Seat Mii 2012 Owner's manual

Manufacturer: SEAT, Model Year: 2012, Model line: Mii, Model: Seat Mii 2012Pages: 308, PDF Size: 4.13 MB

Page 251 of 308

249

Practical information

Full hubcaps

Fig. 139 Removing the

full hubcap

Removing the full hubcap

● Take the wheel brace and the wire hook from the vehicle tool kit

⇒ page 246.

● Hook the wire through one of the grooves on the hubcap.

● Insert the wheel brace onto the wire hook

⇒ Fig. 139 and pull the hub

cap in the direction shown by the arrow.

Fitting hubcaps

Press the hubcap against the wheel so that the space for the valve fits over

the tyre valve. Make sure that the hubcap is correctly fitted all the way

around the wheel. If you are using an anti-theft wheel lock, screw it in the

opposite position to the valve. Wheel bolt capsFig. 140 Removing the

wheel bolt caps

● Take the wire hook from the vehicle tool kit ⇒ page 246.

● Insert the wire hook in the cap through the opening ⇒ Fig. 140 and pull

outwards in the direction of the arrow.

The caps protect the wheel bolts and should be remounted after changing

the tyre.

The anti-theft wheel locking bolt has a special cap. This cap only fits on an-

ti-theft locking bolts and is not for use with standard wheel bolts.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 252 of 308

250Practical information

Changing a wheel

Introduction

Some vehicle versions and models do not have a factory-fitted jack or box

spanner. In this case, we recommend consulting a Specialised workshop to

change the wheel.

You should only change the wheels yourself if the vehicle is parked in a safe

place, you are familiar with the procedure and you have all the necessary

tools! Otherwise, you should seek professional assistance.

Additional information and warnings:

● Exterior detail ⇒ page 6

● Vehicle key set ⇒ page 28

● Wheels and tyres ⇒ page 210

● In case of emergency ⇒ page 240

● Vehicle tools ⇒ page 246

● Wheel trims ⇒ page 248

WARNING

Changing a wheel can be dangerous, especially on the hard shoulder.

Please observe the following rules to minimise the risk of injury:

● Stop the vehicle safely as soon as possible. Park your vehicle as safe

distance from surrounding traffic to change a wheel.

● When changing a wheel, keep all passengers and particularly chil-

dren a safe distance away from the work area.

● Turn on the hazard warning lights to warn other road users.

● Ensure the ground on which you park is flat and solid. If necessary,

support the jack on a wide solid base.

WARNING (Continued)

● If you are changing a wheel yourself, you should be familiar with the

required procedure. Otherwise, you should seek professional assistance.

● Only use suitable tools that are not damaged when changing a wheel.

● Always stop the engine, apply the handbrake lever firmly and place

the selector lever in position P, or engage a gear for a manual gearbox to

reduce the risk of the vehicle moving accidentally.

● Have the tightening torque of the wheel bolts checked as soon as

possible with a reliable torque wrench.

Page 253 of 308

251

Practical information

Preparations for changing a wheel

Check list

Before changing a wheel, complete the following operations in the order

given ⇒

:

1. In the event of a flat tyre, park the vehicle a safe distance from traffic and on suitable ground.

2. Apply the handbrake firmly ⇒ page 134.

3. Automatic gearbox: move the selector lever to position P

⇒ page 124.

4. Stop the engine and remove the key from the ignition ⇒ page 119.

5. Manual gearbox: Select a gear ⇒ page 124.

6. Have all vehicle occupants get out of the vehicle and wait in a safe place (for example, behind the safety barrier).

7. Chock the wheel opposite the wheel being changed with a stone or similar object.

8. If the luggage compartment is full: take the baggage out of the vehi- cle.

9. Remove the spare wheel or the temporary spare wheel and the vehi- cle tool kit from the luggage compartment.

10. Remove the wheel trims ⇒ page 248.

WARNING

Failure to follow the checklist prepared for your own safety could lead to

accidents and severe injuries.

● Always complete the operations given in the checklist and observe

the general rules of safety.

Wheel bolts

Fig. 141 Changing the

wheel: Slacken the wheel

bolts

Fig. 142 Changing the

wheel: Tyre valve

1 and

position of anti-theft

wheel locking bolt 2

Only use the tool supplied with the vehicle to loosen the wheel bolts.

Loosen the wheel bolts only about one turn before raising the vehicle with

the jack.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 254 of 308

252Practical information

If the wheel bolt is very tight, you may be able to loosen it by pushing down

on the end of the wheel brace carefully with your foot. Hold on to the vehicle

for support and take care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over the wheel bolt ⇒ Fig. 141.

● Hold the wheel brace at the end and rotate the bolt approximately one

turn anticlockwise ⇒

.

Loosening anti-theft wheel bolts

For wheels with full hubcap, the anti-theft wheel lock must be threaded into

position ⇒ Fig. 142 2

before mounting the hubcap. Otherwise it will not be

possible to mount the full hubcap.

● Take the adapter for anti-theft wheel bolts out of the vehicle tool kit.

● Insert the adapter onto the wheel bolt ⇒ Fig. 142. Push it on as far as it

will go.

● Fit the wheel brace onto the adapter as far as possible.

● Hold the wheel brace at the end and rotate the bolt approximately one

turn anticlockwise ⇒

.

Important information about wheel bolts

The wheel rims and bolts have been designed to be fitted to factory op-

tions. If different rims are fitted, the correct wheel bolts with the right length

and correctly shaped bolt heads must be used. This ensures that wheels are

fitted securely and that the brake system functions correctly.

In some circumstances, wheel bolts from the same model vehicle should

not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel bolts for steel and alloy wheels

is 110 Nm. Have the tightening torque of the wheel bolts checked as soon

as possible with a reliable torque wrench. If wheel bolts are rusty and it is difficult to tighten them, the threads should

be replaced and cleaned before checking the tightening torque.

Never grease or lubricate wheel bolts or the wheel hub threads. Although

they have been tightened to the prescribed torque, they could come loose

while driving.

WARNING

If the wheel bolts are not fitted correctly they could be released while

driving leading to loss of vehicle control and serious damage.

● Only use wheel bolts which correspond to the wheel rims in question.

● Never use different wheel bolts.

● The bolts and threads should be clean, free of oil and grease and easy

to thread.

● To loosen and tighten the wheel bolts, always use the wheel brace

supplied with the vehicle.

● Loosen the wheel bolts only about one turn before raising the vehicle

with the jack.

● Never grease or lubricate wheel bolts or the wheel hub threads. Al-

though they have been tightened to the prescribed torque, they could

come loose while driving.

● Never loosen the bolted joints of wheel trims with bolted ring trims.

● If the wheel bolts are not tightened to the correct torque, they may

come loose while driving, and the bolts and rims may come out. If the

tightening torque is too high, the wheel bolts and threads can be dam-

aged.

Page 255 of 308

253

Practical information

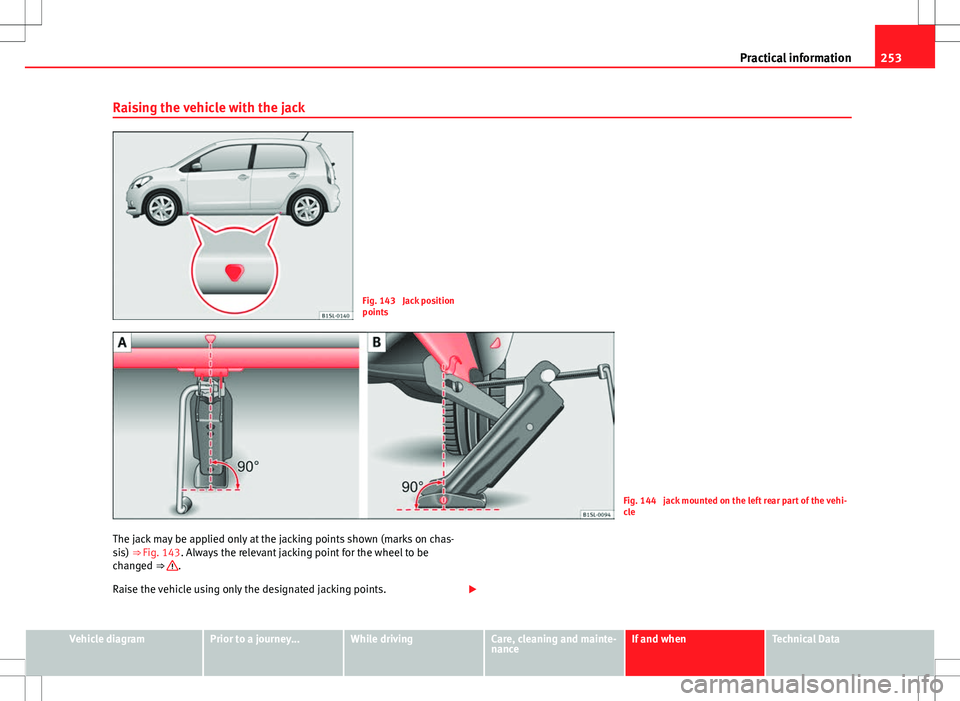

Raising the vehicle with the jack

Fig. 143 Jack position

points

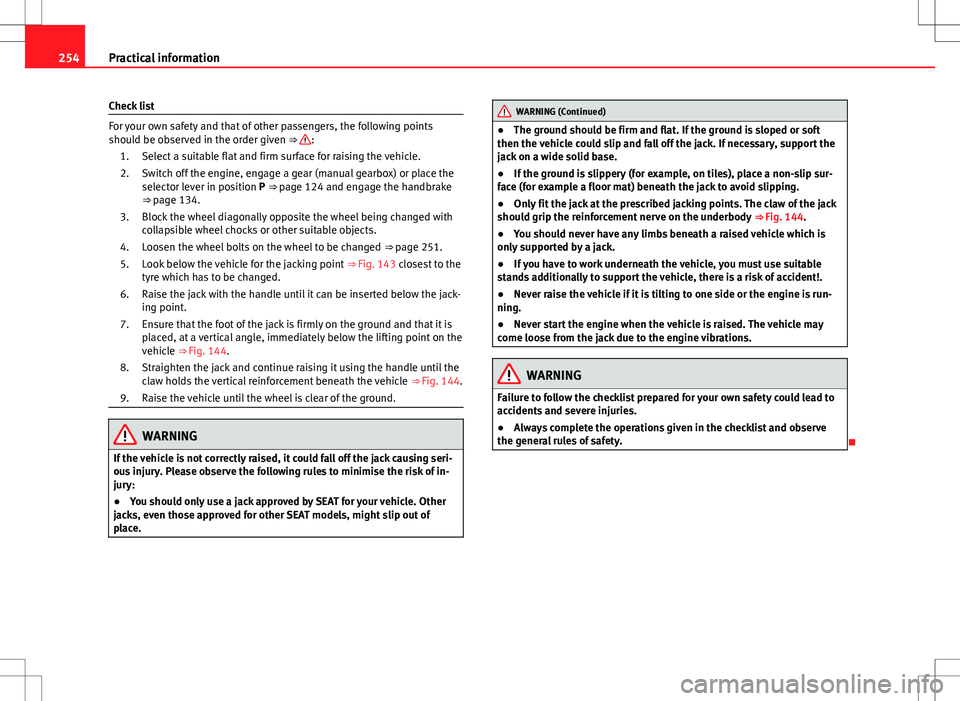

Fig. 144 jack mounted on the left rear part of the vehi-

cle

The jack may be applied only at the jacking points shown (marks on chas-

sis) ⇒ Fig. 143. Always the relevant jacking point for the wheel to be

changed ⇒

.

Raise the vehicle using only the designated jacking points.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 256 of 308

254Practical information

Check list

For your own safety and that of other passengers, the following points

should be observed in the order given ⇒

:

1. Select a suitable flat and firm surface for raising the vehicle.

2. Switch off the engine, engage a gear (manual gearbox) or place the selector lever in position P ⇒ page 124 and engage the handbrake

⇒ page 134.

3. Block the wheel diagonally opposite the wheel being changed with collapsible wheel chocks or other suitable objects.

4. Loosen the wheel bolts on the wheel to be changed ⇒ page 251.

5. Look below the vehicle for the jacking point ⇒ Fig. 143 closest to the

tyre which has to be changed.

6. Raise the jack with the handle until it can be inserted below the jack- ing point.

7. Ensure that the foot of the jack is firmly on the ground and that it is placed, at a vertical angle, immediately below the lifting point on the

vehicle ⇒ Fig. 144.

8. Straighten the jack and continue raising it using the handle until the claw holds the vertical reinforcement beneath the vehicle ⇒ Fig. 144.

9. Raise the vehicle until the wheel is clear of the ground.

WARNING

If the vehicle is not correctly raised, it could fall off the jack causing seri-

ous injury. Please observe the following rules to minimise the risk of in-

jury:

● You should only use a jack approved by SEAT for your vehicle. Other

jacks, even those approved for other SEAT models, might slip out of

place.

WARNING (Continued)

● The ground should be firm and flat. If the ground is sloped or soft

then the vehicle could slip and fall off the jack. If necessary, support the

jack on a wide solid base.

● If the ground is slippery (for example, on tiles), place a non-slip sur-

face (for example a floor mat) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking points. The claw of the jack

should grip the reinforcement nerve on the underbody ⇒ Fig. 144.

● You should never have any limbs beneath a raised vehicle which is

only supported by a jack.

● If you have to work underneath the vehicle, you must use suitable

stands additionally to support the vehicle, there is a risk of accident!.

● Never raise the vehicle if it is tilting to one side or the engine is run-

ning.

● Never start the engine when the vehicle is raised. The vehicle may

come loose from the jack due to the engine vibrations.

WARNING

Failure to follow the checklist prepared for your own safety could lead to

accidents and severe injuries.

● Always complete the operations given in the checklist and observe

the general rules of safety.

Page 257 of 308

255

Practical information

Changing a wheel

Fig. 145 Changing the

wheel: loosen wheel

bolts with the socket at

the end of the wheel

brace

Removing the wheel

● Please observe the check list ⇒ page 251.

● Loosen the wheel bolts ⇒ page 251.

● Jacking up the vehicle ⇒ page 253.

● Using the hexagonal socket in the wheel brace ⇒ Fig. 145, unscrew the

slackened wheel bolts and place them on a clean surface.

● Take off the wheel.

How to use the spare wheel or temporary spare wheel

Check the direction of rotation of the tyre ⇒ page 218, Tyre code.

● Place the spare wheel or temporary spare wheel into position.

● Replace the wheel bolts and tighten slightly using the hexagonal socket

on the end of the wheel brace.

● To tighten the anti-theft locking wheel bolts use the corresponding

adaptor.

● Lower the vehicle with the jack. ●

Tighten all of the wheel bolts clockwise ⇒

. Tighten the bolts in diago-

nal pairs (not in a circle).

● Put the caps, trim or full hubcap back on ⇒ page 248.

WARNING

If the wheel bolts are not treated suitably or not tightened to the correct

torque then this could lead to loss of vehicle control and to a serious ac-

cident.

● All the wheel bolts and hub threads should be clean and free of oil

and grease. The wheel bolts should be easily tightened to the correct tor-

que.

● The hexagonal socket in the wheel brace should be used for turning

wheel bolts only. Do not use it to loosen or tighten the wheel bolts.

After changing the wheel

● Clean the vehicle tools, if necessary and put them away in the luggage

compartment foam holder ⇒ page 246.

● Store the spare wheel, the temporary spare wheel or the changed wheel

securely in the luggage compartment.

● Have the tightening torque of the wheel bolts checked as soon as possi-

ble with a torque wrench ⇒ page 252.

● Have the flat tyre replaced as quickly as possible.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 258 of 308

256Practical information

Anti-puncture kit*

Introduction

The Tyre Mobility Set* will reliably seal punctures caused by the penetration

of a foreign body of up to about 4 mm in diameter. Do not remove foreign

objects, e.g. screws or nails, from the tyre.

After inserting the sealant residue in the tyre, you must again check the tyre

pressure about 10 minutes after starting the engine.

You should only use the tire mobility set if the vehicle is parked in a safe

place, you are familiar with the procedure and you have the necessary tire

mobility set! Otherwise, you should seek professional assistance.

The tyre sealant must not be used in the following cases:

● If the wheel rim has been damaged.

● In outside temperatures below -20 °C (-4 °F).

● In the event of cuts or perforations in the tyre greater than 4 mm.

● If you have been driving with very low pressure or a completely flat tyre.

● If the sealant bottle has passes its use by date.

Additional information and warnings:

● Vehicle key set ⇒ page 28

● Braking, stopping and parking ⇒ page 134

● Wheels and tyres ⇒ page 210

● In case of emergency ⇒ page 240

● Wheel trims ⇒ page 248

WARNING

Using the tire mobility set can be dangerous, especially when filling the

tyre at the roadside. Please observe the following rules to minimise the

risk of injury:

● Stop the vehicle safely as soon as possible. Park your vehicle as safe

distance from surrounding traffic to fill the tyre.

● Ensure the ground on which you park is flat and solid.

● All passengers and particularly children must keep a safe distance

from the work area.

● Turn on the hazard warning lights to warn other road users.

● Use the tire mobility set only if you are familiar with the necessary

procedure. Otherwise, you should seek professional assistance.

● The tire mobility set is intended for temporary, emergency use only.

Use only until you can reach the nearest specialised workshop.

● Replace the repaired tyre with the tire mobility set as soon as possi-

ble.

● The sealant is a health hazard and must be cleaned immediately if it

comes into contact with the skin.

● Always keep the tire mobility set out of the reach of small children.

● Never use the approved jack, even if it has been approved for your ve-

hicle.

● Always stop the engine, apply the handbrake lever firmly and engage

gear if using a manual gearbox, in order to reduce the risk of vehicle in-

voluntary movement.

WARNING

A tyre filled with sealant does not have the same performance properties

as a conventional tyre.

● Never drive faster than 80 km/h (50 mph).

Page 259 of 308

257

Practical information

WARNING (Continued)

● Avoid heavy acceleration, hard braking and fast cornering.

● Drive only during 10 minutes at a maximum speed of 80 km/h

(50 mph) and subsequently check the tyre.

For the sake of the environment

Dispose of used or expired sealant observing any legal requirements.

Note

A new bottle of sealant can be purchased at SEAT dealerships.

Note

Take into account the separate instruction manual of the tire mobility set

manufacturer*. Components of the tire mobility set*Fig. 146 Standard repre-

sentation: Contents of

the tire mobility set

The tire mobility set is located underneath the floor covering in the luggage

compartment. It includes the following components ⇒ Fig. 146:

Tyre valve remover

Sticker indicating maximum speed “max. 80 km/h” or “max. 50 mph”

Filler tube with cap

Air compressor

Tube for inflating tyres

Warning provided by tyre pressure monitoring system 1)

Air bleed screw 2)

ON/OFF switch

12 volt connector

1

23456789

1)

A compressor may also be included.

2) In its place, the compressor may have a button.

Vehicle diagramPrior to a journey...While drivingCare, cleaning and mainte-

nanceIf and whenTechnical Data

Page 260 of 308

258Practical information

Bottle of sealant 1)

Spare tyre valve

The valve insert remover 1

has a gap at the lower end for a valve insert.

The valve insert can only be screwed or unscrewed in this way. This also ap-

plies to its replacement part 11

.

Preparation

Checklist

Before filling a tyre, complete the following operations in the order given

⇒

:

1. In the event of a puncture, park the vehicle as far as possible from traffic and on flat, suitable ground.

2. Apply the handbrake firmly ⇒ page 134.

3. Stop the engine and remove the key from the ignition ⇒ page 119.

4. Manual gearbox: Select a gear ⇒ page 124.

5. Have all vehicle occupants get out of the vehicle and wait in a safe place (for example, behind the safety barrier).

6. Switch on the hazard warning lights and set the warning triangle in position ⇒ page 240. Observe legal requirements.

7. Check whether a repair is possible using the Tyre Mobility Set ⇒ page 256

8. If the luggage compartment is full: take the baggage out of the vehi- cle.

9. Remove the tire mobility set from the luggage compartment.

10. Apply the sticker ⇒ Fig. 146 2

from the tire mobility set to the dash

panel where it can be seen clearly.

11. Do not remove foreign objects, e.g. screws or nails, from the tyre.

1011WARNING

Failure to follow the checklist prepared for your own safety could lead to

accidents and severe injuries.

● Always complete the operations given in the checklist and observe

the general rules of safety.

Sealing and inflating a tyre

Sealing a tyre

● Unscrew the tyre valve cap.

● Use the corresponding enclosed extractor ⇒ Fig. 146 1

to unscrew the

tyre valve insert. Place the valve insert on a clean surface.

● Vigorously shake the sealant bottle ⇒ Fig. 146 10

for several seconds.

● Screw the inflator tube ⇒ Fig. 146 3 securely into the sealant bottle in

a clockwise direction. The seal on the mouth of the bottle moves automati-

cally.

● Remove the lid from the filling tube ⇒ Fig. 146 3

and screw the open

end of the tube into the tyre valve.

● Hold the tyre sealant can upside down and fill the complete contents of

the can into the tyre.

● Remove the tyre sealant bottle from the valve.

● Screw the valve insert again with the corresponding enclosed extractor

⇒ Fig. 146 1

into the tyre valve.

Inflating the tyre

● Securely screw the tyre inflator tube ⇒ Fig. 146 5

of the compressor in-

to the tyre valve.

● Check whether the air bleed screw ⇒ Fig. 146 7

is closed.

1)

A compressor may also be included.