engine Seat Leon 5D 2017 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2017, Model line: Leon 5D, Model: Seat Leon 5D 2017Pages: 332, PDF Size: 7.25 MB

Page 51 of 332

The essentials

Ignition: Do not carry on

driving! Engine coolant level

too low, coolant temperature

too high

››› page

274

Flashing: Fault in the engine

coolant system.

Do not continue driving!

Engine oil pressure too low. If

the warning lamp flashes,

stop driving, even if the oil

level is correct. Do not even

run the engine at idle speed!

››› page

272

Fault in the battery.›››

page

277

Driving light totally or partially

faulty.›››

page

103

Fault in the cornering light

system.››› page

140

Diesel particulate filter

blocked›››

page

203

Level of windscreen washer

fluid too low.›››

page

148

Flashing: Fault in the oil level

detection. Control manually.

›››

page

272

Ignition: Insufficient engine

oil.

Fault in the gearbox.›››

page

198

Light Assist on.›››

page

142

Immobiliser active.›››

page

131

Service interval display›››

page 44

Mobile telephone is connec-

ted via Bluetooth to the origi-

nal telephone device.›››

page

121

››› page

123

››› Booklet

Audio or

navigation

system

Mobile telephone battery

charge meter. Available only

for devices pre-installed in fac-

tory.

Freezing warning. The outside

temperature is lower than

+4°C (+39°F).›››

page 42

Start-Stop system activated.›››

page

205

Start-Stop system unavailable.

Low consumption driving sta-

tus›››

page

115

›››

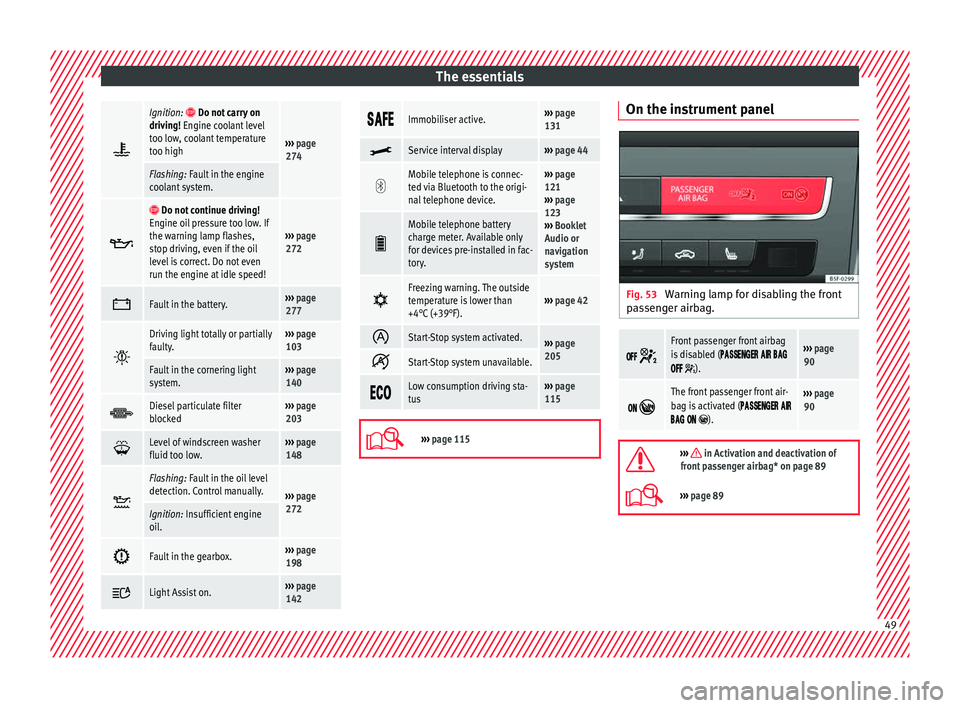

page 115 On the instrument panel

Fig. 53

Warning lamp for disabling the front

p a

s

senger airbag.

Front passenger front airbag

is disabled (

).

››› page

90

The front passenger front air-

bag is activated (

).

››› page

90

››› in Activation and deactivation of

front passenger airbag* on page 89

››› page 89 49

Page 55 of 332

The essentials4Indications on the temperature display screen selected for the right and left sides.

Defrost functionThe air drawn in from outside the vehicle is directed at the windscreen and air recirculation is automatically switched off. To defrost the wind-

screen more quickly, the air is dehumidified at temperatures over approximately +3°C (+38°F) and the fan runs at maximum output.

Heated rear window: this only works when the engine is running and switches off automatically after a maximum of 10 minutes.

Air recirculation

Seat heating buttons

Press the button to switch on or off the cooling system.

Press the button to make maximum cooling capacity available. The recirculation of air and the cooling system turn on automatically and air distri-

bution adjusts automatically to the position .

When the warning light for button lights up, the settings on the driver side also apply to the passenger side. Press the button or the temper-

ature control on the passenger side

Automatic adjustment of temperature, fan, and air distribution. Press the button: the warning lamp on the button will light up .

Press the configuration button : the air conditioning operation menu will be displayed on the Easy Connect system screen.

Switching offTurn the blower control to the position or press the button.

››› in Introduction on page 173

›››

page 173 53

Page 57 of 332

The essentials3Air distribution

: Defrost function. The airflow is directed at the windscreen. Air recirculation is automatically switched off or is not switched on. Increase the fan power

to clear the windscreen of condensation as soon as possible. To dehumidify the air, the cooling system will automatically switch on.

: The air is directed at the chest of driver and passengers by the dash panel air vents.

: Distribution of air towards the chest and the footwell area.

: Air distribution to footwells.

: Air distribution towards the windscreen and the footwell.

Press the button to switch on or off the cooling system.

Heated rear window: this only works when the engine is running and switches off automatically after a maximum of 10 minutes.

Air recirculation

Seat heating buttons

››› in Introduction on page 173

›››

page 173 55

Page 59 of 332

The essentials

Heated rear window: this only works when the engine is running and switches off automatically after a maximum of 10 minutes

Air recirculation

››› page 176

››› in Introduction on page 173

›››

page 173 57

Page 60 of 332

The essentials

Fluid Level control Fi l

lin

g capacities

Tank level

Petrol and diesel

engines50 l, of which, approx. 7 l reserveVehicles with all-wheel-drive :

55 l, of which, approx. 8.5 l re- serve

Natural gas en-

ginea)approx. 15 kg

a)

The capacity depends on the efficacy and characteristics of

the natural gas pumps. The capacity indicated is based on a

minimum loading pressure of 200 bar.

Capacity of the windscreen washer fluid container

Versions without

headlight washer

systemapprox. 3 litres

Versions with

headlight washer

systemapprox. 5 litres Fuel

Fig. 60

Fuel tank flap with tank cap attached. The flap that covers the tank cap is unlocked

and loc

k

ed aut

omatically using the central

locking.

Opening the fuel tank cap

● Open the fuel tank flap by pressing on the

left

side.

● Unscrew the cap by turning it to the left. ●

Place it

in the space on the hinge of the

open flap ››› Fig. 60.

Closing the fuel tank cap ● Unscrew the cap by turning it to the right as

far as

it will go.

● Close the lid.

››› in Refuelling on page 265

››› page 264 58

Page 61 of 332

The essentials

Oil Fig. 61

Engine oil dipstick. Fig. 62

In the engine compartment: Engine

oil fi

ller cap. The level is measured using the dipstick loca-

t

ed in the en

gine c

ompartment

››› page 270.

The oil should leave a mark between zones A and

C . It should never exceed zone

A .

● Zone A : Do not add oil.

● Zone B : You can add oil but keep the level

in th at

zone. ●

Zone C : Add oil up to zone

B .

T op

pin

g up engine oil

● Unscrew cap from oil filler opening.

● Add oil slowly.

● At the same time, check the level to ensure

you do not a

dd too much. ●

When the oil l

evel reaches at least zone B ,

u n

s

crew the engine oil filler cap carefully.

Engine oil additives

No type of additive should be mixed with the

engine oil. The deterioration caused by these

additives is not covered by the warranty. » 59

Page 62 of 332

The essentials

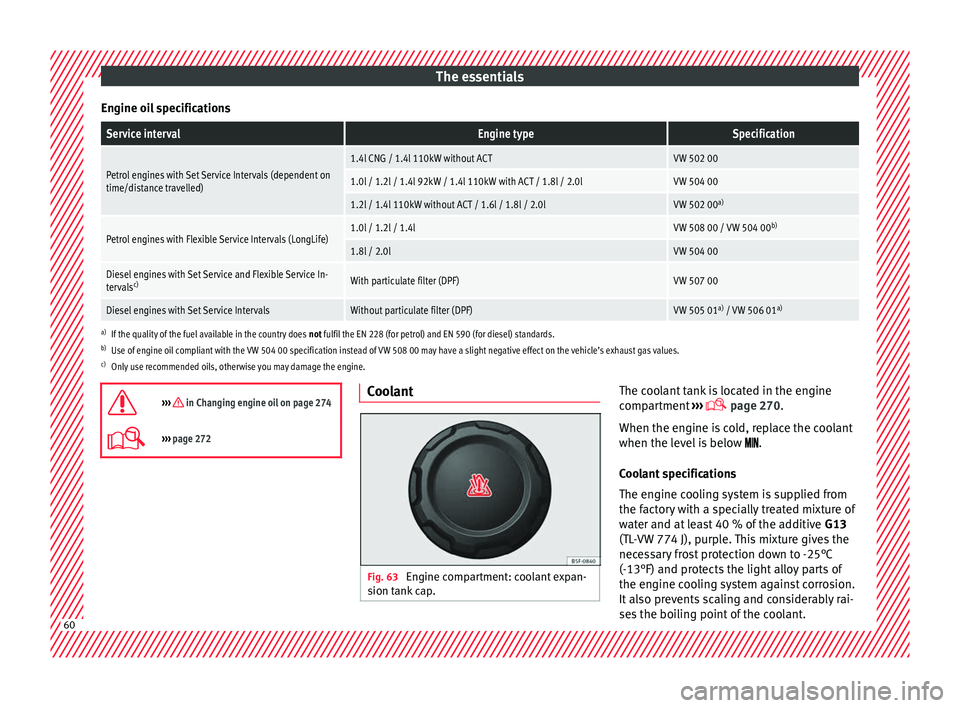

Engine oil specificationsService intervalEngine typeSpecification

Petrol engines with Set Service Intervals (dependent on

time/distance travelled)1.4l CNG / 1.4l 110kW without ACTVW 502 00

1.0l / 1.2l / 1.4l 92kW / 1.4l 110kW with ACT / 1.8l / 2.0lVW 504 00

1.2l / 1.4l 110kW without ACT / 1.6l / 1.8l / 2.0lVW 502 00 a)

Petrol engines with Flexible Service Intervals (LongLife)1.0l / 1.2l / 1.4lVW 508 00 / VW 504 00 b)

1.8l / 2.0lVW 504 00

Diesel engines with Set Service and Flexible Service In-

tervalsc)With particulate filter (DPF)VW 507 00

Diesel engines with Set Service IntervalsWithout particulate filter (DPF)VW 505 01 a)

/ VW 506 01 a)

a)

If the quality of the fuel available in the country does not fulfil the EN 228 (for petrol) and EN 590 (for diesel) standards.

b) Use of engine oil compliant with the VW 504 00 specification instead of VW 508 00 may have a slight negative effect on the vehicle’s exhaust gas values.

c) Only use recommended oils, otherwise you may damage the engine.

››› in Changing engine oil on page 274

››› page 272 Coolant

Fig. 63

Engine compartment: coolant expan-

s ion t

ank

cap. The coolant tank is located in the engine

c

omp

ar

tment ›››

page 270.

When the engine is cold, replace the coolant

when the level is below .

Coolant specifications

The engine cooling system is supplied from

the factory with a specially treated mixture of

water and at least 40 % of the additive G13

(TL-VW 774 J), purple. This mixture gives the

necessary frost protection down to -25°C

(-13°F) and protects the light alloy parts of

the engine cooling system against corrosion.

It also prevents scaling and considerably rai-

ses the boiling point of the coolant. 60

Page 63 of 332

The essentials

To protect the cooling system, the percentage

of a

d

ditive must always be at least 40 %,

even in warm climates where anti-freeze pro-

tection is not required.

If for weather reasons further protection is

necessary, the proportion of additive may be

increased, but only up to 60 %; otherwise an-

tifreeze protection will diminish and this will

worsen cooling.

When the coolant is topped up, use a mixture

of distilled water and at least 40 % of the

G13 or G12 plus-plus (TL-VW 774 G) additive

(both are purple) to obtain an optimum anti-

corrosion protection ››› in Topping up cool-

ant on p ag

e 275

. The mixture of G13 with

G12 plus (TL-VW 774 F), G12 (red) or G11

(green-blue) engine coolants will significant-

ly reduce anti-corrosion protection and

should therefore be avoided ››› in Topping

up c oo

l

ant on page 275.

››› in Topping up coolant on page 275

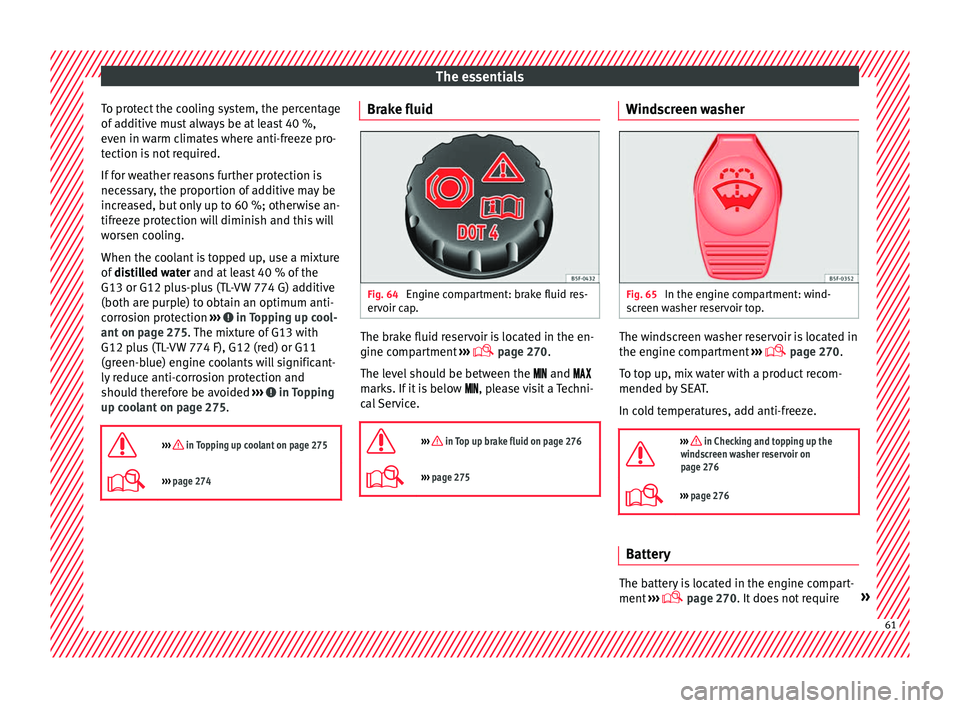

››› page 274 Brake fluid

Fig. 64

Engine compartment: brake fluid res-

er v

oir c

ap. The brake fluid reservoir is located in the en-

gine c

omp

ar

tment ›››

page 270

.

The level should be between the and

marks. If it is below , please visit a Techni-

cal Service.

››› in Top up brake fluid on page 276

››› page 275 Windscreen washer

Fig. 65

In the engine compartment: wind-

s c

r

een washer reservoir top. The windscreen washer reservoir is located in

the en

gine c

omp

artment ›››

page 270.

To top up, mix water with a product recom-

mended by SEAT.

In cold temperatures, add anti-freeze.

››› in Checking and topping up the

windscreen washer reservoir on

page 276

››› page 276 Battery

The battery is located in the engine compart-

ment

›

›

› page 270. It does not require » 61

Page 65 of 332

The essentials

Emergencies F u

se

s

Fuse location Fig. 66

On the driver-side dash panel: fuse

bo x

c

over. Fig. 67

In the engine compartment: fuse box

c o

v

er. Underneath the instrument panel

The f

use bo

x is located behind the storage

compartment ››› Fig. 66.

In the engine compartment

Press the locking tabs to release the fuse box

cover ››› Fig. 67.

Identifying fuses situated below the dash

panel by colours

ColourAmp rating

Black1

Purple3

Light brown5

Brown7.5

Red10

Blue15

Yellow20

White or transparent25

Green30

Orange40

››› in Introduction on page 101

›››

page 101 Replacing a blown fuse

Fig. 68

Image of a blown fuse. Preparation

●

Switch off the ignition, lights and all elec-

tric al

equipment

.

● Open the corresponding fuse box

›››

page 102.

Identifying a blown fuse

A fuse is blown if its metal strip is ruptured

››› Fig. 68.

● Point a lamp at the fuse to see if it has

blown.

T

o replace a fuse

● Remove the fuse.

● Replace the blown fuse by one with an

identica

l amperage rating (same colour and

markings) and identical size. » 63

Page 67 of 332

The essentials

Repairing a tyre with the anti-punc-

t ur

e k

it Fig. 69

Standard representation: contents of

the anti-p u

nct

ure kit. The anti-puncture kit is located under the

floor p

anel

in the lug

gage compartment.

Sealing the tyre

● Unscrew the tyre valve cap and insert. Use

the ›››

Fig. 69 1 tool to remove the insert.

Pl ac

e it

on a clean surface.

● Shake the tyre sealant bottle vigorously

›››

Fig. 69 10 .

● Screw the inflator tube ››

›

Fig. 69 3 into

the se al

ant

bottle. The bottle's seal will break

automatically. ●

Remov

e the lid from the filling tube

››› Fig. 69 3 and screw the open end of the

t ube int

o the ty

re valve.

● With the tyre sealant bottle upside down,

fill

the tyre with the contents of the sealant

bottle.

● Remove the bottle from the valve.

● Place the insert back into the tyre valve us-

ing the too

l ››› Fig. 69 1 .

Infl atin

g the ty

re

● Screw the compressor tyre inflator tube

›››

Fig. 69 5 into the tyre valve.

● Check that the air bleed screw is closed

› ›

›

Fig. 69 7 .

● Start the engine and leave it running.

● Insert the connector ››

›

Fig. 69 9 into the

v ehic

l

e's 12-volt socket ›››

page 159.

● Turn the air compressor on with the ON/OFF

switc

h ››› Fig. 69 8 .

● Keep the air compressor running until it

r e

ac

hes 2.0 to 2.5 bar

(29-36 psi/200-250 kPa). A maximum of 8

minutes.

● Disconnect the air compressor.

● If it does not reach the pressure indicated,

uns

crew the tyre inflator tube from the valve.

● Move the vehicle 10m so that the sealant is

dis trib

uted throughout the tyre. ●

Scr ew the c

ompressor tyre inflator into the

valve.

● Repeat the inflation process.

● If the indicated pressure still cannot be

reac

hed, the tyre is too badly damaged. Stop

and request assistance from an authorised

technician.

● Disconnect the air compressor. Unscrew

the tyre infl

ator tube from the tyre valve.

● When the tyre pressure is between 2.5 and

2.0 bars, c

ontinue driving without exceeding

80 km/h (50 mph).

● Check the pressure again after 10 minutes

›››

page 97.

››› in TMS (Tyre Mobility System)* on

page 95

››› page 95 65