oil Seat Leon SC 2014 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Leon SC, Model: Seat Leon SC 2014Pages: 284, PDF Size: 5.85 MB

Page 149 of 284

Driver assistance systems

Low brake fluid level

Malfunctions can occur in the brake system if

the brake fluid level is too low. The brake flu-

id level is monitored electronically.

Brake servo

The brake servo increases the pressure you

apply to the brake pedal. It works only when

the engine is running. WARNING

● Apply the brakes heavily to clean the brake

system only in a suitable traffic situation. Do

not put other road users in danger: there is

risk of causing an accident.

● Ensure the vehicle does not move while in

neutral, when the engine is stopped. Failure

to follow this instruction could result in an

accident.

● If the brake fluid loses its viscosity and is

subjected to heavy use, vapour bubbles can

form in the brake system. This reduces the ef-

ficiency of the brakes. CAUTION

● Never let the brakes “drag” by leaving your

foot on the pedal when it is not necessary to

brake. This overheats the brakes, resulting in

longer stopping distances and greater wear.

● Before driving down a long, steep gradient,

it is advisable to reduce speed and select a

lower gear. This makes use of engine braking and relieves the brakes. If you still have to

use the brakes, it is better to brake firmly at

intervals than to apply the brakes continu-

ously.

Note

● If the brake servo is out of action, for exam-

ple when the car is being towed, you will

have to press the brake pedal considerably

harder than normal to make up for the lack of

servo assistance.

● If you wish to equip the vehicle with acces-

sories such as a front spoiler or wheel covers,

it is important that the flow of air to the front

wheels is not obstructed, otherwise the

brakes can overheat. Hill driving assistant*

This function is only included in vehicles with

ESC.

The hill driving assistant helps the driver to

move off and upward on a hill when the vehi-

cle is stationary.

The system maintains brake pressure for ap-

proximately two seconds after the driver

takes his foot off the brake pedal to prevent

the vehicle from lurching backward when it is

started. During these 2 seconds, the driver

has enough time to release the clutch pedal

and accelerate without the vehicle moving

and without having to use the handbrake,making start-up easier, more comfortable

and safer.

These are the basic operation conditions:

● being on a ramp or hill/slope,

● doors closed,

● vehicle completely stationary,

● engine running and foot on the brake,

● besides having a gear engaged or being in

neutral for manual gear change and with the

selector lever at position S,

D or R for an au-

tomatic gearbox.

This system is also active when reversing up-

hill. WARNING

● If you do not start the vehicle immediately

after taking your foot off the brake pedal, the

vehicle may start to roll back under certain

conditions. Depress the brake pedal or use

the hand brake immediately.

● If the engine stalls, depress the brake ped-

al or use the hand brake immediately.

● When following a line of traffic uphill, if you

want to prevent the vehicle from rolling back

accidentally when starting off, hold the brake

pedal down for a few seconds before starting

off. » 147

Technical specifications

Advice

Operation

Safety

The essentials

Page 156 of 284

Operation

ACC operation may be affected by a strong ra-

dar reverse reflection. This may occur, for ex-

ample, in a closed car park or due to the

presence of metallic objects (e.g. rails on the

road or sheets used in road works).

The area in front of and around the radar sen-

sor should not be covered with adhesives,

additional or similar headlights, as this may

negatively affect ACC operation.

If structural modifications are made to the ve-

hicle, for example, if the suspension is low-

ered or the front spoiler is modified, ACC op-

eration may be affected. So structural modifi-

cations should only be made by specialised

workshops. SEAT recommends visiting a SEAT

dealership for this purpose.

If work is done incorrectly on the front of the

vehicle, the radar sensor could be damaged

or lose its settings, and ACC operation may

be affected. So repair work should only be

made by specialised workshops. SEAT recom-

mends visiting a SEAT dealership for this pur-

pose. CAUTION

If you have the sensation that the radar sen-

sor is damaged or has lost its settings, dis-

connect the ACC. This will avoid possible

damage. If this occurs have it adjusted. ● The sensor may become damaged or lose

its settings when knocked, for example, dur- ing a parking manoeuvre. This may compro-

mise the system's efficacy or disconnect it.

●

Repairs to the radar sensor require special-

ist knowledge and special tools. SEAT recom-

mends visiting a SEAT dealership for this pur-

pose.

● Clean away the snow with a brush and the

ice preferably with a solvent-free de-icer

spray. Operating the Adaptive Cruise Control

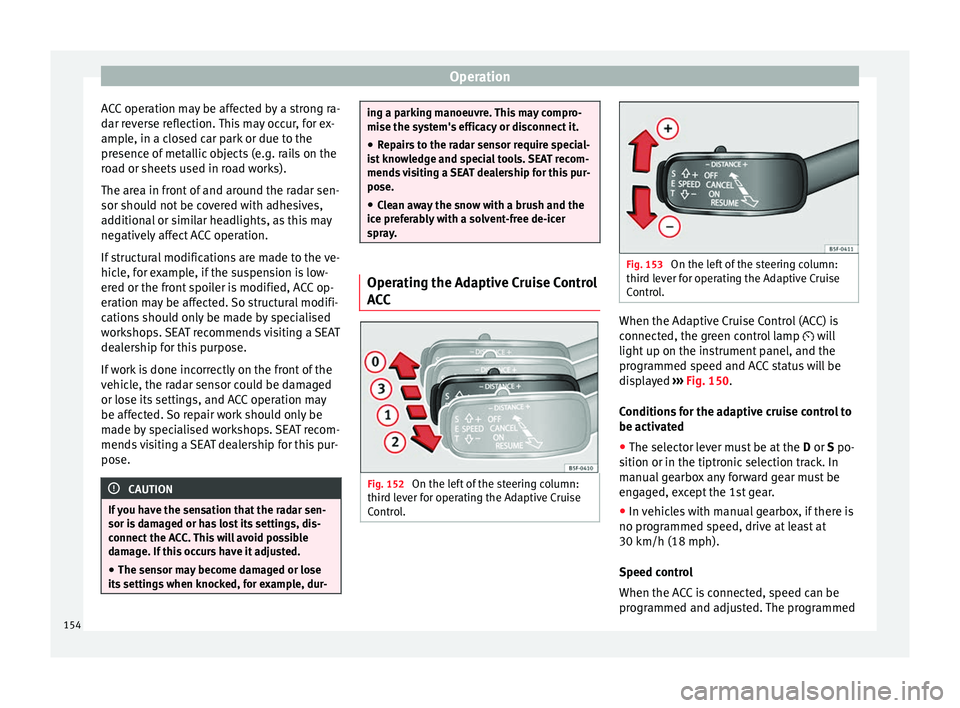

ACC

Fig. 152

On the left of the steering column:

third lever for operating the Adaptive Cruise

Control. Fig. 153

On the left of the steering column:

third lever for operating the Adaptive Cruise

Control. When the Adaptive Cruise Control (ACC) is

connected, the green control lamp will

light up on the instrument panel, and the

programmed speed and ACC status will be

displayed

››› Fig. 150 .

C ondition

s for the adaptive cruise control to

be activated

● The selector lever must be at the D or S po-

sition or in the tiptronic selection track. In

manual gearbox any forward gear must be

engaged, except the 1st gear.

● In vehicles with manual gearbox, if there is

no programmed speed, drive at least at

30 km/h (18 mph).

Speed control

When the ACC is connected, speed can be

programmed and adjusted. The programmed

154

Page 165 of 284

Driver assistance systems

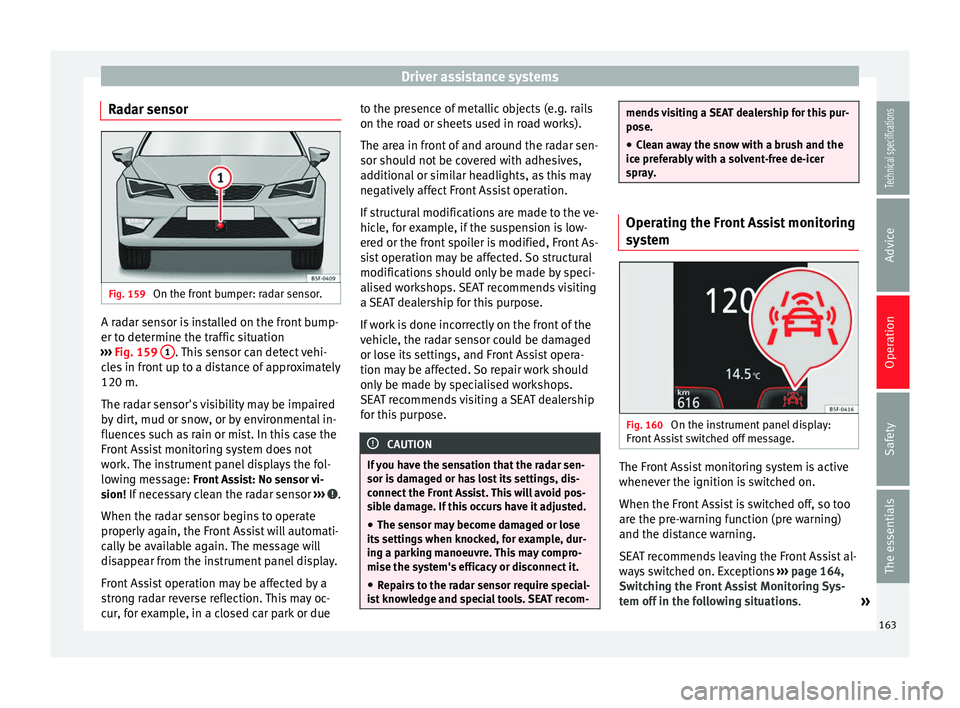

Radar sensor Fig. 159

On the front bumper: radar sensor. A radar sensor is installed on the front bump-

er to determine the traffic situation

››› Fig. 159 1 . This sensor can detect vehi-

cles in front up to a distance of approximately

120 m.

The radar sensor's visibility may be impaired

by dirt, mud or snow, or by environmental in-

fluences such as rain or mist. In this case the

Front Assist monitoring system does not

work. The instrument panel displays the fol-

lowing message: Front Assist: No sensor vi- sion! If necessary clean the radar sensor ››› .

When the radar sensor begins to operate

properly again, the Front Assist will automati-

cally be available again. The message will

disappear from the instrument panel display.

Front Assist operation may be affected by a

strong radar reverse reflection. This may oc-

cur, for example, in a closed car park or due to the presence of metallic objects (e.g. rails

on the road or sheets used in road works).

The area in front of and around the radar sen-

sor should not be covered with adhesives,

additional or similar headlights, as this may

negatively affect Front Assist operation.

If structural modifications are made to the ve-

hicle, for example, if the suspension is low-

ered or the front spoiler is modified, Front As-

sist operation may be affected. So structural

modifications should only be made by speci-

alised workshops. SEAT recommends visiting

a SEAT dealership for this purpose.

If work is done incorrectly on the front of the

vehicle, the radar sensor could be damaged

or lose its settings, and Front Assist opera-

tion may be affected. So repair work should

only be made by specialised workshops.

SEAT recommends visiting a SEAT dealership

for this purpose.

CAUTION

If you have the sensation that the radar sen-

sor is damaged or has lost its settings, dis-

connect the Front Assist. This will avoid pos-

sible damage. If this occurs have it adjusted. ● The sensor may become damaged or lose

its settings when knocked, for example, dur-

ing a parking manoeuvre. This may compro-

mise the system's efficacy or disconnect it.

● Repairs to the radar sensor require special-

ist knowledge and special tools. SEAT recom- mends visiting a SEAT dealership for this pur-

pose.

● Clean away the snow with a brush and the

ice preferably with a solvent-free de-icer

spray. Operating the Front Assist monitoring

system

Fig. 160

On the instrument panel display:

Front Assist switched off message. The Front Assist monitoring system is active

whenever the ignition is switched on.

When the Front Assist is switched off, so too

are the pre-warning function (pre warning)

and the distance warning.

SEAT recommends leaving the Front Assist al-

ways switched on. Exceptions

››› page 164,

Switching the Front Assist Monitoring Sys-

tem off in the following situations .

»

163Technical specifications

Advice

Operation

Safety

The essentials

Page 186 of 284

Advice

Automatic car washes

Before going through a car wash, be sure to

take the usual precautions such as closing

the windows and roof. If the vehicle has spe-

cial accessories such as spoilers or a roof

rack or two-way radio aerial, etc., it is advisa-

ble to consult the car wash tunnel operator.

It is best to use a car wash without revolving

bristles if possible.

Washing the vehicle with a high pressure

cleaner

When washing the vehicle with a high-pres-

sure cleaner, always follow the operating in-

structions for the equipment. This applies

particularly to the operating pressure and the

spraying distance . Do not hold the nozzle too

c lo

se to soft materials such as rubber hoses

or seals. The same applies to the parking aid

sensors*, which are located in the rear bump-

er.

Do not use a nozzle that sprays the water out

in a

direct stream or one that has a rotating

jet for forcing off dirt.

Washing the car by hand

When washing the car by hand, use plenty of

water to soften the dirt first, and rinse off as

well as possible.

Then clean the vehicle with a soft sponge,

glove

or brush using only slight pressure.

You should start on the roof and work down. Special car

soap

should only be used for very

persistent dirt.

Rinse the sponge or glove thoroughly and of-

ten.

Wheels, sills and similar should be cleaned

last. Use a second sponge for this. WARNING

● The vehicle should only be washed with the

ignition switched off. Failure to follow this in-

struction could result in an accident.

● Do not clean the underside of chassis, the

inside of wheel arches or wheel trims without

protecting your hands and arms. You may cut

yourself on sharp-edged metal parts. Other-

wise, there is a risk of sustaining cuts.

● When washing the car during the winter

season: water and ice in the brake system

can reduce braking effectiveness: risk of acci-

dent! CAUTION

● Do not wash the vehicle in direct sunlight –

otherwise the paint can be damaged.

● Do not use sponges, abrasive household

sponges or similar to clean insect remains.

This could damage the surface.

● Clean off stubborn dirt (insects, etc.) from

the headlights at regular intervals, for in-

stance when filling the fuel tank. The head-

lights should only be washed with water, do not wipe them with a dry cloth or sponge. It

is best to use soapy water.

● Never wash tyres with a jet that sprays the

water out in a direct stream. This could dam-

age the tyres even if the spray is kept at a

distance and only used for a very short time.

● Before washing the vehicle in an automatic

car wash, please make sure to retract the ex-

terior mirrors to prevent them from being

damaged. Electrically retractable exterior

mirrors must not be folded in or out by hand,

always use the electrical power control. CAUTION

● Before washing the vehicle in an automatic

car wash, please proceed as follows to lock

the wiper arms so that they are not moved to-

wards the top of the windscreen:

–the bonnet must be closed.

– switch the ignition on and off.

– press the windscreen wiper lever forward

briefly (windscreen washer function).

This will lock the wiper arms. For the sake of the environment

The car should only be washed in special

wash bays. These areas are prepared to pre-

vent oily water from getting into the public

drains. In some places, washing vehicles out-

side the areas intended for this purpose is

prohibited. 184

Page 188 of 284

Advice

Carbon components The carbon parts on your vehicle have a pain-

ted surface. They do not need any special

care and are cleaned just like any other pain-

ted part

››› page 183.

P aint

damage Minor damage to the paint, such as scratches

or stone chips, should be touched up without

delay

before the metal starts to corrode. Suit-

ab l

e touch-up brushes or sprays for your car

can be obtained from a SEAT Official Service.

The number of the original paint finish on the

vehicle is given on the data sticker

››› page 241

.

If corrosion is already visible it must be thor-

oughly removed by a specialised workshop.

Windows Clear vision is an essential safety factor.

The windscreen must not be cleaned with in-

sect remover or wax, otherwise the wind-

screen wipers will not function properly (jud-

dering).

Traces of rubber, oil, grease or silicone can

be removed with a

window cleaning solution

or a silicone remover. Wax residue can only be remo

ved with a special cleaner. Your SEAT

Official Service will be able to provide you

with more detailed information.

The windows should also be cleaned on the

inside at regular intervals.

Use a separate cloth or chamois to dry the

windows. Cloths used for waxing and polish-

ing contain residues that will cause smears

on the glass. WARNING

Do not use water-repellent coatings on the

windscreen. In bad visibility conditions (e.g.

in the rain, dark or with a low sun), these

coatings may cause dazzle: risk of accident!

Such coatings can also cause the windscreen

wiper blades to make noise. CAUTION

● Remove snow and ice from windows and ex-

terior mirrors with a plastic scraper only. To

avoid scratches caused by dirt on the glass,

the scraper should only be pushed in one di-

rection and not moved to and fro.

● The heating element for the rear window is

located on the inner side of the window. To

avoid damaging them, do not apply stickers

to these heating elements.

● Never use warm or hot water to remove

snow and ice from windows and mirrors. This

could cause the glass to crack! Wheels

The wheels require regular attention to pre-

serve their appearance. It is important to re-

move road salt and brake dust by washing

the wheels at regular intervals, otherwise the

finish will be impaired.

After washing, the wheels should only be

cleaned with an "acid-free" cleaning agent

for alloy wheels. This is available from SEAT

Official Services and specialist retailers. Nev-

er leave the cleaning agent on the rims for

any longer than specified in the instructions

before rinsing it off. If the wheel cleaner fluid

contains acid it can attack the surfaces of the

wheel bolts.

Car polish or other abrasive agents should

not be used for maintaining the rims. If the

protective coating is damaged, e.g. by flying

stones, the damaged area should be re-

paired immediately.

WARNING

Please note when cleaning the wheels that

water, ice and road salt can impair the effec-

tiveness of the brakes; this can cause an acci-

dent. Exhaust tail pipe

It is important to remove road salt and brake

dust by washing the wheels at regular

186

Page 189 of 284

Care and maintenance

intervals, otherwise the exhaust tail pipe ma-

terial could be damaged. To remove impuri-

ties, do not use rim, paint or chrome cleaners

or other abrasive products. Clean the exhaust

tail pipes with cleaning products that are

suitable for stainless steel.

SEAT Official Services carry stocks of cleaning

products that have been tested and ap-

proved for use on your vehicle.

Care of the vehicle interior

Radio display/Easy Connect* and

control panel* The display can be cleaned with a soft cloth

and a professionally available “LCD cleaner”.

Moisten the cloth with a small amount of the

cleaning fluid.

The Easy Connect control panel* should first

be cleaned with a brush so that no dirt goes

into the device or between the keys and

housing. Next, we recommend cleaning the

Easy Connect control panel* using a cloth

dampened with water and washing-up liquid.

CAUTION

● To avoid scratching the screen, do not wipe

the display with a dry cloth.

● To avoid damage, ensure that no liquid

goes into the Easy Connect control panel*. Plastic and leatherette parts

Plastic parts and leatherette can be cleaned

with a damp cloth. If this is not sufficient,

plastic parts and leatherette should only be

treated with a special solvent-free plastic

c l

eaner.

Te

xtile covers and trim parts Textile covers and trim parts (e.g. seats, door

trim) should be cleaned regularly with a vac-

uum cleaner. This will remove surface dirt

which could otherwise be rubbed into the

textile material during use. Do not use steam

cleaners, as the steam could carry the dirt

deeper into the textile material.

Normal cleaning

We recommend that you use a soft sponge or

a commercially available lint-free, micro-fibre

cloth for normal cleaning. Only use brushes

on floor coverings and mats, as other textile

surfaces could become damaged.

In the case of normal surface dirt you can use

a foam cleaner. Use a sponge to spread the

foam on the textile surface and to work it into

the material lightly. However, make sure that

the textile material does not become soaking

wet. Then dab off the foam with a dry and ab-

sorbent cloth (e.g. a micro-fibre cloth) andvacuum off any residue once the surface is

completely dry.

Cleaning stains

Treat drink stains (such as coffee or fruit

juice, etc.) with a cleaning solution for deli-

cate fabrics. This solution should be applied

with a sponge. If the stains are difficult to re-

move, a washing paste can be applied direct-

ly onto the stain and worked into the fabric.

The surface will then have to be wiped with

clear water to remove any residue left by the

paste. To do so, use a damp cloth or sponge

and then dab the stain with an absorbent

cloth.

Remove chocolate or make-up stains with a

cleaning paste (for e.g., soft soap). Then re-

move the soap with water (wet sponge).

A spirit-based cleaner can be used to remove

grease, oil, lipstick or ball point pen. Then

dab the dissolved grease or colour particles

off with an absorbent cloth or similar. You

may also have to treat the stain once more

using washing paste and water.

If the covers or textile trim panels are badly

soiled we recommend that you have them

cleaned by a professional cleaning company

with a shampoo and spray.

»

187Technical specifications

Advice

Operation

Safety

The essentials

Page 200 of 284

Advice

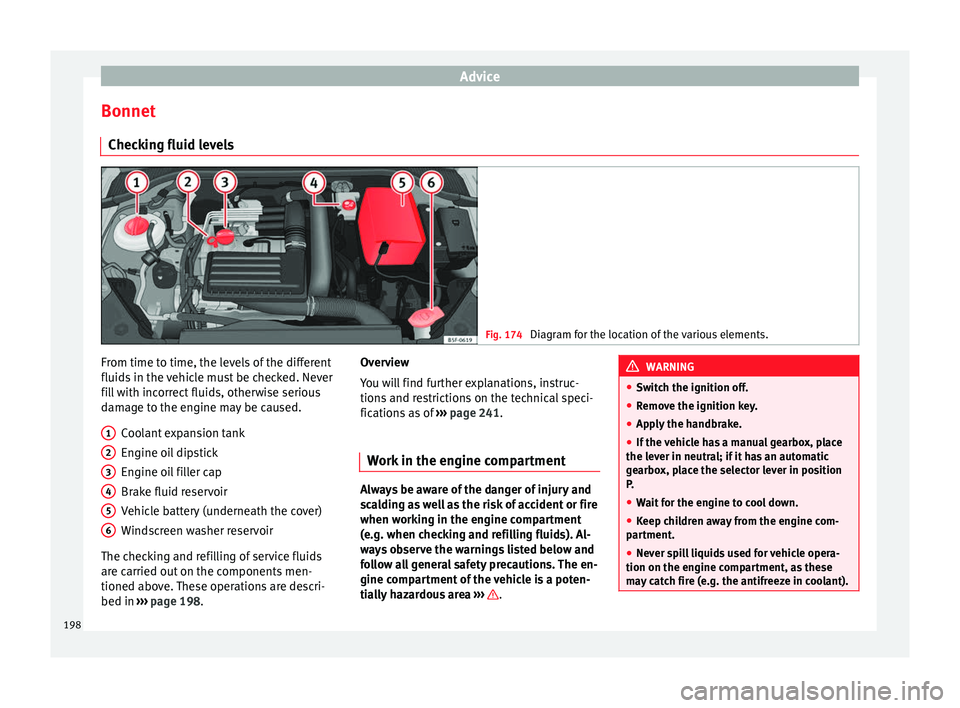

Bonnet Checking fluid levels Fig. 174

Diagram for the location of the various elements. From time to time, the levels of the different

fluids in the vehicle must be checked. Never

fill with incorrect fluids, otherwise serious

damage to the engine may be caused.

Coolant expansion tank

Engine oil dipstick

Engine oil filler cap

Brake fluid reservoir

Vehicle battery (underneath the cover)

Windscreen washer reservoir

The checking and refilling of service fluids

are carried out on the components men-

tioned above. These operations are descri-

bed in ››› page 198 .

1 2

3

4

5

6 Overview

You will find further explanations, instruc-

tions and restrictions on the technical speci-

fications as of

››› page 241 .

W ork

in the engine compartment Always be aware of the danger of injury and

scalding as well as the risk of accident or fire

when working in the engine compartment

(e.g. when checking and refilling fluids). Al-

ways observe the warnings listed below and

follow all general safety precautions. The en-

gine compartment of the vehicle is a poten-

tially hazardous area

››› . WARNING

● Switch the ignition off.

● Remove the ignition key.

● Apply the handbrake.

● If the vehicle has a manual gearbox, place

the lever in neutral; if it has an automatic

gearbox, place the selector lever in position

P.

● Wait for the engine to cool down.

● Keep children away from the engine com-

partment.

● Never spill liquids used for vehicle opera-

tion on the engine compartment, as these

may catch fire (e.g. the antifreeze in coolant). 198

Page 201 of 284

Checking and refilling levels

●

Take care not to cause short circuits in the

electrical system, especially when working

on the battery.

● If working inside the engine compartment,

remember that, even when the ignition is

switched off, the radiator fan may start up au-

tomatically, and therefore there is a risk of in-

jury.

● Never cover the engine with additional in-

sulating materials such as a blanket. Risk of

fire!

● Do not unscrew the cap on the coolant ex-

pansion tank when the engine is hot. The

cooling system is under pressure.

● Protect face, hands and arms by covering

the cap with a large, thick rag to protect

against escaping coolant and steam.

● If it is necessary to work in the engine com-

partment while the engine is running, the ro-

tating components (for example, poly-V belt,

alternator, radiator fan) and the high voltage

ignition system are an additional hazard.

● Observe the following additional warnings

if work on the fuel system or the electrical

system is necessary:

– Always disconnect the battery from the

on-board network.

– Do not smoke.

– Never work near naked flames.

– Always keep an approved fire extinguish-

er immediately available. CAUTION

When topping up fluids make sure the correct

fluid is put into the correct filler opening, oth-

erwise this can cause serious malfunctions or

engine damage. For the sake of the environment

Inspect the ground underneath your vehicle

regularly so that any leaks are detected at an

early stage. If you find spots of oil or other

fluids in the area where it was parked, have

your vehicle inspected at the workshop. Note

On right-hand drive vehicles* some of the

containers/reservoirs mentioned below are

located on the other side of the engine com-

partment. Opening the bonnet

Read the additional information carefully

››› page 10

The bonnet is released from inside the vehi-

cle.

Check that the windscreen wiper arms are

not unfolded. Otherwise the paint may be

damaged.

The bonnet can only be unlocked when the

driver door is open. WARNING

Never open the bonnet if you see steam or

drips of coolant being released from the en-

gine compartment. Failure to comply could

result in burns. Wait until no steam or coolant

can be seen before opening the bonnet. Closing the bonnet

–

Slightly lift the bonnet.

– Release the bonnet stay before pressing it

back into its support.

– Carefully close the bonnet.

– Press the bonnet down until it locks into

place.

– Make sure that the bonnet catches onto its

clasp. Do not press down too hard › › › .

WARNING

● For safety reasons the bonnet must always

be completely closed when the vehicle is

moving. Therefore, after closing the bonnet,

always check that the locking element is

properly engaged. This is the case if the bon-

net is flush with the adjacent body panels.

● Should you notice that the bonnet is not

safely secured when the vehicle is moving,

stop the vehicle immediately and close the

bonnet. Failure to follow this instruction

could result in an accident. 199

Technical specifications

Advice

Operation

Safety

The essentials

Page 202 of 284

Advice

Engine oil General notes The engine comes with a special, multi-grade

oil that can be used all year round.

Because the use of high-quality oil is essen-

tial for the correct operation of the engine

and its long useful life, when topping up or

changing oil, use only those oils that comply

with VW standards.

The specifications (VW standards) set out in

the following page should appear on the con-

tainer of the service oil; when the container

displays the specific standards for petrol and

diesel engines together, it means that the oil

can be used for both types of engines.

We recommend that the oil change indicated

in the Maintenance Programme, be per-

formed by a technical service or specialised

workshop.

The correct oil specifications for your engine

are listed in the

›››

page 201, Oil properties .

Service intervals

Service intervals can be flexible (LongLife

service) or fixed (dependent on time/dis-

tance travelled).

If the PR code that appears on the back of the

Maintenance Programme booklet is PR QI6,

this means that your vehicle has the LongLife service programmed. If it lists the codes QI1,

QI2, QI3, QI4 or QI7, the interval service is

dependent on time/distance travelled.

Flexible service intervals (LongLife service

intervals*)

Special oils and processes have been devel-

oped which, depending on the characteris-

tics and individual driving profiles, enable

the extension of the oil change service (Long-

Life service intervals).

Because this oil is essential for extending the

service intervals, it

must only be used ob-

serving the following indications:

● Avoid mixing it with oil for fixed service in-

tervals.

● Only in exceptional circumstances, if the

engine oil level is too low ››› page 201 and

LongLife oil is not available, it is permitted to

top up (once) with oil for fixed service inter-

vals › ››

page 201 (up to a maximum of 0.5 li-

tres).

Fixed service intervals*

If your vehicle does not have the “LongLife

service interval” or it has been disabled (by

request), you may use oils for fixed service

intervals

, which also appear in ››› page 201,

Oil properties . In this case, your vehicle must

be serviced after a fixed interval of 1

year/15,000 km (10,000 miles)(whatever comes first)

››› Booklet Maintenance Pro-

gramme.

● In ex

ceptional circumstances, if the engine

oil level is too low ››› page 201 and you can-

not o

btain the oil specified for your vehicle,

you can add a small quantity of oil conform-

ing to the specification ACEA A2 or ACEA A3

(petrol engines) or ACEA B3 or ACEA B4 (die-

sel engines) (up to 0.5 l).

Vehicles with diesel particulate filter*

The Maintenance Programme states whether

your vehicle is fitted with a diesel particulate

filter.

Only VW 507 00 engine oil, with reduced ash

formation, may be used in diesel engines

equipped with particulate filter. Using other

types of oil will cause a higher soot concen-

tration and reduce the life of the DPF. There-

fore:

● Avoid mixing this oil with other engine oils.

● Only in exceptional circumstances, if the

engine oil level is too low ››› page 201 and

you cannot obtain the oil specified for your

vehicle, you can use a small quantity of oil

(once) conforming to the VW 506 00,

VW 506 01, VW 505 00, VW 505 01 or

ACEA B3/ACEA B4 specification. (up to 0.5 l).

200

Page 203 of 284

Checking and refilling levels

Oil propertiesEngine typeSpecification

Petrol without flexible

service intervalVW 502 00/VW 504 00

Petrol with flexible serv-

ice interval (LongLife)VW 504 00

Diesel. Engines without

Particulate filter (DPF)VW 505 01/VW 506 01/VW

507 00

Diesel. Particulate Filter

Engines (DPF).

With or without flexible

service interval (with

and without LongLife) a)VW 507 00

Natural gas enginesVW 502 00

a)

Only use recommended oils, otherwise you may damage the

engine.

Engine oil additives

No type of additive should be mixed with the

engine oil. The deterioration caused by these

additives is not covered by the warranty. Note

Before a long trip, we recommend finding an

engine oil that conforms to the correspond-

ing VW specifications and recommend keep-

ing it in the vehicle. This way, the correct en-

gine oil will always be available for a top-up if

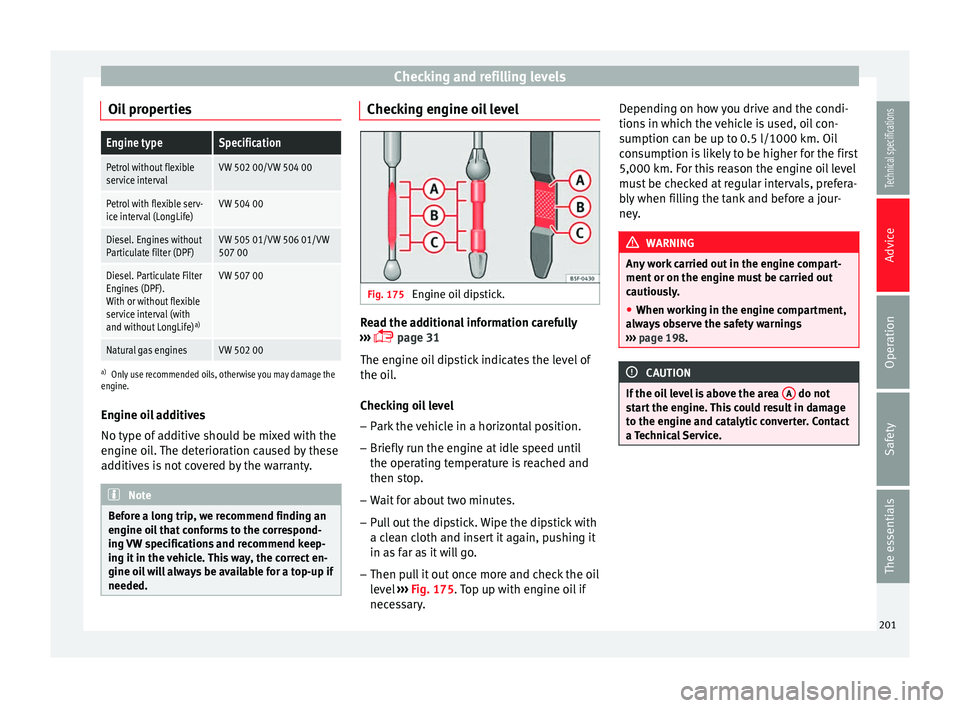

needed. Checking engine oil level

Fig. 175

Engine oil dipstick. Read the additional information carefully

››› page 31

The engine oil dipstick indicates the level of

the oil.

Checking oil level

– Park the vehicle in a horizontal position.

– Briefly run the engine at idle speed until

the operating temperature is reached and

then stop.

– Wait for about two minutes.

– Pull out the dipstick. Wipe the dipstick with

a clean cloth and insert it again, pushing it

in as far as it will go.

– Then pull it out once more and check the oil

level ››› Fig. 175 . Top up with engine oil if

nec e

ssary. Depending on how you drive and the condi-

tions in which the vehicle is used, oil con-

sumption can be up to 0.5 l/1000 km. Oil

consumption is likely to be higher for the first

5,000 km. For this reason the engine oil level

must be checked at regular intervals, prefera-

bly when filling the tank and before a jour-

ney.

WARNING

Any work carried out in the engine compart-

ment or on the engine must be carried out

cautiously.

● When working in the engine compartment,

always observe the safety warnings

››› page 198. CAUTION

If the oil level is above the area A do not

start the engine. This could result in damage

to the engine and catalytic converter. Contact

a Technical Service. 201

Technical specifications

Advice

Operation

Safety

The essentials