battery Seat Leon 5D 2013 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Leon 5D, Model: Seat Leon 5D 2013Pages: 339, PDF Size: 4.8 MB

Page 254 of 339

252Checking and refilling levels

WARNING (Continued)

● Protect face, hands and arms by covering the cap with a large, thick

rag to protect against escaping coolant and steam.

● If it is necessary to work in the engine compartment while the engine

is running, the rotating components (for example, poly-V belt, alternator,

radiator fan) and the high voltage ignition system are an additional haz-

ard.

● Observe the following additional warnings if work on the fuel system

or the electrical system is necessary:

–Always disconnect the battery from the on-board network.

– Do not smoke.

– Never work near naked flames.

– Always keep an approved fire extinguisher immediately available.

CAUTION

When changing or topping up service fluids, make absolutely certain that

you fill the fluids into the correct reservoirs. Using the wrong fluids could

cause serious malfunctions and engine damage!

For the sake of the environment

Inspect the ground underneath your vehicle regularly so that any leaks are

detected at an early stage. If you find spots of oil or other fluids, have your

vehicle inspected at the workshop.

Note

On right-hand drive vehicles* some of the containers/reservoirs mentioned

below are located on the other side of the engine compartment. Opening the bonnet

The bonnet is released from inside the vehicle.

Fig. 153 Release lever in driver footwell and cam below the bonnet

Check that the windscreen wiper arms are not unfolded. Otherwise

the paint may be damaged.

The bonnet can only be unlocked when the driver door is open.

– Pull the lever under the dash panel in the direction of the arrow

1

⇒ Fig. 153.

– Lift the bonnet slightly ⇒

.

– Press the release catch under the bonnet upwards ⇒ Fig. 153

2

. This will release the arrester hook under the bonnet.

– Open the bonnet. Release the bonnet stay and secure it in fix-

ture designed for this in the bonnet.

Page 262 of 339

260Checking and refilling levels

WARNING

● Brake fluid should be stored in the closed original container in a safe

place out of reach of children. Risk of poisoning!

● If the brake fluid is left in the system for too long and the brakes are

subjected to heavy use, vapour bubbles may form in the brake system.

This would seriously affect the efficiency of the brakes and the safety of

the vehicle. This may cause an accident.

CAUTION

Brake fluid should not come into contact with the vehicle paintwork, as it is

abrasive.

Battery General information

The battery is located in the engine compartment and is almost mainte-

nance-free. It is checked as part of the Inspection Service. Nevertheless,

check the terminals are clean and have the correct tightening torque, espe-

cially in summer and winter.

Disconnecting the battery

The battery should only be disconnected in exceptional cases. When the

battery is disconnected, some of the vehicle's functions are “lost” ( ⇒ table

on page 260). These functions will require resetting after the battery is re-

connected.

Deactivate the anti-theft alarm* before you disconnect the battery Other-

wise the alarm will be triggered.

effectReprogrammingOne-touch function of the electric

windows⇒ page 104, One-touch opening and

closing*

Remote control keyIf the vehicle does not respond to the

key, they should be synchronised

⇒ page 91

Digital clock⇒ page 63

ESC warning lampAfter driving for a few metres, the

warning lamp goes out again.

If the vehicle is not used for long periods

The vehicle has a system for monitoring the current consumption when the

engine is left unused for long periods of time ⇒ page 226. Some functions,

such as the interior lights, or the remote door opening, may be temporarily

disabled to prevent the battery from running flat. These functions will come

back on as soon as the ignition is switched on and the engine started.

Winter conditions

During the winter, the starting power may be reduced, and if necessary, the

battery should be charged ⇒

in Important safety warnings for handling a

vehicle battery on page 261

Important safety warnings for handling a vehicle battery

All work on batteries requires specialist knowledge. Please refer to a SEAT

Official Service or a workshop specialising in batteries: risk of burns or ex-

ploding battery!

The battery must not be opened. Never try to change the fluid level of the

battery. Explosive gas is released from the battery that could cause an ex-

plosion.

Page 263 of 339

261

Checking and refilling levels

Wear eye protection.

Battery acid is very corrosive and caustic. Wear protective gloves

and eye protection. In the event of electrolyte splashes, rinse off

with plenty of water.

Fires, sparks, open flames and smoking are prohibited.

The battery should only be charged in a well-ventilated zone. Risk

of explosion!

Keep children away from acid and batteries!

WARNING

● When repairing or working on the electrical system, proceed as fol-

lows:

● 1. Remove the key from the ignition. The negative cable on the bat-

tery must be disconnected.

● 2. When the repair is finished, reconnect the negative pole of the bat-

tery.

● Switch off all electrical consumers before reconnecting the battery.

Reconnect first the positive cable and then the negative cable. Never re-

verse the polarity of the connections. This could cause an electrical fire.

● Ensure that the vent hose is always connected to the battery.

● Never use damaged batteries. This could cause an explosion! Replace

a damaged battery immediately.

CAUTION

● Never disconnect the battery if the ignition is switched on or if the en-

gine is running. This could damage the electrical system or electronic com-

ponents. Charging the battery

Terminals for charging the battery are fitted in the engine

compartment.

–

Note the warnings ⇒

in Important safety warnings for han-

dling a vehicle battery on page 261 and ⇒ .

– Switch off all electrical equipment. Remove the ignition key.

– Raise the bonnet ⇒ page 252.

– Open the battery cover.

– Connect the charger clamps as described to the positive pole of

the battery (+) and, exclusively to an earth on the bodywork

(–).

– Only use a charger which is compatible for use with 12 V nomi-

nal voltage batteries. The charge must not exceed a voltage of

15 V.

– Now connect the battery charger to the power socket and switch

on.

– After charging the battery: switch off the battery charger and

disconnect the power socket cable.

– Finally disconnect the charger cables from the battery.

– Replace the battery cover correctly.

– Close the bonnet ⇒ page 253.

Important: Before you charge the battery make sure you read the manufac-

turer's instructions for using the battery charger.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 264 of 339

262Checking and refilling levels

WARNING

Never charge a battery that has frozen: replace battery! Failure to do so

may lead to an explosion.

Note

Use only the terminals in the engine compartment to charge the battery.

Replacing the battery

The new battery should have the same specifications (am-

perage, load and voltage) as the used battery.

Your vehicle is equipped with an intelligent power management system to

control the distribution of electrical energy ⇒ page 226. The power manage-

ment function ensures that the battery is charged much more efficiently

than on vehicles without a power management system. To maintain this

function after replacing the battery, we recommend that the replacement

battery used is of the same make and type as the original fitted battery. To

make proper use of the power management function after the battery has

been changed, have the battery coded to the power management mode at a

specialised workshop.

CAUTION

● Some vehicles, for example those with the Start-Stop system* are fitted

with a special battery (AGM-type or EFB-type battery). If any other type of

battery is fitted, the Start-Stop function may be considerably reduced and

the vehicle may not stop on repeated occasions.

● Make sure that the vent hose is always attached to the original opening

on the side of the battery. Gases or battery acid can otherwise escape and

possibly cause damage.

● The battery holder and clamps must always be correctly secured. ●

Before starting any work on the battery, always observe the warnings lis-

ted under ⇒ page 260, Important safety warnings for handling a vehicle

battery.

● Do not forget to replace the battery coverings, where applicable. This

helps to protect against excess temperatures. This in turn extends the vehi-

cle service life.

For the sake of the environment

Batteries contain toxic substances including sulphuric acid and lead. They

must be disposed of appropriately and must not be disposed of with ordi-

nary household waste. Make sure disconnected batteries cannot tip over.

Sulphuric acid could be spilt!

Windscreen washer reservoir and wiper

blades

Windscreen washer

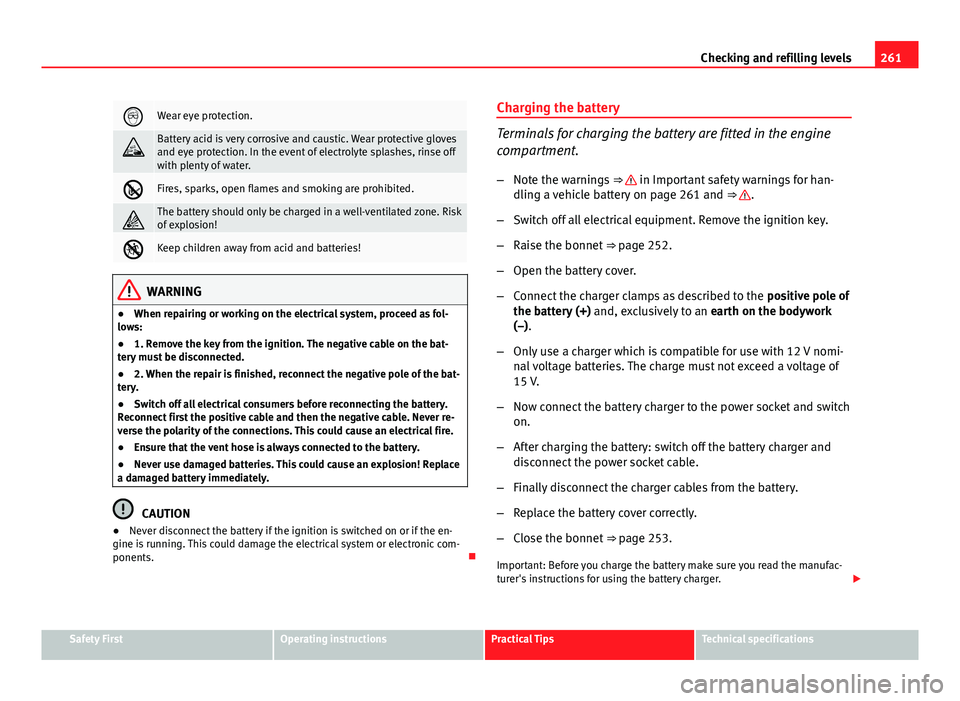

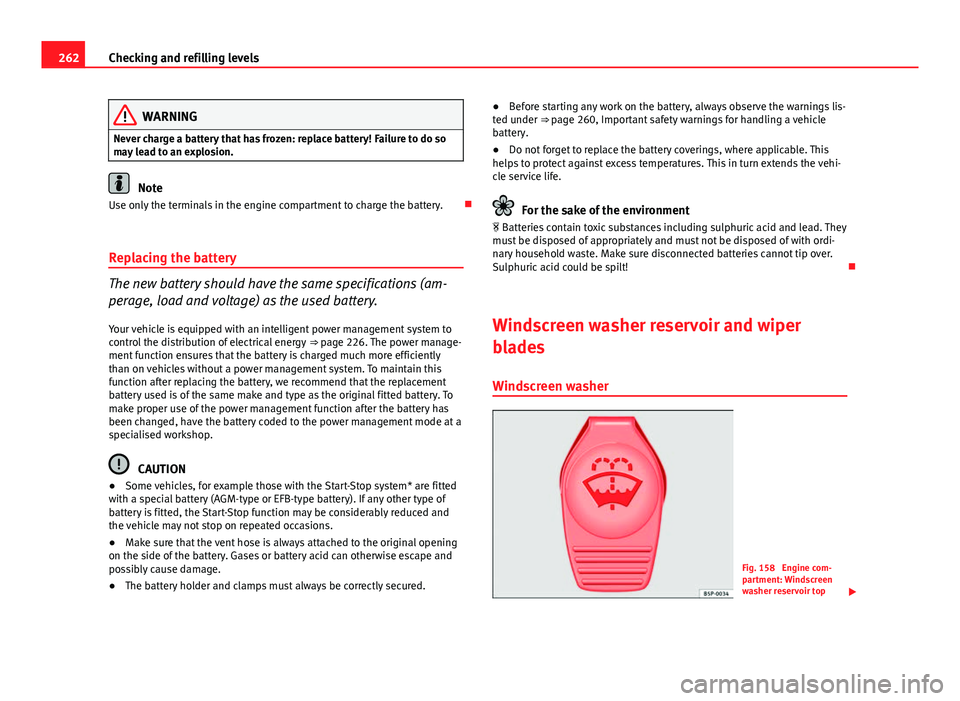

Fig. 158 Engine com-

partment: Windscreen

washer reservoir top

Page 285 of 339

283

Emergencies

– Take out the temporary spare wheel.

Chains

For technical reasons, snow chains must not be used on the temporary

spare wheel.

If you have a puncture on one of the front wheels when using snow chains,

fit the temporary spare wheel in place of one of the rear wheels. Fit the snow

chains on the rear wheel that you have removed and replace the punctured

front wheel with this wheel.

WARNING

● After fitting the temporary spare wheel, check the tyre pressures as

soon as possible. Failure to do so may cause an accident. The tyre pres-

sures are listed on the inside of the fuel tank flap.

● Do not drive at over 80 km/h (50 mph) when the temporary spare

wheel is fitted on the vehicle: risk of accident!

● Avoid heavy acceleration, hard braking and fast cornering: risk of ac-

cident!

● Never use more than one temporary spare wheel at the same time,

risk of accident.

● No other type of tyre (normal summer or winter tyre) may be fitted on

the compact temporary spare wheel rim.

Extraction of the spare wheel in vehicles with SEAT SOUND

10 speakers (with subwoofer)*

– Disassemble the subwoofer’s floor panel (carpet) as follows:

– LEON / LEON SC model: first, pull the carpet in the direction of

the backrest and then pull the carpet upwards to remove it. LEON ST Model: lift and secure the luggage compartment floor

as explained in

⇒ page 148.

– Disconnect the subwoofer’s speaker cable.

– Turn the securing wheel anti-clockwise.

– Remove the subwoofer speaker and the spare wheel.

– When replacing the spare wheel, place the subwoofer speaker

in the direction indicated by the arrow and with the word

“FRONT” facing forward.

– Reconnect the speaker cable and firmly rotate the securing

wheel clockwise so that the subwoofer system and wheel are

firmly in place.

Jump starting Jump leads

The jump lead must have a sufficient wire cross section.

If the engine fails to start because of a discharged battery, the battery can

be connected to the battery of another vehicle to start the engine.

Jump leads

Jump leads must comply with standard DIN 72553 (see cable manufactur-

er's instructions). The wire cross section must be at least 25 mm 2

for petrol

engines and at least 35 mm 2

for diesel engines.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 286 of 339

284Emergencies

Note

● The vehicles must not touch each other, otherwise electricity could flow

as soon as the positive terminals are connected.

● The discharged battery must be properly connected to the on-board net-

work.

How to jump start: description

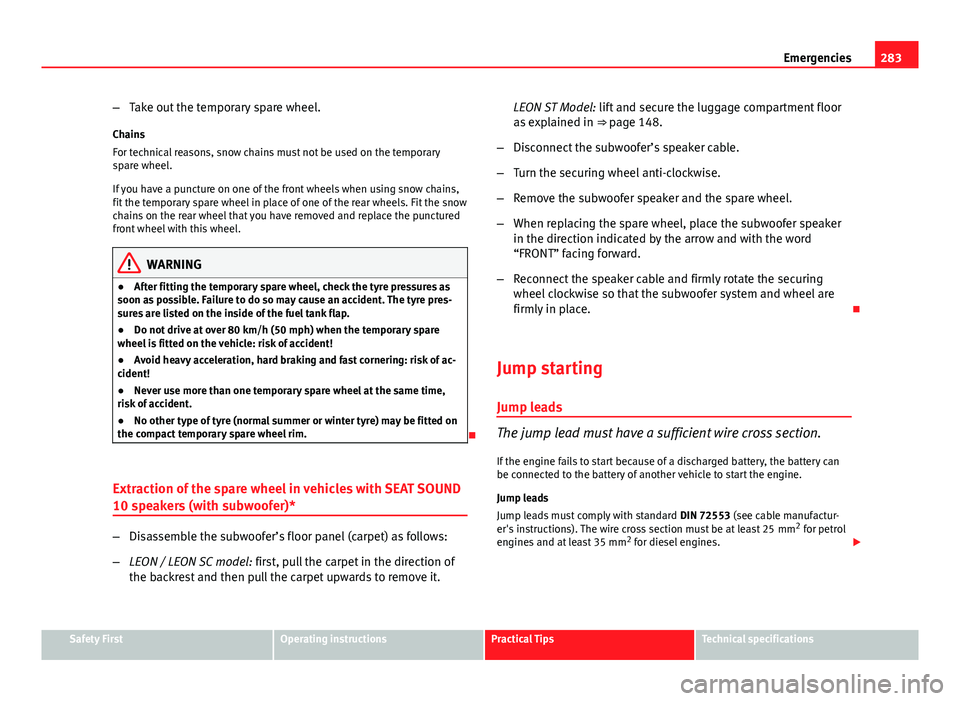

Fig. 172 Diagram of con-

nections for vehicles

without Start Stop sys-

tem

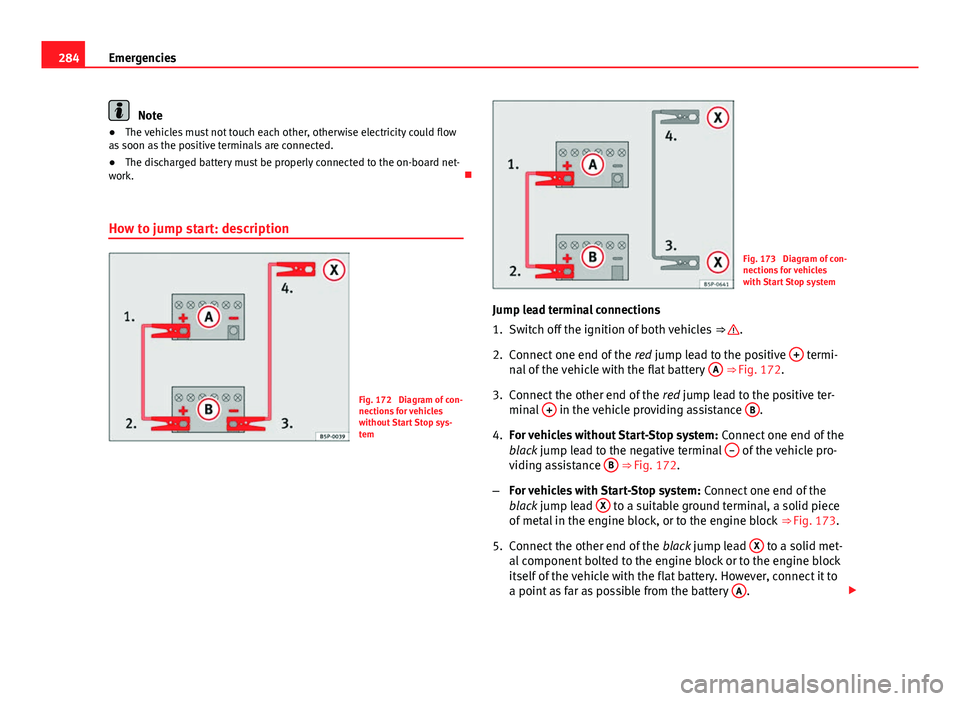

Fig. 173 Diagram of con-

nections for vehicles

with Start Stop system

Jump lead terminal connections

1. Switch off the ignition of both vehicles ⇒

.

2. Connect one end of the red jump lead to the positive +

termi-

nal of the vehicle with the flat battery A ⇒ Fig. 172.

3. Connect the other end of the red jump lead to the positive ter-

minal +

in the vehicle providing assistance B.

4. For vehicles without Start-Stop system: Connect one end of the

black jump lead to the negative terminal –

of the vehicle pro-

viding assistance B ⇒ Fig. 172.

– For vehicles with Start-Stop system: Connect one end of the

black jump lead X

to a suitable ground terminal, a solid piece

of metal in the engine block, or to the engine block ⇒ Fig. 173.

5. Connect the other end of the black jump lead X

to a solid met-

al component bolted to the engine block or to the engine block

itself of the vehicle with the flat battery. However, connect it to

a point as far as possible from the battery A

.

Page 287 of 339

285

Emergencies

6. Position the leads in such a way that they cannot come into contact with any moving parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boosting battery and let it run at idling speed.

8. Start the engine of the vehicle with the flat battery and wait two or three minutes until the engine is “running”.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped beam headlights (if they are switched on).

10.Turn on the heater blower and heated rear window in the vehi- cle with the flat battery. This helps minimise voltage peaks

which are generated when the leads are disconnected.

11.When the engine is running, disconnect the leads in reverse or- der to the details given above.

Connect the battery clamps so they have good metal-to-metal contact with

the battery terminals.

If the engine fails to start, switch off the starter after about 10 seconds and

try again after about half a minute.

WARNING

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 251.

● The battery providing assistance must have the same voltage as the

flat battery (12V) and approximately the same capacity (see imprint on

battery). Failure to comply could result in an explosion.

● Never use jump leads when one of the batteries is frozen. Danger of

explosion! Even after the battery has thawed, battery acid could leak and

cause chemical burns. If a battery freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes away from batteries, dan-

ger of explosion. Failure to comply could result in an explosion.

● Observe the instructions provided by the manufacturer of the jump

leads.

● Do not connect the negative cable from the other vehicle directly to

the negative terminal of the flat battery. The gas emitted from the battery

could be ignited by sparks. Danger of explosion.

● Do not attach the negative cable from the other vehicle to parts of the

fuel system or to the brake line.

● The non-insulated parts of the battery clamps must not be allowed to

touch. The jump lead attached to the positive battery terminal must not

touch metal parts of the vehicle, this can cause a short circuit.

● Position the leads in such a way that they cannot come into contact

with any moving parts in the engine compartment.

● Do not lean on the batteries. This could result in chemical burns.

Note

The vehicles must not touch each other, otherwise electricity could flow as

soon as the positive terminals are connected.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 288 of 339

286Emergencies

Towing and tow-starting the vehicle

General information

Points to observe when tow-starting or towing away If you use a tow rope:

Notes for the driver of the towing vehicle

– The tow rope must be taut before you drive off.

– Release the clutch very carefully when starting the vehicle

(manual gearbox), or accelerate gently (automatic gearbox).

Notes for the driver of the towed vehicle

– The ignition should be switched on so that the turn signals,

windscreen wipers and washers can be used. Please ensure

that the steering wheel is unlocked when you switch on the ig-

nition, and that it moves freely.

– Put the gearbox lever in neutral (manual gearbox) or move the

selector lever to position N (automatic gearbox).

– The brake servo only works when the engine is running. Consid-

erably more effort is required on the brake pedal when the en-

gine is switched off.

– Remember that the power steering only works when the ignition

is switched on and the vehicle is moving 1)

. Otherwise, consider-

ably more strength than usual will be required when steering. –

Ensure that the tow rope remains taut at all times.

Tow rope or tow bar

It is easier and safer to tow a vehicle with a tow bar. You should only use a

tow rope if you do not have a tow bar.

A tow rope should be slightly elastic to avoid damage to both vehicles. It is

advisable to use a tow rope made of synthetic fibre or similarly elastic mate-

rial.

Only attach the tow rope or the tow bar to the towing rings ⇒ page 287.

Driving style

Towing requires some experience, especially when using a tow rope. Both

drivers should be familiar with the technique required for towing. Inexper-

ienced drivers should not attempt to tow.

Do not pull too hard with the towing vehicle and take care to avoid jerking

the tow rope. When towing on an unpaved road, there is always a risk of

overloading and damaging the anchorage points.

WARNING

If the vehicle has no electrical power, the brake lights, turn signals and

all other lights will no longer function. Do not have the vehicle towed

away. Failure to do so could result in an accident.

CAUTION

If there is no oil in the gearbox or no lubricant in the automatic transmission

the car may only be towed with the driven wheels lifted clear of the road, or

transported on a special car transporter or trailer.

1)

Important: the battery must be correctly charged.

Page 291 of 339

289

Emergencies

Tow-starting

As a general rule, tow-starting is not recommended.

– Engage 2nd or 3rd gear before moving off.

– Press the clutch and hold the pedal down.

– Switch the ignition on.

– Once both vehicles are moving, release the clutch.

– As soon as the engine starts: press the clutch and put the gear

lever in neutral.

If the engine will not start, it is best to try starting it using the battery of an-

other vehicle ⇒ page 283 before attempting to tow start. You should only try

to tow-start the engine if jump starting is not successful. Tow-starting is an

attempt to start the engine via the movement of the wheels.

When tow-starting a vehicle with a petrol engine, do not tow it more than a

short distance, otherwise unburned fuel can enter the catalytic converter

and cause damage.

WARNING

The risk of accidents is high when tow-starting, as the towed vehicle can

easily be driven into the towing vehicle.

CAUTION

Do not tow vehicles for more than 50 m. Risk of damage to the catalytic con-

verter. Towing vehicles with a manual gearbox

Towing is relatively straightforward.

Please observe the relevant instructions ⇒ page 286.

The vehicle can be towed using a tow bar or tow rope in the normal way,

with all four wheels on the road; it can also be towed with either the front or

rear wheels lifted off the road. The maximum towing speed is 50 km/h (30

mph).

Towing a vehicle equipped with automatic gearbox

Certain restrictions must be observed when towing your ve-

hicle. Please observe the relevant instructions ⇒ page 286.

The vehicle can be towed with a tow bar or tow rope in the normal way, with

all four wheels on the ground. When doing so, please note the following

points:

● Make sure the selector lever is in the N position.

● The vehicle must not be towed faster than 50 km/h (30 mph).

● The vehicle must not be towed further than 50 km (30 miles). Reason:

when the engine is not running, the gearbox oil pump does not work and

the gearbox is not adequately lubricated for higher speeds or longer distan-

ces.

If the vehicle has to be towed with a breakdown truck, it must only be sus-

pended at the front wheels. Reason: the drive shafts are located on the front

wheels. If the car is towed with the rear wheels lifted off the road (I.e. travel-

ling backwards), the drive shafts also turn backwards. The planetary gears

in the automatic gearbox then turn at such high speeds that the gearbox

will be severely damaged in a short time.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 311 of 339

309

Technical specifications

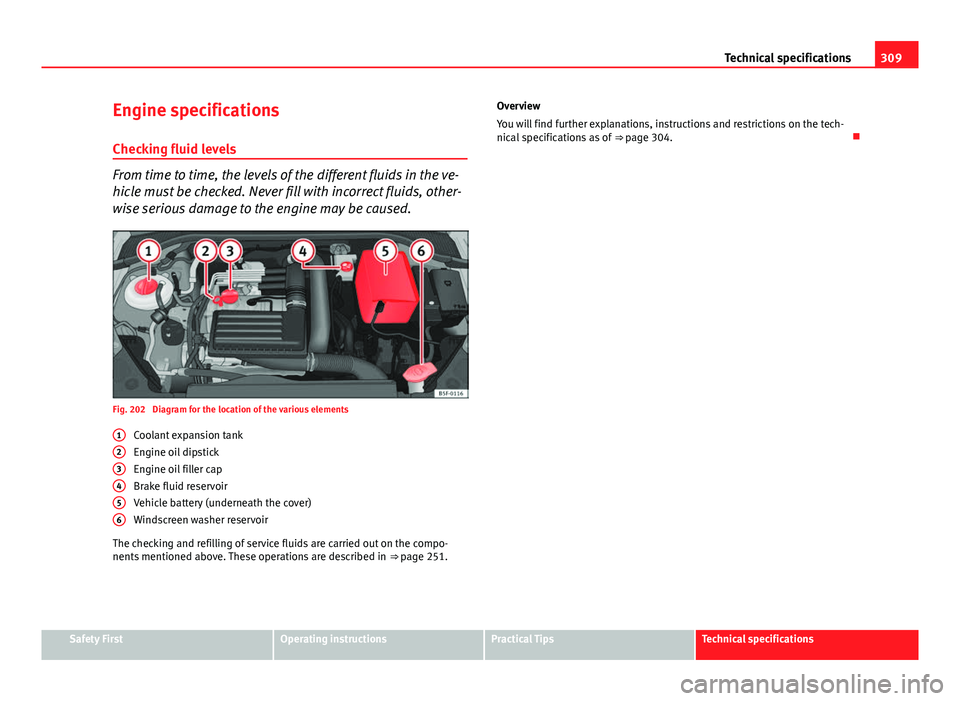

Engine specifications

Checking fluid levels

From time to time, the levels of the different fluids in the ve-

hicle must be checked. Never fill with incorrect fluids, other-

wise serious damage to the engine may be caused.

Fig. 202 Diagram for the location of the various elements Coolant expansion tank

Engine oil dipstick

Engine oil filler cap

Brake fluid reservoir

Vehicle battery (underneath the cover)

Windscreen washer reservoir

The checking and refilling of service fluids are carried out on the compo-

nents mentioned above. These operations are described in ⇒ page 251.

1

23456

Overview

You will find further explanations, instructions and restrictions on the tech-

nical specifications as of

⇒ page 304.

Safety FirstOperating instructionsPractical TipsTechnical specifications