warning Seat Ibiza ST 2011 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2011, Model line: Ibiza ST, Model: Seat Ibiza ST 2011Pages: 280, PDF Size: 4.01 MB

Page 222 of 280

220Checking and refilling levels

If you have a flat tyre, please refer to the notes on the spare wheel

⇒ page 217, New tyres and wheels.

WARNING

The maximum speed for the winter tyres must not be exceeded. Other-

wise, this could lead to tyre damage and risk of accident.

For the sake of the environment

Fit your summer tyres again as soon as possible. They are quieter, do not

wear so quickly and reduce fuel consumption.

Snow chains

Snow chains may be fitted only to the front wheels, and only for the follow-

ing tyres:

175/70R14

185/60R15Chains with links not exceeding 15 mm (including the chain

closure)

215/45R16Chains with links not exceeding 9 mm (including the chain

closure)

215/40R17Chains with links not exceeding 7 mm (including the chain

closure)

Remove wheel hub covers and trim rings before fitting snow chains. For

safety reasons cover caps, available in any Authorised Service Centre, must

then be fitted over the wheel bolts.

WARNING

Snow chains should be correctly tightened in accordance with the manu-

facturer's instructions. This will prevent the chains coming into contact

with the wheel housing.

CAUTION

Remove the snow chains to drive on roads without snow. Otherwise they

will impair handling, damage the tyres and wear out very quickly.

Note

In some countries, the speed limit for using snow chains is 50 km/h. The

legal requirements of the country should be followed.

Page 223 of 280

221

If and when

If and when

Vehicle tools, spare wheel

Vehicle Tools

The vehicle onboard tools are located under the floor panel

in the luggage compartment.

– Lift floor panel

– Take the on-board tools out of the vehicle.

The tool kit includes:

● Jack*

● Hook to remove integral* trim and screw caps.

● Box spanner for wheel bolts*

● Towing ring*

● Adapter for the anti-theft wheel bolts*

Some of the items listed are only provided in certain model versions, or are

optional extras.

WARNING

● The factory-supplied jack is only designed for changing wheels on

this model. On no account attempt to use it for lifting heavier vehicles or

other loads. Risk of injury.

● Use the jack only on a firm, level ground.

WARNING (Continued)

● Never start the engine when the vehicle is on the jack. Risk of acci-

dent.

● If work is to be carried out underneath the vehicle, this must be se-

cured by suitable means. Otherwise, there is a risk of injury.

Spare wheel (emergency wheel)*

The spare wheel (emergency wheel) must only be used for

the minimum necessary time. The temporary spare wheel is stored under the floor panel in the luggage

compartment and is attached by a thumbnut.

How to use the temporary spare wheel

If you ever have a punctured tyre or loss of pressure, the emergency wheel

is only intended for temporary use until you reach a workshop. Change it for

a duty wheel as soon as possible.

Please note the following restrictions when using the temporary spare

wheel. This spare wheel has been specially designed for your vehicle, thus,

it cannot be changed with the spare wheel from another vehicle.

No other type of tyre (normal summer or winter tyre) may be fitted on the

compact temporary spare wheel rim.

Snow chains

For technical reasons, snow chains must not be used on the compact tem-

porary spare wheel.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 224 of 280

222If and when

If you have a puncture on one of the front wheels when using snow chains,

fit the compact temporary spare in place of one of the rear wheels. You can

then attach the snow chains to the wheel taken from the rear and use this

wheel to replace the punctured front wheel.

WARNING

● The tyre pressures must be checked and corrected as soon as possi-

ble.

● Do not drive faster than 80 km/h. Higher speeds can cause an acci-

dent.

● Avoid heavy acceleration, hard braking and fast cornering. Risk of ac-

cident.

● Never use two or more compact spare tyres at the same time, risk of

accident.

● No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.

Tyre repair kit*

The tyre repair kit (for vehicles not including a spare wheel)

is stored under the floor panel in the luggage compartment. Your vehicle is equipped with the Tyre Mobility System “Tyre repair kit”.

The tyre repair kit consists of a container with sealing compound to repair

the puncture and a compressor to generate the required tyre pressure. The

kit will reliably seal punctures up to a size of about 4 mm caused by the

penetration of a foreign body into the tyre.

Note

● Seek professional assistance if the repair of a tyre puncture is not possi-

ble with the sealing compound. Wheel change

Preparation work

What you must do before changing a wheel.

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible. Choose a location that is as

level as possible.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Switch the engine off. Switch the hazard warning lights on and

place the warning triangles in position.

– Apply the handbrake firmly.

– Engage the first gear , or put the selector lever to position P for

those vehicles with an automatic gearbox.

– If you are towing a trailer, unhitch it from your vehicle.

– Take the vehicle tools and the spare wheel out of the luggage

compartment.

WARNING

Switch on the hazard warning lights and place the warning triangles in

position. This is for your own safety and also warns other road users.

Page 227 of 280

225

If and when

WARNING

Loosen the wheel bolts only about one turn before raising the vehicle

with the jack, otherwise there is a risk of accident.

Note

● If the wheel bolt is very tight, you may be able to loosen it by pushing

down the end of the spanner carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

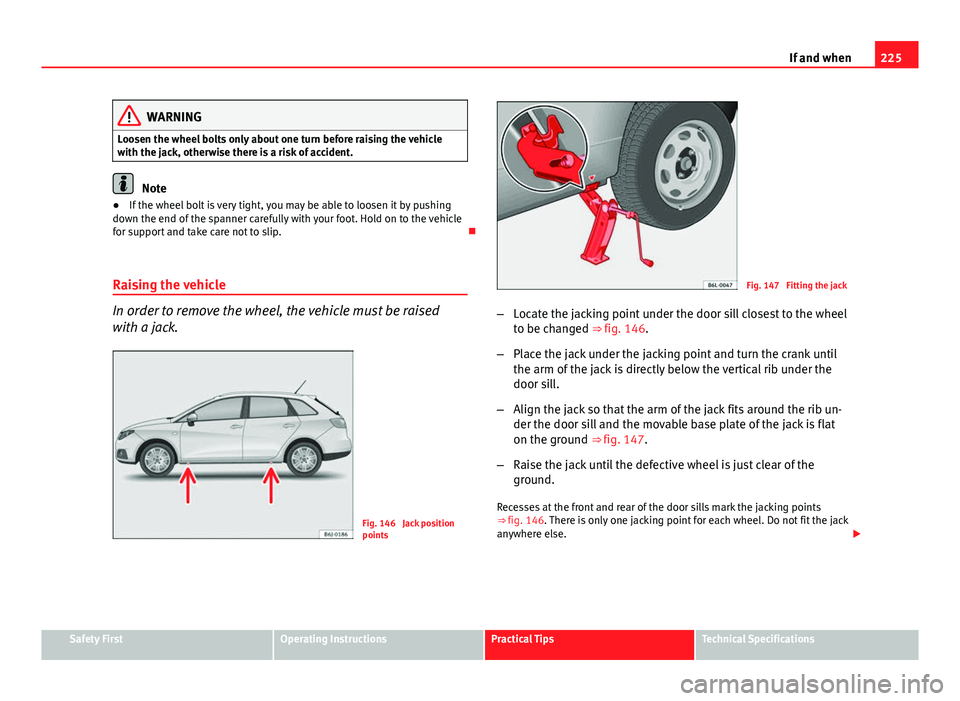

Raising the vehicle

In order to remove the wheel, the vehicle must be raised

with a jack.

Fig. 146 Jack position

points

Fig. 147 Fitting the jack

– Locate the jacking point under the door sill closest to the wheel

to be changed ⇒ fig. 146.

– Place the jack under the jacking point and turn the crank until

the arm of the jack is directly below the vertical rib under the

door sill.

– Align the jack so that the arm of the jack fits around the rib un-

der the door sill and the movable base plate of the jack is flat

on the ground ⇒ fig. 147.

– Raise the jack until the defective wheel is just clear of the

ground.

Recesses at the front and rear of the door sills mark the jacking points

⇒ fig. 146. There is only one jacking point for each wheel. Do not fit the jack anywhere else.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 228 of 280

226If and when

An unstable surface under the jack may cause the vehicle to slip off the

jack. Therefore, the jack must be fitted on solid ground offering good sup-

port. Use a large and stable base, if necessary. On a hard, slippery surface

(such as tiles) use a rubber mat or similar to prevent the jack from slipping.

WARNING

● Take all precautions so that the base of the jack does not slip. Failure

to do so could result in an accident.

● The vehicle can be damaged if the jack is not applied at the correct

jacking points. There is also a risk of injury since the jack can slip off

suddenly if it is not properly engaged.

Removing and fitting the wheel

For removal and fitting the wheel, the following tasks must

be completed.

After loosening the wheel bolts and raising the vehicle with the

jack, change the wheel as described below:

Removing a wheel

– Unscrew the wheel bolts using the box spanner and place them

on a clean surface.

Fitting a wheel

– Screw on the wheel bolts and tighten slightly with the box

spanner.

The wheel bolts should be clean and easily screwed. Before fitting the spare

wheel, inspect the wheel condition and hub mounting surfaces. These sur-

faces must be clean before fitting the wheel. If tyres with a specific direction of rotation are fitted, note the direction of

rotation.

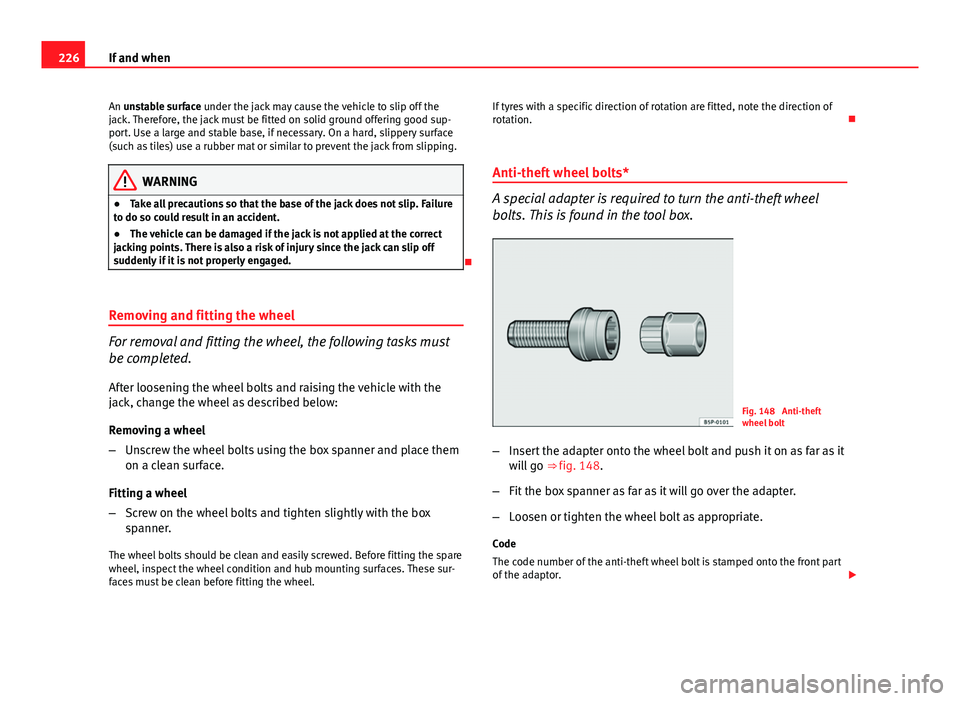

Anti-theft wheel bolts*

A special adapter is required to turn the anti-theft wheel

bolts. This is found in the tool box.

Fig. 148 Anti-theft

wheel bolt

– Insert the adapter onto the wheel bolt and push it on as far as it

will go ⇒ fig. 148.

– Fit the box spanner as far as it will go over the adapter.

– Loosen or tighten the wheel bolt as appropriate.

Code

The code number of the anti-theft wheel bolt is stamped onto the front part

of the adaptor.

Page 229 of 280

227

If and when

The code number should be noted and kept in a safe place, as it is only by

using the code number that a duplicate adaptor can be obtained from an

Authorised Service Centre.

Tyres with directional tread pattern

Tyres with directional tread pattern must be fitted so that

they rotate in the correct direction. A directional tread pattern can be identified by arrows on the sidewall that

point in the direction of rotation. Always note the direction of rotation indi-

cated when fitting the wheel. This is important so that these tyres can give

maximum grip and avoid excessive noise, tread wear and aquaplaning.

If, in an emergency, you have to fit the spare wheel so it rotates in the wrong

direction, you must drive extremely carefully. The tyre will not give optimum

performance. This is particularly important when driving on wet roads.

To benefit from the advantages of tyres with this type of tread pattern, the

defective tyre should be replaced as soon as possible so that all tyres again

rotate in the correct direction.

Tyre repair kit (Tyre-Mobility-System)*

General information and safety notes

Your vehicle is equipped with a tyre repair kit: the Tyre Mobility System.

In the event of a tyre puncture, a sealing compound and an air compressor

are located in the luggage compartment under the floor panel. The Tyre Mobility System will reliably seal punctures caused by the penetra-

tion of a foreign body of up to about 4 mm in diameter.

It is not necessary to remove the foreign body from the tyre.

Instructions for the sealing compound are located on the sealing compound

container.

It also contains the instructions for using the compressor.

WARNING

● Do not attempt to repair a puncture with the sealing compound if the

tyre has been damaged by driving the vehicle after the tyre has lost its

air.

● Always observe warnings and follow safety instructions concerning

compressor and sealing compound carefully.

● Do not drive faster than 80 km/h, avoid heavy acceleration, hard

braking and fast cornering.

● Tyres which have been repaired with sealing compound are only suit-

able for temporary use over a short period. Therefore, please drive care-

fully to the next available specialised workshop.

For the sake of the environment

If you have to dispose of a sealant can, go to a specialised waste service or

to a SEAT Technical Service, where the product can be recycled in an appro-

priate waste container.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 230 of 280

228If and when

Note

● If sealant should leak out, leave it to dry. This way you can pull it off like

a piece of foil.

● Observe the expiry date stated on the sealing compound can. Have the

sealing compound exchanged by a specialised workshop.

● Seek professional assistance if the repair of a tyre puncture is not possi-

ble with the sealing compound.

What to do first

Certain steps must be taken before repairing a tyre.

– If you have a flat tyre or puncture, park the vehicle as far away

from the flow of traffic as possible.

– Apply the handbrake firmly.

– Engage first gear , or put the selector lever to position P.

– All passengers should leave the vehicle. They should wait in a

safe area (for instance behind the roadside crash barrier).

– Check whether a repair is possible using the Tyre Mobility Sys-

tem “General information and safety notes.”

– Unscrew inflation cap from the affected wheel.

– Take the tyre repair kit out of the luggage compartment.

WARNING

Switch on the hazard warning lights and place the warning triangles in

position. This is for your own safety and also warns other road users.

CAUTION

Take special care if you have to repair a tyre on a slope.

Note

● Please observe legal requirements when doing so.

● Remember to replace the sealing compound as soon as possible.

Tyre repair

The following sections describe the procedures for repairing

a tyre.

Using the sealing compound

– The instructions on the container give detailed information on

how to use the sealing compound.

Inflating the tyre.

– Remove the air compressor and hose from the container.

– Screw the retaining nut onto the valve.

– Plug the compressor cable into a 12 volt power point.

– Turn on compressor and monitor the pressure shown on the

pressure gauge.

Completing the repair

– Remove the compressor hose from the valve.

– Fit the valve cap.

Page 231 of 280

229

If and when

– Unplug the compressor from the socket.

– Return all tools to their proper storing location.

Note

The compressor should never be allowed to run for longer than 6 minutes.

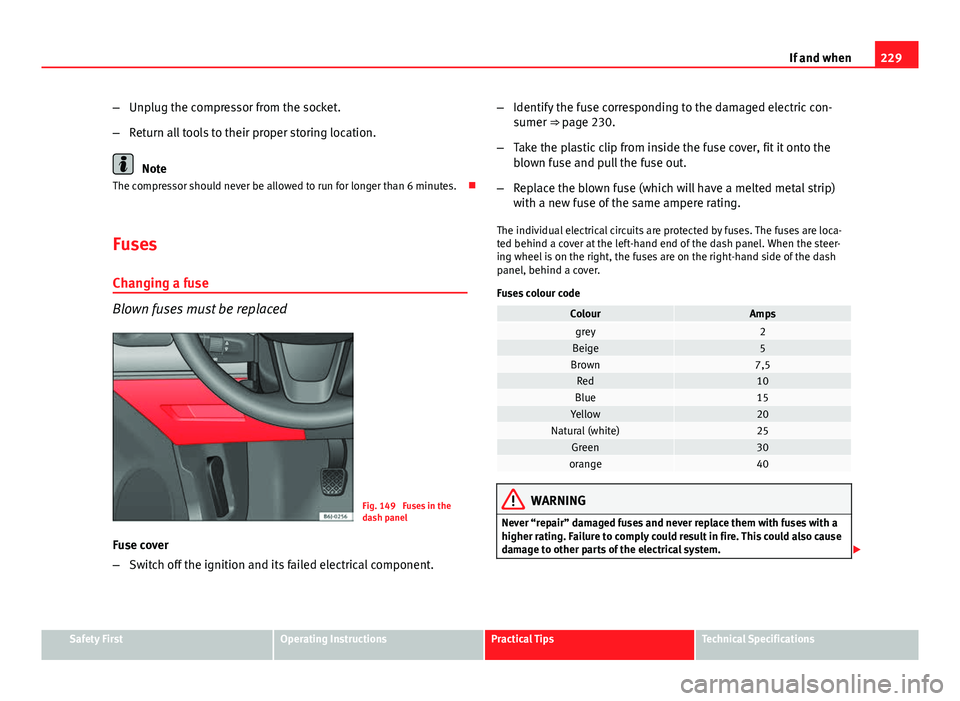

Fuses Changing a fuse

Blown fuses must be replaced

Fig. 149 Fuses in the

dash panel

Fuse cover

– Switch off the ignition and its failed electrical component. –

Identify the fuse corresponding to the damaged electric con-

sumer ⇒ page 230.

– Take the plastic clip from inside the fuse cover, fit it onto the

blown fuse and pull the fuse out.

– Replace the blown fuse (which will have a melted metal strip)

with a new fuse of the same ampere rating.

The individual electrical circuits are protected by fuses. The fuses are loca-

ted behind a cover at the left-hand end of the dash panel. When the steer-

ing wheel is on the right, the fuses are on the right-hand side of the dash

panel, behind a cover.

Fuses colour code

ColourAmpsgrey2Beige5Brown7,5Red10Blue15Yellow20Natural (white)25Green30orange40

WARNING

Never “repair” damaged fuses and never replace them with fuses with a

higher rating. Failure to comply could result in fire. This could also cause

damage to other parts of the electrical system.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 235 of 280

233

If and when

Xenon 1)

/ adaptive headlights*

- D1S2)

- LED 3)

- LED 3)

- PY 21W

Fog lights - H11

WARNING

● Take particular care when working on components in the engine com-

partment if the engine is warm - risk of burns!

● Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

● The high voltage element of gas discharge bulbs* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.

● When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.

CAUTION

● Remove the ignition key before working on the electric system. If not, a

short circuit could occur.

● Switch off the lights or parking lights before you change a bulb.

Dipped and full beam

Position

DRL (day light)

Turn signals

Fog light/cornering

For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the prop-

er manner.

Note

● Depending on weather conditions (cold or wet), the front lights, the fog

lights, the tail lights and the turn signals may be temporarily misted. This

has no influence on the useful life of the lighting system. By switching on

the lights, the area through which the beam of light is projected will quickly

be demisted. However, the edges may continue to be misted.

● Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the inter-

est of your own safety, but also that of all other road users.

● Before changing a bulb, make sure you have the correct new bulb.

● Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will va-

porise as a result of the heat generated by the bulb, they will be deposited

on the reflector and will impair its surface.

1)

With these types of headlights, the user can replace the turn signal bulb. Replacement of

the dipped/main beam bulb must be done by a Technical Service, given that complex ele-

ments must be removed from the vehicle and the automatic control system that incorpo-

rates it must be reset.

2) The Xenon bulbs discharge 2.5 times the light flux and have an average lifespan of 5 times

more than that of halogen bulbs, this means that, except due to unusual circumstances,

there is no need to change the bulbs for the whole life of the vehicle.

3) In the event that there is a fault in the LEDs, the complete headlight must be replaced.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 242 of 280

240If and when

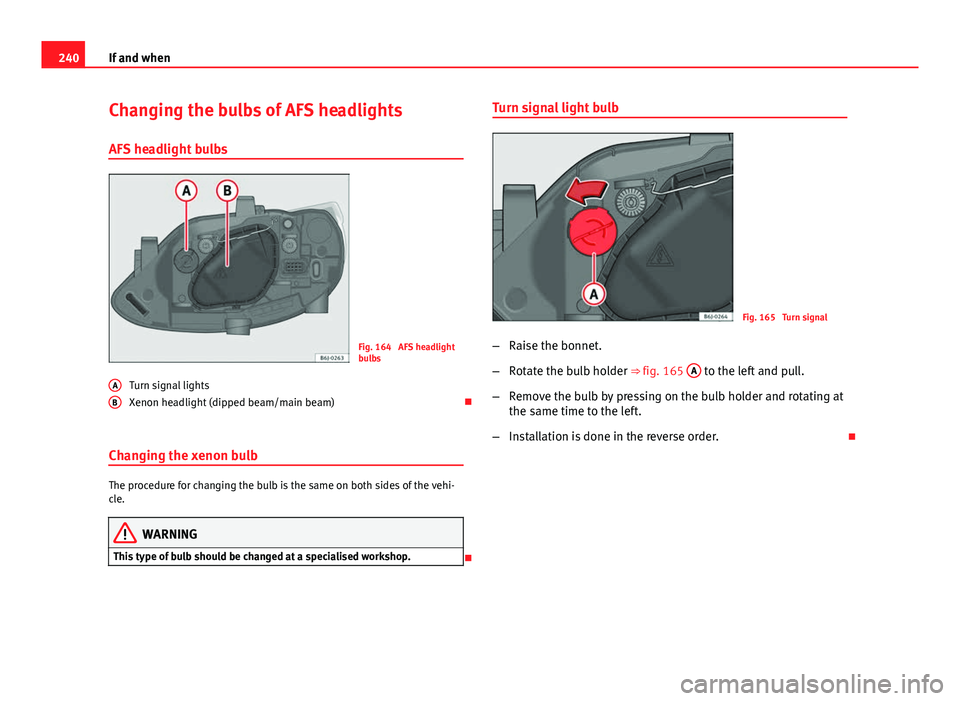

Changing the bulbs of AFS headlights

AFS headlight bulbs

Fig. 164 AFS headlight

bulbs

Turn signal lights

Xenon headlight (dipped beam/main beam)

Changing the xenon bulb

The procedure for changing the bulb is the same on both sides of the vehi-

cle.

WARNING

This type of bulb should be changed at a specialised workshop.

A

B

Turn signal light bulb

Fig. 165 Turn signal

– Raise the bonnet.

– Rotate the bulb holder ⇒ fig. 165 A

to the left and pull.

– Remove the bulb by pressing on the bulb holder and rotating at

the same time to the left.

– Installation is done in the reverse order.