fuel Seat Leon SC 2014 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Leon SC, Model: Seat Leon SC 2014Pages: 284, PDF Size: 5.85 MB

Page 180 of 284

Operation

to be reduced accordingly. The weight of the

vehicle and trailer combination must be re-

duced by 10% for every further 1000 m (or

part thereof). The gross combination weight

is the actual weight of the laden vehicle plus

the actual weight of the laden trailer. When

possible, operate the trailer with the maxi-

mum permitted drawbar load on the ball joint

of the t

owing bracket, but do not exceed the

specified limit.

The figures for trailer weights

and drawbar

loads that are given on the data plate of the

to

wing bracket are for certification purposes

only. The correct figures for your specific

model, which may be lower than these fig-

ures for the towing bracket, are given in the

vehicle documentation or in ››› chapter Tech-

nical Data .

Distributing the load

Distribute loads in the trailer so that heavy

objects are as near to the axle as possible.

Loads carried in the trailer must be secured

to prevent them moving.

Tyre pressure

Set tyre pressure to the maximum permissi-

ble pressure shown on the sticker on the in-

side of the fuel tank flap. Set the tyre pres-

sure of the trailer tyres in accordance with the

trailer manufacturer's recommendations. Exterior mirrors

Check whether you can see enough of the

road behind the trailer with the standard rear

vision mirrors. If this is not the case, you

should have additional exterior mirrors fitted.

Both exterior mirrors should be mounted on

hinged extension brackets. Adjust the mirrors

to give sufficient vision to the rear.

Tow rope

Always use a cable between the vehicle and

the trailer

››› page 178.

Tr

ailer rear lights

The trailer's rear lights should comply with

the statutory safety regulations ››› page 178. WARNING

Never transport people in a trailer. This could

result in fatal accidents. Note

● Towing a trailer places additional demands

on the vehicle. We recommend additional

services between the normal inspection inter-

vals if the vehicle is used frequently for tow-

ing a trailer.

● Find out whether special regulations apply

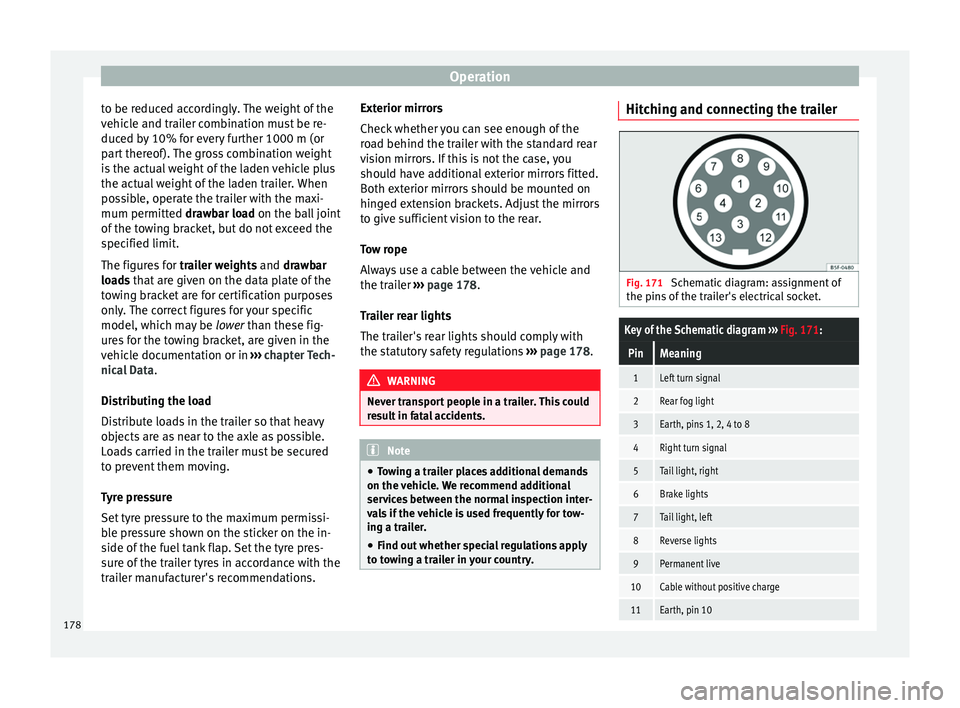

to towing a trailer in your country. Hitching and connecting the trailer

Fig. 171

Schematic diagram: assignment of

the pins of the trailer's electrical socket.

Key of the Schematic diagram ››› Fig. 171:

PinMeaning

1Left turn signal

2Rear fog light

3Earth, pins 1, 2, 4 to 8

4Right turn signal

5Tail light, right

6Brake lights

7Tail light, left

8Reverse lights

9Permanent live

10Cable without positive charge

11Earth, pin 10178

Page 186 of 284

Advice

Automatic car washes

Before going through a car wash, be sure to

take the usual precautions such as closing

the windows and roof. If the vehicle has spe-

cial accessories such as spoilers or a roof

rack or two-way radio aerial, etc., it is advisa-

ble to consult the car wash tunnel operator.

It is best to use a car wash without revolving

bristles if possible.

Washing the vehicle with a high pressure

cleaner

When washing the vehicle with a high-pres-

sure cleaner, always follow the operating in-

structions for the equipment. This applies

particularly to the operating pressure and the

spraying distance . Do not hold the nozzle too

c lo

se to soft materials such as rubber hoses

or seals. The same applies to the parking aid

sensors*, which are located in the rear bump-

er.

Do not use a nozzle that sprays the water out

in a

direct stream or one that has a rotating

jet for forcing off dirt.

Washing the car by hand

When washing the car by hand, use plenty of

water to soften the dirt first, and rinse off as

well as possible.

Then clean the vehicle with a soft sponge,

glove

or brush using only slight pressure.

You should start on the roof and work down. Special car

soap

should only be used for very

persistent dirt.

Rinse the sponge or glove thoroughly and of-

ten.

Wheels, sills and similar should be cleaned

last. Use a second sponge for this. WARNING

● The vehicle should only be washed with the

ignition switched off. Failure to follow this in-

struction could result in an accident.

● Do not clean the underside of chassis, the

inside of wheel arches or wheel trims without

protecting your hands and arms. You may cut

yourself on sharp-edged metal parts. Other-

wise, there is a risk of sustaining cuts.

● When washing the car during the winter

season: water and ice in the brake system

can reduce braking effectiveness: risk of acci-

dent! CAUTION

● Do not wash the vehicle in direct sunlight –

otherwise the paint can be damaged.

● Do not use sponges, abrasive household

sponges or similar to clean insect remains.

This could damage the surface.

● Clean off stubborn dirt (insects, etc.) from

the headlights at regular intervals, for in-

stance when filling the fuel tank. The head-

lights should only be washed with water, do not wipe them with a dry cloth or sponge. It

is best to use soapy water.

● Never wash tyres with a jet that sprays the

water out in a direct stream. This could dam-

age the tyres even if the spray is kept at a

distance and only used for a very short time.

● Before washing the vehicle in an automatic

car wash, please make sure to retract the ex-

terior mirrors to prevent them from being

damaged. Electrically retractable exterior

mirrors must not be folded in or out by hand,

always use the electrical power control. CAUTION

● Before washing the vehicle in an automatic

car wash, please proceed as follows to lock

the wiper arms so that they are not moved to-

wards the top of the windscreen:

–the bonnet must be closed.

– switch the ignition on and off.

– press the windscreen wiper lever forward

briefly (windscreen washer function).

This will lock the wiper arms. For the sake of the environment

The car should only be washed in special

wash bays. These areas are prepared to pre-

vent oily water from getting into the public

drains. In some places, washing vehicles out-

side the areas intended for this purpose is

prohibited. 184

Page 195 of 284

Checking and refilling levels

especially if the battery is not fully charged

initially.

To restore the necessary energy balance, the

system will then temporarily shut off the elec-

trical devices that are using a lot of power, or

reduce the current they are consuming. Heat-

ing systems in particular use a large amount

of electrical power. If you notice, for instance,

that the seat heating* or the rear window

heater is not working, they may have been

temporarily switched off or regulated to a

lower heat output. These systems will be

available again as soon as sufficient electri-

cal power is available.

You may also notice that the engine runs at a

slightly faster idling speed when necessary.

This is quite normal, and no cause for con-

cern. The increased idling speed allows the

alternator to meet the greater power require-

ment and charge the battery at the same

time. Checking and refilling levels

Refuelling Filling the tank Read the additional information carefully

››› page 31

If the automatic filler nozzle is operated cor-

rectly, it will switch itself off as soon as the

fuel tank is “full”. Do not try to put in more

fuel after the nozzle cuts out, as this will fill

the expansion chamber in the fuel tank.

The correct fuel grade for your vehicle is giv-

en on a sticker on the inside of the fuel tank

flap. Further notes on fuel can be found at

››› page 195 .

The c ap

acity of the fuel tank is listed in the

vehicle

technical specifications ›››

page 268. WARNING

Fuel is highly flammable and can cause seri-

ous burns and other injuries.

● Do not smoke when filling the fuel tank or a

canister. Naked flames are forbidden in the

vicinity due to the risk of explosion.

● Observe legislation governing the use,

storage and carrying of a spare fuel canister

in the vehicle.

● For safety reasons we do not recommend

carrying a spare fuel canister in the vehicle. In an accident the canister could be damaged

and could leak.

●

If, in exceptional circumstances, you have

to carry a spare fuel canister, please observe

the following points:

– Never fill fuel into the spare fuel canister

if it is inside or on top of the vehicle. An

electrostatic charge could build up during

filling, causing the fuel vapour to ignite.

Danger of explosion. Always place the

canister on the ground to fill it.

– Insert the filling nozzle as far as possible

into the spare fuel canister.

– If the spare fuel canister is made of met-

al, the filling nozzle must be in contact

with the canister during filling. This

helps prevent an electrostatic charge

building up.

– Never spill fuel in the vehicle or in the

luggage compartment. Fuel vapour is ex-

plosive. Risk of fatal accident! CAUTION

● If any fuel is spilt onto the vehicle, it

should be removed immediately. It could oth-

erwise damage the paintwork.

● Never run the tank completely dry. An irreg-

ular fuel supply could cause misfiring. As a

result, unburnt fuel could enter the exhaust

system and damage the catalytic converter.

● When filling the fuel tank after having run it

completely dry on a vehicle with a diesel en-

gine, the ignition must be switched on for at » 193

Technical specifications

Advice

Operation

Safety

The essentials

Page 196 of 284

Advice

least 30 seconds before starting the engine.

When you then start the engine it may take

longer than normal (up to one minute) to

start firing. This is because air needs to be

bled from the fuel system while starting.

For the sake of the environment

Do not overfill the fuel tank, it may cause the

fuel to overflow if it becomes warm. Note

Diesel vehicles are fitted with a protective de-

vice that prevents the insertion of the wrong

fuel hose 1)

. It is only possible to refuel with

Diesel nozzles.

● If the pump nozzle is worn, damaged, or if

it is very small, it is possible that it will not

be able to open the protective device. Before

trying to insert the pump nozzle by turning it,

try a different pump or request specialist

help.

● If you fill the tank from a reserve fuel canis-

ter, the protective device will not open. One

way to resolve this is to pour the fuel in very

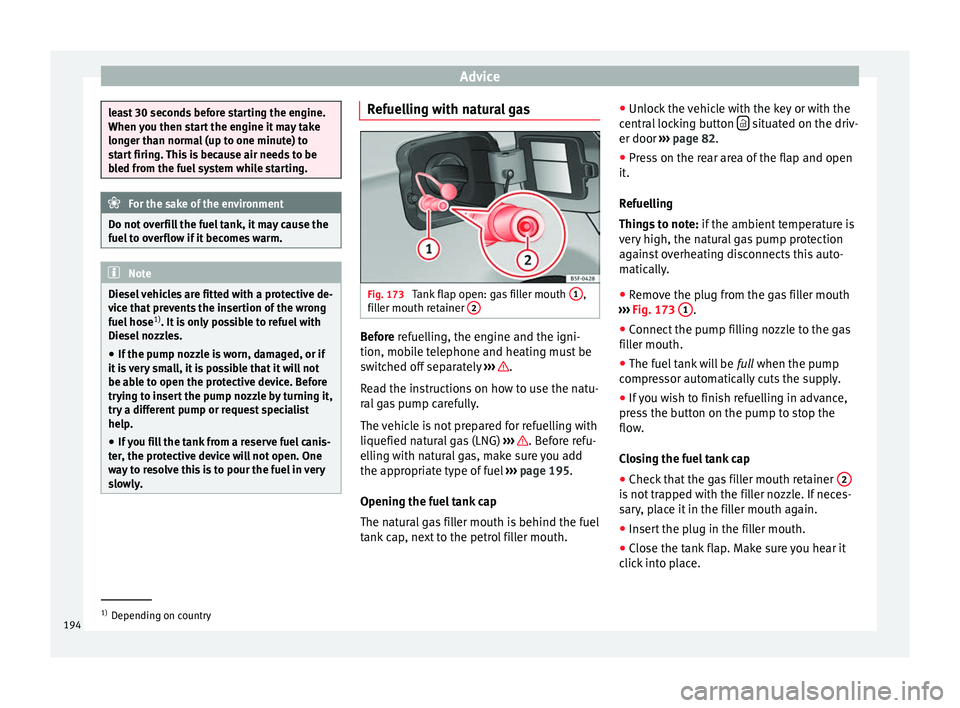

slowly. Refuelling with natural gas

Fig. 173

Tank flap open: gas filler mouth 1 ,

filler mouth retainer 2 Before refuelling, the engine and the igni-

tion, mobile telephone and heating must be

switched off separately

››› .

Read the instructions on how to use the natu-

ral gas pump carefully.

The vehicle is not prepared for refuelling with

liquefied natural gas (LNG) ››› . Before refu-

elling with natural gas, make sure you add

the appropriate type of fuel ››› page 195.

Opening the fuel tank cap

The natural gas filler mouth is behind the fuel

tank cap, next to the petrol filler mouth. ●

Unlock the vehicle with the key or with the

central locking button situated on the driv-

er door ››› page 82 .

● Pr e

ss on the rear area of the flap and open

it.

Refuelling

Things to note: if the ambient temperature is

very high, the natural gas pump protection

against overheating disconnects this auto-

matically.

● Remove the plug from the gas filler mouth

››› Fig. 173 1 .

● Connect the pump filling nozzle to the gas

filler mouth.

● The fuel tank will be full when the pump

c ompr

essor automatically cuts the supply.

● If you wish to finish refuelling in advance,

press the button on the pump to stop the

flow.

Closing the fuel tank cap

● Check that the gas filler mouth retainer 2 is not trapped with the filler nozzle. If neces-

sary, place it in the filler mouth again.

●

Insert the plug in the filler mouth.

● Close the tank flap. Make sure you hear it

click into place. 1)

Depending on country

194

Page 197 of 284

Checking and refilling levels

WARNING

Natural gas is a highly explosive, easily flam-

mable substance. Incorrect handling of the

natural gas can cause accidents serious

burns and other injuries.

● Before refuelling with natural gas, engage

the filling mouth correctly. If you can smell

gas, stop refuelling immediately. WARNING

The vehicle is not prepared to use liquefied

natural gas (LNG), and this fuel must not be

added under any circumstances. Liquefied

natural gas can cause the natural gas tank to

explode, resulting in serious injury. Note

● The filling nozzles of natural gas pumps

can differ in the way they are operated. If you

do not know, ask a qualified employee at the

petrol station to do the refuelling.

● Noises heard when refuelling are normal

and do not indicate the presence of a fault in

the system.

● The vehicle natural gas system is prepared

both for refuelling with a small compressor

(slow refuel) and a large compressor (fast re-

fuel) in natural gas service stations. Fuel

Types of petrol The correct grade of petrol is listed inside the

fuel tank flap.

The vehicle is equipped with a catalytic con-

verter and must only be run on

unleaded pet-

rol. The petrol must comply with European

St and

ard EN 228 or German standard DIN

51626-1 and must be unleaded. You can re-

fuel with a maximum ethanol proportion of

10 % (E10). The types of petrol are differenti-

ated by their octane rating (RON).

The f o

llowing titles appear on the corre-

sponding adhesive on the fuel tank flap:

Super unleaded 95 octane or normal 91

octane unleaded petrol

We recommend you use super 95 octane pet-

rol. If this is not available: normal 91 octane

petrol, with a slight decrease in power.

Super unleaded petrol with a minimum of 95

octanes

You should use super petrol with a minimum

of 95 octanes.

If super is not available, in an emergency you

may refuel with normal 91 octane petrol. In

this case only use moderate engine speeds

and a light throttle. Refuel with super as soon

as possible. Super unleaded 98 octane or super 95

octane unleaded petrol

We recommend you use super plus 98 octane

petrol. If this is not available: super 95 oc-

tane petrol, with a slight decrease in power.

If super is not available,

in an emergency you

may refuel with normal 91 octane petrol. In

this case only use moderate engine speeds

and a light throttle. Refuel with super as soon

as possible.

Petrol additives

The quality of the fuel influences the behav-

iour, power and service life of the engine.

This is why the petrol you use should carry

suitable additives already included by the

petrol industry, free of metals. These addi-

tives will help to prevent corrosion, keep the

fuel system clean and prevent deposits from

building up in the engine.

If good-quality petrol with metal-free addi-

tives is not available or engine problems

arise, the necessary additives must be added

when refuelling ››› .

Not all petrol additives have been shown to

be effective. The use of unsuitable petrol ad-

ditives may cause significant damage to the

engine and the catalytic converter. Metal ad-

ditives should never be used. Metal additives

may also be contained in petrol additives for

improving anti-detonation ratings or octane

ratings ››› .

»

195

Technical specifications

Advice

Operation

Safety

The essentials

Page 198 of 284

Advice

SEAT recommends “genuine Volkswagen

Group Fuel Additives for petrol engines”.

These additives can be bought at SEAT deal-

ers, where information on how to use them

can also be obtained. CAUTION

● Do not refuel if the filler indicates that the

fuel contains metal. LRP ( lead replacement

petrol) fuels contain high concentrations of

met a

l additives. Using them may damage the

engine!

● Never refuel with fuels containing a large

proportion of ethanol (for example, E50, E85).

This could damage the fuel system.

● Just filling one full tank of leaded fuel or

fuel containing other metal additives would

seriously impair the efficiency of the catalytic

converter.

● Only use fuel additives that have been ap-

proved by SEAT. Octane boosting or anti-

knock additives may contain metal additives

that could seriously damage the engine or

the catalytic converter. These additives must

not be used.

● High engine speed and full throttle can

damage the engine when using petrol with an

octane rating lower than the correct grade for

the engine. Note

● You may use petrol with a high octane num-

ber than the one recommended for your en-

gine.

● In those countries where unleaded petrol is

not available, you may refuel with a fuel with

a low lead content. Diesel Fuel

Please note the information on the inside of

the fuel tank flap.

We recommend the use of

diesel fuel which

c omp

lies to European standard EN 590. If

diesel fuel which meets European standard

EN 590 is not available, the Cetane number

(CZ) must, at minimum, be 51. If the engine

is equipped with a particulate filter, the sul-

phur content of the fuel must be below 50

parts per million.

Winter-grade diesel

Summer fuel becomes thicker in winter and it

is more difficult to start the engine. For this

reason, petrol stations in some countries al-

so offer winter diesel with improved fluidity

when cold (winter-grade diesel). Water in the fuel filter

1)

If your vehicle has a diesel engine and is

equipped with a

fuel filter with a water sepa-

rator, the instrument panel may display the

following warning: Water in the fuel filter.

If thi

s is the case, take the vehicle to a speci-

alised workshop so that they can drain the

fuel filter. CAUTION

● The vehicle is not designed for the use of

FAME fuel (biodiesel). The fuel system would

be damaged if you used biodiesel.

● Do not mix fuel additives, the so-called

“thinners”, petrol or similar additives with

diesel fuel.

● If poor-quality diesel fuel is used, it may be

necessary to drain the fuel filter more fre-

quently than is specified in the Maintenance

Programme. We recommend having this done

by a specialised workshop. If water is allowed

to collect in the filter, this can cause engine

performance problems. Natural gas

Natural gas

Natural gas can be compressed or in liquid

form, addition to others.

1)

Valid for the market: Algeria.

196

Page 199 of 284

Checking and refilling levels

Liquefied natural gas (LNG) is the result of

heavy cooling of natural gas. Therefore its

volume is considerably reduced compared

with compressed natural gas (CNG). In vehi-

cles with a natural gas engine, liquefied nat-

ural gas cannot be directly refilled, as the gas

would expand excessively in the vehicle gas

tank.

Therefore, vehicles with a natural gas engine

must only be refuelled using compressed

natural gas ››› .

Natural gas quality and consumption

Natural gas is divided into the groups H and

L depending on its quality.

Gas type H has a superior heating power and

inferior nitrogen and carbon dioxide content

than type L. The higher the heating power of

the natural gas, the lower the consumption

will be.

However, the heating power and the propor-

tion of nitrogen and carbon dioxide can fluc-

tuate within the quality groups. Therefore, ve-

hicle consumption can also vary when using

a single type of gas only.

The engine management automatically

adapts to the natural gas used according to

its quality. Therefore, different quality gases

can be mixed in the tank, without the need

for comprehensive draining before applying a

different quality gas. Updated information relating to natural gas

quality is displayed on the instrument panel

››› page 72 .

Nat ur

al gas and safety

If you can smell gas or suspect that there is a

leak ››› :

● Stop the vehicle immediately.

● Switch the ignition off.

● Open the doors to appropriately ventilate

the vehicle.

● Extinguish cigarettes immediately.

● Move away from the vehicle or switch off

objects that may cause sparks or a fire.

● If you continue to smell gas, do not contin-

ue driving!

● Seek specialist assistance. Have the fault

repaired. WARNING

Failure to act when you can smell gas in the

vehicle or when refuelling can cause serious

injuries.

● Carry out the necessary operations.

● Leave the danger zone.

● If necessary, warn the emergency services. WARNING

The vehicle is not prepared to use liquefied

natural gas (LNG) and this fuel must not be

added under any circumstances. Liquefied

natural gas can cause the natural gas tank to

explode, resulting in serious injury. Note

Have the natural gas system checked regular-

ly by a specialised workshop, according to

the Maintenance Programme. 197

Technical specifications

Advice

Operation

Safety

The essentials

Page 201 of 284

Checking and refilling levels

●

Take care not to cause short circuits in the

electrical system, especially when working

on the battery.

● If working inside the engine compartment,

remember that, even when the ignition is

switched off, the radiator fan may start up au-

tomatically, and therefore there is a risk of in-

jury.

● Never cover the engine with additional in-

sulating materials such as a blanket. Risk of

fire!

● Do not unscrew the cap on the coolant ex-

pansion tank when the engine is hot. The

cooling system is under pressure.

● Protect face, hands and arms by covering

the cap with a large, thick rag to protect

against escaping coolant and steam.

● If it is necessary to work in the engine com-

partment while the engine is running, the ro-

tating components (for example, poly-V belt,

alternator, radiator fan) and the high voltage

ignition system are an additional hazard.

● Observe the following additional warnings

if work on the fuel system or the electrical

system is necessary:

– Always disconnect the battery from the

on-board network.

– Do not smoke.

– Never work near naked flames.

– Always keep an approved fire extinguish-

er immediately available. CAUTION

When topping up fluids make sure the correct

fluid is put into the correct filler opening, oth-

erwise this can cause serious malfunctions or

engine damage. For the sake of the environment

Inspect the ground underneath your vehicle

regularly so that any leaks are detected at an

early stage. If you find spots of oil or other

fluids in the area where it was parked, have

your vehicle inspected at the workshop. Note

On right-hand drive vehicles* some of the

containers/reservoirs mentioned below are

located on the other side of the engine com-

partment. Opening the bonnet

Read the additional information carefully

››› page 10

The bonnet is released from inside the vehi-

cle.

Check that the windscreen wiper arms are

not unfolded. Otherwise the paint may be

damaged.

The bonnet can only be unlocked when the

driver door is open. WARNING

Never open the bonnet if you see steam or

drips of coolant being released from the en-

gine compartment. Failure to comply could

result in burns. Wait until no steam or coolant

can be seen before opening the bonnet. Closing the bonnet

–

Slightly lift the bonnet.

– Release the bonnet stay before pressing it

back into its support.

– Carefully close the bonnet.

– Press the bonnet down until it locks into

place.

– Make sure that the bonnet catches onto its

clasp. Do not press down too hard › › › .

WARNING

● For safety reasons the bonnet must always

be completely closed when the vehicle is

moving. Therefore, after closing the bonnet,

always check that the locking element is

properly engaged. This is the case if the bon-

net is flush with the adjacent body panels.

● Should you notice that the bonnet is not

safely secured when the vehicle is moving,

stop the vehicle immediately and close the

bonnet. Failure to follow this instruction

could result in an accident. 199

Technical specifications

Advice

Operation

Safety

The essentials

Page 210 of 284

Advice

Wheels

Wheels and tyres General notes –

When driving with new tyres, be especially

car

eful during the first 500 km (300 miles).

– If you have to drive over a kerb or similar

obstacle, drive very slowly and as near as

possible at a right angle to the obstacle.

– Check from time to time if the tyres are

damaged (punctures, cuts, cracks or

dents). Remove any foreign objects embed-

ded in the treads.

– Damaged wheels and tyres must be re-

placed immediately.

– Keep grease, oil and fuel off the tyres.

– Replace any missing valve caps as soon as

possible.

– Mark the wheels before taking them off so

that they rotate in the same direction when

put back.

– When removed, the wheels or tyres should

be stored in a cool, dry and preferably dark

place.

New tyres

New tyres do not give maximum grip straight

a w

ay and should therefore be “run in” by driving carefully and at moderate speeds for

about the first 500 km (300 miles). This will

also increase the useful life of the tyres.

The tread depth of new tyres may

v

ary, ac-

cording to the type and make of tyre and the

tread pattern.

Concealed damage

Damage to tyres and rims is often not readily

visible. If you notice unusual vibration

or the

car pulling to one side, this may indicate that

one of the tyres is damaged. Reduce speed

immediately if there is any reason to suspect

that damage may have occurred. Inspect the

tyres for damage. If no external damage is

visible, drive slowly and carefully to the near-

est specialised workshop and have the car

inspected.

Tyres with directional tread pattern

An arrow on the tyre sidewall indicates the di-

rection of rotation on single drive tyres. Al-

ways note the direction of rotation indicated

when mounting the wheel. This guarantees

optimum grip and helps to avoid aquaplan-

ing, excessive noise and wear.

Retrofitting Accessories

If you wish to change or fit wheels, rims or

wheel trims, we recommend that you consult

with a SEAT Official Service centre for advice

regarding current techniques. Useful life of tyres Correct inflation pressures and sensible driv-

ing habits will increase the useful life of your

tyres.

– Check tyre pressure at least once a month,

and also prior to any long trip.

– The tyre pressure should only be checked

when the tyres are cold. Do not reduce the

pressure of warm tyres.

– Adjust tyre pressure to the load being car-

ried by the vehicle.

– In vehicles with a tyre pressure indicator,

save the pressure of modified tyres

››› page 212 , ››

›

page 208.

– Avoid fast cornering and hard acceleration.

– Inspect the tyres for irregular wear from

time to time.

The useful life of your tyres depends on the

following factors:

Tyre pressure

Tyre pressure values are indicated on the

sticker on the inside of the fuel tank flap.

Insufficient or excessive pressure greatly re-

duces the useful life of the tyres and adverse-

ly affects vehicle performance and ride. Cor-

rect inflation pressures are very important,

especially at high speeds.

208

Page 211 of 284

Wheels

Depending on the vehicle, tyre pressure can

be adjusted (“comfort” tyre pressure) to in-

crease driving comfort. When driving with

comfort tyre pressure fuel consumption may

increase slightly.

The tyre pressure must be adjusted according

to the load the vehicle is carrying. If the vehi-

cle is going to carry the maximum load, the

tyre pressure should be increased to maxi-

mum value indicated on the sticker on the in-

side of the fuel tank flap.

Do not forget the spare wheel when checking

the tyre pressures: Keep this spare wheel in-

flated to the highest pressure required for the

road wheels.

In the case of a minimised temporary spare

wheel (125/70 R16 or 125/70 R18) inflate to

a pressure of 4.2 bar as indicated on the tyre

pressure label on the fuel tank flap.

Driving style

Fast cornering, heavy acceleration and hard

braking (squealing tyres) all increase tyre

wear.

Wheel balance

The wheels on new vehicles are balanced.

However, certain circumstances may lead to

imbalance (run-out), which is detected as vi-

brations in the steering wheel. Unbalanced wheels should be rebalanced, as

they otherwise cause excessive wear on

steering, suspension and tyres. A wheel must

also be rebalanced when a new tyre is fitted

or if a tyre is repaired.

Incorrect wheel alignment

Incorrect wheel alignment causes excessive

tyre wear, impairing the safety of the vehicle.

If you notice excessive tyre wear, you should

check wheel alignment at a SEAT Official

Service.

WARNING

● Always adapt the tyre pressure accordingly

when the vehicle load changes.

● A tyre with low air pressure has to flex a lot

more when the vehicle is heavily loaded or at

high speeds, therefore causing overheating

to occur. Under these conditions, the tyre

bead may be released or the tyre may burst.

Risk of accident! For the sake of the environment

Under-inflated tyres will increase fuel con-

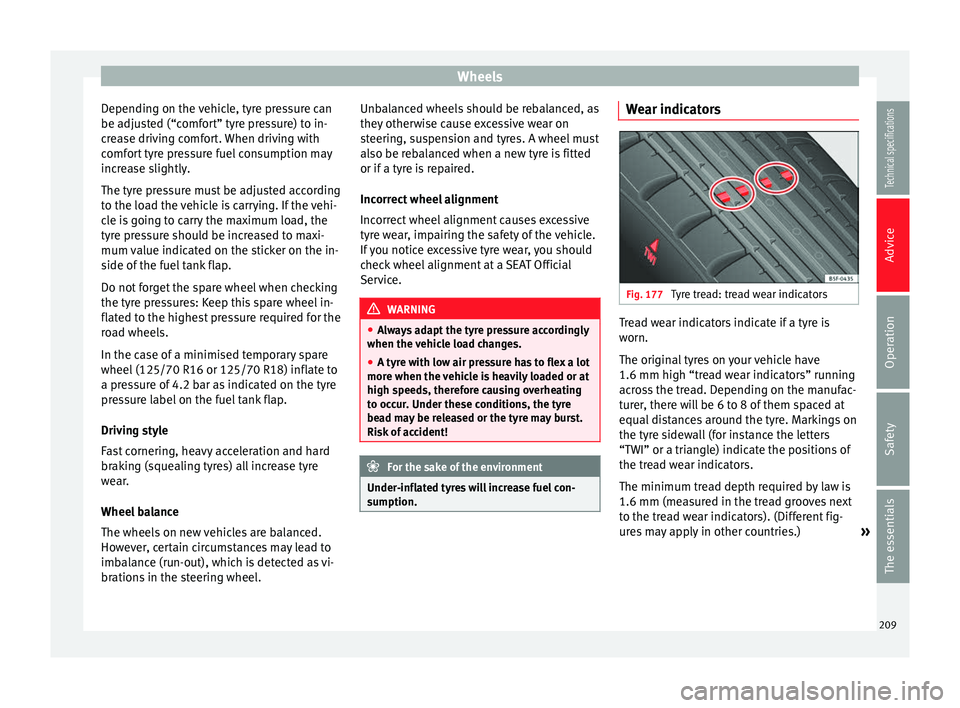

sumption. Wear indicators

Fig. 177

Tyre tread: tread wear indicators Tread wear indicators indicate if a tyre is

worn.

The original tyres on your vehicle have

1.6 mm high “tread wear indicators” running

across the tread. Depending on the manufac-

turer, there will be 6 to 8 of them spaced at

equal distances around the tyre. Markings on

the tyre sidewall (for instance the letters

“TWI” or a triangle) indicate the positions of

the tread wear indicators.

The minimum tread depth required by law is

1.6 mm (measured in the tread grooves next

to the tread wear indicators). (Different fig-

ures may apply in other countries.)

»

209Technical specifications

Advice

Operation

Safety

The essentials