torque Seat Leon SC 2017 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2017, Model line: Leon SC, Model: Seat Leon SC 2017Pages: 332, PDF Size: 7.25 MB

Page 69 of 332

The essentials

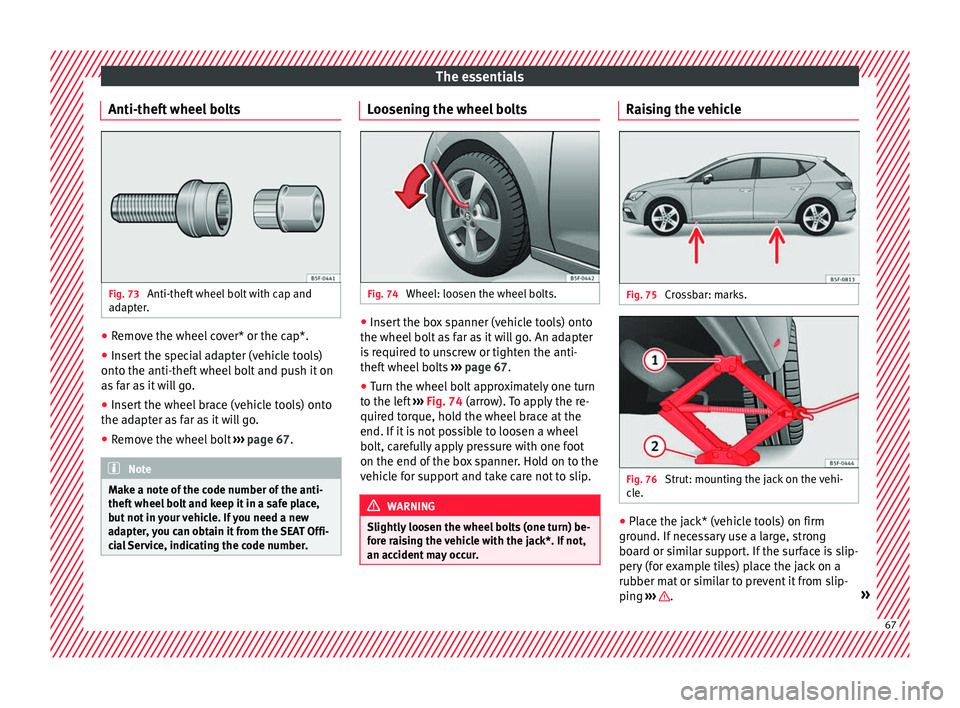

Anti-theft wheel bolts Fig. 73

Anti-theft wheel bolt with cap and

a d

apt

er. ●

Remove the wheel cover* or the cap*.

● Insert the special adapter (vehicle tools)

ont o the anti-thef

t

wheel bolt and push it on

as far as it will go.

● Insert the wheel brace (vehicle tools) onto

the adapt

er as far as it will go.

● Remove the wheel bolt ›››

page 67 . Note

Make a note of the code number of the anti-

theft wheel

bolt and keep it in a safe place,

but not in your vehicle. If you need a new

adapter, you can obtain it from the SEAT Offi-

cial Service, indicating the code number. Loosening the wheel bolts

Fig. 74

Wheel: loosen the wheel bolts. ●

Insert the box spanner (vehicle tools) onto

the wheel bo

lt

as far as it will go. An adapter

is required to unscrew or tighten the anti-

theft wheel bolts ››› page 67.

● Turn the wheel bolt approximately one turn

to the lef

t ››› Fig. 74 (arrow). To apply the re-

quired torque, hold the wheel brace at the

end. If it is not possible to loosen a wheel

bolt, carefully apply pressure with one foot

on the end of the box spanner. Hold on to the

vehicle for support and take care not to slip. WARNING

Slightly loosen the wheel bolts (one turn) be-

for e r

aising the vehicle with the jack*. If not,

an accident may occur. Raising the vehicle

Fig. 75

Crossbar: marks. Fig. 76

Strut: mounting the jack on the vehi-

c l

e. ●

Place the jack* (vehicle tools) on firm

gr ou

nd. If

necessary use a large, strong

board or similar support. If the surface is slip-

pery (for example tiles) place the jack on a

rubber mat or similar to prevent it from slip-

ping ››› .

» 67

Page 71 of 332

The essentials

● Ret

urn al

l tools to their proper storing loca-

tion.

● If the replaced wheel does not fit in the

spar

e wheel housing, store it safely in the

luggage compartment ›››

page 160.

● Check the tyre pressure of the newly moun-

ted tyr

e as soon as possible.

● In vehicles fitted with a tyre pressure indi-

cator

, adjust the pressure and store the read-

ing in the radio/Easy Connect system*

››› page 283.

● Have the tightening torque of the wheel

bolts c

hecked as soon as possible with a tor-

que wrench (it should be 120 Nm). Mean-

while, drive carefully.

● Have the flat tyre replaced as quickly as

poss

ible.

Snow chains Use Snow chains should only be used on the

fr

ont

wheel

s.

Check that they are correctly seated after

driving for a few yards; correct the position if

necessary, in accordance with the manufac-

turer's fitting instructions. Keep your speed

below 50 km/h (30 mph). If there is a danger of being trapped despite

havin

g mounted the chains, it is best to disa-

ble the driving wheels (ASR) in the ESC

››› page 188, Switching on/off the ESC

and ASR.

Snow chains will improve braking ability as

well as traction in winter conditions.

For technical reasons snow chains may only

be used with the following wheel rim/tyre

combination.

195/65 R15Chains with links of maximum 15 mm

205/55 R16Chains with links of maximum 15 mm

225/45 R17Chains with links of maximum 9 mm

225/40 R18Chains with links of maximum 9 mm Remove wheel covers and any integral trim

rin

g bef

or

e fitting snow chains.

Remove the chains when roads are free of

snow. Driving characteristics worsen, and the

wheels become damaged quickly and may

even be rendered unusable. Emergency towing of the vehi-

cle

T

owing Fig. 77

Right side of the front bumper: tow-

line anc hor

ag

e screwed in. Fig. 78

Right side of the rear bumper: towline

anc hor

ag

e screwed in. » 69

Page 189 of 332

Driving

CAUTION

● Never l et

the brakes “drag” by leaving your

foot on the pedal when it is not necessary to

brake. This overheats the brakes, resulting in

longer stopping distances and greater wear.

● Before driving down a long, steep gradient,

it is

advisable to reduce speed and select a

lower gear. This makes use of engine braking

and relieves the brakes. If you still have to

use the brakes, it is better to brake firmly at

intervals than to apply the brakes continu-

ously. Note

● If the br ak

e servo is out of action, for exam-

ple when the car is being towed, you will

have to press the brake pedal considerably

harder than normal to make up for the lack of

servo assistance.

● If you wish to equip the vehicle with acces-

sories s

uch as a front spoiler or wheel covers,

it is important that the flow of air to the front

wheels is not obstructed, otherwise the

brakes can overheat. Braking and stability systems

El ectr

onic

Stability Control (ESC)The ESC helps to improve safety. It reduces

the t

endency

t

o skid and improves the stabil-

ity and roadholding of the vehicle. The ESC detects critical handling situations, such as

vehicl

e understeer or oversteer, or wheelspin

on the driving wheels. It stabilises the vehi-

cle by braking individual wheels or by reduc-

ing the engine torque. The warning lamp will

flash on the instrument panel when the ESC

is intervening .

ESC includes the Anti-lock brake system

(ABS), the brake assist system, the traction

control system (ASR), electronic differential

lock (EDL), electronic self-locking*, selective

torque control* and tractor-trailer sway miti-

gation*. ESC also helps stabilise the vehicle

by changing the torque.

Anti-lock brake system (ABS)

ABS prevents the wheels from locking up un-

der braking until the vehicle has reached a

virtual standstill. You can continue to steer

the vehicle even when the brakes are on full.

Keep your foot on the brake pedal and do not

pump the brakes. You will feel the brake ped-

al pulsate while the ABS is working.

Brake assist system

The brake assist system can reduce the re-

quired braking distance. The braking force is

automatically boosted if you press the brake

pedal quickly in an emergency. You must

keep pressing the brake pedal until the dan-

ger has passed. Traction control system (ASR)

In the event of

wheelspin, the traction control

system reduces the engine torque to match

the amount of grip available. This helps the

car to start moving, accelerate or climb a gra-

dient.

Electronic differential lock (EDL)

When the EDL detects wheelspin, it brakes

the spinning wheel and directs the power to

the other driven wheel. This function is active

up to approximately 100 km/h (62 mph).

To prevent the disc brake of the braked wheel

from overheating, the EDL cuts out automati-

cally if subjected to excessive loads. The ve-

hicle can still be driven. The EDL will switch

on again automatically when the brake has

cooled down.

Tractor-trailer sway mitigation*

If the vehicle is pulling a trailer, it will control

the following: Tractor-trailers tend to sway.

When the swaying of the trailer is felt by the

vehicle and detected by the ESC, it will auto-

matically brake the towing vehicle within the

limits of the system and mitigate the sway.

Tractor-trailer sway mitigation is not available

in all countries.

Electronic torque management (XDS)

When taking a curve, the driveshaft differen-

tial mechanism allows the outer wheel to turn »

187

Technical data

Advice

Operation

Emergencies

Safety

Page 190 of 332

Operation

at a higher speed than the inner wheel. In

thi s

w

ay, the wheel that is turning faster (out-

er wheel) receives less drive torque than the

inner wheel. This may mean that in certain

situations the torque delivered to the inner

wheel is too high, causing the wheels to

spin. On the other hand, the outer wheel is

receiving a lower drive torque than it could

transmit. This causes an overall loss of lateral

grip on the front axle, resulting in understeer

or “lengthening” of the trajectory.

The XDS system can detect and correct this

effect via the sensors and signals of the ESC.

Via the ESC, the XDS will brake the inside

wheel and counter the excess driving torque

of that wheel. This means that the driver's

desired trajectory is much more precise.

The XDS system works in combination with

the ESC and is always active, even when ASR

traction control is disconnected, or the ESC in

Sport mode or disconnected.

Multi-collision Brake

In an accident, the multi-collision brake can

help the driver by braking to avoid the risk of

skidding during the accident, which could

lead to further collisions.

The multi-collision brake works for front, side

or rear accidents, when the airbag control

unit records its activation level and the acci-

dent takes place at a speed of over 10 km/h

(6 mph). The ESC automatically brakes the vehicle, as long as the accident has not dam-

aged the ESC, the br

ake hydraulics or the on-

board network

The following actions control automatic brak-

ing during the accident:

● When the driver presses the accelerator,

the automatic

braking does not take place.

● When the braking pressure through press-

ing the brak

e pedal is greater than the sys-

tem’s braking pressure the vehicle will brake

automatically.

● Multi-collision braking will not be available

if ESC

is malfunctioning. WARNING

● The ESC, ABS, ASR, EDL, el ectr

onic self-

locking differential or selective torque control

systems cannot exceed the limits imposed by

the laws of physics. Always bear this in mind,

especially on wet or slippery roads. If you no-

tice the systems cutting in, you should re-

duce your speed immediately to suit the road

and traffic conditions. Do not be encouraged

to take risks by the presence of more safety

systems. If you do, an accident may occur.

● Please remember that the accident risk al-

way

s increases if you drive fast, especially in

corners or on a slippery road, or if you follow

too close behind the vehicle in front of you.

The ESC, ABS, brake assist, EDL, electronic

self-locking and selective torque control sys-

tems cannot prevent accidents: risk of acci-

dents! ●

Ac c

elerate with caution on slippery surfa-

ces (for example, icy or snow-covered). De-

spite the control systems, the driven wheels

could spin, affecting the stability of the vehi-

cle: risk of accident! Note

● The ABS and ASR w i

ll only operate correctly

if the four wheels have identical tyres. Any

differences in the rolling radius of the tyres

can cause the system to reduce engine power

when this is not desired.

● The regulating processes of the systems

can mak

e noises when they intervene.

● If the warning lamp lights up

, or alter-

natively, there could be a fault ››› page 119. Switching on/off the ESC and ASR

Fig. 197

Centre console: Button for switching

on/off the E

SC

and ASR188

Page 193 of 332

Driving

WARNING

If the gear is changed down inappropriately

by sel

ecting a gear that is too low, you may

lose control of the vehicle, causing an acci-

dent and serious injuries. CAUTION

When travelling at high speeds or at high en-

gine speed s, sel

ecting a gear that is too low

can cause considerable damage to the clutch

and the gearbox. This can also occur if the

clutch pedal is pressed and held and it does

not engage. CAUTION

To prevent damage and avoid premature

we ar

, please observe the following:

● Do not rest your hand on the gear lever

while driv

ing. The pressure applied by your

hand is transmitted to the gearbox selector

forks.

● Always ensure that the vehicle is complete-

ly st

opped before engaging the reverse gear.

● Always press the clutch to the floor when

chan

ging gears.

● Never hold the vehicle “on the clutch” on

hill

s with the engine on. Automatic gearbox/DSG auto-

m

atic

g

earbox*

Introduction Your vehicle is equipped with an electronical-

ly c

ontr

olled manual gearbox. Torque be-

tween the engine and the gearbox is trans-

mitted via two independent clutches. They re-

place the torque converter found on conven-

tional automatic gearboxes and allow for

smooth, uninterrupted acceleration of the ve-

hicle.

The tiptronic system allows the driver to

change gears manually if desired

››› page 193, Engaging gears with the trip-

tonic mode*.

Selector lever positions Read the additional information carefully

› ›

›

page 50

The selector lever position engaged is high-

lighted on the display in the instrument clus-

ter. With the selector lever in the manual

gearbox positions G, D, E and S, the engaged

gear is also indicated on the display.

P – Parking lock

When the selector lever is in this position,

the driven wheels are locked mechanically. The parking lock must be engaged only when

the vehic

le is stationary ››› .

The int erloc

k

button (the button on the selec-

tor lever handle) must be pressed in and si-

multaneously the brake pedal must be de-

pressed before moving the selector lever ei-

ther in or out of position P.

R – Reverse gear

Reverse gear must be engaged only when the

vehicle is stationary and the engine is idling

››› .

T o mo

v

e the selector lever to position R, the

interlock button must be pressed in and at

the same time the brake pedal must be de-

pressed. The reverse lights come on when

the selector lever is in the R position with the

ignition on.

N – Neutral (idling)

With the selector lever in this position, the

gear is in neutral.

D/S – Permanent drive (forward) position

The selector lever in the D/S position enables

the gears to be controlled in normal mode (D)

or Sport (S) mode. To select Sport mode (S),

move the selector lever backwards. Moving

the lever again will select normal mode (D).

The selected driving mode is shown on the

instrument panel display. »

191

Technical data

Advice

Operation

Emergencies

Safety

Page 200 of 332

Operation

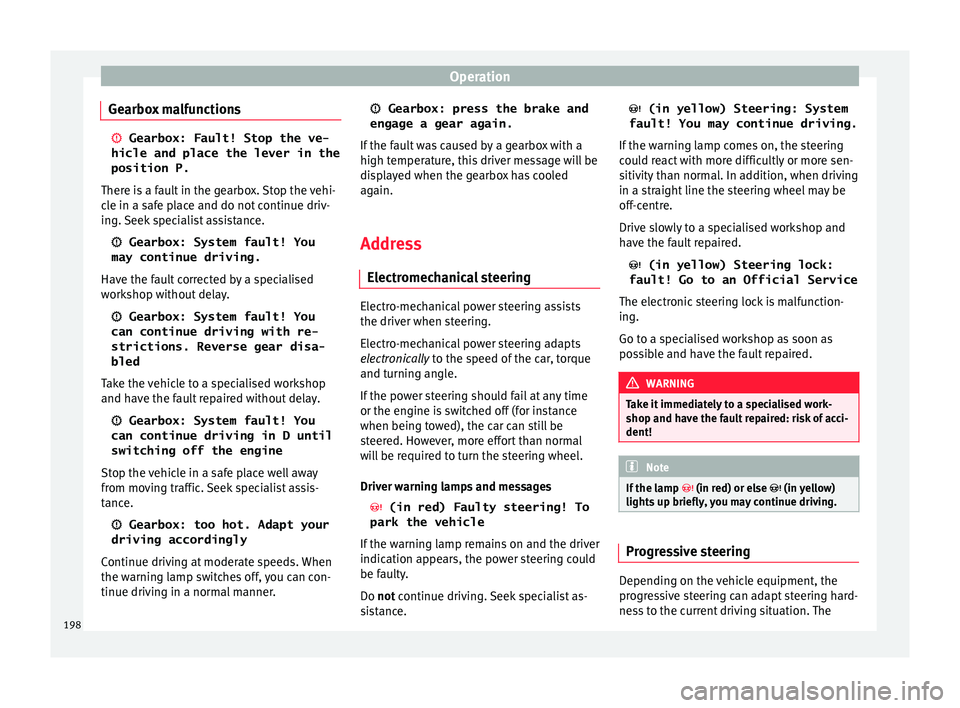

Gearbox malfunctions Gearbox: Fault! Stop the ve-

hicle and place the lever in the

position P.

Ther e is

a fault in the gearbox. Stop the vehi-

cle in a safe place and do not continue driv-

ing. Seek specialist assistance.

Gearbox: System fault! You

may continue driving.

Have the fault corrected by a specialised

workshop without delay. Gearbox: System fault! You

can continue driving with re-

strictions. Reverse gear disa‐

bled

Take the vehicle to a specialised workshop

and have the fault repaired without delay. Gearbox: System fault! You

can continue driving in D until

switching off the engine

Stop the vehicle in a safe place well away

from moving traffic. Seek specialist assis-

tance. Gearbox: too hot. Adapt your

driving accordingly

Continue driving at moderate speeds. When

the warning lamp switches off, you can con-

tinue driving in a normal manner. Gearbox: press the brake and

engage a gear again.

If the fau

lt was caused by a gearbox with a

high temperature, this driver message will be

displayed when the gearbox has cooled

again.

Address Electromec

hanical steering Electro-mechanical power steering assists

the driv

er when s

t

eering.

Electro-mechanical power steering adapts

electronically to the speed of the car, torque

and turning angle.

If the power steering should fail at any time

or the engine is switched off (for instance

when being towed), the car can still be

steered. However, more effort than normal

will be required to turn the steering wheel.

Driver warning lamps and messages (in red) Faulty steering! To

park the vehicle

If the warning lamp remains on and the driver

indication appears, the power steering could

be faulty.

Do not continue driving. Seek specialist as-

sistance. (in yellow) Steering: System

fault! You may continue driving.

If the warnin

g lamp comes on, the steering

could react with more difficultly or more sen-

sitivity than normal. In addition, when driving

in a straight line the steering wheel may be

off-centre.

Drive slowly to a specialised workshop and

have the fault repaired.

(in yellow) Steering lock:

fault! Go to an Official Service

The electronic steering lock is malfunction-

ing.

Go to a specialised workshop as soon as

possible and have the fault repaired. WARNING

Take it immediately to a specialised work-

shop and hav e the f

ault repaired: risk of acci-

dent! Note

If the lamp (in red) or el se

(in yellow)

lights up briefly, you may continue driving. Progressive steering

Depending on the vehicle equipment, the

pr

ogr

e

ssive steering can adapt steering hard-

ness to the current driving situation. The

198

Page 257 of 332

Towing bracket device

If a towing bracket is to be fitted after the ve-

hic l

e i

s purchased, this must be completed

according to the instructions of the towing

bracket manufacturer.

The attachment points for the towing bracket A are on the lower part of the vehicle.

The di s

t

ance between the centre of the ball

coupling and the ground should never be

lower than the indicated value, even with a

fully loaded vehicle and including the maxi-

mum drawbar load.

Elevation values for securing the towing

bracket:

B65 mm (minimum)

C350 mm to 420 mm (fully laden vehicle)

D1040 mm

E317 mm

FLEON/LEON SCLEON ST

319 mm596 mm Fitting a towing bracket

●

Driving with a trailer involves an extra effort

f or the

v

ehicle. Therefore, before fitting a

towing bracket, please contact a Technical

Service to check whether your cooling system

needs modification. ●

The leg

al requirements in your country

must be observed (e.g. the fitting of a sepa-

rate control lamp).

● Certain vehicle components, e.g. the rear

bumper, mu

st be removed and reinstalled.

The towing bracket securing bolts must be

tightened using a torque wrench, and a pow-

er socket must be connected to the vehicle

electrical system. This requires specialised

knowledge and tools.

● Figures in the illustration show the eleva-

tion value and the att

achment points which

must be considered if you are retrofitting a

towing bracket. WARNING

The towing brackets should be fitted at a spe-

ci a

lised workshop.

● If the towing bracket is incorrectly instal-

led, there i

s a serious danger of accident.

● For your own safety, please observe the tow

brack

et manufacturer's instructions. CAUTION

● If the po w

er socket is incorrectly installed,

this could cause damage to the vehicle elec-

trical system. Note

● SEA T r

ecommends that the towing hooks

be fitted at a specialised workshop. Consult your SEAT dealer in case additional modifica-

tions

t

o your vehicle are necessary.

● Due to the specific design of the exhaust,

the fitting of a c

onventional towing hook is

not recommended for some sportier versions.

Please consult your Technical Service. 255

Technical data

Advice

Operation

Emergencies

Safety

Page 279 of 332

Checking and refilling levels

CAUTION

● Do not mi x

cleaning products recommen-

ded by SEAT with other products. This could

lead to flocculation and may block the wind-

screen washer jets.

● When topping up service fluids, make abso-

lutely c

ertain that you fill the fluids into the

correct reservoirs. Using the wrong fluids

could cause serious malfunctions and engine

damage!

● Not having windscreen wiper fluid reduces

vis

ibility through the windscreen, and leads

to loss of visibility in headlights in models

with headlight washer. Battery

Gener a

l

informationRead the additional information carefully

› ›

›

page 61.

The battery is located in the engine compart-

ment and is almost maintenance-free. It is

checked as part of the Inspection Service.

Nevertheless, check the terminals are clean

and have the correct tightening torque, espe-

cially in summer and winter.

Disconnecting the battery

The battery should only be disconnected in

exceptional cases. When the battery is dis- connected, some of the vehicle's functions

are “los

t” (››› table on page 277). These

functions will require resetting after the bat-

tery is reconnected.

Deactivate the anti-theft alarm* before you

disconnect the battery Otherwise the alarm

will be triggered.

FunctionReprogramming

One-touch function of

the electric windows››› page 138, One-touch

opening and closing*.

Remote control key

If the vehicle does not re-

spond to the key, they

should be synchronised

››› page 132.

Digital clock››› page 116.

ESC warning lampAfter driving for a few me-

tres, the warning lamp goes

out again. If the vehicle is not used for long periods

The

v

ehic

le has a system for monitoring the

current consumption when the engine is left

unused for long periods of time ››› page 201.

Some functions, such as the interior lights, or

the remote door opening, may be temporarily

disabled to prevent the battery from running

flat. These functions will come back on as

soon as the ignition is switched on and the

engine started. Winter conditions

During the w

inter, the starting power may be

reduced, and if necessary, the battery should

be charged ››› in Important safety warn-

in g

s

for handling a vehicle battery on

page 278

Important safety warnings for han-

dling a v

ehicle battery All work on batteries requires specialist

kno

wl

edg

e. Please refer to a SEAT Official

Service or a workshop specialising in batter-

ies: risk of burns or exploding battery!

The battery must not be opened. Never try to

change the fluid level of the battery. Other-

wise explosive gas is released from the bat-

tery that could cause an explosion.

Wear eye protection.

Battery acid is very corrosive and caustic. Wear

protective gloves and eye protection. In the event

of electrolyte splashes, rinse off with plenty of

water.

Fires, sparks, open flames and smoking are pro-

hibited.

The battery should only be charged in a well-ven-

tilated zone. Risk of explosion!

Keep children away from acid and batteries!»

277

Technical data

Advice

Operation

Emergencies

Safety

Page 291 of 332

Technical specifications

Technical data

T ec

hnic

al specifications

Important The information in the vehicle documentation

alwa

y

s takes precedence over the informa-

tion in this Instruction Manual.

All technical specifications provided in this

documentation are valid for the standard

model in Spain. The vehicle data card inclu-

ded in the Maintenance Programme or the

vehicle registration documents shows which

engine is installed in the vehicle.

The figures may be different depending

whether additional equipment is fitted, for

different models, for special vehicles and for

other countries. Abbreviations used in the Technical Specifi-

cation

s

section

kWKilowatt, engine power measurement.

PSPferdestärke (horsepower), formerly used

to denote engine power.

rpmRevolutions per minute - engine speed.

NmNewton metres, unit of engine torque.

CZCetane number, indication of the diesel

combustion power.

RONResearch octane number, indication of

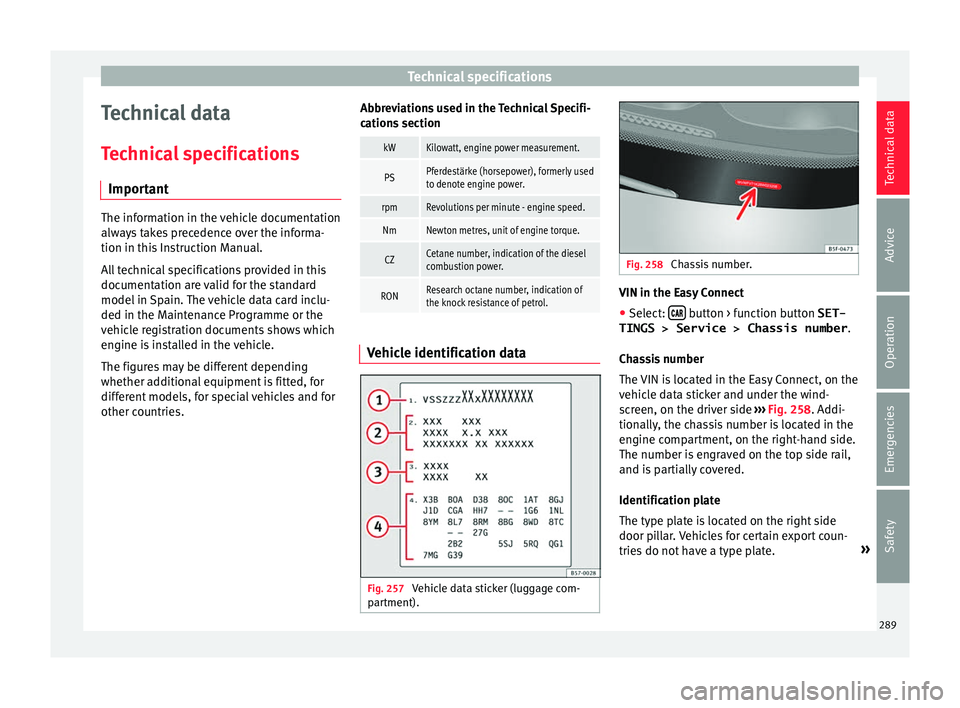

the knock resistance of petrol. Vehicle identification data

Fig. 257

Vehicle data sticker (luggage com-

p ar tment). Fig. 258

Chassis number. VIN in the Easy Connect

● Select:

button > function button SET-

TINGS > Service > Chassis number .

Ch a

s

sis number

The VIN is located in the Easy Connect, on the

vehicle data sticker and under the wind-

screen, on the driver side ››› Fig. 258. Addi-

tionally, the chassis number is located in the

engine compartment, on the right-hand side.

The number is engraved on the top side rail,

and is partially covered.

Identification plate

The type plate is located on the right side

door pillar. Vehicles for certain export coun-

tries do not have a type plate. »

289

Technical data

Advice

Operation

Emergencies

Safety

Page 293 of 332

Technical specifications

km/h (62 mph)). The figures may be different

in other c ou

ntrie

s. All data in the official vehi-

cle documentation takes precedence over

these data at all times ››› .

Dr a

wb

ar loads

The maximum permitted drawbar load on the

ball joint of the towing bracket must not ex-

ceed 80 kg.

In the interest of road safety, we recommend

that you always tow approaching the maxi-

mum drawbar load. The response of the trail-

er on the road will be poor, if the drawbar

load is too small.

If the maximum permissible drawbar load

cannot be met (e.g. with small, empty and

light-weight single axle trailers or tandem

axle trailers with a wheelbase of less than 1

metre), a minimum of 4% of the actual trailer

weight is legally required for the drawbar

load. WARNING

● For s af

ety reasons, you should not drive at

speeds above 80 km/h (50 mph) when towing

a trailer. This also applies in countries where

higher speeds are permitted.

● Never exceed the maximum trailer weights

or the drawb

ar load. If the permissible axle

load or the permissible total weight is excee-

ded, the driving characteristics of the vehicle

may change, leading to accidents, injuries

and damage to the vehicle. Wheels

Ty

r

e pressure, snow chains and wheel

bolts Tyre pressure

The stic

k

er with the tyre pressure values can

be found on the back of the left front door

frame. The tyre pressure values given there

are for cold tyres. The slightly raised pres-

sures of warm tyres must not be reduced.

››› The pressure for win

t

er

tyres is 0.2 bar

(2.9 psi / 20 kPa) higher than that of summer

tyres.

Snow chains

Snow chains may be fitted only to the front

wheels, and only for the following tyres:

195/65 R15Chains with links of maximum 15 mm

205/55 R16Chains with links of maximum 15 mm

205/50 R17Chains with links of maximum 15 mm

225/45 R17Chains with links of maximum 9 mm

225/40 R18Chains with links of maximum 9 mm

225/35 R19Chains with links of maximum 7 mm

205/55 R17Snow chains are not permitted

225/45 R18Snow chains are not permitted Wheel bolts

Af

t

er the wheel

s have been changed, the

tightening torque of the wheel bolts should

be checked as soon as possible with a torque

wrench ››› . The tightening torque for steel

and al lo

y

wheels is 120 Nm. WARNING

● Check the ty

re pressure at least once per

month. Checking the tyre pressure is very im-

portant. If the tyre pressure is too high or too

low, there is an increased danger of accidents

- particularly at high speeds.

● If the tightening torque of the wheel bolts

is t

oo low, they could loosen while the vehi-

cle is in motion. Risk of accident! If the tight-

ening torque is too high, the wheel bolts and

threads can be damaged. Note

We recommend that you ask your Technical

Serv ic

e for information about appropriate

wheel, tyre and snow chain size. 291

Technical data

Advice

Operation

Emergencies

Safety