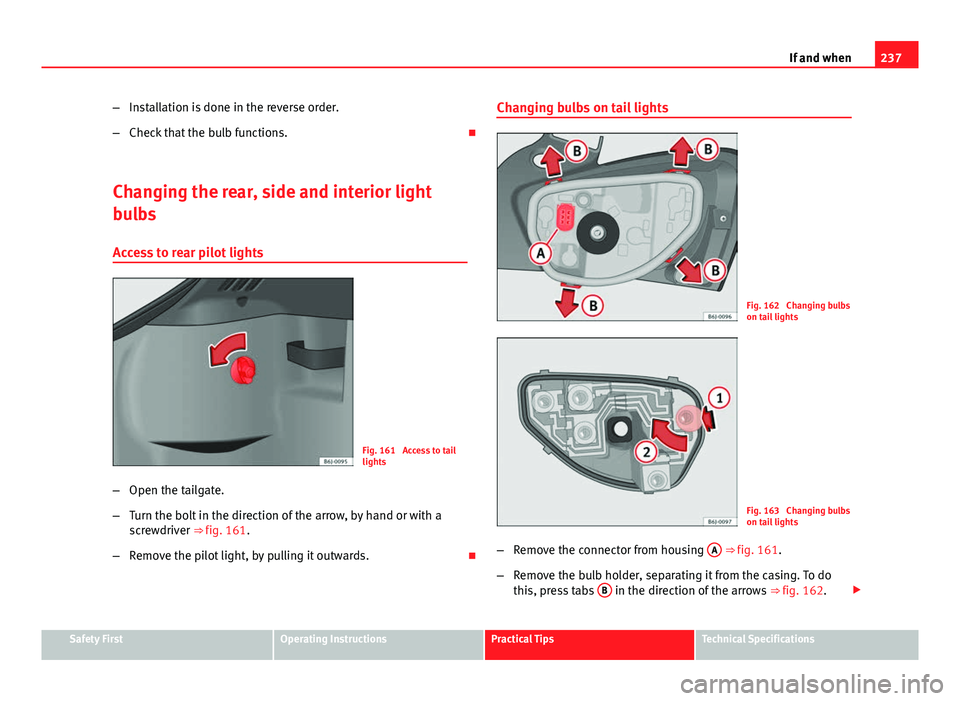

Changing the rear, side and interior light

bulbs Access to rear pilot lights

Fig. 161 Access to tail

lights

– Open the tailgate.

– Turn the bolt in the direction of the arrow, by hand or with a

screwdriver ⇒ fig. 161.

– Remove the pilot light, by pulling it outwards. Changing bulbs on tail lights

Fig. 162 Changing bulbs

on tail lights

Fig. 163 Changing bulbs

on tail lights

– Remove the connector from housing A

⇒ fig. 161.

– Remove the bulb holder, separating it from the casing. To do

this, press tabs B

in the direction of the arrows

⇒ fig. 162.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 241 of 278

239

If and when

– Carefully remove the glass, levering it to avoid possible dam-

age.

To replace the bulbs

– Pull the bulbs outwards.

– To remove the central bulb, hold and press to one side.

Assembly

– Proceed in the reverse order, pressing gently on the outer edge

of the side light.

– First fit the glass with the fastening tabs over the frame of the

switch. Next press the front part until the two long tabs click on

the support.

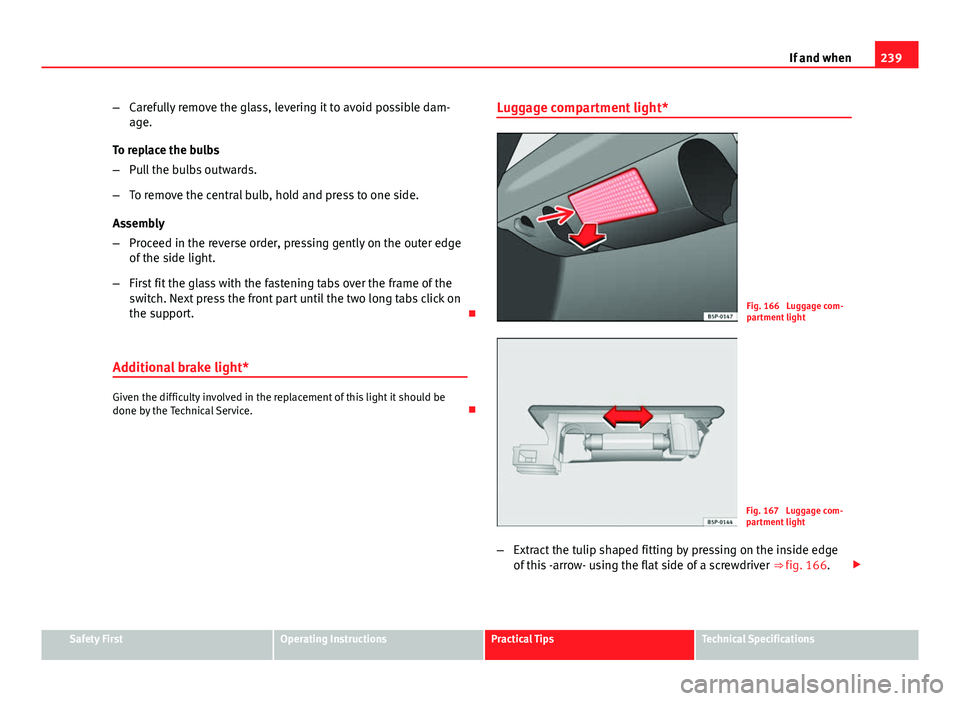

Additional brake light*

Given the difficulty involved in the replacement of this light it should be

done by the Technical Service. Luggage compartment light*

Fig. 166 Luggage com-

partment light

Fig. 167 Luggage com-

partment light

– Extract the tulip shaped fitting by pressing on the inside edge

of this -arrow- using the flat side of a screwdriver ⇒ fig. 166.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications