lock Seat Ibiza ST 2012 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Ibiza ST, Model: Seat Ibiza ST 2012Pages: 282, PDF Size: 3.77 MB

Page 215 of 282

213

Checking and refilling levels

Brake fluid Checking the brake fluid level

The brake fluid is checked at the intervals given in the serv-

ice schedule.

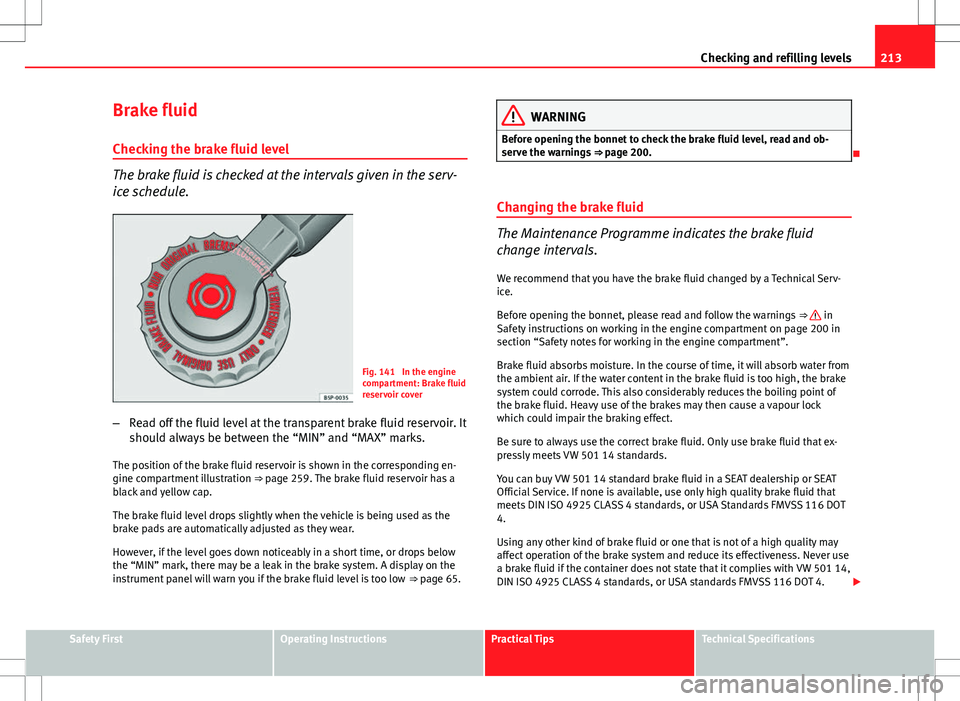

Fig. 141 In the engine

compartment: Brake fluid

reservoir cover

– Read off the fluid level at the transparent brake fluid reservoir. It

should always be between the “MIN” and “MAX” marks.

The position of the brake fluid reservoir is shown in the corresponding en-

gine compartment illustration ⇒ page 259. The brake fluid reservoir has a

black and yellow cap.

The brake fluid level drops slightly when the vehicle is being used as the

brake pads are automatically adjusted as they wear.

However, if the level goes down noticeably in a short time, or drops below

the “MIN” mark, there may be a leak in the brake system. A display on the

instrument panel will warn you if the brake fluid level is too low ⇒ page 65.

WARNING

Before opening the bonnet to check the brake fluid level, read and ob-

serve the warnings ⇒ page 200.

Changing the brake fluid

The Maintenance Programme indicates the brake fluid

change intervals. We recommend that you have the brake fluid changed by a Technical Serv-

ice.

Before opening the bonnet, please read and follow the warnings ⇒

in

Safety instructions on working in the engine compartment on page 200 in

section “Safety notes for working in the engine compartment”.

Brake fluid absorbs moisture. In the course of time, it will absorb water from

the ambient air. If the water content in the brake fluid is too high, the brake

system could corrode. This also considerably reduces the boiling point of

the brake fluid. Heavy use of the brakes may then cause a vapour lock

which could impair the braking effect.

Be sure to always use the correct brake fluid. Only use brake fluid that ex-

pressly meets VW 501 14 standards.

You can buy VW 501 14 standard brake fluid in a SEAT dealership or SEAT

Official Service. If none is available, use only high quality brake fluid that

meets DIN ISO 4925 CLASS 4 standards, or USA Standards FMVSS 116 DOT

4.

Using any other kind of brake fluid or one that is not of a high quality may

affect operation of the brake system and reduce its effectiveness. Never use

a brake fluid if the container does not state that it complies with VW 501 14,

DIN ISO 4925 CLASS 4 standards, or USA standards FMVSS 116 DOT 4.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 216 of 282

214Checking and refilling levels

WARNING

Brake fluid is poisonous. Old brake fluid impairs the braking effect.

● Before opening the bonnet to check the brake fluid level, read and ob-

serve the warnings ⇒ page 200.

● Brake fluid should be stored in the closed original container in a safe

place out of reach of children. There is a toxic risk.

● Complete the brake fluid change according to the Maintenance Pro-

gramme. Heavy use of the brakes may cause a vapour lock if the brake

fluid is left in the brake system for too long. This would seriously affect

the effectiveness of the brakes and the safety of the vehicle. This may

cause an accident.

CAUTION

Brake fluid damages the vehicle paintwork. Wipe off any brake fluid from

the paintwork immediately.

For the sake of the environment

The brake pads and brake fluid must be collected and disposed of accord-

ing the applicable regulations. The SEAT Technical Service network has the

necessary equipment and qualified personnel for collecting and disposing

of this waste material. Vehicle battery

Warnings on handling the battery

Wear eye protection

Battery acid is extremely corrosive. Wear protective gloves and

eye protection!

Fires, sparks, open flames and smoking are prohibited!

A highly explosive mixture of gases is released when the battery

is under charge.

Keep children away from acid and batteries!

WARNING

Always be aware of the danger of injury and chemical burns as well as

the risk of accident or fire when working on the battery and the electrical

system:

● Wear eye protection. Protect your eyes, skin and clothing from acid

and particles containing lead.

● Battery acid is extremely corrosive. Wear protective gloves and eye

protection. Do not tilt the batteries. This could spill acid through the

vents. Rinse battery acid from eyes immediately for several minutes with

clear water. Then seek medical care immediately. Neutralise any acid

splashes on the skin or clothing with a soapy solution, and rinse off with

plenty of water. If acid is swallowed by mistake, consult a doctor immedi-

ately.

Page 217 of 282

215

Checking and refilling levels

WARNING (Continued)

● Fires, sparks, open flames and smoking are prohibited. When han-

dling cables and electrical equipment, avoid causing sparks and electro-

static charge. Never short the battery terminals. High-energy sparks can

cause injury.

● A highly explosive mixture of gases is released when the battery is

under charge. The batteries should be charged in a well-ventilated room

only.

● Keep children away from acid and batteries.

● Before working on the electrical system, you must switch off the en-

gine, the ignition and all consumers. The negative cable on the battery

must be disconnected. When a light bulb is changed, you need only

switch off the light.

● Deactivate the anti-theft alarm by unlocking the vehicle before you

disconnect the battery! The alarm will otherwise be triggered.

● When disconnecting the battery from the vehicle on-board network,

disconnect first the negative cable and then the positive cable.

● Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never re-

verse the polarity of the connections. This could cause an electrical fire.

● Never charge a frozen battery, or one which has thawed. This could

result in explosions and chemical burns. Always replace a battery which

has frozen. A flat battery can freeze at temperatures around 0°C.

● Ensure that the vent hose is always connected to the battery.

● Never use a defective battery. This could cause an explosion. Replace

a damaged battery immediately.

● For vehicles with the battery in the luggage compartment: Check that

the battery gas ventilation hose is securely attached.CAUTION

● Never disconnect the battery if the ignition is switched on or if the en-

gine is running. This could damage the electrical system or electronic com-

ponents.

● Do not expose the battery to direct sunlight over a long period of time,

as the intense ultraviolet radiation can damage the battery housing.

● If the vehicle is left standing in cold conditions for a long period, protect

the battery from freezing. If it freezes it will be damaged.

Checking the electrolyte level

The electrolyte level should be checked regularly in high-

mileage vehicles, in hot countries and in older batteries. – Open the engine bonnet and the battery cover ⇒

in Safety in-

structions on working in the engine compartment on page 201

⇒

in Warnings on handling the battery on page 214.

– Check the colour display in the "magic eye" on the top of the

battery.

– If there are air bubbles in the window, tap the window gently

until they disperse.

The position of the battery is shown in the corresponding engine compart-

ment diagram ⇒ page 259.

The “magic eye” indicator, located on the top of the battery changes colour,

depending on the charge state and electrolyte level of the battery.

There are two different colours:

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 227 of 282

225

If and when

WARNING

Switch on the hazard warning lights and place the warning triangles in

position. This is for your own safety and also warns other road users.

CAUTION

If you have to change the wheel on a slope, it is essential to lock the parallel

wheel on the same axle as that to be changed, with a wedge or similar in

order to immobilise the vehicle.

Note

Please observe legal requirements when doing so.

Changing a wheel

Change the wheel as described below

– Remove the hub caps or the integral trim .

– Slacken the wheel bolts .

– Raise the vehicle with the jack at the corresponding point.

– Remove the wheel and then fit the spare wheel.

– Lower the vehicle.

– Tighten the wheel bolts firmly with the box spanner.

– Replace the hub cap. After changing a wheel

After changing the wheel there are still tasks to complete.

– Put the tools and jack back in the luggage compartment.

– Place the wheel with the defective tyre in the luggage compart-

ment and secure it.

– Check the tyre pressure of the newly fitted tyre as soon as pos-

sible.

– Have the tightening torque of the wheel bolts checked as soon

as possible with a torque wrench. The prescribed torque must

be 120 Nm.

Note

● If you notice that the wheel bolts are corroded and difficult to turn when

changing a wheel, they must be replaced before having the wheel bolt tight-

ening torque checked.

● For safety reasons, drive at moderate speeds until the wheel bolt tight-

ening torque has been checked.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 235 of 282

233

If and when

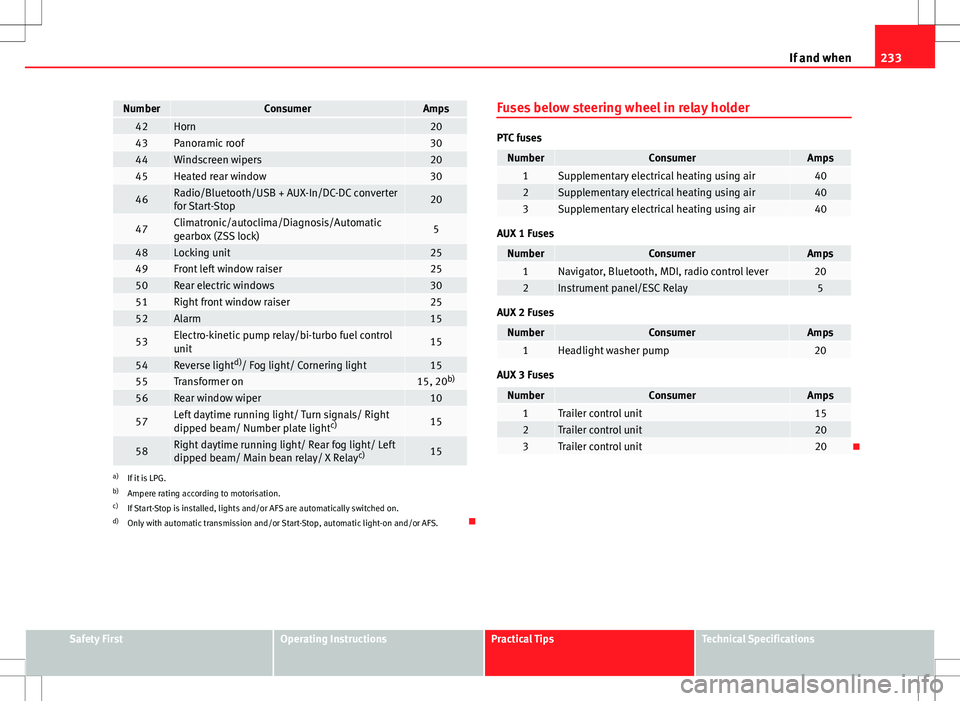

NumberConsumerAmps42Horn2043Panoramic roof3044Windscreen wipers2045Heated rear window30

46Radio/Bluetooth/USB + AUX-In/DC-DC converter

for Start-Stop20

47Climatronic/autoclima/Diagnosis/Automatic

gearbox (ZSS lock)5

48Locking unit2549Front left window raiser2550Rear electric windows3051Right front window raiser2552Alarm15

53Electro-kinetic pump relay/bi-turbo fuel control

unit15

54Reverse light d)

/ Fog light/ Cornering light1555Transformer on15, 20 b)56Rear window wiper10

57Left daytime running light/ Turn signals/ Right

dipped beam/ Number plate light c)15

58Right daytime running light/ Rear fog light/ Left

dipped beam/ Main bean relay/ X Relay c)15

a)

If it is LPG.

b) Ampere rating according to motorisation.

c) If Start-Stop is installed, lights and/or AFS are automatically switched on.

d) Only with automatic transmission and/or Start-Stop, automatic light-on and/or AFS. Fuses below steering wheel in relay holder

PTC fuses

NumberConsumerAmps1Supplementary electrical heating using air402Supplementary electrical heating using air403Supplementary electrical heating using air40

AUX 1 Fuses

NumberConsumerAmps1Navigator, Bluetooth, MDI, radio control lever202Instrument panel/ESC Relay5

AUX 2 Fuses

NumberConsumerAmps1Headlight washer pump20

AUX 3 Fuses

NumberConsumerAmps1Trailer control unit152Trailer control unit203Trailer control unit20

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 245 of 282

243

If and when

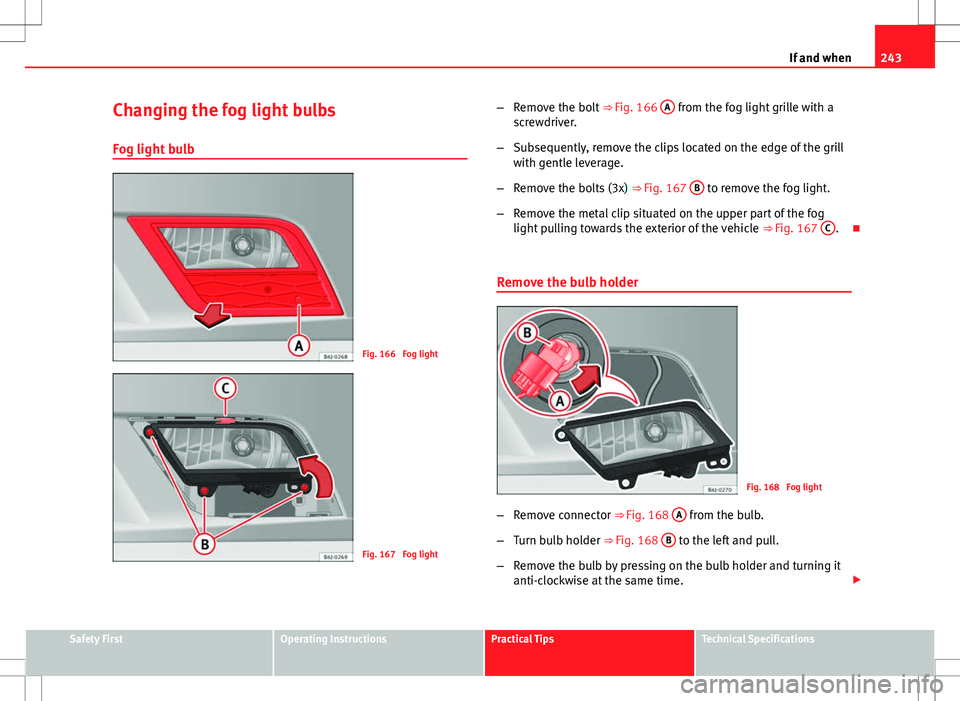

Changing the fog light bulbs

Fog light bulb

Fig. 166 Fog light

Fig. 167 Fog light –

Remove the bolt ⇒ Fig. 166 A

from the fog light grille with a

screwdriver.

– Subsequently, remove the clips located on the edge of the grill

with gentle leverage.

– Remove the bolts (3x) ⇒ Fig. 167 B

to remove the fog light.

– Remove the metal clip situated on the upper part of the fog

light pulling towards the exterior of the vehicle ⇒ Fig. 167 C

.

Remove the bulb holder

Fig. 168 Fog light

– Remove connector ⇒ Fig. 168 A

from the bulb.

– Turn bulb holder ⇒ Fig. 168 B

to the left and pull.

– Remove the bulb by pressing on the bulb holder and turning it

anti-clockwise at the same time.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 251 of 282

249

If and when

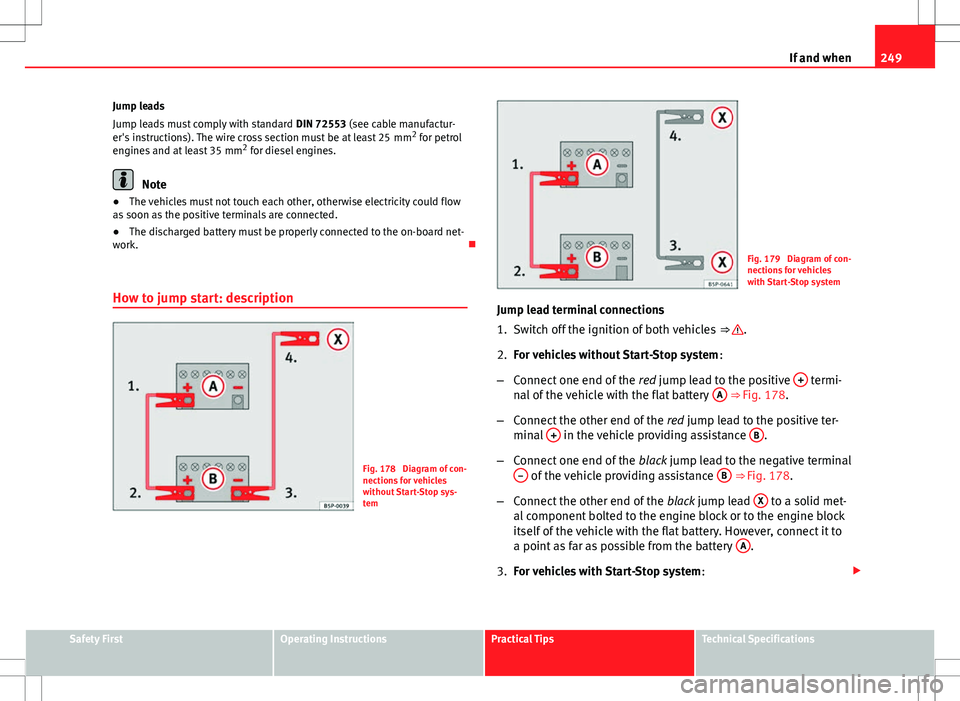

Jump leads

Jump leads must comply with standard DIN 72553 (see cable manufactur-

er's instructions). The wire cross section must be at least 25 mm 2

for petrol

engines and at least 35 mm 2

for diesel engines.

Note

● The vehicles must not touch each other, otherwise electricity could flow

as soon as the positive terminals are connected.

● The discharged battery must be properly connected to the on-board net-

work.

How to jump start: description

Fig. 178 Diagram of con-

nections for vehicles

without Start-Stop sys-

tem

Fig. 179 Diagram of con-

nections for vehicles

with Start-Stop system

Jump lead terminal connections

1. Switch off the ignition of both vehicles ⇒

.

2. For vehicles without Start-Stop system :

– Connect one end of the red jump lead to the positive +

termi-

nal of the vehicle with the flat battery A ⇒ Fig. 178.

– Connect the other end of the red jump lead to the positive ter-

minal +

in the vehicle providing assistance B.

– Connect one end of the black jump lead to the negative terminal

–

of the vehicle providing assistance B ⇒ Fig. 178.

– Connect the other end of the black jump lead X

to a solid met-

al component bolted to the engine block or to the engine block

itself of the vehicle with the flat battery. However, connect it to

a point as far as possible from the battery A

.

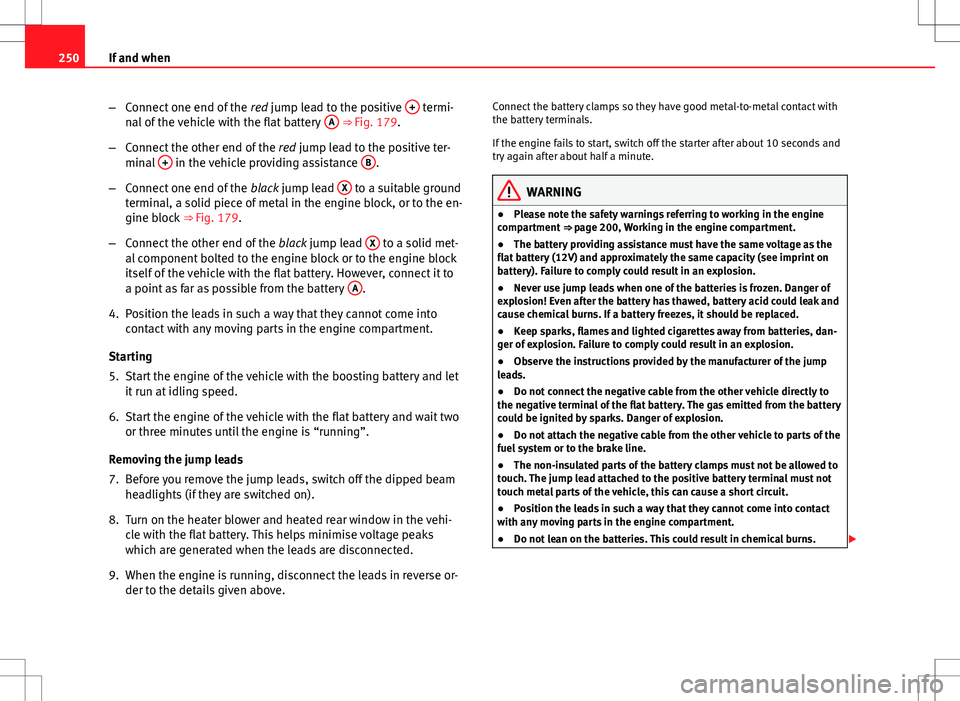

3. For vehicles with Start-Stop system :

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 252 of 282

250If and when

–Connect one end of the red jump lead to the positive +

termi-

nal of the vehicle with the flat battery A ⇒ Fig. 179.

– Connect the other end of the red jump lead to the positive ter-

minal +

in the vehicle providing assistance B.

– Connect one end of the black jump lead X

to a suitable ground

terminal, a solid piece of metal in the engine block, or to the en-

gine block ⇒ Fig. 179.

– Connect the other end of the black jump lead X

to a solid met-

al component bolted to the engine block or to the engine block

itself of the vehicle with the flat battery. However, connect it to

a point as far as possible from the battery A

.

4. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

5. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

6. Start the engine of the vehicle with the flat battery and wait two or three minutes until the engine is “running”.

Removing the jump leads

7. Before you remove the jump leads, switch off the dipped beam headlights (if they are switched on).

8. Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

9. When the engine is running, disconnect the leads in reverse or- der to the details given above. Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 200, Working in the engine compartment.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not lean on the batteries. This could result in chemical burns.

Page 255 of 282

253

If and when

Do not pull too hard with the towing vehicle and take care to avoid jerking

the tow rope. When towing on an unpaved road, there is always a risk of

overloading and damaging the anchorage points.

The ignition of the vehicle being towed must be switched on to prevent the

steering wheel from locking and also to allow the use of the turn signals,

horn, windscreen wipers and washers.

As the brake servo does not work if the engine is not running, you must ap-

ply considerably more pressure to the brake pedal than you normally would.

As the power assisted steering does not work if the engine is not running,

you will need more strength to steer than you normally would.

Towing vehicles with an automatic gearbox

● Put the selector lever into position “N”.

● Do not drive faster than 50 km/h (30 mph).

● Do not tow further than 50 km (30 miles).

● If a breakdown vehicle is used, the vehicle must be towed with the front

wheels raised.

Note

● Observe legal requirements when towing or tow-starting.

● Switch on the hazard warning lights of both vehicles. However, observe

any regulations to the contrary.

● For technical reasons, vehicles with an automatic gearbox must not be

tow-started.

● If damage to your vehicle means that there is no lubricant in the gear-

box, you must raise the driven wheels while the vehicle is being towed.

● If the vehicle has to be towed more than 50 km (30 miles), the front

wheels should be raised during towing, and towing should be carried out by

a qualified person. ●

The steering wheel is locked when the vehicle has no electrical power.

The vehicle must then be towed with the front wheels raised. Towing should

be carried out by a qualified person.

● The towline anchorage should always be kept in the vehicle.

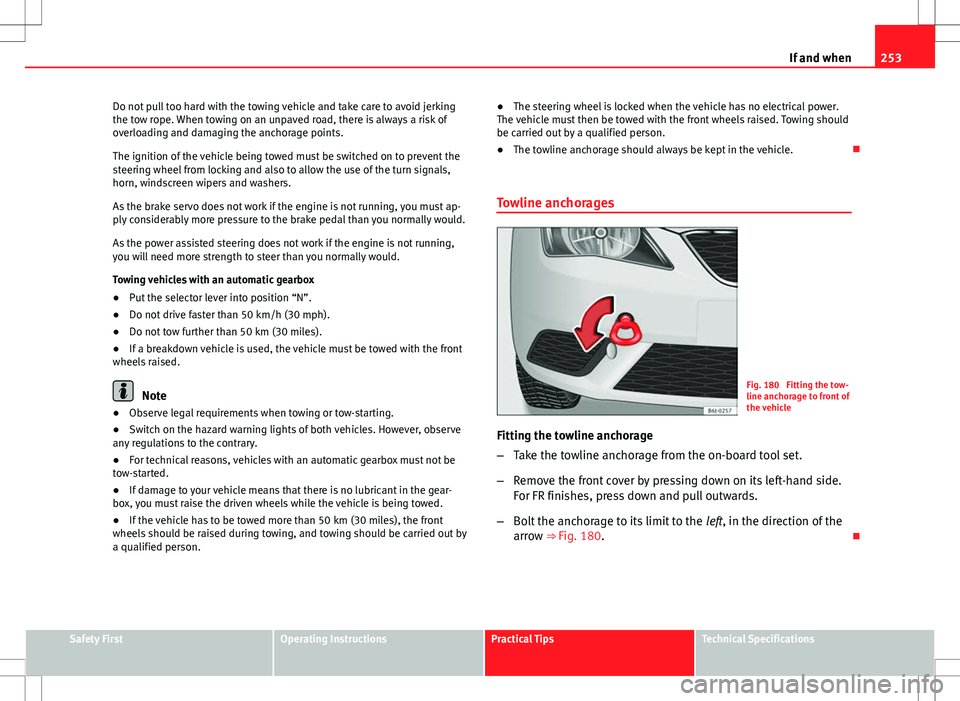

Towline anchoragesFig. 180 Fitting the tow-

line anchorage to front of

the vehicle

Fitting the towline anchorage

– Take the towline anchorage from the on-board tool set.

– Remove the front cover by pressing down on its left-hand side.

For FR finishes, press down and pull outwards.

– Bolt the anchorage to its limit to the left, in the direction of the

arrow ⇒ Fig. 180.

Safety FirstOperating InstructionsPractical TipsTechnical Specifications

Page 273 of 282

Index

A

ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 71

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Acoustic warning . . . . . . . . . . . . . . . . . . . . . . . 145

Adaptive headlights . . . . . . . . . . . . . . . . . . . . . 103

AFS headlight bulbs . . . . . . . . . . . . . . . . . . . . . 242

Airbag covers . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 31

Front airbags . . . . . . . . . . . . . . . . . . . . . . . . 34

side airbags . . . . . . . . . . . . . . . . . . . . . . . . . 38

Air conditioner Climatronic . . . . . . . . . . . . . . . . . . . . . . . . . 140

General notes . . . . . . . . . . . . . . . . . . . . . . . 142

Air conditioning* . . . . . . . . . . . . . . . . . . . . . . . 137

Air outlets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Air recirculation Semi-automatic air conditioning . . . . . . . . 139

Air recirculation mode Climatronic . . . . . . . . . . . . . . . . . . . . . . . . . 142

Alarm system Switching off . . . . . . . . . . . . . . . . . . . . . . . . . 90

Alternator Warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 76

Anti-lock brake system . . . . . . . . . . . . . . . . . . . 169 control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 71 Anti-theft alarm system . . . . . . . . . . . . . . . . . . . 90

Switching off . . . . . . . . . . . . . . . . . . . . . . . . . 90

Anti-theft wheel bolts . . . . . . . . . . . . . . . . . . . 226

Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Aquaplaning . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Ashtray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Aspects to note before setting off . . . . . . . . . . . . 8

ASR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

ASR (Traction control system) Control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 72

Audible warning . . . . . . . . . . . . . . . . . . . . . . . . . 20

Automatic anti-dazzle interior mirror Deactivating the anti-dazzle function . . . . 112

Automatic anti-dazzle interior mirror* Activating the anti-dazzle function . . . . . . 112

Automatic car washing tunnel . . . . . . . . . . . . . 182

Automatic gearbox . . . . . . . . . . . . . . . . . . . . . . 154 Kick-down feature . . . . . . . . . . . . . . . . . . . . 160

Selector lever positions . . . . . . . . . . . . . . . 158

Automatic lighting . . . . . . . . . . . . . . . . . . . . . . 101

Automatic windscreen wiper/washer . . . . . . . 109

AUX/USB input connection . . . . . . . . . . . . . . . 127

Auxiliary audio input connection (AUX) . . . . . 127

B

Ball coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . 179 Battery

Changing . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Winter conditions . . . . . . . . . . . . . . . . . . . . 214

Before setting off . . . . . . . . . . . . . . . . . . . . . . . . . 8

Belt tensioners . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Biodiesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Biodiesel fuel . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Bonnet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213 Changing . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Brake pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Brake servo . . . . . . . . . . . . . . . . . . . . . . . . 168, 173

Brake system . . . . . . . . . . . . . . . . . . . . . . . . . . 213 warning lamp . . . . . . . . . . . . . . . . . . . . . . . . 73

Braking distance . . . . . . . . . . . . . . . . . . . . . . . 173

Bulb change double headlight . . . . . . . . . . . . . . . . . . . . 238

Single headlight bulb . . . . . . . . . . . . . . . . 236

Bulb changes General notes . . . . . . . . . . . . . . . . . . . . . . . 234

Bulb defect Control lamp . . . . . . . . . . . . . . . . . . . . . . . . . 71

Buzzer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107, 145

271

Index