technical data Seat Mii 2015 Manual Online

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Mii, Model: Seat Mii 2015Pages: 232, PDF Size: 4.23 MB

Page 201 of 232

Wheels and tyres

WARNING

Aggressive fluids or substances could result

in v i

sible or invisible damage with the conse-

quent risks.

● Always ensure that tyres do not come into

contact

with chemical products, oil, grease,

fuel, brake fluid or other aggressive substan-

ces. WARNING

Old tyres, even if they have never been used,

ma y

lose air or burst unexpectedly while driv-

ing, resulting in serious accident or damage.

● If tyres are over six years old, they should

only be u

sed in an emergency and with ex-

treme caution. For the sake of the environment

Old tyres must be disposed of by qualified

personnel ac

cording to the laws in the coun-

try concerned. Wheels

The design of wheel bolts is matched to the

rims. If

diff

er

ent rims are fitted, the correct

wheel bolts with the right length and correct-

ly shaped bolt heads must be used. This en-

sures that wheels are fitted securely and that

the brake system functions correctly

››› page 71. For technical reasons, it is not generally pos-

sibl

e to use the wheels from other vehicles.

In some cases, this may also be true for the

same model of wheel.

The tyres and rims approved by SEAT are spe-

cially matched to the characteristics of the

vehicle and are critical to good road holding

and safe handling.

Note for Italy: A SEAT Service Centre should

be consulted whether different sized wheels

or tyres to those originally fitted by SEAT may

be fitted, as well as the combinations al-

lowed between the front axle (axle 1) and

back axle (axle 2).

Wheel bolts

Wheel bolts must be tightened to the correct

torque ››› page 71.

Beadlock wheel rims

Beadlock wheel rims have various compo-

nents. These are joined together by special

bolts using a special procedure. This ensures

good performance, a better seal, improved

safety and wheel run out. Therefore, worn

rims should always be replaced and must on-

ly be repaired in a specialised workshop.

SEAT recommends visiting a technical service

››› .Wheel rims with bolted trims

Wheel

rims

m

ay be fitted with interchangea-

ble trim parts which are attached to the rim

using self-locking bolts. Worn trims should

only be replaced at a specialised workshop.

SEAT recommends visiting a technical service

››› .

WARNING

The use of worn or damaged wheel rims could

mak e driv

ing more dangerous and result in

serious accidents and damage.

● Only wheel rims which have been approved

for use w

ith your vehicle should be used.

● Inspect wheel rims regularly for damage

and repl

ace as required. WARNING

If the bolted joints of wheel rims with bolted

ring trims ar

e not correctly tightened or loos-

ened, this could result in serious accident.

● Never loosen the bolted joints of wheel

rims with bo

lted ring trims.

● Any work relating to wheel rims with bolted

rims shoul

d be carried out at specialised

workshop. SEAT recommends taking your car

in for technical service. 199

Technical data

Advice

Operation

Emergencies

Safety

Page 203 of 232

Wheels and tyres

››› Fig. 173 i s

loc ated on the driver's door pil-

lar.

Under-inflation or over-inflation will reduce

the life of the tyres considerably and also im-

pair the car's handling ››› . It is essential to

m aint

ain the c

orrect tyre pressures, especial-

ly if driving at high speeds. Incorrect tyre

pressure causes premature wear and could

cause tyre blow-out.

The pressure should therefore be checked at

least once a month and before starting a

journey.

As a general rule, the pressures given are for

cold tyres. When the tyres are hot, the pres-

sures are greater.

Never deflate a hot tyre in order to obtain the

required pressure. This could result in very

low tyre pressures which may lead to sudden

blow-outs.

Tyre pressure monitoring system

Check tyre pressures only when the vehicle

has not been driven for more than a few kilo-

metres at low speeds in the past three hours.

● The tyre pressures should be checked regu-

larly, and on

ly when the tyres are cold. Al-

ways check all tyres, including the spare

wheel. Tyre pressures should be checked

more often in colder regions, and only when

the vehicle has not been driven recently. Al-

ways use a correctly-operating tyre gauge. ●

Adjust

tyre pressures to the loads carried in

the vehicle.

● After adjusting the tyre pressure, check that

the caps

are properly screwed on.

The spare wheel or temporary spare wheel

must always be kept at the maximum pres-

sure stipulated. WARNING

If tyre pressures are too high or too low, the

tyr e m

ay deflate or burst suddenly while driv-

ing. This could result in a serious accident.

● If the tyre pressure is too low, they could

overhe

at, resulting in tread detachment or

even burst tyres.

● When driving at high speeds and/or fully

loaded, the ty

re could suddenly overheat,

burst or be subject to tread detachment, with

the resultant loss of control of the vehicle.

● Tyre pressures which are too high or too

low reduc

e the service life of the tyre, affect-

ing the vehicle's performance.

● Tyre pressures should be checked regularly,

at le

ast once a month and before long jour-

neys.

● Adjust the pressures of all the tyres to the

vehicl

e load.

● Never deflate excess pressure from hot

tyre

s. CAUTION

● Tak e c

are not to tilt the manometer when

placing it on the valve. Otherwise, the valve

may be damaged.

● If tyre valves are not protected by caps, or if

the caps

are not screwed on correctly, they

may become damaged. Check that the caps

are identical to the standard caps and have

been correctly tightened. For the sake of the environment

Under-inflated tyres will increase fuel con-

sumption. Wear indicator depth profile

Fig. 174

Tyre tread: tread wear indicators » 201Technical data

Advice

Operation

Emergencies

Safety

Page 205 of 232

Wheels and tyres

tyres wear too quickly, have the wheel align-

ment c

hec

ked at a specialised workshop. WARNING

If you notice unusual vibration or the car pulls

to one s ide whi

le driving, this may indicate

that one of the tyres is damaged.

● Reduce speed immediately and stop, while

obser

ving the highway code.

● Check the wheels and tyres for damage.

● Never carry on driving on worn tyres or

wheels. Reque

st qualified assistance immedi-

ately.

● If there is no visible exterior damage, drive

slowly

and carefully to the nearest special-

ised workshop and have the vehicle checked. Tyre monitor system*

Fig. 175

Centre console: tyre monitor system

b utt

on The tyre control lamp compares wheel revolu-

tion

s

and w

ith it, the wheel diameter of each

wheel using the ESC. If the diameter of a

wheel changes, the tyre control lamp

lights up. The wheel diameter changes when:

● Tyre pressure is insufficient.

● The tyre structure is damaged.

● The vehicle is unbalanced because of a

load.

● The wheel

s of one axle are under more

pres

sure (for example, driving with a trailer or

on steep slopes).

● The vehicle is fitted with snow chains.

● The temporary spare wheel is fitted.

● The wheel on one axle is changed.

Tyr

e pressure adjustment

On adjusting tyre pressure or changing one

or more wheels, the ››› Fig. 175 button must

be kept pressed down, with the ignition on,

until an acoustic signal is heard.

If the wheels are under excessive load (for ex-

ample, driving with a trailer or heavy load),

the tyre pressure must be increased to the

recommended value for a full load (see the

sticker on the inside of the fuel flap). If the

tyre monitor system button is pressed down,

the new tyre pressures are confirmed. The tyre pressure control lamp

lights up

If

the tyre pressure of a wheel is much lower

than the value set by the driver, then the tyre

pressure control lamp ››› will light up.

WARNING

● When the tyr e pr

essure control lamp lights

up, reduce speed immediately and avoid any

sudden turning or braking manoeuvre. Stop

when possible, and check the tyre pressure

and status.

● The driver is responsible for maintaining

correct

tyre pressures. For this reason, tyre

pressure must be regularly checked.

● Under certain circumstances (e.g. when

driving in a s

porty manner, in winter condi-

tions or on a dirt track) the tyre control lamp

may light up belatedly or may function incor-

rectly. Note

If the battery is disconnected, the yellow

warnin g l

amp lights up after turning the

ignition on. This should turn off after a brief

journey. 203

Technical data

Advice

Operation

Emergencies

Safety

Page 207 of 232

Wheels and tyres

●

Rep l

ace the temporary spare wheel for a

normal wheel as soon as possible. The com-

pact temporary spare wheel is only intended

for temporary use over short distances.

● The temporary spare wheel must always be

secured w

ith the factory supplied wheel

bolts.

● You should never use more than one tem-

porary

spare wheel. ●

Aft er mou

nting the temporary spare wheel,

check the tyre pressure as soon as possible

››› page 200.

● Snow chains on the temporary spare wheel

are not permitt

ed. Note

Wherever possible, secure the spare wheel,

t empor ar

y spare wheel or the replaced wheel

safely in the luggage compartment. In vehi- cles with anti-puncture kit, it is not possible

to sec

ur

e the defective wheel. Tyre code

Fig. 177

Universal code on tyres Radial

Rim di

amet

er c

ode

Load index & speed rating

DOT tyre identification number

Severe snow conditions

Tyre ply composition and materials used

Max. load rating

Treadwear, traction and temperature

grades

Max. permissible inflation pressure

Passenger car tyre

Nominal width of tyre in millimetres

Ratio of height to width (aspect ratio) »

1 2

3

4

5

6

7

8

9

10

11

12

205

Technical data

Advice

Operation

Emergencies

Safety

Page 209 of 232

Wheels and tyresTyre code (example)Meaning

Made in GermanyCountry of manufacture.

MAX LOAD 615 KGUS load rating, indicating maximum permitted load per tyre.

MAX INFLATION 350 KPA (51 PSI)US limit, indicating maximum permitted tyre pressure.

SIDEWALL 1 PLY RAYONInformation about tyre wall components:

1 layer of rayon (artificial silk).

TREAD 4 PLIES

1 RAYON + 2 STEEL + 1 NYLONInformation about tread components:

In the example, there are 4 layers below the tread: 1 layer of rayon (artificial silk), 2 layers of steel reinforcement and 1

layer of nylon.

Information for the end consumer concerning the comparative values of the established base tyres (standardised test procedures)

››› page 175:

TREADWEAR 220Relative service life of the tyre, with respect to specific US standard test.

TRACTION ABraking capacity of tyre on wet surface (AA, A, B or C).

TEMPERATURE ATyre temperature resistance at higher test speeds (A, B or C).

If the tyre has other markings, these are specific tyre manufacturer codes or specific national codes, e.g. for Brazil or China.

a)

The letters TIN refer to the tyre serial number.

Tyres with directional tread pattern

Tyres with directional tread pattern have

been designed to operate best when rotating

in only one direction. An arrow on the tyre

sidewall indicates the direction of rotation on

tyres with directional tread. Always observe

the direction of rotation indicated when

mounting the wheel. This guarantees opti-

mum grip and helps to avoid aquaplaning,

grip, noise and wear. If the tyre is mounted in the opposite direc-

tion of rot

ation, drive with extreme caution,

as the tyre is no longer being used correctly.

This is of particular importance when the

road surface is wet. Change the tyre as soon

as possible or remount it with the correct di-

rection of rotation.

Tyre load rating

The load rating code indicates the maximum

load in kilogrammes each wheel can carry

(load capacity). 425 kg

462 kg

487 kg

515 k

g

545 kg

615 kg

Speed rating

The speed rating indicates the maximum

speed permitted for the tyres. »

78

81

83

85

87

91

207

Technical data

Advice

Operation

Emergencies

Safety

Page 211 of 232

Technical features

Technical data

T ec

hnic

al features

Important information Introduction The information in the vehicle documentation

alwa

y

s takes precedence over the informa-

tion in this Instruction Manual.

All technical specifications provided in this

documentation are valid for the standard

model in Spain. The vehicle data card inclu-

ded in the Maintenance Programme or the

vehicle registration documents shows which

engine is installed in the vehicle.

The figures may be different depending

whether additional equipment is fitted, for

different models, for special vehicles and for

other countries. Abbreviations used in the Technical Specifi-

cation

s

section

kWKilowatt, engine power measurement.

PSPferdestärke (horsepower), formerly

used to denote engine power.

rpmRevolutions per minute - engine speed.

NmNewton metres, unit of engine torque.

litres per100 kmFuel consumption in litres per 100 km

(70 miles).

g/kmCarbon dioxide emissions in grams per

km (mile) travelled.

CO 2Carbon dioxide

CNCetane number, indication of the diesel

combustion power.

RONResearch octane number, indication of

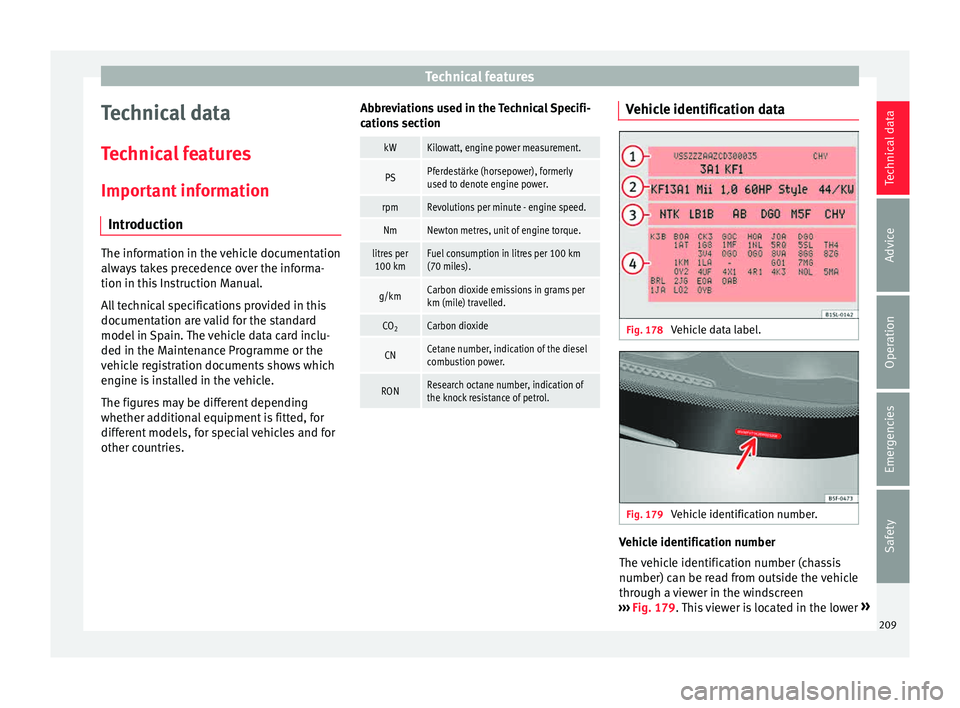

the knock resistance of petrol. Vehicle identification data

Fig. 178

Vehicle data label. Fig. 179

Vehicle identification number. Vehicle identification number

The

v

ehic

le identification number (chassis

number) can be read from outside the vehicle

through a viewer in the windscreen

››› Fig. 179. This viewer is located in the lower »

209

Technical data

Advice

Operation

Emergencies

Safety

Page 212 of 232

Technical data

part of the windscreen. The vehicle identifica-

tion number (c h

a

ssis number) is also stam-

ped on the right water drain channel. The wa-

ter drain channel is located between the sus-

pension tower and the wing. Open the bon-

net to read the vehicle identification number

.

Vehicle data plate

The vehicle data label ››› Fig. 178 is at the

front of the spare wheel well. It contains the

following data:

Vehicle identification number (chassis

number).

Vehicle type, engine power, gearbox type.

Engine and gearbox code, paint number,

interior equipment.

Optional extras, PR numbers.

These data are also provided in the Mainte-

nance Programme.

Specific vehicle weight information The instructions in the official vehicle docu-

ments

t

ak

e precedence. All the technical data

provided in this documentation is applicable

to the basic model. The vehicle data label in

the Maintenance Programme or the vehicle

documentation shows which engine is instal-

led in your vehicle. 1 2

3

4 The figures may be different depending

whether a

d

dition

al equipment is fitted, for

different models and for special vehicles.

Kerb weight values shown in the following ta-

ble apply to a vehicle with driver (75 kg), liq-

uids including a fuel tank 90% full, in addi-

tion to tools and a spare wheel ››› . The

k erb w

eight

indicated increases with optional

equipment and retrofitting of accessories,

while proportionally reducing carrying ca-

pacity.

The load is equivalent to the following

weights:

● Passengers.

● Total equipment.

● Roof load, included in the carrier. WARNING

Exceeding the maximum authorised weight

and the loa d on the ax

les could cause dam-

age to the vehicle, accidents and serious in-

juries.

● The real load on the axles should never ex-

ceed the max

imum permitted.

● The load and its distribution in the vehicle

have eff

ects on the vehicle handling and the

braking ability. Always drive at a suitable

speed. CAUTION

Distribute the load as uniformly and as low

down on the v

ehicle as possible. When trans-

porting heavy objects in the luggage com-

partment, these should be placed as far for-

ward as possible or over the rear axle to have

as little influence on handling as possible. Information on fuel consumption

The consumption and emission values indi-

cat

ed do not

refer to one specific vehicle.

They are only to be used to compare the val-

ues of the different vehicle versions. The fuel

consumption and CO 2 emissions of a vehicle

not only depend on the effective use of fuel.

They also depend on your driving style and

other non-technical factors.

Calculation of fuel consumption

Fuel consumption and emission values are

determined according to the current version

of the 715/2007/EC or 80/1268/EEC regula-

tion and are valid for the vehicle kerb weight.

The specifications do not refer to an individu-

al vehicle. To measure the fuel consumption,

two measuring cycles are carried out on a

rolling road test bed. The test criteria are as

follows:

210

Page 213 of 232

Technical featuresUrban cycle

Measurement of the urban cycle starts

with an engine cold start. City driving is

then simulated at between 0 and

50 km/h (0 and 31 mph).

Road cycle

In the road cycle simulation, the car un-

dergoes frequent acceleration and

braking in all gears, as in normal every-

day driving. The road speed ranges

from 0 to 120 km/h (0 and 75 mph).

Combined

The average combined consumption is

calculated with a weighting of around

37 % for the urban cycle and 63 % for

the road cycle.

CO

2 emis-

sions of the

combination

The exhaust gases are collected during

both driving cycles to calculate carbon

dioxide emissions (urban and road).

The gas composition is analysed below

to evaluate the CO 2 content and other

emissions. Note

● The kerb w eight

may vary according to the

vehicle equipment. This could raise consump-

tion and the CO 2 emissions slightly.

● In practice, consumption values could be

different

to the values calculated based on

the 715/2007/EC or 80/1268/EEC regula-

tions. Wheels

Ty

r

e pressure, snow chains, wheel

bolts Tyre pressures

The stic

k

er with the tyre pressure values can

be found on the inside of the fuel tank flap.

The tyre pressure values are given for cold

tyres ››› page 200. The slightly raised pres-

sures of warm tyres must not be reduced.

››› Snow chains

Sno

w c

h

ains may be fitted only to the front

wheels.

Consult the section “wheels” of this manual.

Wheel bolts

After the wheels have been changed, the

tightening torque of the wheel bolts should

be checked as soon as possible with a torque

wrench ››› . The tightening torque for steel

and al lo

y

wheels is 140 Nm. WARNING

● Check the ty

re pressure at least once per

month. Checking the tyre pressure is very im-

portant. If the tyre pressure is too high or too

low, there is an increased danger of accidents

- particularly at high speeds. ●

If the tight enin

g torque of the wheel bolts

is too low, they could loosen while the vehi-

cle is in motion. Risk of accident! If the tight-

ening torque is too high, the wheel bolts and

threads can be damaged. Note

We recommend that you ask your Technical

Ser vic

e for information about appropriate

wheel, tyre and snow chain size. 211

Technical data

Advice

Operation

Emergencies

Safety

Page 214 of 232

Technical data

Engine data P etr

o

l engine 1.0 44 kW (60 PS) Engine specifications

Power output in kW (PS) at rpmMaximum torque (Nm at rpm)No. of cylinders/displacement (cm

3

)Fuel

44 (60)/5,000-6,00095/3,000-4,3003/999Super 95 RON

PerformanceManualEcomotiveStart-Stop

EcomotiveAutomatic

Top speed (km/h)160 (4)161 (4)161 (4)160 (4)

Acceleration from 0-80 km/h (seconds)9.19.19.49.4

Acceleration from 0-100 km/h (seconds)14.414.415.315.3

Consumption (l/100 km)/ CO 2 (g/km)

Urban cycle5.6/1305/1164.6/1065.3/123

Extra-urban cycle3.9/913.6/843.7/873.9/91

Combined4.5/1054.1/954/934.4/103

Weights (in kg)

Gross vehicle weight1,2901,2901,3001,290

Weight in running order (with driver)929940931932

Gross front axle weight680680680680

Gross rear axle weight640640640640

Permitted roof load50505050 212

Page 215 of 232

Technical features

Petrol engine 1.0 55 kW (75 PS) Engine specificationsPower output in kW (PS) at rpmMaximum torque (Nm at rpm)No. of cylinders/displacement (cm

3

)Fuel

55 (75)/6,20095/3,000-4,3003/999Super 95 RON

PerformanceManualStart-StopStart-Stop

EcomotiveAutomatic

Top speed (km/h)171 (4)172 (4)172 (4)171 (4)

Acceleration from 0-80 km/h (seconds)8.38.39.29.2

Acceleration from 0-100 km/h (seconds)13.213.213.913.9

Consumption (l/100 km)/ CO 2 (g/km)

Urban cycle5.8/1345.1/1184.6/1065.5/127

Extra-urban cycle3.9/903.7/873.8/894/94

Combined4.6/1064.2/984.1/954.5/105

Weights (in kg)

Gross vehicle weight1,2901,2901,3001,290

Weight in running order (with driver)929940931932

Gross front axle weight680680680680

Gross rear axle weight640640640640

Permitted roof load50505050 213

Technical data

Advice

Operation

Emergencies

Safety