run flat Seat Mii 2015 Owner's manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2015, Model line: Mii, Model: Seat Mii 2015Pages: 232, PDF Size: 4.23 MB

Page 37 of 232

The essentials

● Sc r

ew the infl

ator tube ››› Fig. 48 3 into

the se al

ant

bottle. The bottle's seal will break

automatically.

● Remove the lid from the filling tube

›››

Fig. 48 3 and screw the open end of the

t ube int

o the ty

re valve.

● With the tyre sealant bottle upside down,

fill

the tyre with the contents of the sealant

bottle.

● Remove the bottle from the valve.

● Place the insert back into the tyre valve us-

ing the too

l ››› Fig. 48 1 .

Infl atin

g the ty

re

● Screw the compressor tyre inflator tube

›››

Fig. 48 5 into the tyre valve.

● Check that the air bleed screw is closed

› ›

›

Fig. 48 7 .

● Start the engine and leave it running.

● Insert the connector ››

›

Fig. 48 9 into the

v ehic

l

e's 12-volt socket ›››

page 117.

● Turn the air compressor on with the ON/OFF

switc

h ››› Fig. 48 8 .

● Keep the air compressor running until it

r e

ac

hes 2.0 to 2.5 bar

(29-36 psi/200-250 kPa). a maximum of 8

minutes.

● Disconnect the air compressor.

● If it does not reach the pressure indicated,

uns

crew the tyre inflator tube from the valve. ●

Move the

vehicle 10m so that the sealant is

distributed throughout the tyre.

● Screw the compressor tyre inflator into the

valve.

● R

epeat the inflation process.

● If the indicated pressure still cannot be

reac

hed, the tyre is too badly damaged. Stop

and request assistance from an authorised

technician.

● Disconnect the air compressor. Unscrew

the tyre infl

ator tube from the tyre valve.

● When the tyre pressure is between 2.5 and

2.0 bars, c

ontinue driving without exceeding

80 km/h (50 mph).

● Check the pressure again after 10 minutes

›››

page 73.

››› in TMS (Tyre Mobility System)* on

page 72

››› page 71 Changing a wheel

V ehic

l

e tool kit Fig. 49

Components of the vehicle tool kit Screwdriver with hexagon socket in the

h

andl

e

Ad

apter for anti-theft bolt.

Towline anchorage, removable.

Wire hook for removing the hub caps.

Jack.

Wheel spanner.

Wheel bolt cap clips.

››› in What to do first on page 34

››› page 69 1

2

3

4

5

6

7

35

Page 41 of 232

The essentials

WARNING

If the vehicle is not correctly raised, it could

fa l

l off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT f

or your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground i

s sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

plac

e a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The c

law of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 56.

● You should never place a body limb such as

an arm or leg u

nder a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you mus

t use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!.

● Never raise the vehicle if it is tilting to one

side or the engine i

s running.

● Never start the engine when the vehicle is

raised.

The vehicle may come loose from the

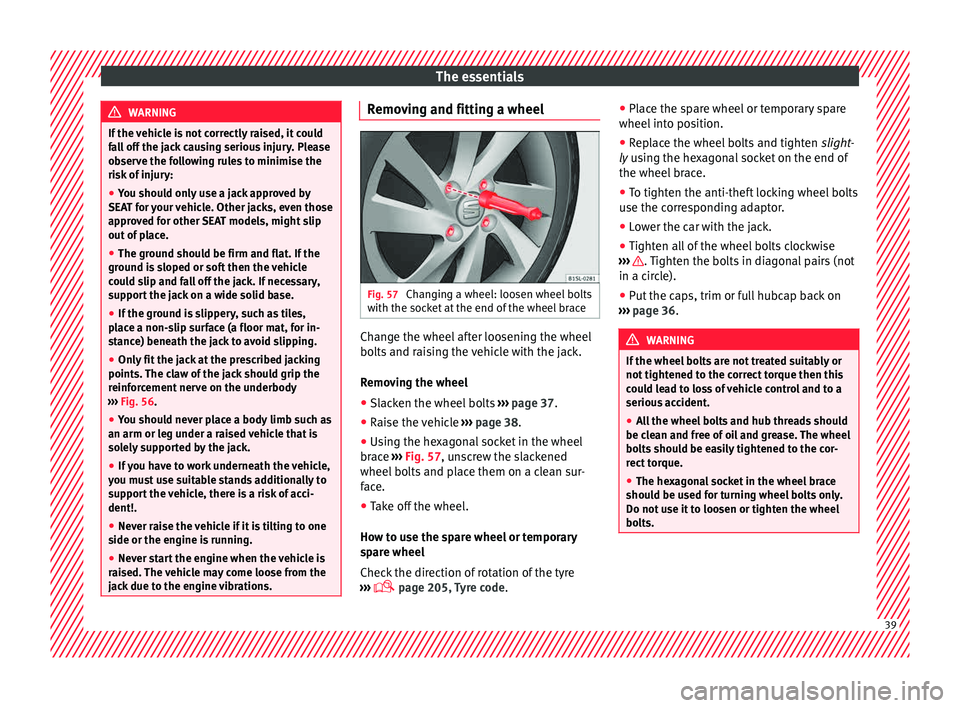

jack due to the engine vibrations. Removing and fitting a wheel

Fig. 57

Changing a wheel: loosen wheel bolts

w ith the soc

k

et at the end of the wheel brace Change the wheel after loosening the wheel

bo

lts

and r

aising the vehicle with the jack.

Removing the wheel

● Slacken the wheel bolts ›››

page 37.

● Raise the vehicle ›››

page 38.

● Using the hexagonal socket in the wheel

brace ›

›› Fig. 57, unscrew the slackened

wheel bolts and place them on a clean sur-

face.

● Take off the wheel.

How to u

se the spare wheel or temporary

spare wheel

Check the direction of rotation of the tyre

››› page 205, Tyre code. ●

Place the s

pare wheel or temporary spare

wheel into position.

● Replace the wheel bolts and tighten slight

-

ly using the hexagonal socket on the end of

the wheel brace.

● To tighten the anti-theft locking wheel bolts

use the corr

esponding adaptor.

● Lower the car with the jack.

● Tighten all of the wheel bolts clockwise

›››

. Tighten the bolts in diagonal pairs (not

in a c ir

c

le).

● Put the caps, trim or full hubcap back on

›››

page 36. WARNING

If the wheel bolts are not treated suitably or

not tight ened t

o the correct torque then this

could lead to loss of vehicle control and to a

serious accident.

● All the wheel bolts and hub threads should

be cle

an and free of oil and grease. The wheel

bolts should be easily tightened to the cor-

rect torque.

● The hexagonal socket in the wheel brace

should be u

sed for turning wheel bolts only.

Do not use it to loosen or tighten the wheel

bolts. 39

Page 45 of 232

The essentials

fire far from the battery. Never use a mobile

tel

ephone when c

onnecting and removing the

jump leads.

● Charge the battery only in well ventilated

area

s given that when the battery is charged

by outside assistance, it creates a mix of

highly explosive gases.

● Jump leads should never enter into contact

with mov

ing parts in the engine compart-

ment.

● Never switch the positive and negative

pole

s or connect the jump leads incorrectly.

● Note the instruction manual provided by

the manufact

urer of the jump leads. CAUTION

To avoid considerable damage to the vehicle

electric a

l system, note the following careful-

ly:

● If the jump leads are incorrectly connected,

this c

ould result in a short circuit.

● The vehicles must not touch each other,

otherwi

se electricity could flow as soon as

the positive terminals are connected. How to jump start: description

Fig. 59

Diagram of connections for vehicles

w ithout

Start Stop system Fig. 60

Diagram of connections for vehicles

w ith

St

art Stop system Jump lead terminal connections

1. Switch off the ignition of both vehicles

››

›

.2. Connect one end of the

re

d

jump lead to

the positive + terminal of the vehicle

w ith the fl

at

battery A

› ››

Fig. 59

.

3.

Connect the other end of the red

jump

lead to the positive terminal + in the ve-

hic l

e pr

oviding assistance B .

4. For vehicles without Start-Stop system:

connect

one end of

the black jump lead to

the negative terminal – of the vehicle

pr o

v

iding the current B

› ››

Fig. 59

.

– F

or vehicles with Start-Stop system: con-

nect one end of

the black jump lead X to a

s uit

ab

le ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 60.

5. Connect the other end of the black

jump

lead X to a solid metal component bolted

t o the en

gine b

lock or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot

c

ome into contact with any moving

parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boostin

g battery and let it run at idling

speed. » 43

Page 46 of 232

The essentials

8. Start the engine of the vehicle with the flat batt

er

y and wait for 2 or 3 minutes until

the engine is running.

Removing the jump leads

9. Before you remove the jump leads, switch off the dipped be

am headlights (if they

are switched on).

10.Turn on the heater blower and heated rear window in the

vehicle with the flat battery.

This helps minimise voltage peaks which

are generated when the leads are discon-

nected.

11.

When the engine is running, disconnect

the leads in reverse order to the details

given above.

Make sure the battery clamps have sufficient

metal-to-metal contact with the battery termi-

nals.

If the engine fails to start, switch off the start-

er after about 10 seconds and try again after

about 1 minute. WARNING

● Ple a

se note the safety warnings referring to

working in the engine compartment

››› page 184.

● The battery providing assistance must have

the same v

oltage as the flat battery (12V) and

approximately the same capacity (see imprint on battery). Failure to comply could result in

an exp

lo

sion.

● Never use jump leads when one of the bat-

teries

is frozen. Danger of explosion! Even af-

ter the battery has thawed, battery acid could

leak and cause chemical burns. If a battery

freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes

awa

y from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufact

urer of the jump leads.

● Do not connect the negative cable from the

other vehic

le directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion.

● Do not attach the negative cable from the

other vehic

le to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamp

s must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot c

ome into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult

in chemical burns. Note

The vehicles must not touch each other, oth-

erw i

se electricity could flow as soon as the

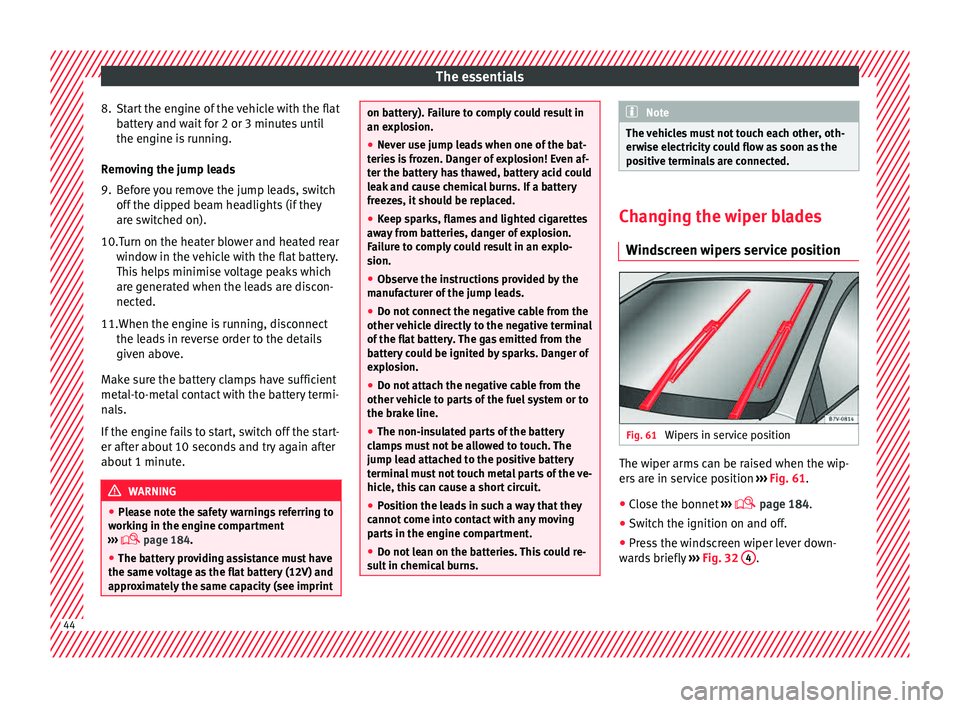

positive terminals are connected. Changing the wiper blades

Wind s

creen wipers service position Fig. 61

Wipers in service position The wiper arms can be raised when the wip-

er

s

ar

e in service position ››› Fig. 61.

● Close the bonnet ›››

page 184.

● Switch the ignition on and off.

● Press the windscreen wiper lever down-

ward

s briefly ››› Fig. 32 4 .

44

Page 133 of 232

Driving

in the car in an emergency and not be able to

get

themselv

es to safety. For example, de-

pending on the time of the year, tempera-

tures inside a locked and closed vehicle can

be extremely high or extremely low resulting

in serious injuries and illness or even death,

particularly for young children.

● Never remove the key from the ignition if

the vehic

le is in motion. The steering may

lock and it will not be possible to turn the

steering wheel. CAUTION

● An attempt t

o start the engine while driving

or starting the engine immediately after turn-

ing it off can cause damage to the engine or

starter motor.

● When the engine is cold, avoid high revs

and heavy ac

celeration and do not make the

engine work hard.

● Do not push or tow start the engine. Un-

burnt f

uel could damage the catalytic con-

verter. For the sake of the environment

Do not warm the engine at idle speed; start

drivin g immedi

ately if the visibility is OK.

This helps the engine reach operating tem-

perature faster and reduces emissions. Note

● If the k ey

is left in the ignition lock with the

engine off for long periods, the vehicle bat-

tery will run flat.

● For automatic gearbox vehicles, the key can

only be r

emoved from the ignition lock if the

gear selector lever is in position P. In this

case, press and release the selector lever

locking button.

● Electrical devices with a high power con-

sumption are sw

itched off temporarily when

the engine starts.

● When the engine is started cold, there may

be stron

g vibrations for a few moments for

technical reasons. This is quite normal, and

no cause for concern.

● Natural gas engines always start up with

petrol, a

s a certain operating temperature is

required for running with gas. Once the re-

quired operating temperature is reached, the

engine will change to operate with natural

gas. Stopping the engine

Switching off the engine

– Stop the vehicle ››

›

.

– Turn the ignition key to position 1 ›››

Fig. 142. Engaging the steering wheel lock

In

v

ehic

les with automatic gearbox, the igni-

tion key can only be removed when the selec-

tor lever is in position P.

– Remove the key from the ignition in posi-

tion 1

› ››

Fig. 142

›

›› .

– Turn the steering wheel until you hear it en-

gag

e.

P

ossible vehicle theft is prevented with the

steering lock engaged. WARNING

Never switch off the engine while the vehicle

is mo

ving. You may lose control of the vehicle

and there is a risk of serious accident.

● The airbags and belt tensioners do not

work when the ignition i

s switched off.

● The brake servo does not work with the en-

gine off. T

o stop, the brake pedal must be

pressed with more force.

● As the power steering does not work if the

engine is

not running, you will need more

strength to steer than normally.

● If the key is removed from the ignition, the

steerin

g may lock and it will not be possible

to steer the vehicle. » 131

Technical data

Advice

Operation

Emergencies

Safety

Page 136 of 232

Operation

wheels lock this could result in loss of vehicle

contr

o

l! If possible, reduce your speed and

drive carefully to a specialised workshop

close by to check the brake system. During

the following journey, avoid sudden braking

and manoeuvres.

● If the ABS warning lamp does not

go out

or if it lights while driving, the ABS is mal-

functioning. The vehicle can only be stopped

using normal braking without ABS. The pro-

tection provided by the ABS is not available.

Visit a specialised workshop as soon as pos-

sible. CAUTION

Failure to heed the warning lamps when they

appe ar m

ay result in faults in the vehicle. Handbrake

Fig. 143

Between the front seats: handbrake. Using the handbrake

●

Pull firmly in an upwards direction on the

h andbr ak

e lever while pressing the button.

● The handbrake is applied when the control

lamp

lights up on the instrument panel

››› page 133 when the ignition is switched

on.

Releasing the handbrake

● Pull gently in an upwards direction on the

handbrak

e lever and press the lock button

››› Fig. 143 (arrow).

● Move the handbrake lever downwards

keeping the loc

k button pressed. WARNING

The incorrect use of the handbrake may result

in a serious ac

cident.

● Never use the handbrake to brake the vehi-

cle e

xcept in an emergency. The braking dis-

tance is considerably longer, because braking

is only applied to the rear wheels. Always use

the foot brake.

● Never drive with the handbrake gently ap-

plied. Thi

s can overheat the brake, affecting

the brakes system. This also causes prema-

ture wear on the rear brake pads.

● Never accelerate from the engine compart-

ment with the en

gine running and a gear en-

gaged. The vehicle could move, even if the

handbrake is applied. Note

If the vehicle moves at a speed superior to

6 km/h (4 mph) with the h andbr

ake applied,

an audible warning is sounded. Parking

When parking your vehicle, all legal require-

ments shou

l

d be observed.

To park the vehicle

Complete operations only in the sequence

given. ● Park the vehicle on a suitable surface ››

›

.

● Press and hold the brake pedal until the ve-

hic l

e c

omes to a standstill.

● Apply the handbrake firmly ›››

page 134.

● For an automatic gearbox, move the selec-

tor lev

er to position P.

● Switch off the engine and release the brake

pedal.

● R

emove the key from the ignition.

● If necessary, turn the steering wheel slight-

ly to loc

k the steering.

● With a manual gearbox, engage 1st gear on

flat gr

ound and slopes, or even reverse gear

on hills, and release the clutch pedal.

● Ensure that all passengers leave the vehi-

cle, e

specially children.

134

Page 190 of 232

Advice

Preparations

● Park the vehicle on flat ground so that the

en gine oi

l

reading is correct.

● The engine must be hot to be able to check

the engine oil

level. Stop the engine and wait

a few minutes for the oil to drain back into

the sump.

● Open the bonnet ›››

page 184.

● The engine oil filler neck can be recognised

by the symbo

l on the cap ››› Fig. 168 and

the dipstick by its coloured handle.

Check the engine oil level

● Pull out the dipstick and wipe it on a clean

cloth.

● Rep

lace the dipstick, pushing it in as far as

it wi

ll go. If the dipstick to measure engine oil

has a mark, when you reintroduce it this

mark should slot into the corresponding

groove located on the upper end of the tube.

● Remove the oil dipstick again and check

the engine oil

level.

● After reading the oil level, replace the dip-

stick

in the tube completely. WARNING

Oil could catch fire if it comes into contact

with hot en

gine components. This could lead

to a fire, explosion and severe injuries.

● Always ensure that after topping of oil, the

engine oil

filler cap is correctly tightened. This will avoid engine oil spilling onto hot en-

gine par

t

s when the engine is running. CAUTION

● If the en gine oi

l level is above the area

››› Fig. 167 A do not start the engine. Seek

spec i

alist assistance. Otherwise catalytic

converter and engine damage may occur.

● When refilling or changing service liquids,

ensur

e that you put the liquids into the right

tank. Making a mistake when refilling could

cause serious malfunctions and damage the

engine! For the sake of the environment

The oil level must never be above area A .

Otherw i

se oil can be drawn in through the

crankcase breather and escape into the at-

mosphere via the exhaust system. Engine oil consumption

The consumption of engine oil can be differ-

ent

fr

om one en

gine to another and can vary

during the useful life of the engine.

Depending on how you drive and the condi-

tions in which the vehicle is used, oil con-

sumption can be up to 1 ltr./2000 km. In the

case of new vehicles, the consumption can

exceed this figure over 5,000 kilometres. For

this reason the engine oil level must be checked at regular intervals, preferably when

fillin

g the tank and before a journey.

When the engine is working hard, for in-

stance during sustained high-speed motor-

way cruising in summer or when climbing

mountain passes, the oil level should pref-

erably be kept within area ››› Fig. 167 A .

Topping up engine oil Read the additional information carefully

›› ›

page 30.

The engine oil must be changed regularly ac-

cording to the specifications of the Mainte-

nance Programme.

Due to the problems linked with disposing of

used oil and the need for suitable tools and

special knowledge, always visit a specialised

workshop to have the engine oil and filter

changed. SEAT recommends taking your car

in for technical service.

Detailed information on the service intervals

is shown in the Maintenance Programme.

Engine oil additives make new oil darker after

the engine has been running for a short peri-

od. This is normal and does not mean more

frequent oil changes are required.

188

Page 196 of 232

AdviceSymbolMeaning

A highly explosive mixture of gases is re-

leased when the battery is under charge.

Keep children away from acid and batter-

ies!

WARNING

Working on the vehicle battery and the elec-

trica l

system can cause corrosion, fire and

electric shocks. Always read and take into ac-

count the following warnings and safety

standards before carrying out any work:

● Before working on the battery, switch off

the engine, the ignition and al

l electrical de-

vices then disconnect the negative connec-

tion on the battery.

● Keep children away from acid and the bat-

tery

itself!

● Wear eye protection.

● Battery acid is very corrosive and caustic. It

can burn sk

in and cause blindness. When

handling the battery, protect yourself from

splashes of acids, above all your hands, arms

and face.

● Do not smoke and never work close to pla-

ces

exposed to flames or sparks.

● Avoid sparks and electrostatic discharges

when workin

g with cables and electrical devi-

ces.

● Never short the battery terminals. ●

Never u se a d

amaged battery. It can ex-

plode. Replace a damaged battery immedi-

ately.

● Replaced damaged or frozen batteries as

soon as po

ssible. A flat battery can also

freeze at temperatures close to 0 °C (+32 °F). CAUTION

● Nev er di s

connect the battery if the ignition

is switched on or if the engine is running.

This could damage the electrical system or

electronic components.

● Do not expose the battery to direct sunlight

over a lon

g period of time, as the intense ul-

traviolet radiation can damage the battery

housing.

● If the car is left standing for long periods,

protect

the battery from extreme cold temper-

ature so that it does not “freeze up” and be-

come damaged. Warning lamp

It lights up

Faulty generator.

Contact a specialised workshop.

Have the electrical system checked.

Disconnect any unnecessary elec-

trical devices. The generator does

not charge the battery while the ve-

hicle is in motion. Several warning and indication lamps light

up f

or a f

ew sec

onds when the ignition is

switched on, signalling that the function is

being verified. They will switch off after a few

seconds. WARNING

Observe the safety warnings ›››

in On the

ins trument

panel on page 27. Checking the electrolyte level of the

vehic

l

e battery Fig. 171

In the engine compartment: Remove

the c o

v

er from the vehicle's battery. The battery's electrolyte level should be

c

hec

k

ed regularly in high-mileage vehicles,

in hot countries and in older batteries. Other

batteries do not require maintenance.

Vehicles fitted with the Start-Stop system are

equipped with special batteries. For technical

194

Page 198 of 232

Advice

Different control lamps may light up after

c onnectin

g the b

attery and switching the ig-

nition on. They will be turned off after a short

trip at a speed of between 15-20 km/h

(10-12 mph). If the warning indicators remain

lit, please visit a specialised workshop to

have the vehicle checked.

If the battery has been disconnected for a

long time, it is possible that the next service

date is not displayed or calculated correctly

››› page 86. Respect the maximum service in-

tervals permitted ››› Booklet Maintenance

Programme.

Automatic device disconnection

The intelligent vehicle electrical system auto-

matically implements a range of measures to

prevent the battery from discharging when

high demands are made on it:

● The idling speed is increased so that the al-

ternat

or provides more electricity.

● Where necessary, the power to the most

power

ful devices is reduced or even com-

pletely disconnected.

● On starting the engine, the power supply

from the 12-v

olt power sockets and the ciga-

rette lighter may be interrupted for a short

time.

The on-board management program cannot

always prevent the battery from running flat.

For example, if the ignition is left on for a long period with the engine off or if the side

lights or park

ing lights are left on while the

vehicle is stationary.

Why the battery runs flat:

● When stationary for a long time without

star

ting the engine, particularly if the ignition

is switched on.

● Use of electrical devices with the engine

switc

hed off. WARNING

Incorrectly securing the battery or using the

wron g b

attery can cause short-circuits, fire

and serious injuries.

● Always use only maintenance-free batter-

ies, prot

ected to prevent a leak, and whose

properties, specifications and size corre-

spond to the standard battery. WARNING

A highly explosive mixture of gases is re-

le a

sed when the battery is under charge.

● The batteries should be charged in a well-

ventil

ated room only.

● Never charge a frozen or recently thawed

batter

y. A flat battery can also freeze at tem-

peratures close to 0 °C (+32 °F).

● Always replace a battery which has frozen.

● Battery cables not correctly connected may

cause a shor

t circuit. Reconnect first the posi-

tive cable and then the negative cable. CAUTION

● Never di s

connect the battery if the ignition

is switched on or if the engine is running.

This could damage the electrical system or

electronic components.

● Never plug accessories that supply current,

such a

s solar panels or a battery charger, to

the 12-volt power socket or the cigarette

lighter. This could damage the vehicle's elec-

trical system. For the sake of the environment

Dispose of the battery in an environment-

friendly m anner

. Batteries contain toxic sub-

stances such as sulphuric acid and lead. For the sake of the environment

Battery acid can contaminate the environ-

ment. C o

llect any spilt service fluids and dis-

pose of them correctly. 196

Page 227 of 232

Index

inflating a tyre . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

se alin

g a ty

re . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Tyre Mobility System see Anti-puncture kit . . . . . . . . . . . . . . . . . . . . . 71

Tyre pressure . . . . . . . . . . . . . . . . . . . . . . . 200, 211 spare wheel or temporary spare wheel . . . . . . 201

Tyre profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Tyre repair kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71 see also Anti-puncture kit . . . . . . . . . . . . . . . . . 71

Tyres avoiding damage . . . . . . . . . . . . . . . . . . . . . . . 198

changing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

errors in wheel alignment . . . . . . . . . . . . . . . . 202

foreign bodies in the tyres . . . . . . . . . . . . . . . . 202

handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

interchanging tyres . . . . . . . . . . . . . . . . . . . . . 198

new . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

old . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

replacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

run-out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

serial number . . . . . . . . . . . . . . . . . . . . . . . . . . 206

snow chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

speed rating . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

technical details . . . . . . . . . . . . . . . . . . . . . . . . 205

tyre code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Tyre identification number (TIN) . . . . . . . . . . . 206

tyre load rating . . . . . . . . . . . . . . . . . . . . . . . . . 207

tyre pressures . . . . . . . . . . . . . . . . . . . . . . . . . . 200

tyres with directional tread pattern . . . . . . . . . 198

valve caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

wear indicators . . . . . . . . . . . . . . . . . . . . . . . . . 202

wheel balancing . . . . . . . . . . . . . . . . . . . . . . . . 202

wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199 with compulsory direction of rotation . . . . . . . . 40

with direction

al tread pattern . . . . . . . . . . . . . 207

Tyre tread depth . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Tyre wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

U Unfastening the seat belt . . . . . . . . . . . . . . . . 13, 55

Unlocking and locking . . . . . . . . . . . . . . . . . . . . . . . 8 by remote control . . . . . . . . . . . . . . . . . . . . . . . . 93

doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

from the inside . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Upholstery cleaning . . . . . . . . . . . . . . . . . . . . . . . 173 textile covers . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Upholstery: cleaning upholstery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

V Valve caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Vanity mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Vehicle chassis number . . . . . . . . . . . . . . . . . . . . . . . . 209

data label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

identification data . . . . . . . . . . . . . . . . . . . . . . 209

identification number . . . . . . . . . . . . . . . . . . . . 209

loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

raising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Vehicle battery . . . . . . . . . . . . . . . . . . . . . . . 32, 193 acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

assisted starting . . . . . . . . . . . . . . . . . . . . . . . . . 42

automatic device disconnection . . . . . . . . . . . 196

charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

checking the battery electrolyte level . . . . . . . 194

connecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

control and warning lamps . . . . . . . . . . . . . . . 194

discharging . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

disconnecting . . . . . . . . . . . . . . . . . . . . . . . . . . 195 preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

repl

acing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

running flat . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Vehicle care Airbag modules (dash panel) . . . . . . . . . . . . . 174

aluminium wheel rims . . . . . . . . . . . . . . . . . . . 170

anodized surfaces . . . . . . . . . . . . . . . . . . . . . . 170

antenna incorporated in window . . . . . . . . . . . 176

chrome wheel rims . . . . . . . . . . . . . . . . . . . . . . 170

cleaning wheels . . . . . . . . . . . . . . . . . . . . . . . . 171

Dash panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

De-icing the door lock cylinder . . . . . . . . . . . . 171

engine compartment . . . . . . . . . . . . . . . . . . . . 172

exterior mirrors . . . . . . . . . . . . . . . . . . . . . . . . . 169

interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Plastic parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

protection of vehicle undercarriage . . . . . . . . 171

rubber seals . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

vehicle paintwork . . . . . . . . . . . . . . . . . . . . . . . 170

windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Wooden trim . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Vehicle care products . . . . . . . . . . . . . . . . . . . . . . 166

Vehicle code Vehicle data label . . . . . . . . . . . . . . . . . . . . . . . 210

Vehicle data label . . . . . . . . . . . . . . . . . . . . . . . . . 209

Vehicle key set . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Vehicle tool kit . . . . . . . . . . . . . . . . . . . . . . . . . 35, 69 components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Vibrations steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

W Warning and control lamp lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

225