lights Seat Mii 2014 Service Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Mii, Model: Seat Mii 2014Pages: 219, PDF Size: 4.19 MB

Page 176 of 219

Advice

Changing a wheel Introduction Some vehicle versions and models do not

have a factory-fitted jack or box spanner. In

this case, we recommend consulting a Speci-

alised workshop to change the wheel.

You should only change the wheels yourself if

the vehicle is parked in a safe place, you are

familiar with the procedure and safety stand-

ards and you have all the necessary tools!

Otherwise, you should seek professional as-

sistance.

WARNING

Changing a wheel can be dangerous, espe-

cially on the hard shoulder. Please observe

the following rules to minimise the risk of in-

jury:

● Stop the vehicle safely as soon as possible.

Park at a safe distance from surrounding traf-

fic to change a wheel.

● When changing a wheel, keep all passen-

gers, and particularly children, a safe dis-

tance away from the work area.

● Turn on the hazard warning lights to warn

other road users.

● Ensure the ground on which you park is flat

and solid. If necessary, support the jack on a

wide solid base. ●

If you are changing a wheel yourself, you

should be familiar with the required proce-

dure. Otherwise, you should seek professio-

nal assistance.

● Only use suitable tools that are not dam-

aged when changing a wheel.

● Always stop the engine, apply the hand-

brake lever firmly and place the selector lever

in position P, or engage a gear for a manual

gearbox to reduce the risk of the vehicle mov-

ing accidentally.

● Have the tightening torque of the wheel

bolts checked as soon as possible with a reli-

able torque wrench. WARNING

If the wheel trims are not appropriate or not

fitted correctly, they could cause major acci-

dents or damage.

● Incorrectly mounted wheel trims may come

off while driving and endanger other road

users.

● Damaged trims must never be mounted on

the wheels.

● Always ensure that the brake ventilation

and cooling is not cut off or blocked. This is

also valid if hubcaps are fitted later. If there

is not enough air, you may require signifi-

cantly longer braking distances. CAUTION

Remove and remount wheel trims taking care

to avoid damage to the vehicle. Hubcaps

Fig. 124

Remove the hubcap of the steel

wheel trim In order to access the wheel bolts, first re-

move the hubcap.

Removing and fitting the hubcap

● To remove , take the vehicle tool kit wire

hook and att

ach it to the edge of the wheel

trim ››› Fig. 124

.

● Remove the trim by pulling it in the direc-

tion of the arrow.

● To replace the hubcap , press the hubcap

against the trim until it clicks into place.

174

Page 181 of 219

Emergencies

● In outside temperatures below -20 °C

(-4 °F).

● In the event of cuts or perforations in the

tyre greater than 4 mm.

● If you have been driving with very low pres-

sure or a completely flat tyre.

● If the sealant bottle has passed its use by

date. WARNING

Using the tyre mobility system can be dan-

gerous, especially when filling the tyre at the

roadside. Please observe the following rules

to minimise the risk of injury:

● Stop the vehicle safely as soon as possible.

Park it at a safe distance from surrounding

traffic to fill the tyre.

● Ensure the ground on which you park is flat

and solid.

● All passengers and particularly children

must keep a safe distance from the work area.

● Turn on the hazard warning lights to warn

other road users.

● Use the tyre mobility system only if you are

familiar with the necessary procedures. Oth-

erwise, you should seek professional assis-

tance.

● The tyre mobility set is intended for tempo-

rary emergency use only until you can reach

the nearest specialised workshop.

● Replace the repaired tyre with the tire mo-

bility set as soon as possible. ●

The sealant is a health hazard and must be

cleaned immediately if it comes into contact

with the skin.

● Always keep the tire mobility set out of the

reach of small children.

● Never use an equivalent jack, even if it has

been approved for your vehicle.

● Always stop the engine, apply the hand-

brake lever firmly and engage gear if using a

manual gearbox, in order to reduce the risk of

vehicle involuntary movement. WARNING

A tyre filled with sealant does not have the

same performance properties as a conven-

tional tyre.

● Never drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and

fast cornering.

● Drive for only 10 minutes at a maximum

speed of 80 km/h (50 mph) and then check

the tyre. For the sake of the environment

Dispose of used or expired sealant observing

any legal requirements. Note

● A new bottle of sealant can be purchased at

SEAT dealerships. ●

Take into account the separate instruction

manual of the tyre mobility set* manufactur-

er. Contents of the tyre mobility system*

Fig. 132

Standard representation: Contents

of the tyre mobility system. The tyre mobility set is located underneath

the floor covering in the luggage compart-

ment. It includes the following components

››› Fig. 132 :

T y

re valve remover

Sticker indicating maximum speed “max.

80 km/h” or “max. 50 mph”

Filler tube with cap

Air compressor »

1 2

3

4

179

Technical specifications

Advice

Operation

Safety

Page 184 of 219

Advice

CAUTION

To avoid considerable damage to the vehicle

electrical system, note the following careful-

ly: ● If the jump leads are incorrectly connected,

this could result in a short circuit.

● The vehicles must not touch each other,

otherwise electricity could flow as soon as

the positive terminals are connected. How to jump start: description

Fig. 133

Diagram of connections for vehicles

without Start-Stop system. Fig. 134

Diagram of connections for vehicles

with Start-Stop system. Jump lead terminal connections

1. Switch off the ignition of both vehicles

››› .

2. Connect one end of the red jump lead to

the po s

itive + terminal of the vehicle

with the flat battery A

››› Fig. 133 .

3. C

onnect the other end of the red

jump

lead to the positive terminal + in the ve-

hicle providing assistance B .

4. For vehicles without Start-Stop system:

connect one end of the black jump lead to

the negative terminal – of the vehicle

providing the current B

››› Fig. 133 .

– For

vehicles with Start-Stop system: con-

nect one end of the black jump lead X to a

suitable ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 134 . 5.

C

onnect the other end of the

black jump

lead X to a solid metal component bolted

to the engine block or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot come into contact with any moving

parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boosting battery and let it run at idling

speed.

8. Start the engine of the vehicle with the flat battery and wait 2 or 3 minutes until the

engine is “running”.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped beam headlights (if they

are switched on).

10. Turn on the heater blower and heated rear

w indo

w in the vehicle with the flat battery.

This helps minimise voltage peaks which

are generated when the leads are discon-

nected.

11.When the engine is running, disconnect the leads in reverse order to the details

given above.

182

Page 186 of 219

Advice

CAUTION

● Carefully fit and remove the towline anchor-

age and its cover to avoid damage to the ve-

hicle (e.g. paintwork).

● When towing, fuel could enter the catalytic

converter and cause damage! Note

Fitting a towline anchorage to the rear bump-

er is not possible. The vehicle is not suitable

for towing other vehicles. Instructions for tow starting

In general, the vehicle should not be started

by towing. Jump-starting is much more pref-

erable

›

› ›

page 181.

For technical reasons, the following vehicles

can

not be tow started:

● Vehicles with an automatic gearbox.

● If the vehicle battery is flat, it is possible

that the engine control unit does not operate

correctly.

However, if your vehicle must absolutely be

tow-started (manual gearbox):

● Put it into second or third gear.

● Keep the clutch pressed down. ●

Switch on the ignition and the hazard warn-

ing lights.

● Release the clutch when both vehicles are

moving.

● As soon as the engine starts, press the

clutch and move the gear lever into neutral.

This helps to prevent a collision with the tow-

ing vehicle. CAUTION

When tow-starting, fuel could enter the cata-

lytic converter and damage it. Notes on towing

Tow rope or tow bar

When towing, the tow bar is the safest and

vehicle friendly way. You should only use a

tow rope if you do not have a tow bar.

A tow rope should be slightly elastic to avoid

damage to both vehicles. It is advisable to

use a tow rope made of synthetic fibre or sim-

ilarly elastic material.

Only secure the tow rope or tow bar to the

towline anchorage or specially designed fit-

ting.

Towing vehicles with an automatic gearbox

Note the following for a towed vehicle:●

Make sure the gear selector lever is in the N

position.

● Do not drive faster than 50 km/h (30 mph)

when towing a vehicle.

● Do not tow further than 50 km (30 miles).

● If a breakdown truck is used, the vehicle

must be towed with the front wheels raised.

Situations in which the vehicle should not be

towed

In the following cases, the vehicle should not

be towed but transported on a trailer or spe-

cial vehicle:

● If the vehicle gearbox does not contain lu-

bricant due to a fault.

● If the battery is flat and the steering cannot

be unlocked as a result, the electronic steer-

ing lock and electronic parking brake cannot

be disengaged.

● If the vehicle to be towed has an automatic

gearbox and the distance to be covered is

greater than 50 km (30 miles). Note

The vehicle can only be towed if the steering

lock electronic gearbox lock is deactivated. If

the vehicle has no power supply or there is

an electric system fault, the engine must be

started using jump leads to deactivate the

steering column electronic gearbox lock. 184

Page 187 of 219

Emergencies

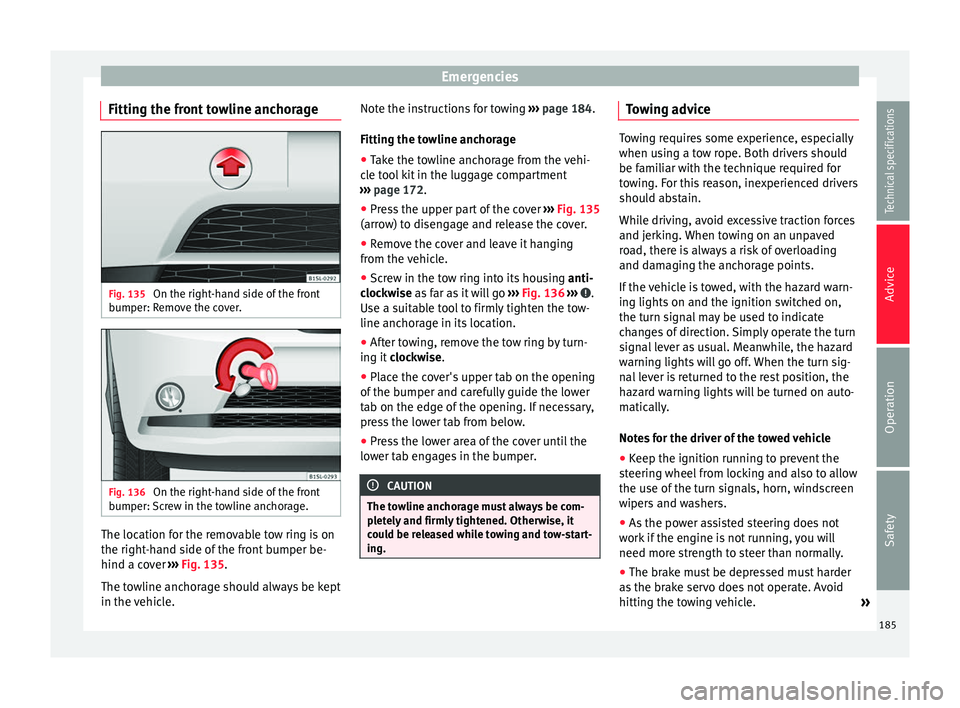

Fitting the front towline anchorage Fig. 135

On the right-hand side of the front

bumper: Remove the cover. Fig. 136

On the right-hand side of the front

bumper: Screw in the towline anchorage. The location for the removable tow ring is on

the right-hand side of the front bumper be-

hind a cover

››› Fig. 135 .

The t o

wline anchorage should always be kept

in the vehicle. Note the instructions for towing

››› page 184.

Fitting the towline anchorage

● Take the towline anchorage from the vehi-

cle tool kit in the luggage compartment

››› page 172.

● Pre

ss the upper part of the cover ››› Fig. 135

(arrow) to disengage and release the cover.

● Remove the cover and leave it hanging

from the vehicle.

● Screw in the tow ring into its housing anti-

clockwise as far as it will go ››

› Fig. 136 ››› .

Use a suitable tool to firmly tighten the tow-

line anchorage in its location.

● After towing, remove the tow ring by turn-

ing it clockwise .

● Plac

e the cover's upper tab on the opening

of the bumper and carefully guide the lower

tab on the edge of the opening. If necessary,

press the lower tab from below.

● Press the lower area of the cover until the

lower tab engages in the bumper. CAUTION

The towline anchorage must always be com-

pletely and firmly tightened. Otherwise, it

could be released while towing and tow-start-

ing. Towing advice

Towing requires some experience, especially

when using a tow rope. Both drivers should

be familiar with the technique required for

towing. For this reason, inexperienced drivers

should abstain.

While driving, avoid excessive traction forces

and jerking. When towing on an unpaved

road, there is always a risk of overloading

and damaging the anchorage points.

If the vehicle is towed, with the hazard warn-

ing lights on and the ignition switched on,

the turn signal may be used to indicate

changes of direction. Simply operate the turn

signal lever as usual. Meanwhile, the hazard

warning lights will go off. When the turn sig-

nal lever is returned to the rest position, the

hazard warning lights will be turned on auto-

matically.

Notes for the driver of the towed vehicle

●

Keep the ignition running to prevent the

steering wheel from locking and also to allow

the use of the turn signals, horn, windscreen

wipers and washers.

● As the power assisted steering does not

work if the engine is not running, you will

need more strength to steer than normally.

● The brake must be depressed must harder

as the brake servo does not operate. Avoid

hitting the towing vehicle. »

185

Technical specifications

Advice

Operation

Safety

Page 191 of 219

Fuses and bulbs

CAUTION

● Damaged or dirty windscreen wipers could

scratch the glass.

● If products containing solvents, rough

sponges or sharp objects are used to clean

the blades, the graphite layer will be dam-

aged.

● Never use fuel, nail varnish remover, paint

thinner or similar products to clean the win-

dows. Note

If wax deposits, other cleaning products from

the automatic car wash, or other care prod-

ucts, are left on the windscreen and the rear

window, the blades can scratch the glass. Re-

move wax deposits with a special product or

cleaning cloths. Fuses and bulbs

Fuses Introduction Due to the constant updating of vehicles,

fuse assignments based on equipment and

the use of the same fuse for various electrical

components, it is not possible to provide an

up-to-date summary of the fuse positions for

the electrical components at the time of

printing this manual. For detailed information

about the fuse positions, please consult a

technical service.

In general, a fuse can be assigned to various

electrical components. Likewise, an electrical

component can be protected by several

fuses.

Only replace fuses when the cause of the

problem has been solved. If a newly inserted

fuse blows after a short time, you must have

the electrical system checked by a special-

ised workshop as soon as possible.

WARNING

The high voltages in the electrical system can

give serious electrical shocks, causing burns

and even death!

● Never touch the electrical wiring of the igni-

tion system. ●

Take care not to cause short circuits in the

electrical system. WARNING

Using unsuitable fuses, repairing fuses or

bridging a current circuit without fuses can

cause a fire and serious injury.

● Never use a fuse with a higher value. Only

replace fuses with a fuse of the same amper-

age (same colour and markings) and size.

● Never repair a fuse.

● Never replace a fuse by a metal strip, staple

or similar. CAUTION

● To prevent damage to the vehicle's electric

system, before replacing a fuse always turn

off the ignition, the lights and all electrical

elements and remove the key from the igni-

tion.

● If you replace a fuse with higher-rating

fuse, you could cause damage to another part

of the electrical system.

● Protect the fuse boxes when open to pre-

vent the entry of dust or humidity as they can

damage the electrical system. Note

One component may have more than one

fuse. » 189Technical specifications

Advice

Operation

Safety

Page 193 of 219

Fuses and bulbs

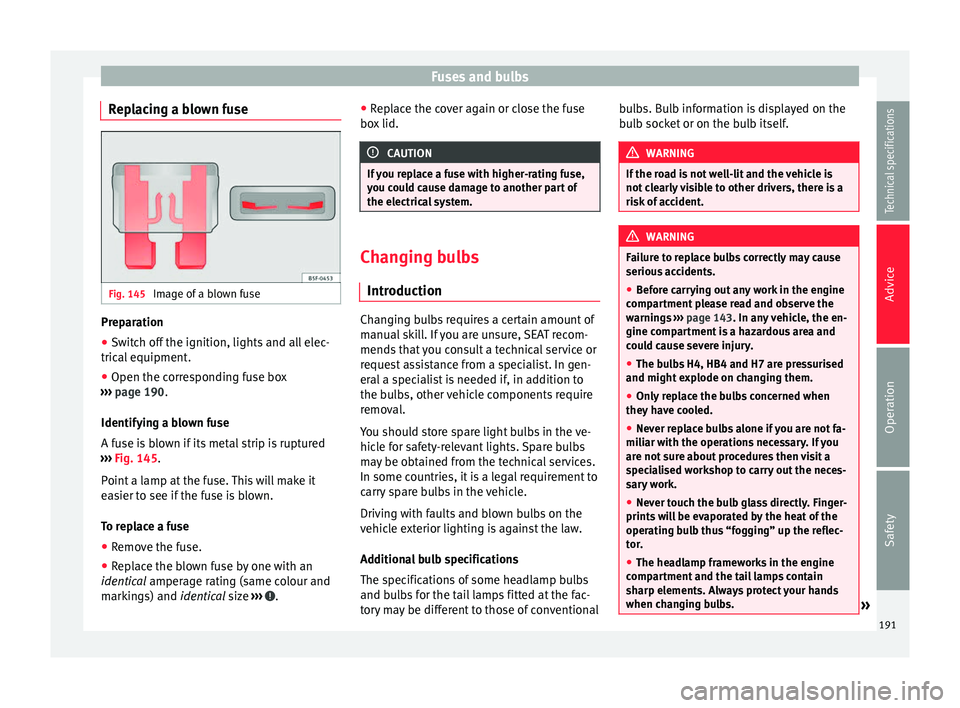

Replacing a blown fuse Fig. 145

Image of a blown fuse Preparation

● Switch off the ignition, lights and all elec-

trical equipment.

● Open the corresponding fuse box

››› page 190 .

Identif y

ing a blown fuse

A fuse is blown if its metal strip is ruptured

››› Fig. 145.

Point a lamp at the fuse. This will make it

easier to see if the fuse is blown.

To replace a fuse ● Remove the fuse.

● Replace the blown fuse by one with an

identical amperage rating (same colour and

mark

ings) and identical size ››› .●

Replace the cover again or close the fuse

box lid. CAUTION

If you replace a fuse with higher-rating fuse,

you could cause damage to another part of

the electrical system. Changing bulbs

Introduction Changing bulbs requires a certain amount of

manual skill. If you are unsure, SEAT recom-

mends that you consult a technical service or

request assistance from a specialist. In gen-

eral a specialist is needed if, in addition to

the bulbs, other vehicle components require

removal.

You should store spare light bulbs in the ve-

hicle for safety-relevant lights. Spare bulbs

may be obtained from the technical services.

In some countries, it is a legal requirement to

carry spare bulbs in the vehicle.

Driving with faults and blown bulbs on the

vehicle exterior lighting is against the law.

Additional bulb specifications

The specifications of some headlamp bulbs

and bulbs for the tail lamps fitted at the fac-

tory may be different to those of conventionalbulbs. Bulb information is displayed on the

bulb socket or on the bulb itself.

WARNING

If the road is not well-lit and the vehicle is

not clearly visible to other drivers, there is a

risk of accident. WARNING

Failure to replace bulbs correctly may cause

serious accidents.

● Before carrying out any work in the engine

compartment please read and observe the

warnings ››› page 143. In any vehicle, the en-

gine c omp

artment is a hazardous area and

could cause severe injury.

● The bulbs H4, HB4 and H7 are pressurised

and might explode on changing them.

● Only replace the bulbs concerned when

they have cooled.

● Never replace bulbs alone if you are not fa-

miliar with the operations necessary. If you

are not sure about procedures then visit a

specialised workshop to carry out the neces-

sary work.

● Never touch the bulb glass directly. Finger-

prints will be evaporated by the heat of the

operating bulb thus “fogging” up the reflec-

tor.

● The headlamp frameworks in the engine

compartment and the tail lamps contain

sharp elements. Always protect your hands

when changing bulbs. » 191

Technical specifications

Advice

Operation

Safety

Page 194 of 219

Advice

CAUTION

● After changing a bulb, if the rubber covers

are not replaced correctly on the headlamp

framework, the electrical installation may be damaged, especially if water is allowed to en-

ter.

● Remove the ignition key before working on

the electric system. Otherwise, a short circuit could occur. ●

Switch off the lights and the parking light

before changing a bulb.

● Take good care to avoid damaging any com-

ponents. Replacing the bulbs in the headlights

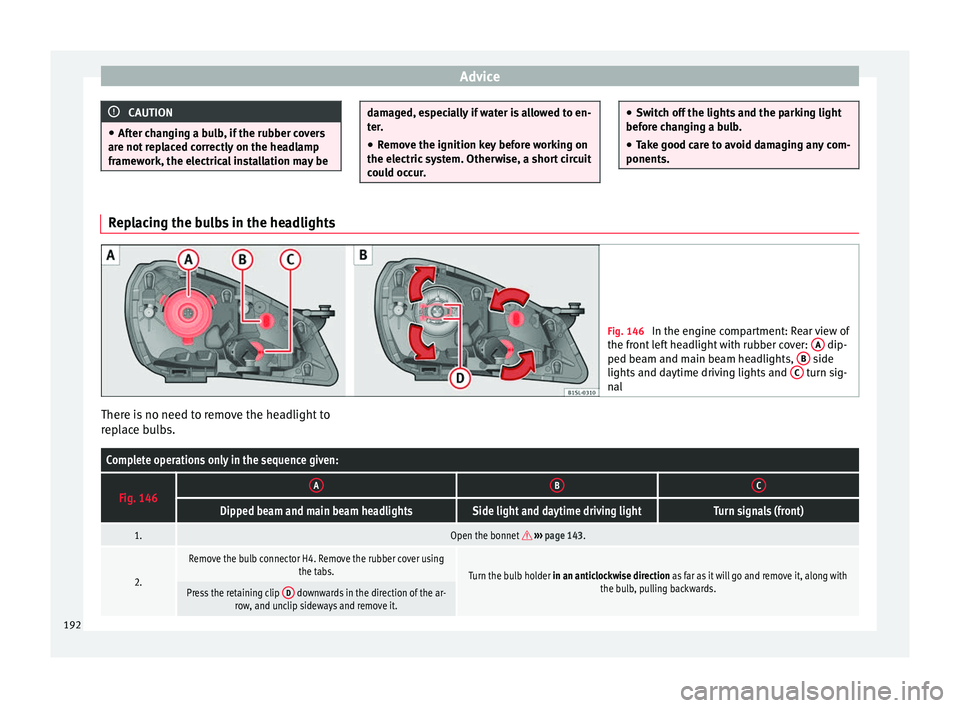

Fig. 146

In the engine compartment: Rear view of

the front left headlight with rubber cover: A dip-

ped beam and main beam headlights, B side

lights and daytime driving lights and C turn sig-

nal There is no need to remove the headlight to

replace bulbs.Complete operations only in the sequence given:

Fig. 146ABC

Dipped beam and main beam headlightsSide light and daytime driving lightTurn signals (front)

1.Open the bonnet

››› page 143.

2.

Remove the bulb connector H4. Remove the rubber cover using

the tabs.Turn the bulb holder in an anticlockwise direction as far as it will go and remove it, along with the bulb, pulling backwards.Press the retaining clip D downwards in the direction of the ar-

row, and unclip sideways and remove it. 192

Page 195 of 219

Fuses and bulbsComplete operations only in the sequence given:

Fig. 146ABC

Dipped beam and main beam headlightsSide light and daytime driving lightTurn signals (front)

3.Remove the bulb from the holder. If necessary, press the lock on the bulb holder.

4.Replace the faulty bulb by a new identical bulb.

5.Insert the bulb, return it to its position and insert the retaining

clip DInsert the bulb holder in the headlight and

turn it clockwise as far as the stop.Insert the bulb holder in the headlight and

turn it clockwise as far as the stop.

6.Place the rubber cover and check that is in the correct position.

Insert the connector to the bulb H4. Note

The images show the left hand headlight

from behind. The structure of the right hand

side headlight is symmetric. To replace the front bumper bulbs

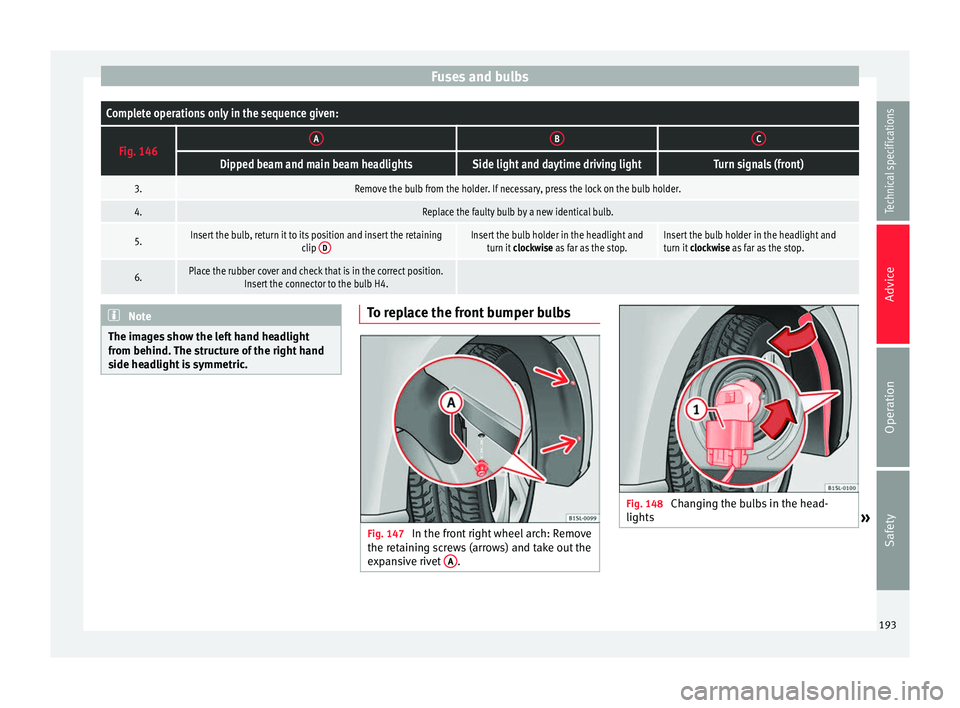

Fig. 147

In the front right wheel arch: Remove

the retaining screws (arrows) and take out the

expansive rivet A . Fig. 148

Changing the bulbs in the head-

lights » 193

Technical specifications

Advice

Operation

Safety

Page 196 of 219

AdviceComplete operations only in the sequence giv-

en:

1.Unscrew the 2 retaining screws of the wheel arch

trim

››› Fig. 147 (arrows) with the screwdriver from

the vehicle took kit ››› page 172.

2.

Unscrew the expansive rivet in the lower front part

of the wheel arch trim A with the screwdriver

from the vehicle tool kit and completely remove it

››› page 172.

3.Carefully fold the wheel arch trim to the side.

4.Release the connector ››› Fig. 148 1 and remove

it.

5.

Turn the bulb holder ››› Fig. 148 in the direction of

the arrow, in an anticlockwise direction as far as it

will go and remove it, along with the bulb, pulling

backwards.

6.Replace the faulty bulb by a new identical bulb.

7.Insert the bulb holder in the headlight and turn it

clockwise as far as the stop.

8.Plug the connector 1 into the bulb holder. The

connector must audibly click into place.

9.Replace the wheel arch trim into its position.

10.Place the expansive rivet in the wheel arch trim

and bumper and press it completely inwards

››› Fig. 147 A

.

11.Securely screw the 2 retaining screws

››› Fig. 147

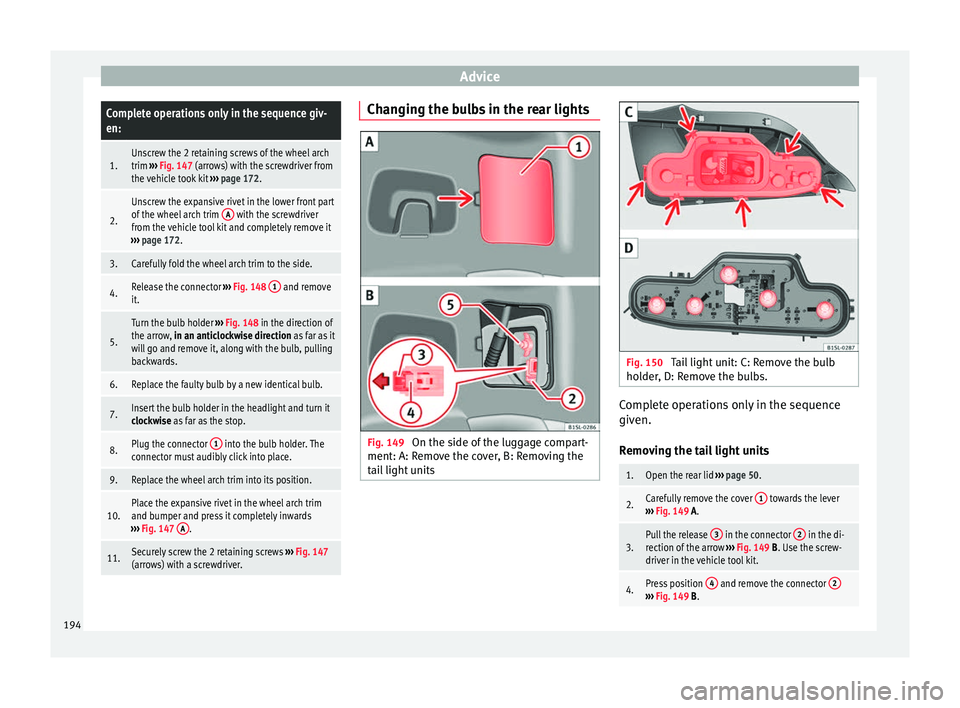

(arrows) with a screwdriver. Changing the bulbs in the rear lights

Fig. 149

On the side of the luggage compart-

ment: A: Remove the cover, B: Removing the

tail light units Fig. 150

Tail light unit: C: Remove the bulb

holder, D: Remove the bulbs. Complete operations only in the sequence

given.

Removing the tail light units

1.Open the rear lid

››› page 50.

2.Carefully remove the cover 1 towards the lever

››› Fig. 149 A.

3.Pull the release 3 in the connector 2 in the di-

rection of the arrow ››› Fig. 149 B. Use the screw-

driver in the vehicle tool kit.

4.Press position 4 and remove the connector 2›››

Fig. 149 B. 194