rims Seat Mii 2012 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Mii, Model: Seat Mii 2012Pages: 308, PDF Size: 4.13 MB

Page 215 of 308

213

Vehicle care and maintenance

WARNING

The use of worn or damaged wheel trims could make driving more dan-

gerous and result in serious accidents and damage.

● Only wheel trims which have been approved for use with your vehicle

should be used.

● Inspect wheel trims regularly for damage and replace as required.

WARNING

If the bolted joints of wheel trims with bolted ring trims are not correctly

tightened or loosened, this could result in serious accident.

● Never loosen the bolted joints of wheel trims with bolted ring trims.

● Any work relating to wheel trims with bolted trims should be carried

out at Specialised workshop. SEAT recommends visiting a Technical Serv-

ice.

Replacement of new tyres and wheel trims

New tyres

● When tyres are new, drive with extreme caution for the first 600 km

(400 miles), as all tyres need to be run-in. Tyres which have not been run-in

do not have such good grip ⇒

or braking capacity ⇒ .

● All four wheels must be fitted with radial tyres of the same type, size

(rolling circumference) and the same tread pattern.

● The tread depth of new tyres may vary, according to the type and make

of tyre and the tread pattern. Replacing tyres

●

Where possible, always replace both wheels on an axle (both wheels on

the front axle or both wheels on the rear axle) ⇒

.

● Only replace used tyres with those authorised by SEAT for the corre-

sponding type vehicle. Pay special attention to size, diameter, and maxi-

mum load and speed capacity.

● Never use tyres which are larger than SEAT approved tyres. If the tyres

are too big, they may knock or rub against the chassis or other components,

resulting in damage.

WARNING

New tyres do not give maximum grip and will not have reached their max-

imum braking capacity to start with, and therefore need running in.

● To prevent accidents and major damage, extreme caution should be

taken for the first 600 km (400 miles).

WARNING

There should be adequate space between the tyres and the vehicle in ac-

cordance with the vehicle design. If this is not the case, the tyres may

rub against parts of the running gear, chassis or brake lines, leading to

faults in the brake system or to tread detachment, and the risk of burst

tyres.

● The true tyre dimension should not be greater than the dimensions of

tyres manufactured and approved by SEAT and should not rub against

parts of the vehicle.

Note

Although tyres may be shown as being the same size, the true dimensions

of different types of tyre may vary with respect to the nominal size, or tread

patterns may be different.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 222 of 308

220Vehicle care and maintenance

Tyre code (example)MeaningTEMPERATURE ATyre temperature resistance at higher test

speeds (A, B or C).

If the tyre has other markings, these are specific tyre manufacturer codes

or specific national codes, e.g. for Brazil or China.

a)

The letters TIN refer to the tyre serial number.

Tyres with directional tread pattern

Tyres with directional tread pattern have been designed to operate best

when rotating in only one direction. An arrow on the tyre sidewall indicates

the direction of rotation on tyres with directional tread. Always observe the

direction of rotation indicated when mounting the wheel. This guarantees

optimum grip and helps to avoid aquaplaning, excessive noise and wear.

If the tyre is mounted in the opposite direction of rotation, drive with ex-

treme caution, as the tyre is no longer being used correctly. This is of partic-

ular importance when the road surface is wet. Change the tyre as soon as

possible or remount it with the correct direction of rotation.

Tyre load rating

The load rating code indicates the maximum load in kilograms each wheel

can carry (load capacity).

425 kg

462 kg

487 kg

515 kg

545 kg

615 kg

Speed rating

The speed rating indicates the maximum speed permitted for the tyres.

max. 150 km/h (93 mph)

max. 160 km/h (99 mph)

78

81

83

85

87

91

P

Q max. 170 km/h (106 mph)

max. 180 km/h (112 mph)

max. 190 km/h (118 mph)

max. 200 km/h (124 mph)

max. 210 km/h (130 mph)

max. 240 km/h (149 mph)

max. 240 km/h (149 mph)

max. 270 km/h (168 mph)

max. 300 km/h (186 mph)

Some manufacturers use the letters “ZR” for tyres with a maximum author-

ised speed above 240 km/h (149 mph).

Snow chains

When using snow chains, applicable local legislation and maximum permit-

ted speed limits must be observed.

In winter weather, snow chains not only help to improve grip but also im-

prove the braking capacity.

The fitting of chains is permitted only on front wheels and only with the fol-

lowing combinations of wheel trims and tyres :

Tyre sizeWheel rim165/70 R145 J x 14 offset of 35

SEAT recommends you ask a Technical Service for further information on

wheel, tyre and chain sizes.

Wherever possible use fine-link chains measuring less than 15 mm includ-

ing the lock.

R

S

T

U

H

V

Z

W

Y

Page 223 of 308

221

Vehicle care and maintenance

Remove wheel hub covers and trim rings before fitting snow chains ⇒

.

The wheel bolts should be covered with caps for safety reasons. These are

available from Technical Services.

Temporary spare wheel

For technical reasons, snow chains must not be used on the compact tem-

porary spare wheel ⇒ page 217.

If it is necessary to fit chains with the temporary spare wheel in use, install

the temporary spare wheel on the rear axle in the event of a fault in a front

wheel. Then, fit the rear wheel that is free, instead of the damaged front

wheel. In this situation, observe the rotating direction of the wheels. SEAT

recommends attaching the snow chains before fitting the wheel.

WARNING

The use of unsuitable or incorrectly fitted chains could lead to serious ac-

cidents and damage.

● Always the appropriate snow chains.

● Observe the fitting instructions provided by the snow chain manufac-

turer.

● Never exceed the maximum permitted speeds when driving with snow

chains.

CAUTION

● You must remove the snow chains to drive on roads which are free of

snow. Otherwise they will impair handling, damage the tyres and wear out

very quickly.

● Wheel trims may be damaged or scratched if the chains come into direct

contact with them. SEAT recommends the use of covered snow chains.

Note

Snow chains are available in different sizes according to the vehicle type.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 225 of 308

223

Vehicle care and maintenance

Running-in

Please observe the instructions for running-in new components.

Running-in the engine

The engine needs to be run in over the first 1500 km (1000 miles). During

its first few hours of running, the internal friction in the engine is greater

than later on when all the moving parts have bedded down.

How the vehicle is driven for the first 1500 km (1000 miles) influences the

future engine performance. Throughout the life of the vehicle, it should be

driven at a moderate speed, especially when the engine is cold, as this will

reduce engine wear and increase its useful life. Never drive at extremely low

engine speeds. Change down to a lower gear when the engine no longer

runs “smoothly”. Up to 1000 kilometres the following instructions apply:

● Do not use full throttle.

● Do not force the engine above two thirds of its maximum speed.

Between 1000 and 1500 kilometres (600 to 1000 miles), gradually in-

crease power until reaching the maximum speed and high engine speeds.

Running in new tyres and brake pads

● Replacement of new tyres and wheel trims ⇒ page 210

● Notes on the brakes ⇒ page 134

For the sake of the environment

If the engine is run in gently, the life of the engine will be increased and the

engine oil consumption reduced.

Accessories and spare parts

SEAT recommends you consult an Official Service before purchasing acces-

sories and spare parts or consumables. For example, when fitting accesso- ries at a later date, or when replacing a component. A SEAT Official Service

will advise you as to the legal requirements and manufacturer's recommen-

dations regarding accessories, spare parts and other components.

SEAT recommend you use only approved

SEAT accessories and genuine

SEAT spare parts ®

. These parts and accessories have been specially tested

by SEAT for suitability, reliability and safety. In addition the SEAT Technical

Service will guarantee that the assembly is carried out professionally.

Although we continually monitor the market, SEAT cannot guarantee that

products not approved by SEAT are reliable, safe and suitable for the vehi-

cle. Therefore, SEAT cannot accept liability, even in those cases authorised

by an officially recognised technical inspection office or other official body.

Any retro-fitted equipment which has a direct effect on vehicle control must

be approved by SEAT for use in your vehicle and bear the e mark (the Euro-

pean Union's authorisation symbol). This includes cruise control systems or

electronically controlled suspension.

If any additional electrical components are fitted which do not serve to con-

trol the vehicle itself, these must bear the mark (European Union manu-

facturer conformity declaration). This includes refrigerator boxes, laptops or

ventilator fans.

WARNING

Unprofessional repairs or modifications to the vehicle may affect the per-

formance of the airbags, resulting in operating faults or fatal accident.

● Never mount, fasten or fit objects such as drink holders or telephone

cradles over or next to the covers of the airbag modules or within their

deployment zones.

● Objects placed over the airbag covers, or within their deployment

zones, could lead to serious injury or loss of life if the airbags are trig-

gered.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 240 of 308

238Practical information

If and when

Practical information

Frequently asked questions

If you suspect that the vehicle has a fault or is damaged when using it, be-

fore consulting a SEAT dealership or a specialised workshop, carefully read

the following instructions. Similarly, the terms in the alphabetical index

“Things to note” or “Checklist” may be of help.

ProblemPossible causes,

among othersPossible solution

The engine does

not start.

The vehicle battery is

flat.– Carry out the jump start

⇒ page 273.

– Charge the battery

⇒ page 193.

You are using an incor-

rect vehicle key.Use the correct key

⇒ page 28.

The fuel tank level is

insufficient.Refuel ⇒ page 171.

The vehicle cannot

be locked or un-

locked with the

key.

– Vehicle key battery is

flat.

– Too far away from

the vehicle.

– Buttons pressed out-

side the radius of

reach.– Change the battery

⇒ page 28.

– Move closer to the vehicle.

– Synchronize the vehicle

key ⇒ page 28.

– Manually lock or unlock

the vehicle ⇒ page 243.

Unusual noises.

Engine cold, City Safe-

ty Assist system, steer-

ing column electronic

lock.See entry “Noises” in the de-

tailed alphabetical index.

ProblemPossible causes,

among othersPossible solution

Handling is

strange.

Assistance systems ac-

tive.See entry “Assistance sys-

tems” in the detailed alpha-

betical index.

You are using an incor-

rect tyre pressure.Check the tyre pressure

⇒ page 210.

Damage to the wheel

trims or tyres.

Inspect wheel trims and

tyres regularly for damage

⇒ page 210 and replace

them if necessary

⇒ page 250.

Vehicle has no

jack, spare wheel

or tire mobility set

present.Equipment subject to

the vehicle.

No direct solution, depends

on the equipment. In this

case, you should contact a

SEAT Dealership

⇒ page 246.

Surface not correct-

ly illuminated.

– Headlights covered

for driving on the left-

hand side or right-

hand side.

– Headlight adjust-

ment too high.

– Faulty bulbs.

– Dipped headlights

switched off.– Cover the headlights for

driving on the left-hand side

or right-hand side

⇒ page 84.

– Adjust the headlight range

⇒ page 84.

– Change the bulbs

⇒ page 264.

– Switch on the dipped

headlights ⇒ page 84.

Page 249 of 308

247

Practical information

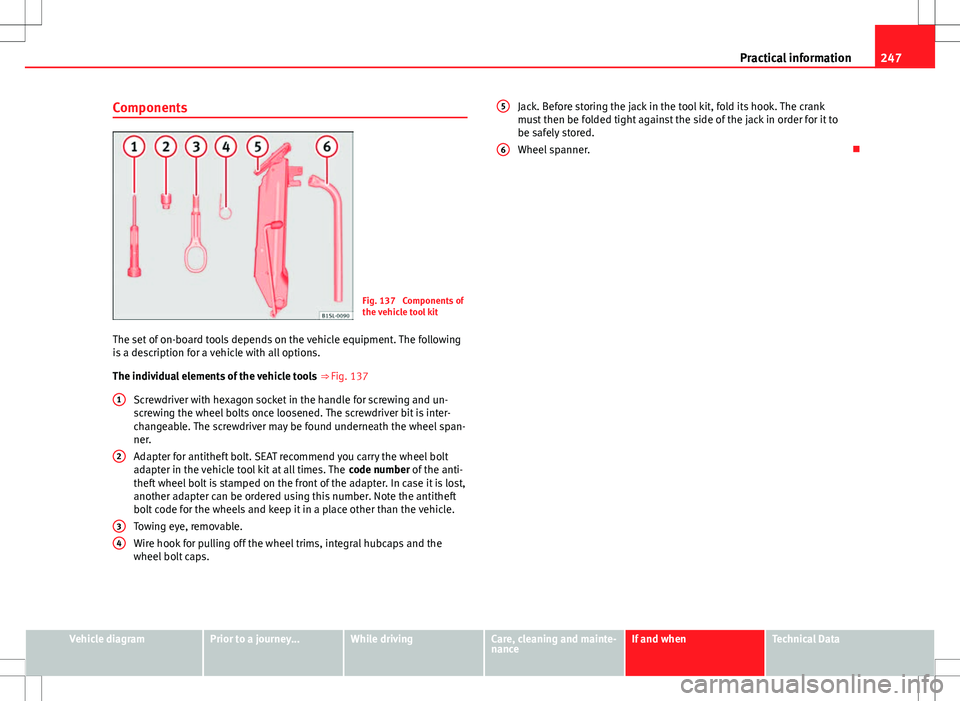

Components

Fig. 137 Components of

the vehicle tool kit

The set of on-board tools depends on the vehicle equipment. The following

is a description for a vehicle with all options.

The individual elements of the vehicle tools ⇒ Fig. 137

Screwdriver with hexagon socket in the handle for screwing and un-

screwing the wheel bolts once loosened. The screwdriver bit is inter-

changeable. The screwdriver may be found underneath the wheel span-

ner.

Adapter for antitheft bolt. SEAT recommend you carry the wheel bolt

adapter in the vehicle tool kit at all times. The code number of the anti-

theft wheel bolt is stamped on the front of the adapter. In case it is lost,

another adapter can be ordered using this number. Note the antitheft

bolt code for the wheels and keep it in a place other than the vehicle.

Towing eye, removable.

Wire hook for pulling off the wheel trims, integral hubcaps and the

wheel bolt caps.

1

2

34

Jack. Before storing the jack in the tool kit, fold its hook. The crank

must then be folded tight against the side of the jack in order for it to

be safely stored.

Wheel spanner.

5

6

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 250 of 308

248Practical information

Wheel trims

Introduction

Additional information and warnings:

● Caring for and cleaning the vehicle exterior ⇒ page 197

● Vehicle tools ⇒ page 246

● Change wheel ⇒ page 250

● Tire Mobility Set ⇒ page 256

WARNING

If the wheel trims are not appropriate or not fitted correctly, they could

cause major accidents or damage.

● Incorrectly mounted wheel trims may come off while driving and en-

danger other road users.

● Damaged trims must never be mounted on the wheels.

● Always ensure that the brake ventilation and cooling is not cut off or

blocked. This is also valid if hubcaps are fitted later. If there is not

enough air, you may require significantly longer braking distances.

CAUTION

Remove and remount wheel trims taking care to avoid damage to the vehi-

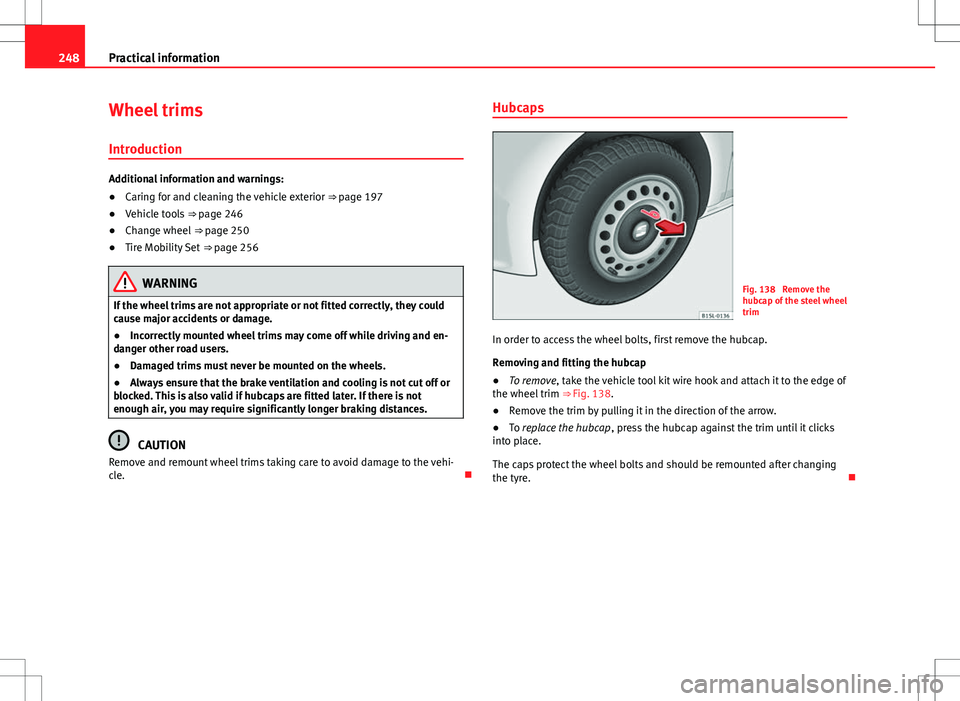

cle. Hubcaps

Fig. 138 Remove the

hubcap of the steel wheel

trim

In order to access the wheel bolts, first remove the hubcap.

Removing and fitting the hubcap

● To remove, take the vehicle tool kit wire hook and attach it to the edge of

the wheel trim ⇒ Fig. 138.

● Remove the trim by pulling it in the direction of the arrow.

● To replace the hubcap , press the hubcap against the trim until it clicks

into place.

The caps protect the wheel bolts and should be remounted after changing

the tyre.

Page 252 of 308

250Practical information

Changing a wheel

Introduction

Some vehicle versions and models do not have a factory-fitted jack or box

spanner. In this case, we recommend consulting a Specialised workshop to

change the wheel.

You should only change the wheels yourself if the vehicle is parked in a safe

place, you are familiar with the procedure and you have all the necessary

tools! Otherwise, you should seek professional assistance.

Additional information and warnings:

● Exterior detail ⇒ page 6

● Vehicle key set ⇒ page 28

● Wheels and tyres ⇒ page 210

● In case of emergency ⇒ page 240

● Vehicle tools ⇒ page 246

● Wheel trims ⇒ page 248

WARNING

Changing a wheel can be dangerous, especially on the hard shoulder.

Please observe the following rules to minimise the risk of injury:

● Stop the vehicle safely as soon as possible. Park your vehicle as safe

distance from surrounding traffic to change a wheel.

● When changing a wheel, keep all passengers and particularly chil-

dren a safe distance away from the work area.

● Turn on the hazard warning lights to warn other road users.

● Ensure the ground on which you park is flat and solid. If necessary,

support the jack on a wide solid base.

WARNING (Continued)

● If you are changing a wheel yourself, you should be familiar with the

required procedure. Otherwise, you should seek professional assistance.

● Only use suitable tools that are not damaged when changing a wheel.

● Always stop the engine, apply the handbrake lever firmly and place

the selector lever in position P, or engage a gear for a manual gearbox to

reduce the risk of the vehicle moving accidentally.

● Have the tightening torque of the wheel bolts checked as soon as

possible with a reliable torque wrench.

Page 253 of 308

251

Practical information

Preparations for changing a wheel

Check list

Before changing a wheel, complete the following operations in the order

given ⇒

:

1. In the event of a flat tyre, park the vehicle a safe distance from traffic and on suitable ground.

2. Apply the handbrake firmly ⇒ page 134.

3. Automatic gearbox: move the selector lever to position P

⇒ page 124.

4. Stop the engine and remove the key from the ignition ⇒ page 119.

5. Manual gearbox: Select a gear ⇒ page 124.

6. Have all vehicle occupants get out of the vehicle and wait in a safe place (for example, behind the safety barrier).

7. Chock the wheel opposite the wheel being changed with a stone or similar object.

8. If the luggage compartment is full: take the baggage out of the vehi- cle.

9. Remove the spare wheel or the temporary spare wheel and the vehi- cle tool kit from the luggage compartment.

10. Remove the wheel trims ⇒ page 248.

WARNING

Failure to follow the checklist prepared for your own safety could lead to

accidents and severe injuries.

● Always complete the operations given in the checklist and observe

the general rules of safety.

Wheel bolts

Fig. 141 Changing the

wheel: Slacken the wheel

bolts

Fig. 142 Changing the

wheel: Tyre valve

1 and

position of anti-theft

wheel locking bolt 2

Only use the tool supplied with the vehicle to loosen the wheel bolts.

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 254 of 308

252Practical information

If the wheel bolt is very tight, you may be able to loosen it by pushing down

on the end of the wheel brace carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over the wheel bolt ⇒ Fig. 141.

● Hold the wheel brace at the end and rotate the bolt approximately one

turn anticlockwise ⇒

.

Loosening anti-theft wheel bolts

For wheels with full hubcap, the anti-theft wheel lock must be threaded into

position ⇒ Fig. 142 2

before mounting the hubcap. Otherwise it will not be

possible to mount the full hubcap.

● Take the adapter for anti-theft wheel bolts out of the vehicle tool kit.

● Insert the adapter onto the wheel bolt ⇒ Fig. 142. Push it on as far as it

will go.

● Fit the wheel brace onto the adapter as far as possible.

● Hold the wheel brace at the end and rotate the bolt approximately one

turn anticlockwise ⇒

.

Important information about wheel bolts

The wheel rims and bolts have been designed to be fitted to factory op-

tions. If different rims are fitted, the correct wheel bolts with the right length

and correctly shaped bolt heads must be used. This ensures that wheels are

fitted securely and that the brake system functions correctly.

In some circumstances, wheel bolts from the same model vehicle should

not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel bolts for steel and alloy wheels

is 110 Nm. Have the tightening torque of the wheel bolts checked as soon

as possible with a reliable torque wrench. If wheel bolts are rusty and it is difficult to tighten them, the threads should

be replaced and cleaned before checking the tightening torque.

Never grease or lubricate wheel bolts or the wheel hub threads. Although

they have been tightened to the prescribed torque, they could come loose

while driving.

WARNING

If the wheel bolts are not fitted correctly they could be released while

driving leading to loss of vehicle control and serious damage.

● Only use wheel bolts which correspond to the wheel rims in question.

● Never use different wheel bolts.

● The bolts and threads should be clean, free of oil and grease and easy

to thread.

● To loosen and tighten the wheel bolts, always use the wheel brace

supplied with the vehicle.

● Loosen the wheel bolts only about one turn before raising the vehicle

with the jack.

● Never grease or lubricate wheel bolts or the wheel hub threads. Al-

though they have been tightened to the prescribed torque, they could

come loose while driving.

● Never loosen the bolted joints of wheel trims with bolted ring trims.

● If the wheel bolts are not tightened to the correct torque, they may

come loose while driving, and the bolts and rims may come out. If the

tightening torque is too high, the wheel bolts and threads can be dam-

aged.