technical specifications Seat Ibiza ST 2011 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Ibiza ST, Model: Seat Ibiza ST 2011Pages: 280, PDF Size: 4.01 MB

Page 205 of 280

203

Checking and refilling levels

Vehicles with diesel particulate filter*

The “Maintenance Programme” states whether your vehicle is fitted with a

diesel particulate filter.

Only VW 507 00 engine oil, with reduced ash formation, may be used in die-

sel engines equipped with particulate filter. Using other types of oil will

cause a higher soot concentration and reduce the life of the DPF. Therefore:

● Avoid mixing this oil with other engine oils.

● Only in exceptional circumstances, if the engine oil level is too low

⇒ page 203 and you cannot obtain the oil specified for your vehicle, you

can use a small quantity of oil (once) conforming to the VW 506 00,

VW 506 01, VW 505 00, VW 505 01 or ACEA B3 / ACEA B4 specification. (up

to 0.5 l).

Oil properties

Engine typeSpecificationPetrol without flexible service in-

tervalVW 502 00/ VW 504 00

Petrol with flexible service inter-

val (LongLife)VW 504 00

Diesel. Engines without Particu-

late filter (DPF)VW 505 01 / VW 506 01 / VW 507 00

Diesel. Particulate Filter Engines

(DPF).

With or without flexible service

interval (with and without Long-

life) a)VW 507 00

a)

Only use recommended oils, otherwise you may damage the engine. Engine oil additives

No type of additive should be mixed with the engine oil. The deterioration

caused by these additives is not covered by the warranty.

Note

Before a long trip, we recommend finding an engine oil that conforms to the

corresponding VW specifications and keeping it in the vehicle. This way, the

correct engine oil will always be available for a top-up if needed.

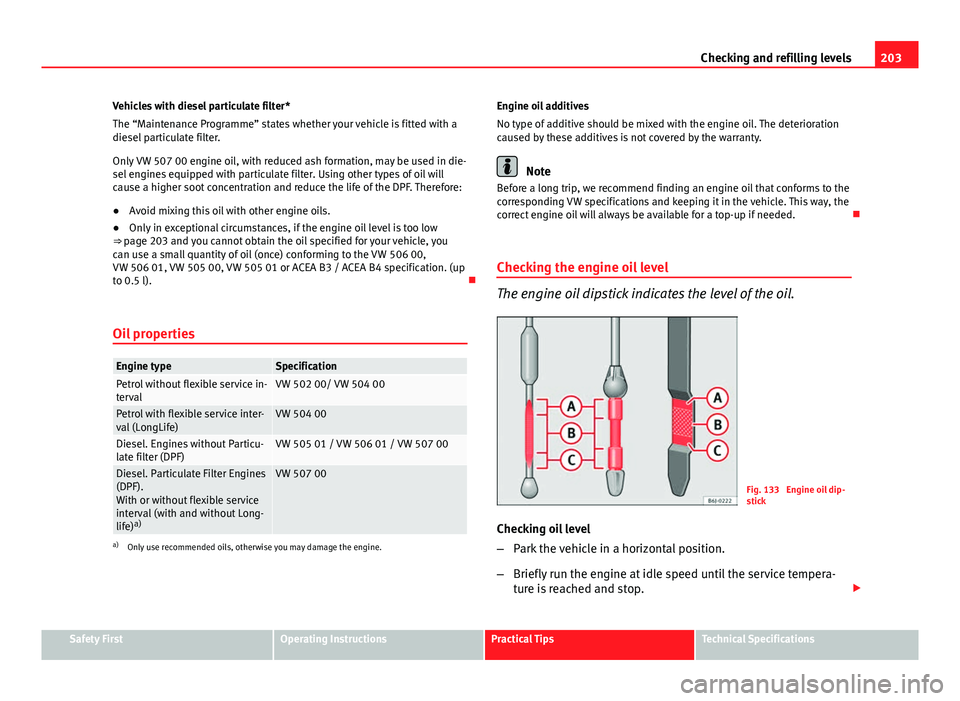

Checking the engine oil level

The engine oil dipstick indicates the level of the oil.

Fig. 133 Engine oil dip-

stick

Checking oil level

– Park the vehicle in a horizontal position.

– Briefly run the engine at idle speed until the service tempera-

ture is reached and stop.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 207 of 280

205

Checking and refilling levels

Engine oil specification ⇒ page 203.

WARNING

Oil is highly inflammable! Ensure that no oil comes into contact with hot

engine components when topping up.

CAUTION

If the oil level is above the area A do not start the engine. This could result

in damage to the engine and catalytic converter. Contact a specialised work-

shop.

For the sake of the environment

The oil level must never be above area A. Otherwise oil can be drawn in

through the crankcase breather and escape into the atmosphere via the ex-

haust system.

Changing engine oil

The engine oil must be changed at the intervals given in the

service schedule. We recommend that you have the engine oil changed by an Authorised

Service Centre.

The oil change intervals are shown in the Maintenance Programme.

WARNING

Only change the oil yourself if you have the specialist knowledge re-

quired!

● Before opening the bonnet, read and observe the warnings

⇒ page 199, Safety instructions on working in the engine compartment.

● Wait for the engine to cool down. Hot oil may cause burn injuries.

● Wear eye protection to avoid injuries caused by splashes of oil.

● When removing the oil drain plug with your fingers, keep your arm

horizontal to help prevent oil from running down your arm.

● Wash your skin thoroughly if it comes into contact with engine oil.

● Engine oil is poisonous! Used oil must be stored in a safe place out of

the reach of children.

CAUTION

No additives should be used with engine oil. This could result in engine

damage. Any damage caused by the use of such additives would not be

covered by the factory warranty.

For the sake of the environment

● Because of the disposal problems, the necessary special tools and spe-

cialist knowledge required, we recommend that you have the engine oil and

filter changed by an Authorised Service Centre.

● Never pour oil down drains or into the ground.

● Use a suitable container when draining the used oil. It must be large

enough to hold all the engine oil.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 209 of 280

207

Checking and refilling levels

Opening the coolant expansion tank

– Switch off the engine and allow it to cool.

– To prevent scalding, cover the cap on the expansion tank with a

thick cloth and carefully unscrew the cap ⇒

.

Checking coolant level

– Look into the open coolant expansion tank and read off the

coolant level.

– If the level is below the “MIN” mark, top up with coolant.

Topping up coolant

– Only use new coolant liquid.

– Do not fill above the “MAX” mark.

Closing the coolant expansion tank

– Screw the cap on again tightly.

The position of the coolant expansion reservoir is shown in the correspond-

ing engine compartment illustration ⇒ page 256.

Ensure the coolant conforms to the required specifications. Do not use a dif-

ferent type of additive if additive G 12++ is not available. In this case use

only water and bring the coolant concentration back up to the correct level

as soon as possible by putting in the specified additive.

Always top up with new coolant.

Do not fill above the “MAX” mark. Otherwise the excess coolant will be

forced out of the cooling system when the engine is hot.

The additive G 12++ can be mixed with the G 12+ in any proportion.

WARNING

Any work carried out in the engine compartment or on the engine must

be carried out cautiously.

● When working in the engine compartment, always observe the safety

warnings ⇒ page 199.

● When the engine is warm or hot, the cooling system is pressurised!

Do not unscrew the cap on the expansion tank when the engine is hot.

This is a burn injury risk.

CAUTION

● If you notice a change in the colour of the liquid because it has been in

use for a long time, it is recommended to change it, as it will have lost some

of its properties and could cause damage to the vehicle.

● If a lot of coolant fluid has been lost, wait for the engine to cool down

before putting in cold coolant. This avoids damaging the engine. Large cool-

ant losses are an indication of leaks in the cooling system. See a special-

ised workshop immediately and have the cooling system checked. Other-

wise, there is a risk of engine damage.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 211 of 280

209

Checking and refilling levels

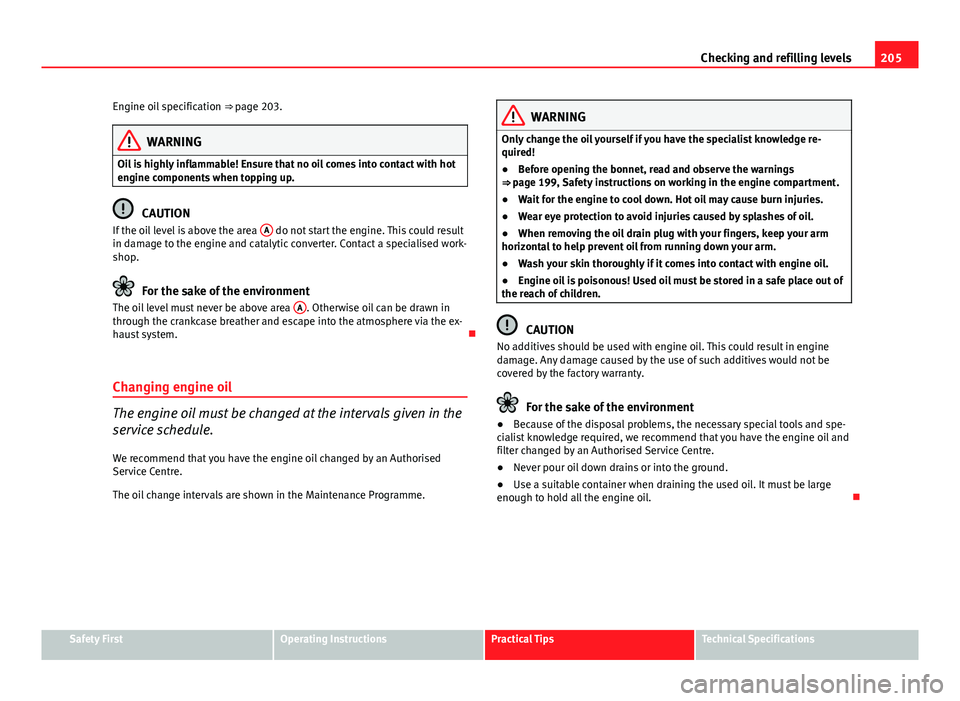

Changing windscreen wiper blades

If the windscreen wiper blades are in perfect condition, you

will benefit from an improved visibility. Damaged wiper

blades should be replaced immediately.

Fig. 137 Windscreen

wipers in service position

Fig. 138 Change wind-

screen wiper blade To change the blades it is necessary to change the rest position of

the wipers to the service position.

Do not change the windscreen wipers when out of the service posi-

tion, as it could cause paint to flake off the bonnet due to friction

with the windscreen wiper arm.

Service position (For changing wiper blades)

–

Ensure that the wiper blades are not frozen.

– Turn ignition on and off and then (before approx. 9 sec.) move

the windscreen wiper lever to the intermittent wipe position.

The windscreen wipers will move to the service position

⇒ fig. 137.

Removing the wiper blade

– Lift the windscreen wiper arm.

– Press on the securing tab ⇒ fig. 138.

– Extract the wiper blade from the wiper arm.

Fitting the wiper blade

– Insert the wiper blade onto the windscreen wiper arm until it

clicks into place.

– Place the wiper arms to their initial position.

If the windscreen wipers smear , they should be replaced if they are dam-

aged, or cleaned if they are soiled.

If this does not produce the desired results, the setting angle of the wind-

screen wiper arms might be incorrect. They should be checked by a special-

ised workshop and corrected if necessary.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 213 of 280

211

Checking and refilling levels

Removing the wiper blade

– Lift the wiper arm away from the glass ⇒ fig. 139.

– Slide the blade adapter in the direction of the arrow and remove

the blade ⇒ fig. 139.

Fitting the wiper blade

– With one hand, hold the top end of the wiper arm.

– Place the blade as shown in the ⇒ fig. 140 and slide the adapt-

er along until it engages.

Check the condition of the wiper blade regularly. Change as required.

If the windscreen wiper scrapes, it should be replaced if damaged, or

cleaned if soiled.

If this is not sufficient, refer to a specialised workshop.

WARNING

Do not drive unless you have good visibility through all windows!

● Clean the windscreen wiper blades and all windows regularly.

● The wiper blades should be changed once or twice a year.

CAUTION

● A damaged or dirty window wiper could scratch the rear window.

● Never use fuel, nail varnish remover, paint thinner or similar products to

clean the window.

● Never move the windscreen wiper by hand. This could cause damage. Brake fluid

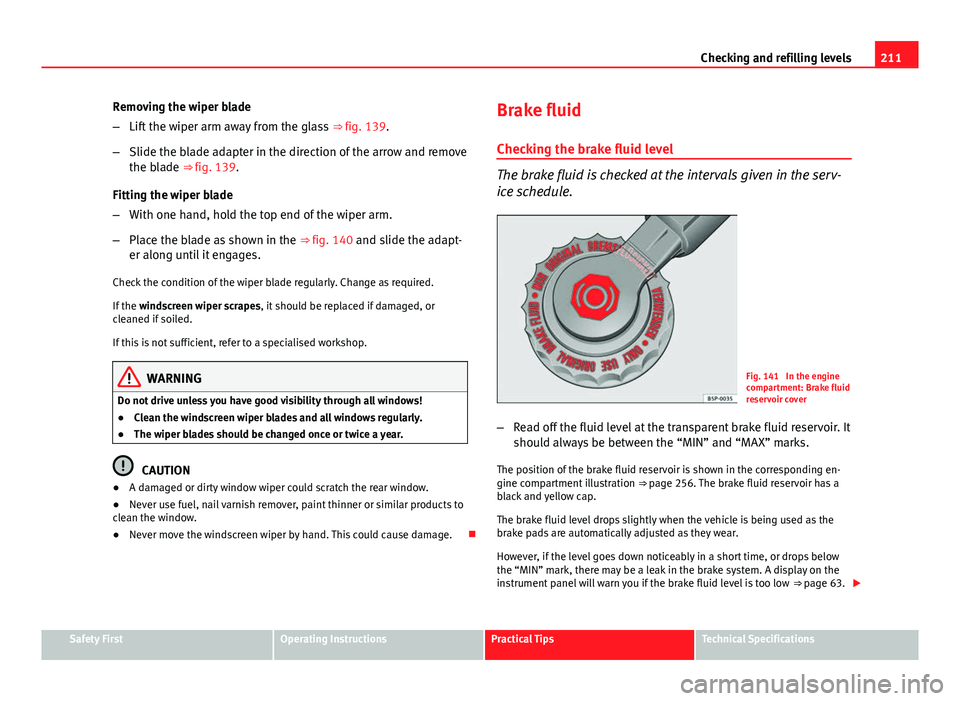

Checking the brake fluid level

The brake fluid is checked at the intervals given in the serv-

ice schedule.

Fig. 141 In the engine

compartment: Brake fluid

reservoir cover

– Read off the fluid level at the transparent brake fluid reservoir. It

should always be between the “MIN” and “MAX” marks.

The position of the brake fluid reservoir is shown in the corresponding en-

gine compartment illustration ⇒ page 256. The brake fluid reservoir has a

black and yellow cap.

The brake fluid level drops slightly when the vehicle is being used as the

brake pads are automatically adjusted as they wear.

However, if the level goes down noticeably in a short time, or drops below

the “MIN” mark, there may be a leak in the brake system. A display on the

instrument panel will warn you if the brake fluid level is too low ⇒ page 63.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 215 of 280

213

Checking and refilling levels

Vehicle battery

Warnings on handling the battery

Wear eye protection

Battery acid is very corrosive and caustic. Wear protective gloves

and eye protection!

Fires, sparks, open flames and smoking are prohibited!

A highly explosive mixture of gases is released when the battery

is under charge.

Keep children away from acid and batteries!

WARNING

Always be aware of the danger of injury and chemical burns as well as

the risk of accident or fire when working on the battery and the electrical

system:

● Wear eye protection. Protect your eyes, skin and clothing from acid

and particles containing lead.

● Battery acid is very corrosive and caustic. Wear protective gloves and

eye protection. Do not tilt the batteries. This could spill acid through the

vents. Rinse battery acid from eyes immediately for several minutes with

clear water. Then seek medical care immediately. Neutralise any acid

splashes on the skin or clothing with a soapy solution, and rinse off with

plenty of water. If acid is swallowed by mistake, consult a doctor immedi-

ately.

WARNING (Continued)

● Fires, sparks, open flames and smoking are prohibited. When han-

dling cables and electrical equipment, avoid causing sparks and electro-

static charge. Never short the battery terminals. High-energy sparks can

cause injury.

● A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.

● Keep children away from acid and batteries.

● Before working on the electrical system, you must switch off the en-

gine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bulb is changed, you need only

switch off the light.

● Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alarm will otherwise be triggered.

● When disconnecting the battery from the vehicle electrical system,

disconnect first the negative cable and then the positive cable.

● Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never re-

verse the polarity of the connections. This could cause an electrical fire.

● Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can freeze at temperatures around 0 °C.

● Ensure that the vent hose is always connected to the battery.

● Never use a defective battery. This could cause an explosion. Replace

a damaged battery immediately.

● For vehicles with the battery in the luggage compartment: Check that

the battery gas ventilation hose is securely attached.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 217 of 280

215

Checking and refilling levels

WARNING

● We recommend you use only maintenance-free or cycle free leak-proof

batteries which comply with standards T 825 06 and VW 7 50 73. This

standard applies as of 2001.

● Before starting any work on the batteries, you must read and observe

the warnings ⇒

in Warnings on handling the battery on page 213.

For the sake of the environment

Batteries contain toxic substances such as sulphuric acid and lead. They

must be disposed of appropriately and must not be disposed of with ordi-

nary household waste.

Wheels

General notes

Avoiding damage

– If you have to drive over a kerb or similar obstacle, drive very

slowly and at a right angle.

– Keep grease, oil and fuel off the tyres.

– Inspect the tyres regularly for damage (cuts, cracks or blisters,

etc.). Remove any foreign objects embedded in the treads.

Storing tyres

– When you remove the tyres, mark them in order to maintain the

same direction of rotation when they are installed again. –

When removed, the wheels and/or tyres should be stored in a

cool, dry and preferably dark location.

– Store tyres in a vertical position if they are not fitted on wheel

rims.

New tyres

New tyres must be run in ⇒ page 172.

The tread depth of new tyres may vary, according to the type and make of

tyre and the tread pattern.

Concealed damage

Damage to tyres and rims is often not readily visible. If you notice unusual

vibrations or the vehicle pulling to one side, this may indicate that one of

the tyres is damaged. The tyres should be checked immediately by an Au-

thorised Service Centre.

Tyres with directional tread pattern

An arrow on the tyre sidewall indicates the direction of rotation on tyres with

directional tread. Always observe the direction of rotation indicated when

fitting the wheel. This guarantees optimum grip and helps to avoid aqua-

planing, excessive noise and wear.

WARNING

● New tyres do not have maximum grip during the first 500 km. Drive

particularly carefully to avoid possible accidents.

● Never drive with damaged tyres. This may cause an accident.

● If you notice unusual vibrations or if the vehicle pulls to one side

when driving, stop the vehicle immediately and check the tyres for dam-

age.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 219 of 280

217

Checking and refilling levels

Wear indicators

The original tyres on your vehicle have 1.6 mm high “tread wear indicators”

⇒ fig. 142, running across the tread. Depending on the make, there will be

6 to 8 of them evenly spaced around the tyre. Markings on the tyre sidewall

(for instance the letters “TWI” or other symbols) indicate the positions of

the tread wear indicators. The minimum tread depth required by law is

1.6 mm (measured in the tread grooves next to the tread wear indicators).

Worn tyres must be replaced. Different figures may apply in export countries

⇒

.

Tyre pressure

Incorrect tyre pressure causes premature wear and could cause tyre blow-

out. For this reason, the tyre pressure should be checked at least once per

month ⇒ page 216.

Driving style

Fast cornering, heavy acceleration and hard braking all increase tyre wear.

Changing wheels around

If the front tyres are worn considerably more than the rear ones it is advisa-

ble to change them around as shown ⇒ fig. 143. All the tyres will then last

for about the same time.

Wheel balance

The wheels on new vehicles are balanced. However, various factors encoun-

tered in normal driving can cause them to become unbalanced, which re-

sults in steering vibration.

Unbalanced wheels should be rebalanced, as they otherwise cause exces-

sive wear on steering, suspension and tyres. A wheel must also be reba-

lanced when a new tyre is fitted.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive tyre wear, impairing the safety

of the vehicle. If tyres show excessive wear, you should have the wheel

alignment checked by an Authorised Service Centre.

WARNING

There is a serious danger of accidents if a tyre bursts during driving!

● The tyres must be replaced at the latest when the tread wear indica-

tors are worn ⇒ page 217. Failure to do so could result in an accident.

Worn tyres do not grip well at high speeds on wet roads. There is also a

greater risk of aquaplaning.

● At continuously high speeds, a tyre with insufficient pressure flexes

more. This causes it to overheat. This can cause tread separation and tyre

blow-out. Risk of accident. Always observe the recommended tyre pres-

sures.

● If tyres show excessive wear, you should have the running gear

checked by an Authorised Service Centre.

● Keep chemicals such as oil, fuel and brake fluid away from tyres.

● Damaged wheels and tyres must be replaced immediately!

For the sake of the environment

Under-inflated tyres will increase fuel consumption.

New tyres and wheels

New tyres and wheels have to be run in.

The tyres and wheel rims are an essential part of the vehicle's design. The

tyres and rims approved by SEAT are specially matched to the characteris-

tics of the vehicle and make a major contribution to good road holding and

safe handling ⇒

.

Tyres should be replaced at least in pairs and not individually (i.e. both front

tyres or both rear tyres together). A knowledge of tyre designations makes it

easier to choose the correct tyres. Radial tyres have the tyre designations

marked on the sidewall, for example:

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 221 of 280

219

Checking and refilling levels

Wheel bolts

Wheel bolts must be tightened to the correct torque.

The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped

bolt heads must be used. This ensures that wheels are fitted securely and

that the brake system functions correctly.

In certain circumstances, you should not use wheel bolts from a different

vehicle, even if it is the same model ⇒ page 189.

WARNING

If the wheel bolts are not tightened correctly, the wheel could become

loose while driving. Risk of accident.

● The wheel bolts must be clean and turn easily. Never apply grease or

oil to them.

● Use only wheel bolts which belong to the wheel.

● If the prescribed torque of the wheel bolts is too low, they could loos-

en whilst the vehicle is in motion. Risk of accident! If the tightening tor-

que is too high, the wheel bolts and threads can be damaged.

CAUTION

The prescribed torque for wheel bolts for steel and alloy wheels is 120 Nm. Winter tyres

Winter tyres will improve the vehicles handling on snow and

ice.

In winter conditions winter tyres will considerably improve the vehicle's han-

dling. The design of summer tyres (width, rubber compound, tread pattern)

gives less grip on ice and snow.

Winter tyres must be inflated to a pressure 0.2 bar higher than the pres-

sures specified for summer tyres (see sticker on tank flap).

Winter tyres must be fitted on all four wheels.

Information on permitted winter tyre sizes can be found in the vehicle's reg-

istration documents. Use only radial winter tyres. All tyre sizes listed in the

vehicle documentation also apply to winter tyres.

Winter tyres lose their effectiveness when the tread is worn down to a depth

of 4 mm.

The speed rating code ⇒ page 217, New tyres and wheels determines the

following speed limits for winter tyres: ⇒

Qmax. 160 km/hSmax. 180 km/hTmax. 190 km/hHmax. 210 km/h

In some countries, vehicles which can exceed the speed rating of the fitted

tyre must have an appropriate sticker in the driver's field of view. These

stickers are available from your Authorised Service Centre. The legal require-

ments of each country must be followed.

Do not have winter tyres fitted for unnecessarily long periods. Vehicles with

summer tyres handle better when the roads are free of snow and ice.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 223 of 280

221

If and when

If and when

Vehicle tools, spare wheel

Vehicle Tools

The vehicle onboard tools are located under the floor panel

in the luggage compartment.

– Lift floor panel

– Take the on-board tools out of the vehicle.

The tool kit includes:

● Jack*

● Hook to remove integral* trim and screw caps.

● Box spanner for wheel bolts*

● Towing ring*

● Adapter for the anti-theft wheel bolts*

Some of the items listed are only provided in certain model versions, or are

optional extras.

WARNING

● The factory-supplied jack is only designed for changing wheels on

this model. On no account attempt to use it for lifting heavier vehicles or

other loads. Risk of injury.

● Use the jack only on a firm, level ground.

WARNING (Continued)

● Never start the engine when the vehicle is on the jack. Risk of acci-

dent.

● If work is to be carried out underneath the vehicle, this must be se-

cured by suitable means. Otherwise, there is a risk of injury.

Spare wheel (emergency wheel)*

The spare wheel (emergency wheel) must only be used for

the minimum necessary time. The temporary spare wheel is stored under the floor panel in the luggage

compartment and is attached by a thumbnut.

How to use the temporary spare wheel

If you ever have a punctured tyre or loss of pressure, the emergency wheel

is only intended for temporary use until you reach a workshop. Change it for

a duty wheel as soon as possible.

Please note the following restrictions when using the temporary spare

wheel. This spare wheel has been specially designed for your vehicle, thus,

it cannot be changed with the spare wheel from another vehicle.

No other type of tyre (normal summer or winter tyre) may be fitted on the

compact temporary spare wheel rim.

Snow chains

For technical reasons, snow chains must not be used on the compact tem-

porary spare wheel.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications