clock Seat Mii 2014 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Mii, Model: Seat Mii 2014Pages: 219, PDF Size: 4.19 MB

Page 154 of 219

Advice

Topping up the engine coolant level

● Always protect your face, hands and arms

from hot coolant and steam using a large,

thick cloth over the coolant expansion tank

cap.

● Remove the cap very carefully ››› .

● Only refill using new engine coolant ac-

c or

ding to SEAT specifications ( ››› page 150)

››› .

● The engine coolant level should be be-

tween the marks on the coolant expansion

tank ››› Fig. 109 .

Do not exceed the top level

of

the marked area ››› .

● Screw on the cap tightly.

● If, in the event of an emergency, you have

no coolant that is compliant to the required

specifications ( ››› page 150), do not use an-

other type of additive. Instead, top up with

distilled water only

›

›› . Then re-establish

the correct proportion of the mixture with the

correct additive as soon as possible

››› page 150 . WARNING

Hot vapours and coolant can cause serious

burns.

● Never open the coolant expansion tank if

steam or coolant is coming from the engine

compartment. Wait until you cannot see or

hear any steam or coolant escaping. ●

Always wait until the engine has complete-

ly cooled before very carefully opening the

expansion tank cap. Contact with hot ele-

ments of the engine can cause skin burns.

● When the engine is warm or hot, the cool-

ing system is pressurised. Do not unscrew

the cap on the expansion tank when the en-

gine is hot. Otherwise, coolant may spray out

under pressure causing burns and serious in-

jury.

– Carefully and slowly unscrew the cap an-

ti-clockwise, gently pressing down on it.

– Always protect your face, hands and arms

from hot coolant and steam using a large,

thick cloth.

● When refilling liquids, avoid spilling them

on parts of the engine and the exhaust sys-

tem. Spilled liquids could cause a fire. Under

specific circumstances, the ethylene glycol

can catch fire. CAUTION

● Top up with distilled water only. Any other

type of water may lead to considerable rust-

ing in the engine due to its chemical compo-

nents. This could consequently damage the

engine. If you have not used distilled water

but another type of water to top up the cool-

ant, a specialised workshop must immediate-

ly replace all of the fluid in the engine cooling

system.

● Only top up coolant to the top level of the

marked area ››› Fig. 109. Otherwise the ex- cess coolant will be forced out of the cooling

system when the engine is hot, causing dam-

age.

● If a lot of liquid coolant has been lost, wait

for the engine to cool down completely before

adding coolant. Extensive coolant loss is an

indication of leaks in the engine cooling sys-

tem. Have the engine cooling system inspec-

ted immediately by a specialised workshop.

Otherwise engine damage may occur.

● When refilling or changing service liquids,

ensure that you put the liquids into the right

tank. Making a mistake when refilling could

cause serious malfunctions and damage the

engine! Brake fluid

Checking the brake fluid level Fig. 111

In the engine compartment: brake

fluid reservoir, lid 152

Page 167 of 219

Wheels and tyres

The tyre pressure control lamp lights up

If the ty

re pressure of a wheel is much lower

than the value set by the driver, then the tyre

pressure control lamp ››› will light up.

WARNING

● When the tyre pressure control lamp lights

up, reduce speed immediately and avoid any

sudden turning or braking manoeuvre. Stop

when possible, and check the tyre pressure

and status.

● The driver is responsible for maintaining

correct tyre pressures. For this reason, tyre

pressure must be regularly checked.

● Under certain circumstances (e.g. when

driving in a sporty manner, in winter condi-

tions or on a dirt track) the tyre control lamp

may light up belatedly or may function incor-

rectly. Note

If the battery is disconnected, the yellow

warning lamp lights up after turning the

ignition on.

This should turn off after a brief

journey. Spare wheel or temporary spare

wheel*

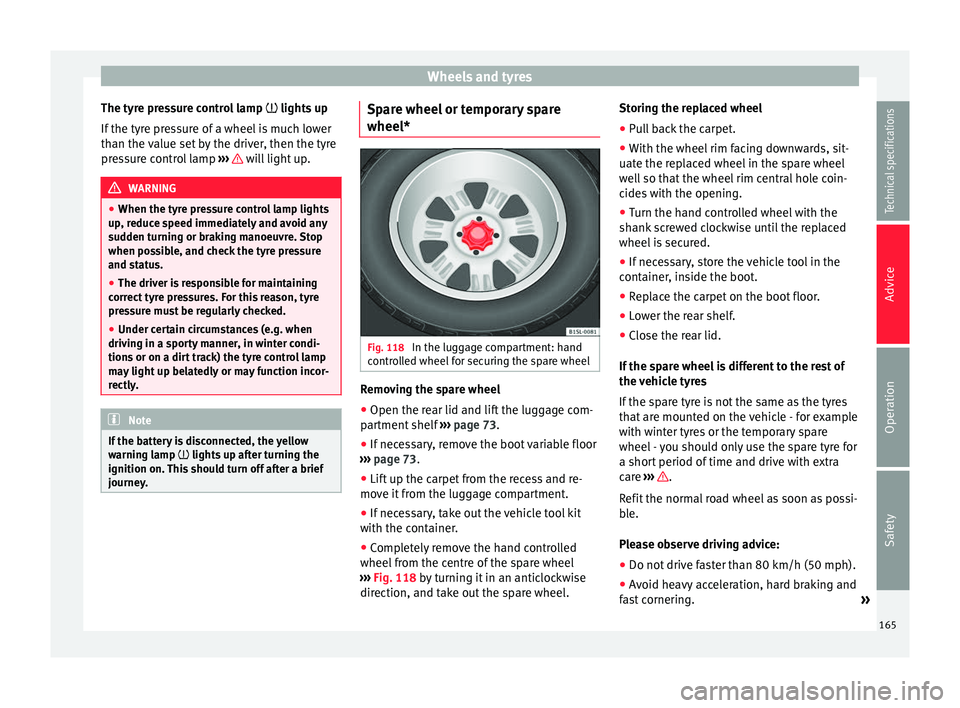

Fig. 118

In the luggage compartment: hand

controlled wheel for securing the spare wheel Removing the spare wheel

● Open the rear lid and lift the luggage com-

partment shelf ››› page 73 .

● If nec

essary, remove the boot variable floor

››› page 73.

● Lift

up the carpet from the recess and re-

move it from the luggage compartment.

● If necessary, take out the vehicle tool kit

with the container.

● Completely remove the hand controlled

wheel from the centre of the spare wheel

››› Fig. 118 by turning it in an anticlockwise

direction, and t

ake out the spare wheel. Storing the replaced wheel

● Pull back the carpet.

● With the wheel rim facing downwards, sit-

uate the replaced wheel in the spare wheel

well so that the wheel rim central hole coin-

cides with the opening.

● Turn the hand controlled wheel with the

shank screwed clockwise until the replaced

wheel is secured.

● If necessary, store the vehicle tool in the

container, inside the boot.

● Replace the carpet on the boot floor.

● Lower the rear shelf.

● Close the rear lid.

If the spare wheel is different to the rest of

the vehicle tyres

If the spare tyre is not the same as the tyres

that are mounted on the vehicle - for example

with winter tyres or the temporary spare

wheel - you should only use the spare tyre for

a short period of time and drive with extra

care ››› .

Refit the normal road wheel as soon as possi-

ble.

Please observe driving advice:

● Do not drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and

fast cornering. »

165

Technical specifications

Advice

Operation

Safety

Page 175 of 219

Emergencies

● Raise the carpet at the recess (arrow)

››› Fig. 122 . Note

After use, return the jack to its initial position

using the handle in order to securely store it

in the vehicle. Accessing the vehicle tool kit and tyre

mobility system in vehicles fitted with

the SEAT SOUND 7 speaker system

(with subwoofer)*

●

Open the boot hatch and lift the shelf.

● If necessary, remove the boot variable floor

››› page 76 .

● Lif t

up the carpet from the recess and re-

move it from the luggage compartment.

● Disconnect the subwoofer’s speaker cable.

● Completely remove the hand-controlled

wheel from the centre of the subwoofer

speaker by turning it anti-clockwise.

● Take out the subwoofer, which is on top of

the tools and tyre mobility system.

● When finished, place the tools and system

back in the same way and place as before to

ensure the speaker sits properly in its hous-

ing. ●

Place the subwoofer in the direction of the

arrow and with the word “FRONT” facing for-

ward.

● Reconnect the speaker cable and firmly ro-

tate the securing wheel clockwise so that the

subwoofer is firmly in place.

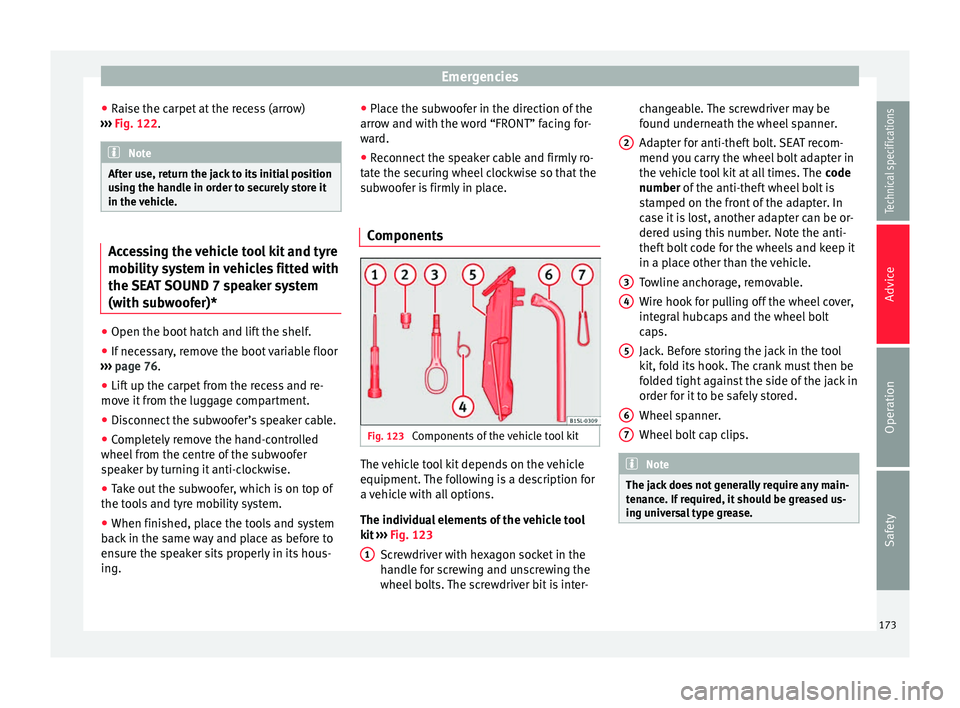

Components Fig. 123

Components of the vehicle tool kit The vehicle tool kit depends on the vehicle

equipment. The following is a description for

a vehicle with all options.

The individual elements of the vehicle tool

kit

›

›› Fig. 123

Sc

rewdriver with hexagon socket in the

handle for screwing and unscrewing the

wheel bolts. The screwdriver bit is inter-

1 changeable. The screwdriver may be

found underneath the wheel spanner.

Adapter for anti-theft bolt. SEAT recom-

mend you carry the wheel bolt adapter in

the vehicle tool kit at all times. The

code

number of the anti-theft wheel bolt is

s t

amped on the front of the adapter. In

case it is lost, another adapter can be or-

dered using this number. Note the anti-

theft bolt code for the wheels and keep it

in a place other than the vehicle.

Towline anchorage, removable.

Wire hook for pulling off the wheel cover,

integral hubcaps and the wheel bolt

caps.

Jack. Before storing the jack in the tool

kit, fold its hook. The crank must then be

folded tight against the side of the jack in

order for it to be safely stored.

Wheel spanner.

Wheel bolt cap clips. Note

The jack does not generally require any main-

tenance. If required, it should be greased us-

ing universal type grease. 2

3

4

5

6

7

173

Technical specifications

Advice

Operation

Safety

Page 178 of 219

Advice

If the wheel bolt is very tight, you may be

able to loosen it by pushing down on the end

of the wheel brace carefully with your foot.

Hold on to the vehicle for support and take

care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over

the wheel bolt ››› Fig. 127 .

● Ho l

d the wheel brace at the end and rotate

the bolt approximately one turn anticlockwise

››

› .

Loosening anti-theft wheel bolts

For wheels with full hubcap, the anti-theft

wheel lock must be threaded into position

››› Fig. 128 2 before mounting the hubcap.

Otherwise it will not be possible to mount the

entire hubcap.

● Take the adapter for anti-theft wheel bolts

out of the vehicle tool kit.

● Insert the adapter onto the wheel bolt

››› Fig. 128 . Push it on as far as it will go.

● Fit the wheel

brace onto the adapter as far

as possible.

● Hold the wheel brace at the end and rotate

the bolt approximately one turn anticlockwise

››

› . Important information about wheel bolts

The wheel rims and bolts have been de-

signed to be fitted to factory options. If differ-

ent rims are fitted, the correct wheel bolts

with the right length and correctly shaped

bolt heads must be used. This ensures that

wheels are fitted securely and that the brake

system functions correctly.

In some circumstances, wheel bolts from the

same model vehicle should not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is

110 Nm

.

Hav e the tight

ening torque of the wheel bolts

checked as soon as possible with a reliable

torque wrench.

If wheel bolts are rusty and it is difficult to

tighten them, the threads should be replaced

and cleaned before checking the tightening

tor

que.

Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving. WARNING

If the wheel bolts are not fitted correctly they

could be released while driving leading to

loss of vehicle control and serious damage. ●

Only use wheel bolts which correspond to

the wheel rims in question.

● Never use different wheel bolts.

● The bolts and threads should be clean, free

of oil and grease and easy to thread.

● To loosen and tighten the wheel bolts, al-

ways use the wheel brace supplied with the

vehicle.

● Loosen the wheel bolts only about one turn

before raising the vehicle with the jack.

● Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving.

● Never loosen the bolted joints of wheel

rims with bolted ring trims.

● If the wheel bolts are not tightened to the

correct torque, they may come loose while

driving, and the bolts and rims may come

out. If the tightening torque is too high, the

wheel bolts and threads can be damaged. 176

Page 180 of 219

Advice

Changing a wheel Fig. 131

Changing a wheel: loosen wheel

bolts with the socket at the end of the wheel

brace Removing the wheel

● Loosen the wheel bolts ››› page 175 .

● Jacking up the vehicle ››› page 177.

● Using the hexagonal socket in the wheel

brace ››› Fig. 131 , unscrew the slackened

wheel bo

lts and place them on a clean sur-

face.

● Take off the wheel.

How to use the spare wheel or temporary

spare wheel

Check the direction of rotation of the tyre

››› page 167, Tyre code.

● Plac

e the spare wheel or temporary spare

wheel into position. ●

Replace the wheel bolts and tighten slight-

ly using the hexagonal socket on the end of the wheel br

ace.

● To tighten the anti-theft locking wheel bolts

use the corresponding adaptor.

● Lower the car with the jack.

● Tighten all of the wheel bolts clockwise

››› . Tighten the bolts in diagonal pairs (not

in a circle).

● Put the caps, trim or full hubcap back on

››› page 174 . WARNING

If the wheel bolts are not treated suitably or

not tightened to the correct torque then this

could lead to loss of vehicle control and to a

serious accident.

● All the wheel bolts and hub threads should

be clean and free of oil and grease. The wheel

bolts should be easily tightened to the cor-

rect torque.

● The hexagonal socket in the wheel brace

should be used for turning wheel bolts only.

Do not use it to loosen or tighten the wheel

bolts. After changing the wheel

●

Clean the vehicle tools, if necessary and

put them away in the luggage compartment

foam holder ›››

page 172 . ●

St or

e the spare wheel, the temporary spare

wheel or the changed wheel securely in the

luggage compartment.

● Have the tightening torque of the wheel

bolts checked as soon as possible with a tor-

que wrench ››› page 176

.

● Have the flat tyre replaced as quickly as

possible.

Tyre repair

TMS (Tyre Mobility System)* The Anti-puncture kit* (Tyre Mobility System)

will reliably seal punctures caused by the

penetration of a foreign body of up to about

4 mm

in diameter.

Do not remove foreign ob-

j

ects, e.g. screws or nails, from the tyre.

After inserting the sealant residue in the tyre,

you must again check the tyre pressure about

10 minutes after starting the engine.

You should only use the tire mobility set if

the vehicle is parked in a safe place, you are

familiar with the procedure and you have the

necessary tire mobility set! Otherwise, you

should seek professional assistance.

The tyre sealant must not be used in the

following cases: ● If the wheel rim has been damaged.

178

Page 182 of 219

Advice

Tube for inflating tyres

Warning provided by tyre pressure moni-

toring system 1)

Air bleed screw 2)

ON/OFF switch

12 volt connector

Bottle of sealant

Spare tyre valve

The valve insert remover

1 has a gap at the

lower end for a valve insert. The valve insert

can only be screwed or unscrewed in this

way. This also applies to its replacement part 11 .

Sealing and inflating a tyre Sealing a tyre

● Unscrew the tyre valve cap.

● Use the corresponding enclosed extractor

››› Fig. 132 1 to unscrew the tyre valve in-

sert. Place the valve insert on a clean surface.

● Vigorously shake the sealant bottle

››› Fig. 132 10 for several seconds.

● Screw the inflator tube ›››

Fig. 132 3 se-

curely into the sealant bottle in a clockwise 5 6

7

8

9

10

11 direction. The seal on the mouth of the bottle

moves automatically.

●

Remove the lid from the filling tube

››› Fig. 132 3 and screw the open end of the

tube into the tyre valve.

● Hold the tyre sealant can upside down and

fill the complete contents of the can into the

ty r

e.

● Remove the tyre sealant bottle from the

valve.

● Screw the valve insert again with the corre-

sponding enclosed extractor ››› Fig. 132 1 into the tyre valve.

Inflating the tyre

●

Securely screw the tyre inflator tube

››› Fig. 132 5 of the compressor into the tyre

valve.

● Check whether the air bleed screw

››› Fig. 132 7 is closed.

● Start the vehicle engine and leave it run-

ning.

● Attach the connector ››› Fig. 132 9 to a 12

volt socket of the vehicle ››› page 72.

● Connect the air compressor with the

ON/OFF switch ››› Fig. 132 8 .●

Keep the air compressor running until it

reaches 2.0 to 2.5 bar (29-36 psi /

200-250 kPa) ››› .

Maximum operation time

8 minut e

s ››› .

● Disconnect the air compressor.

● If it is not possible to achieve an air pres-

sure of 2.0 to 2.5 bar (29-36 psi /

200-250 kPa), unscrew the tyre inflator tube

from the tyre valve.

● Move the vehicle some 10 metres forward

or backward so that the sealant is evenly dis-

tributed in the tyre interior.

● Securely screw the compressor tyre inflator

tube into the tyre valve and repeat the infla-

tion process.

● If the indicated pressure can still not be

reached, the tyre is too badly damaged. The

tyre cannot be sealed with the anti-puncture

kit. Do not continue driving. You should ob-

tain professional assistance ››› .

● Disconnect the air compressor and unscrew

the flexible inflator tube from the tyre valve.

● When the tyre pressure is between 2.5 and

2.0 bars, immediately continue driving with-

out exceeding 80 km/h (50 mph).

● After 10 minutes

, Check the pressure again

›

›› page 181. 1)

It can also be integrated in the compressor.

2) In its place, the compressor may have a button.

180

Page 187 of 219

Emergencies

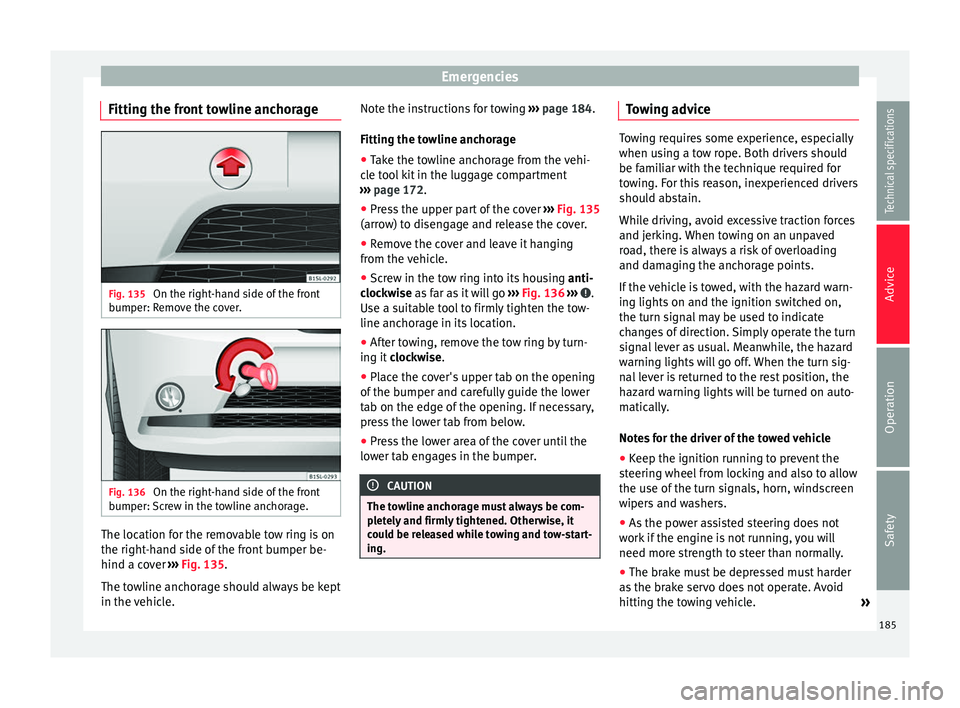

Fitting the front towline anchorage Fig. 135

On the right-hand side of the front

bumper: Remove the cover. Fig. 136

On the right-hand side of the front

bumper: Screw in the towline anchorage. The location for the removable tow ring is on

the right-hand side of the front bumper be-

hind a cover

››› Fig. 135 .

The t o

wline anchorage should always be kept

in the vehicle. Note the instructions for towing

››› page 184.

Fitting the towline anchorage

● Take the towline anchorage from the vehi-

cle tool kit in the luggage compartment

››› page 172.

● Pre

ss the upper part of the cover ››› Fig. 135

(arrow) to disengage and release the cover.

● Remove the cover and leave it hanging

from the vehicle.

● Screw in the tow ring into its housing anti-

clockwise as far as it will go ››

› Fig. 136 ››› .

Use a suitable tool to firmly tighten the tow-

line anchorage in its location.

● After towing, remove the tow ring by turn-

ing it clockwise .

● Plac

e the cover's upper tab on the opening

of the bumper and carefully guide the lower

tab on the edge of the opening. If necessary,

press the lower tab from below.

● Press the lower area of the cover until the

lower tab engages in the bumper. CAUTION

The towline anchorage must always be com-

pletely and firmly tightened. Otherwise, it

could be released while towing and tow-start-

ing. Towing advice

Towing requires some experience, especially

when using a tow rope. Both drivers should

be familiar with the technique required for

towing. For this reason, inexperienced drivers

should abstain.

While driving, avoid excessive traction forces

and jerking. When towing on an unpaved

road, there is always a risk of overloading

and damaging the anchorage points.

If the vehicle is towed, with the hazard warn-

ing lights on and the ignition switched on,

the turn signal may be used to indicate

changes of direction. Simply operate the turn

signal lever as usual. Meanwhile, the hazard

warning lights will go off. When the turn sig-

nal lever is returned to the rest position, the

hazard warning lights will be turned on auto-

matically.

Notes for the driver of the towed vehicle

●

Keep the ignition running to prevent the

steering wheel from locking and also to allow

the use of the turn signals, horn, windscreen

wipers and washers.

● As the power assisted steering does not

work if the engine is not running, you will

need more strength to steer than normally.

● The brake must be depressed must harder

as the brake servo does not operate. Avoid

hitting the towing vehicle. »

185

Technical specifications

Advice

Operation

Safety

Page 194 of 219

Advice

CAUTION

● After changing a bulb, if the rubber covers

are not replaced correctly on the headlamp

framework, the electrical installation may be damaged, especially if water is allowed to en-

ter.

● Remove the ignition key before working on

the electric system. Otherwise, a short circuit could occur. ●

Switch off the lights and the parking light

before changing a bulb.

● Take good care to avoid damaging any com-

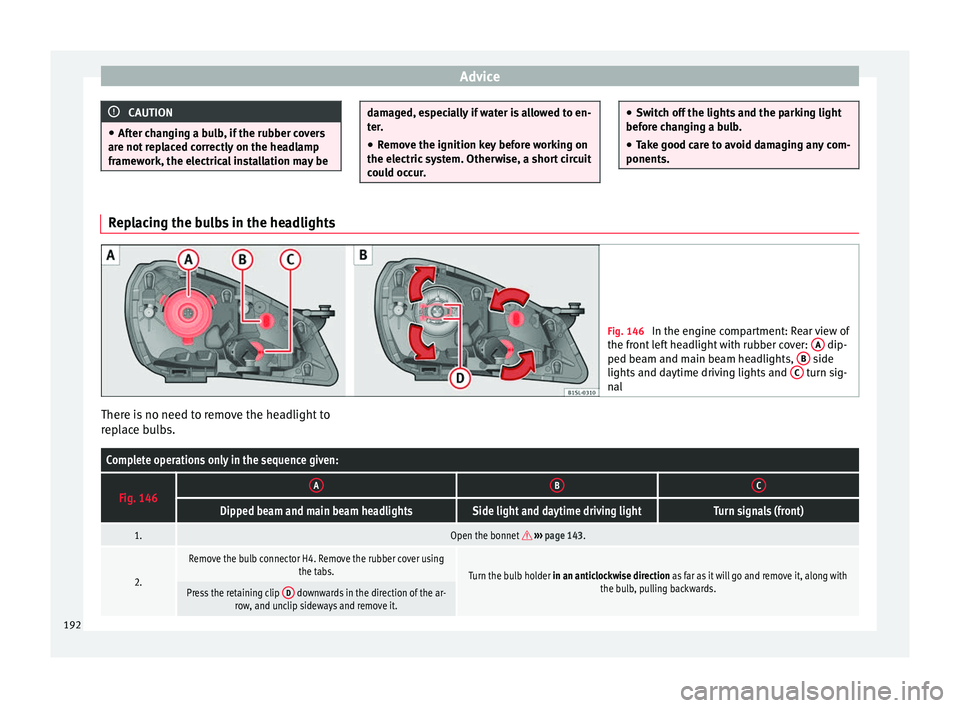

ponents. Replacing the bulbs in the headlights

Fig. 146

In the engine compartment: Rear view of

the front left headlight with rubber cover: A dip-

ped beam and main beam headlights, B side

lights and daytime driving lights and C turn sig-

nal There is no need to remove the headlight to

replace bulbs.Complete operations only in the sequence given:

Fig. 146ABC

Dipped beam and main beam headlightsSide light and daytime driving lightTurn signals (front)

1.Open the bonnet

››› page 143.

2.

Remove the bulb connector H4. Remove the rubber cover using

the tabs.Turn the bulb holder in an anticlockwise direction as far as it will go and remove it, along with the bulb, pulling backwards.Press the retaining clip D downwards in the direction of the ar-

row, and unclip sideways and remove it. 192

Page 195 of 219

Fuses and bulbsComplete operations only in the sequence given:

Fig. 146ABC

Dipped beam and main beam headlightsSide light and daytime driving lightTurn signals (front)

3.Remove the bulb from the holder. If necessary, press the lock on the bulb holder.

4.Replace the faulty bulb by a new identical bulb.

5.Insert the bulb, return it to its position and insert the retaining

clip DInsert the bulb holder in the headlight and

turn it clockwise as far as the stop.Insert the bulb holder in the headlight and

turn it clockwise as far as the stop.

6.Place the rubber cover and check that is in the correct position.

Insert the connector to the bulb H4. Note

The images show the left hand headlight

from behind. The structure of the right hand

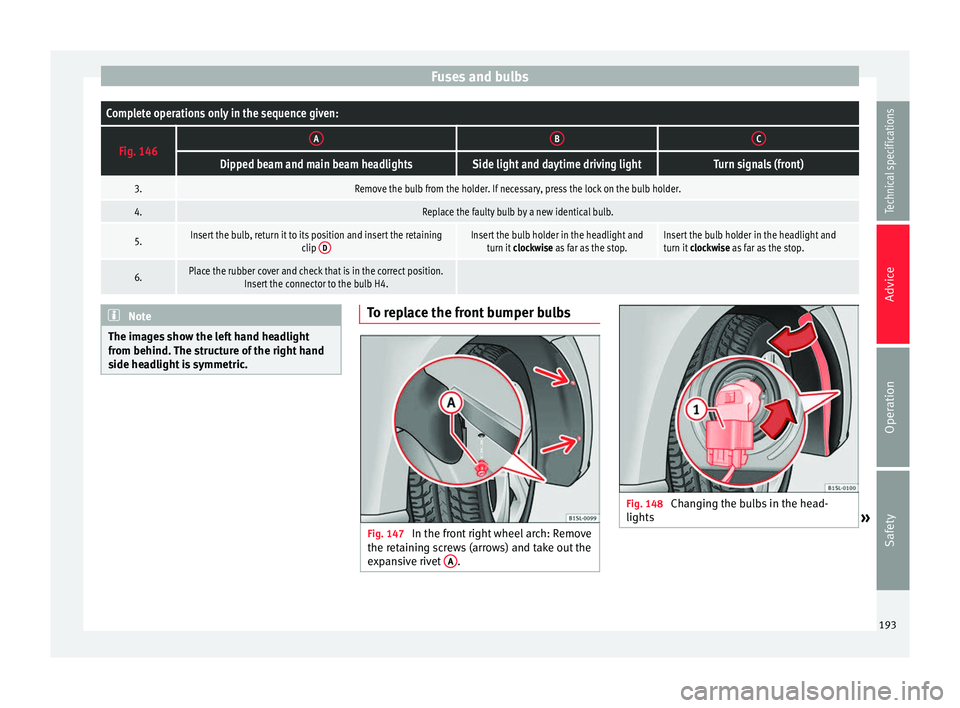

side headlight is symmetric. To replace the front bumper bulbs

Fig. 147

In the front right wheel arch: Remove

the retaining screws (arrows) and take out the

expansive rivet A . Fig. 148

Changing the bulbs in the head-

lights » 193

Technical specifications

Advice

Operation

Safety

Page 196 of 219

AdviceComplete operations only in the sequence giv-

en:

1.Unscrew the 2 retaining screws of the wheel arch

trim

››› Fig. 147 (arrows) with the screwdriver from

the vehicle took kit ››› page 172.

2.

Unscrew the expansive rivet in the lower front part

of the wheel arch trim A with the screwdriver

from the vehicle tool kit and completely remove it

››› page 172.

3.Carefully fold the wheel arch trim to the side.

4.Release the connector ››› Fig. 148 1 and remove

it.

5.

Turn the bulb holder ››› Fig. 148 in the direction of

the arrow, in an anticlockwise direction as far as it

will go and remove it, along with the bulb, pulling

backwards.

6.Replace the faulty bulb by a new identical bulb.

7.Insert the bulb holder in the headlight and turn it

clockwise as far as the stop.

8.Plug the connector 1 into the bulb holder. The

connector must audibly click into place.

9.Replace the wheel arch trim into its position.

10.Place the expansive rivet in the wheel arch trim

and bumper and press it completely inwards

››› Fig. 147 A

.

11.Securely screw the 2 retaining screws

››› Fig. 147

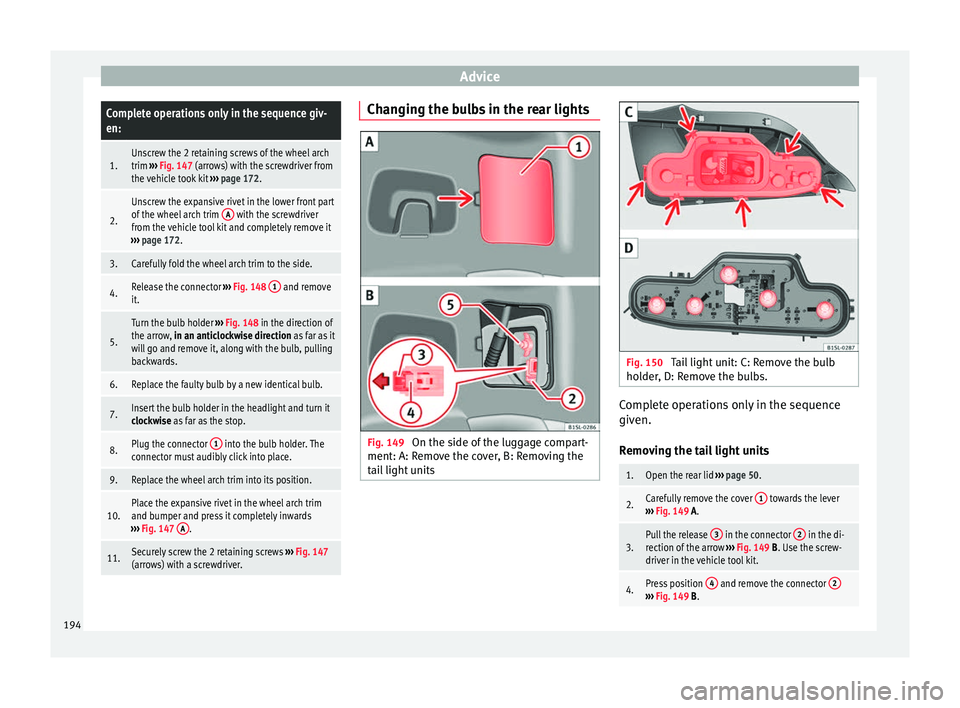

(arrows) with a screwdriver. Changing the bulbs in the rear lights

Fig. 149

On the side of the luggage compart-

ment: A: Remove the cover, B: Removing the

tail light units Fig. 150

Tail light unit: C: Remove the bulb

holder, D: Remove the bulbs. Complete operations only in the sequence

given.

Removing the tail light units

1.Open the rear lid

››› page 50.

2.Carefully remove the cover 1 towards the lever

››› Fig. 149 A.

3.Pull the release 3 in the connector 2 in the di-

rection of the arrow ››› Fig. 149 B. Use the screw-

driver in the vehicle tool kit.

4.Press position 4 and remove the connector 2›››

Fig. 149 B. 194