lock Seat Mii 2016 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2016, Model line: Mii, Model: Seat Mii 2016Pages: 232, PDF Size: 4.9 MB

Page 36 of 232

The essentials

Emergencies F u

se

s

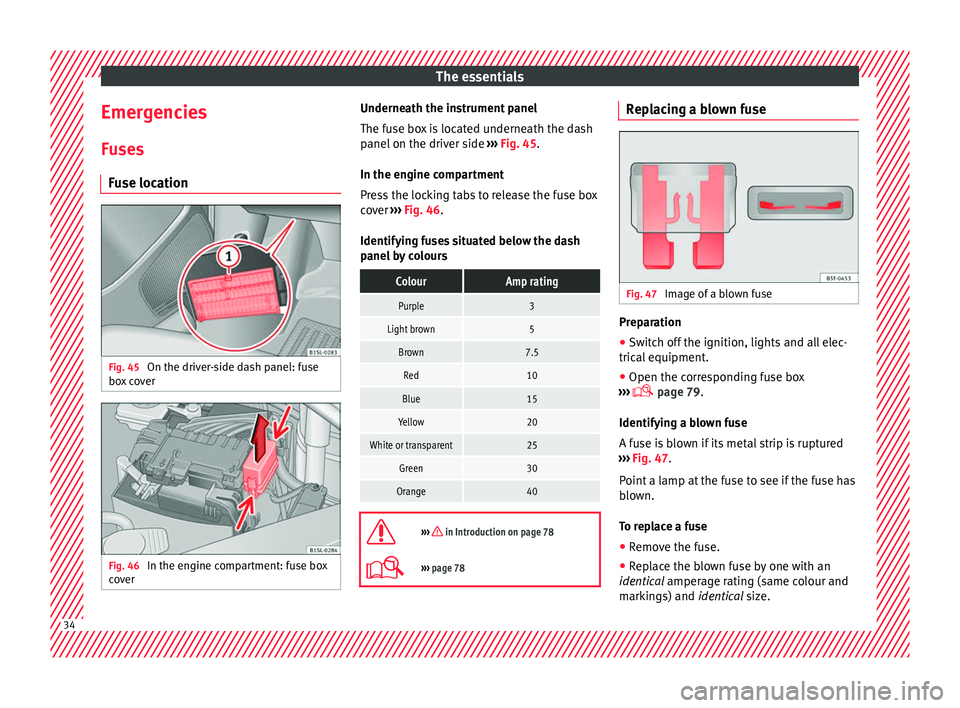

Fuse location Fig. 45

On the driver-side dash panel: fuse

bo x

c

over Fig. 46

In the engine compartment: fuse box

c o v

er Underneath the instrument panel

The f

use bo

x is located underneath the dash

panel on the driver side ››› Fig. 45.

In the engine compartment

Press the locking tabs to release the fuse box

cover ››› Fig. 46.

Identifying fuses situated below the dash

panel by colours

ColourAmp rating

Purple3

Light brown5

Brown7.5

Red10

Blue15

Yellow20

White or transparent25

Green30

Orange40

››› in Introduction on page 78

›››

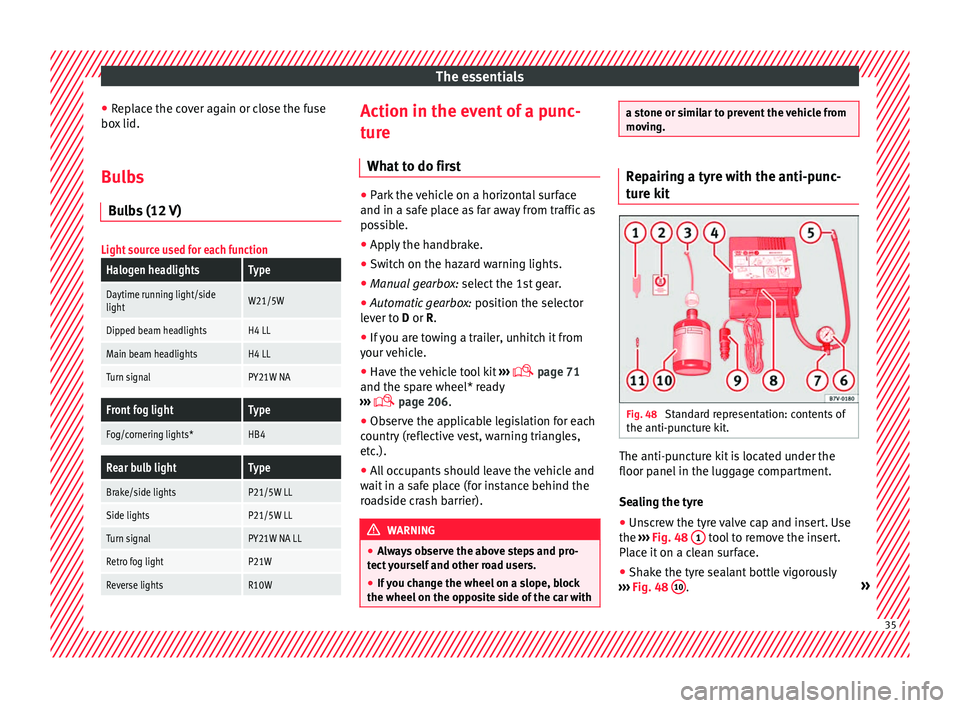

page 78 Replacing a blown fuse

Fig. 47

Image of a blown fuse Preparation

● Switch off the ignition, lights and all elec-

tric al

equipment

.

● Open the corresponding fuse box

›››

page 79.

Identifying a blown fuse

A fuse is blown if its metal strip is ruptured

››› Fig. 47.

Point a lamp at the fuse to see if the fuse has

blown.

To replace a fuse

● Remove the fuse.

● Replace the blown fuse by one with an

identica

l amperage rating (same colour and

markings) and identical size. 34

Page 37 of 232

The essentials

● Rep

l

ace the cover again or close the fuse

box lid.

Bulbs Bul

bs (12 V)

Light source used for each function

Halogen headlightsType

Daytime running light/side

lightW21/5W

Dipped beam headlightsH4 LL

Main beam headlightsH4 LL

Turn signalPY21W NA

Front fog lightType

Fog/cornering lights*HB4

Rear bulb lightType

Brake/side lightsP21/5W LL

Side lightsP21/5W LL

Turn signalPY21W NA LL

Retro fog lightP21W

Reverse lightsR10W Action in the event of a punc-

t

ur

e

Wh

at to do first ●

Park the vehicle on a horizontal surface

and in a saf e p

lace as far away from traffic as

possible.

● Apply the handbrake.

● Switch on the hazard warning lights.

● Manual gearbox: select the 1s

t gear.

● Automatic gearbox: position the sel

ector

lever to D or R.

● If you are towing a trailer, unhitch it from

your v

ehicle.

● Have the vehicle tool kit ›››

page 71

and the spare wheel* ready

››› page 206.

● Observe the applicable legislation for each

countr

y (reflective vest, warning triangles,

etc.).

● All occupants should leave the vehicle and

wait in a s

afe place (for instance behind the

roadside crash barrier). WARNING

● Alw a

ys observe the above steps and pro-

tect yourself and other road users.

● If you change the wheel on a slope, block

the wheel on the oppo

site side of the car with a stone or similar to prevent the vehicle from

mov

in

g. Repairing a tyre with the anti-punc-

tur

e k

it Fig. 48

Standard representation: contents of

the anti-p u

nct

ure kit. The anti-puncture kit is located under the

floor p

anel

in the lug

gage compartment.

Sealing the tyre

● Unscrew the tyre valve cap and insert. Use

the ›››

Fig. 48 1 tool to remove the insert.

Pl ac

e it

on a clean surface.

● Shake the tyre sealant bottle vigorously

›› ›

Fig. 48 10 .

» 35

Page 39 of 232

The essentials

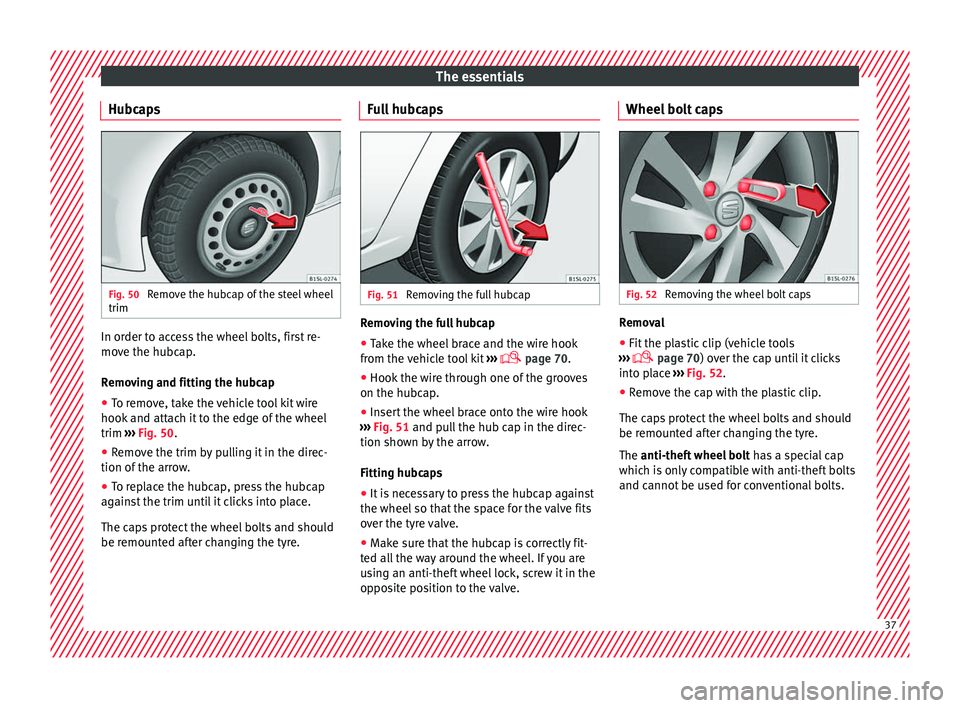

Hubcaps Fig. 50

Remove the hubcap of the steel wheel

trim In order to access the wheel bolts, first re-

mo

v

e the hubc

ap.

Removing and fitting the hubcap

● To remove, take the vehicle tool kit wire

hook and attac

h it to the edge of the wheel

trim ››› Fig. 50.

● Remove the trim by pulling it in the direc-

tion of the arro

w.

● To replace the hubcap, press the hubcap

agains

t the trim until it clicks into place.

The caps protect the wheel bolts and should

be remounted after changing the tyre. Full hubcaps

Fig. 51

Removing the full hubcap Removing the full hubcap

● Take the wheel brace and the wire hook

fr om the

v

ehicle tool kit ›››

page 70.

● Hook the wire through one of the grooves

on the hubcap.

● In

sert the wheel brace onto the wire hook

›››

Fig. 51 and pull the hub cap in the direc-

tion shown by the arrow.

Fitting hubcaps

● It is necessary to press the hubcap against

the wheel so that

the space for the valve fits

over the tyre valve.

● Make sure that the hubcap is correctly fit-

ted all

the way around the wheel. If you are

using an anti-theft wheel lock, screw it in the

opposite position to the valve. Wheel bolt caps

Fig. 52

Removing the wheel bolt caps Removal

● Fit the plastic clip (vehicle tools

› ›

›

page 70) over the cap until it clicks

into place ››› Fig. 52.

● Remove the cap with the plastic clip.

The caps

protect the wheel bolts and should

be remounted after changing the tyre.

The anti-theft wheel bolt has a special cap

which is only compatible with anti-theft bolts

and cannot be used for conventional bolts. 37

Page 40 of 232

The essentials

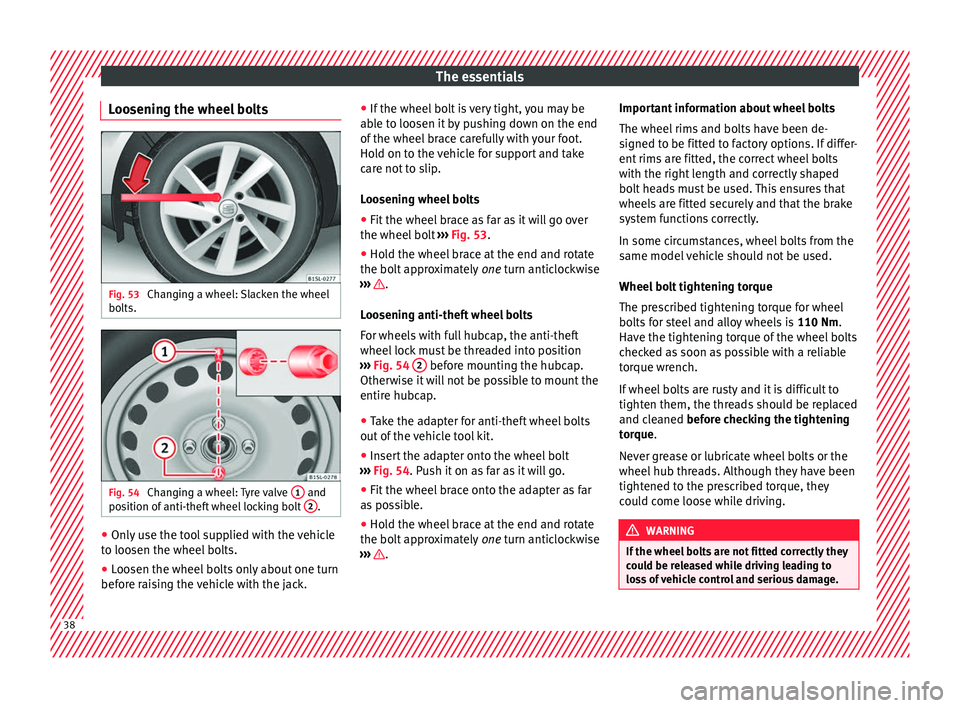

Loosening the wheel bolts Fig. 53

Changing a wheel: Slacken the wheel

bo lts. Fig. 54

Changing a wheel: Tyre valve 1 and

po s

ition of

anti-theft wheel locking bolt 2 .

●

Only use the tool supplied with the vehicle

t o loo

sen the wheel

bolts.

● Loosen the wheel bolts only about one turn

before r

aising the vehicle with the jack. ●

If the wheel bo

lt is very tight, you may be

able to loosen it by pushing down on the end

of the wheel brace carefully with your foot.

Hold on to the vehicle for support and take

care not to slip.

Loosening wheel bolts

● Fit the wheel brace as far as it will go over

the wheel bolt

››› Fig. 53.

● Hold the wheel brace at the end and rotate

the bolt ap

proximately one turn anticlockwise

››› .

L oo

senin

g anti-theft wheel bolts

For wheels with full hubcap, the anti-theft

wheel lock must be threaded into position

››› Fig. 54 2 before mounting the hubcap.

Other w

i

se it will not be possible to mount the

entire hubcap.

● Take the adapter for anti-theft wheel bolts

out of the

vehicle tool kit.

● Insert the adapter onto the wheel bolt

›››

Fig. 54. Push it on as far as it will go.

● Fit the wheel brace onto the adapter as far

as po

ssible.

● Hold the wheel brace at the end and rotate

the bolt ap

proximately one turn anticlockwise

››› .Important information about wheel bolts

The wheel

rims and bo

lts have been de-

signed to be fitted to factory options. If differ-

ent rims are fitted, the correct wheel bolts

with the right length and correctly shaped

bolt heads must be used. This ensures that

wheels are fitted securely and that the brake

system functions correctly.

In some circumstances, wheel bolts from the

same model vehicle should not be used.

Wheel bolt tightening torque

The prescribed tightening torque for wheel

bolts for steel and alloy wheels is 110 Nm.

Have the tightening torque of the wheel bolts

checked as soon as possible with a reliable

torque wrench.

If wheel bolts are rusty and it is difficult to

tighten them, the threads should be replaced

and cleaned before checking the tightening

torque.

Never grease or lubricate wheel bolts or the

wheel hub threads. Although they have been

tightened to the prescribed torque, they

could come loose while driving. WARNING

If the wheel bolts are not fitted correctly they

cou l

d be released while driving leading to

loss of vehicle control and serious damage. 38

Page 42 of 232

The essentials

WARNING

If the vehicle is not correctly raised, it could

fa l

l off the jack causing serious injury. Please

observe the following rules to minimise the

risk of injury:

● You should only use a jack approved by

SEAT f

or your vehicle. Other jacks, even those

approved for other SEAT models, might slip

out of place.

● The ground should be firm and flat. If the

ground i

s sloped or soft then the vehicle

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

● If the ground is slippery, such as tiles,

plac

e a non-slip surface (a floor mat, for in-

stance) beneath the jack to avoid slipping.

● Only fit the jack at the prescribed jacking

points. The c

law of the jack should grip the

reinforcement nerve on the underbody

››› Fig. 56.

● You should never place a body limb such as

an arm or leg u

nder a raised vehicle that is

solely supported by the jack.

● If you have to work underneath the vehicle,

you mus

t use suitable stands additionally to

support the vehicle, there is a risk of acci-

dent!.

● Never raise the vehicle if it is tilting to one

side or the engine i

s running.

● Never start the engine when the vehicle is

raised.

The vehicle may come loose from the

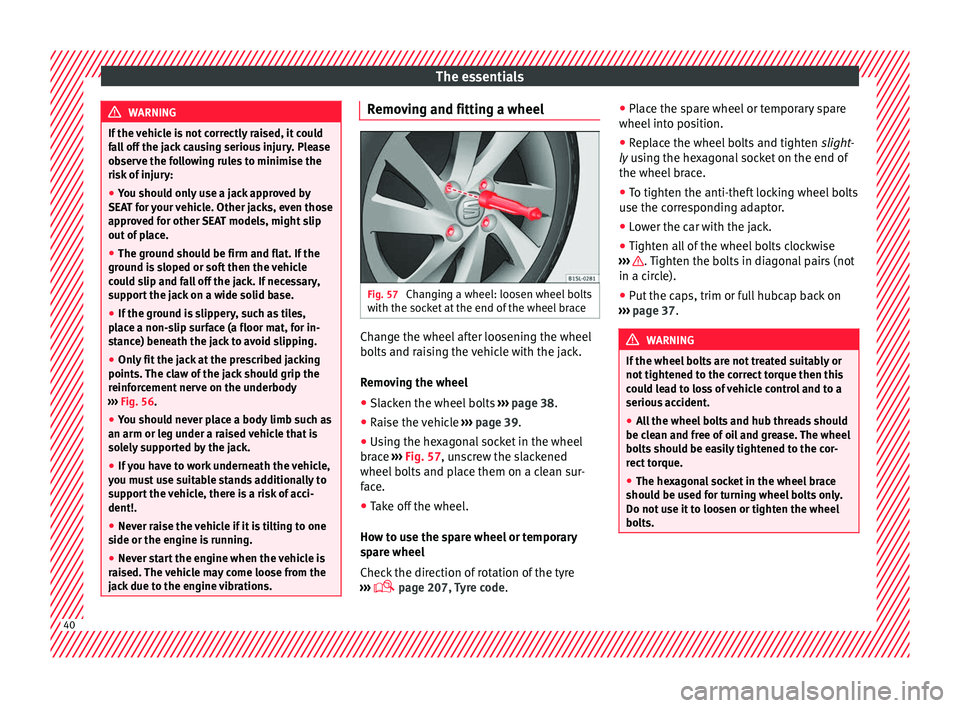

jack due to the engine vibrations. Removing and fitting a wheel

Fig. 57

Changing a wheel: loosen wheel bolts

w ith the soc

k

et at the end of the wheel brace Change the wheel after loosening the wheel

bo

lts

and r

aising the vehicle with the jack.

Removing the wheel

● Slacken the wheel bolts ›››

page 38.

● Raise the vehicle ›››

page 39.

● Using the hexagonal socket in the wheel

brace ›

›› Fig. 57, unscrew the slackened

wheel bolts and place them on a clean sur-

face.

● Take off the wheel.

How to u

se the spare wheel or temporary

spare wheel

Check the direction of rotation of the tyre

››› page 207, Tyre code. ●

Place the s

pare wheel or temporary spare

wheel into position.

● Replace the wheel bolts and tighten slight

-

ly using the hexagonal socket on the end of

the wheel brace.

● To tighten the anti-theft locking wheel bolts

use the corr

esponding adaptor.

● Lower the car with the jack.

● Tighten all of the wheel bolts clockwise

›››

. Tighten the bolts in diagonal pairs (not

in a c ir

c

le).

● Put the caps, trim or full hubcap back on

›››

page 37. WARNING

If the wheel bolts are not treated suitably or

not tight ened t

o the correct torque then this

could lead to loss of vehicle control and to a

serious accident.

● All the wheel bolts and hub threads should

be cle

an and free of oil and grease. The wheel

bolts should be easily tightened to the cor-

rect torque.

● The hexagonal socket in the wheel brace

should be u

sed for turning wheel bolts only.

Do not use it to loosen or tighten the wheel

bolts. 40

Page 43 of 232

The essentials

Tyres with compulsory direction of ro-

t ation A directional tread pattern can be identified

by

the arr

ows on the sidewall that point in

the direction of rotation. Always observe the

direction of rotation indicated when fitting

the wheel to guarantee optimum properties

of this type of tyres with regard to grip,

noises, wear and aquaplaning.

If it is absolutely necessary to fit the spare

tyre* against the direction of rotation, drive

with care as this means the tyre does not of-

fer optimum driving properties. This is of par-

ticular importance when the road surface is

wet.

To return to directional tread tires, replace

the punctured tyre as soon as possible and

restore the obligatory direction of rotation of

all tyres.

After the wheel change ●

Clean the vehicle tools, if necessary and

p ut

them a

way in the luggage compartment

foam holder ›››

page 70.

● Store the spare wheel, the temporary spare

wheel or the ch

anged wheel securely in the

luggage compartment. ●

Have the tightenin

g torque of the wheel

bolts checked as soon as possible with a tor-

que wrench ››› page 38.

● Have the flat tyre replaced as quickly as

poss

ible.

Snow chains Use When using snow chains, applicable local

l

e

gi

slation and maximum permitted speed

limits must be observed.

In winter weather, snow chains not only help

to improve grip but also improve the braking

capacity.

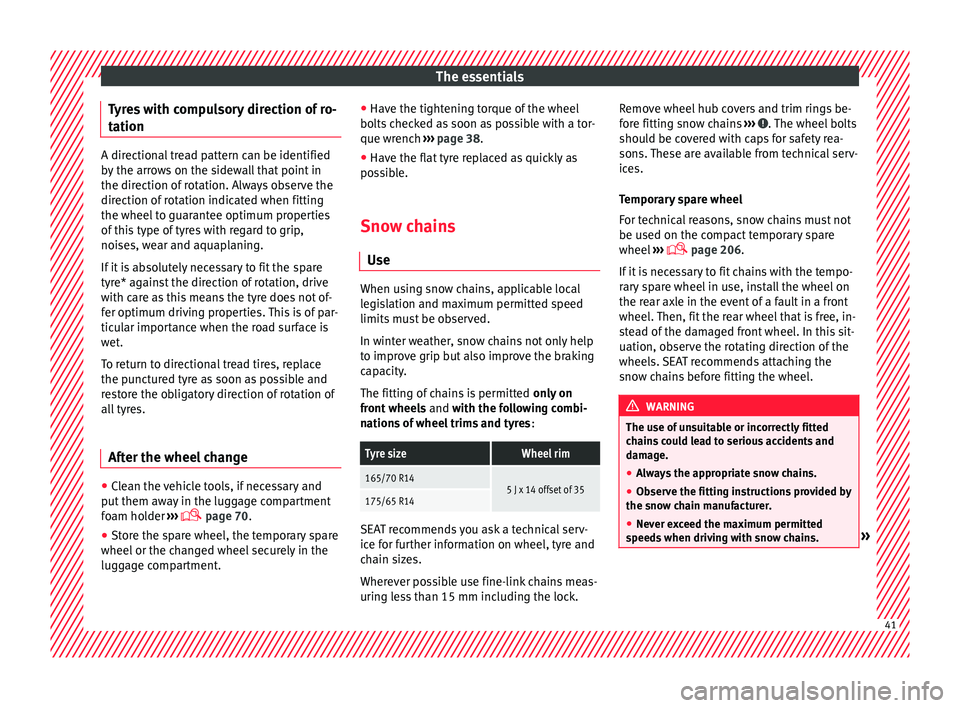

The fitting of chains is permitted only on

front wheels and with the following combi-

nations of wheel trims and tyres :

Tyre sizeWheel rim

165/70 R145 J x 14 offset of 35175/65 R14 SEAT recommends you ask a technical serv-

ic

e f

or f

urther information on wheel, tyre and

chain sizes.

Wherever possible use fine-link chains meas-

uring less than 15 mm including the lock. Remove wheel hub covers and trim rings be-

fore fittin

g snow chains ››› . The wheel bolts

shou l

d be c

overed with caps for safety rea-

sons. These are available from technical serv-

ices.

Temporary spare wheel

For technical reasons, snow chains must not

be used on the compact temporary spare

wheel ›››

page 206.

If it is necessary to fit chains with the tempo-

rary spare wheel in use, install the wheel on

the rear axle in the event of a fault in a front

wheel. Then, fit the rear wheel that is free, in-

stead of the damaged front wheel. In this sit-

uation, observe the rotating direction of the

wheels. SEAT recommends attaching the

snow chains before fitting the wheel. WARNING

The use of unsuitable or incorrectly fitted

ch ain

s could lead to serious accidents and

damage.

● Always the appropriate snow chains.

● Observe the fitting instructions provided by

the snow c

hain manufacturer.

● Never exceed the maximum permitted

speeds

when driving with snow chains. » 41

Page 44 of 232

The essentials

CAUTION

● Remo v

e the snow chains to drive on roads

without snow. Otherwise they will impair

vehicle handling, damage the tyres and wear

out very quickly.

● Wheel rims may be damaged or scratched if

the chain

s come into direct contact with

them. SEAT recommends the use of covered

snow chains. Note

Snow chains are available in different sizes

acc or

ding to the vehicle type. Emergency towing of the vehi-

c

l

e

T

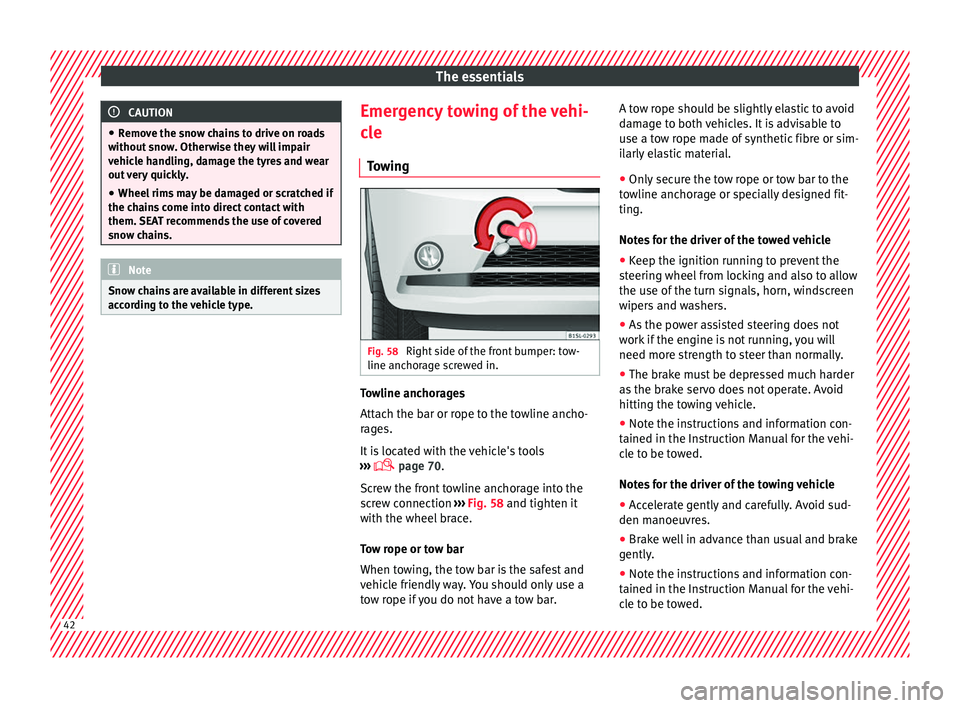

owing Fig. 58

Right side of the front bumper: tow-

line anc hor

ag

e screwed in. Towline anchorages

Att

ac

h the b

ar or rope to the towline ancho-

rages.

It is located with the vehicle's tools

››› page 70.

Screw the front towline anchorage into the

screw connection ››› Fig. 58 and tighten it

with the wheel brace.

Tow rope or tow bar

When towing, the tow bar is the safest and

vehicle friendly way. You should only use a

tow rope if you do not have a tow bar. A tow rope should be slightly elastic to avoid

damag

e to both vehicles. It is advisable to

use a tow rope made of synthetic fibre or sim-

ilarly elastic material.

● Only secure the tow rope or tow bar to the

towline anc

horage or specially designed fit-

ting.

Notes for the driver of the towed vehicle

● Keep the ignition running to prevent the

steerin

g wheel from locking and also to allow

the use of the turn signals, horn, windscreen

wipers and washers.

● As the power assisted steering does not

work if

the engine is not running, you will

need more strength to steer than normally.

● The brake must be depressed much harder

as the br

ake servo does not operate. Avoid

hitting the towing vehicle.

● Note the instructions and information con-

tained in the Ins

truction Manual for the vehi-

cle to be towed.

Notes for the driver of the towing vehicle

● Accelerate gently and carefully. Avoid sud-

den manoeuvr

es.

● Brake well in advance than usual and brake

gently.

● Not

e the instructions and information con-

tained in the In s

truction Manual for the vehi-

cle to be towed. 42

Page 45 of 232

The essentials

Driving style

T o

w

ing requires some experience, especially

when using a tow rope. Both drivers should

realise how difficult it is to tow a vehicle. In-

experienced drivers should not attempt to

tow.

Do not pull too hard with the towing vehicle

and take care to avoid jerking the tow rope.

When towing on an unpaved road, there is al-

ways a risk of overloading and damaging the

anchorage points.

Switch on the ignition so that the turn sig-

nals, windscreen wipers and windscreen

washer can work. Ensure that the steering

wheel is unlocked and moves freely.

Place the gear lever in neutral on vehicles

with a manual gearbox. With an automatic

gearbox, place the lever in N.

To brake, press the brake pedal firmly. The

brake servo does not work when the engine

is switched off.

The power steering only works when the igni-

tion is switched on and the vehicle is moving,

provided that the battery is sufficiently charg-

ed. Otherwise, it will need more force.

Ensure that the tow rope remains taut at all

times. ››› in Instructions for tow-starting on

page 76

››› page 75 Tow-starting

In general, the vehicle should not be started

by

t

owing. Jump-starting is much more pref-

erable ››› page 43.

For technical reasons, the following vehicles

can not be tow started:

● Vehicles with an automatic gearbox.

● If the vehicle battery is flat, it is possible

that the en

gine control unit does not operate

correctly.

However, if your vehicle must absolutely be

tow-started (manual gearbox):

● Put it into second or third gear.

● Keep the clutch pressed down.

● Switch on the ignition and the hazard warn-

ing lights.

● Rel

ease the clutch when both vehicles are

movin

g.

● As soon as the engine starts, press the

clutc

h and move the gear lever into neutral.

This helps to prevent a collision with the tow-

ing vehicle. How to jump start

Jump lea

ds If the engine fails to start because of a dis-

ch

ar

ged battery, the battery of another vehi-

cle can be used to start the engine. Before

starting, check the magic eye on the battery

››› page 196.

For starting assistance, jump lead cables con-

forming to the standard DIN 72553 are re-

quired (see the cable manufacturer instruc-

tions). The cable section in vehicles with pet-

rol engine must be at least 25 mm 2

. WARNING

Incorrect use of jump leads and incorrectly

jump st ar

ting could cause the battery to ex-

plode resulting in serious injury. Please ob-

serve the following rules to minimise the risk

of a battery explosion:

● The battery providing current must have

the same v

oltage (12V) and approximately

the same capacity (see markings on battery)

as the flat battery.

● Never charge a frozen or recently thawed

batter

y. A flat battery can also freeze at tem-

peratures close to 0 °C (+32 °F).

● If a battery is frozen and/or has been frozen

then it mus

t be replaced.

● A highly explosive mixture of gases is re-

lea

sed when the battery is being charged. Al-

ways keep lit cigarettes, flames, sparks and » 43

Page 46 of 232

The essentials

fire far from the battery. Never use a mobile

tel

ephone when c

onnecting and removing the

jump leads.

● Charge the battery only in well ventilated

area

s given that when the battery is charged

by outside assistance, it creates a mix of

highly explosive gases.

● Jump leads should never enter into contact

with mov

ing parts in the engine compart-

ment.

● Never switch the positive and negative

pole

s or connect the jump leads incorrectly.

● Note the instruction manual provided by

the manufact

urer of the jump leads. CAUTION

To avoid considerable damage to the vehicle

electric a

l system, note the following careful-

ly:

● If the jump leads are incorrectly connected,

this c

ould result in a short circuit.

● The vehicles must not touch each other,

otherwi

se electricity could flow as soon as

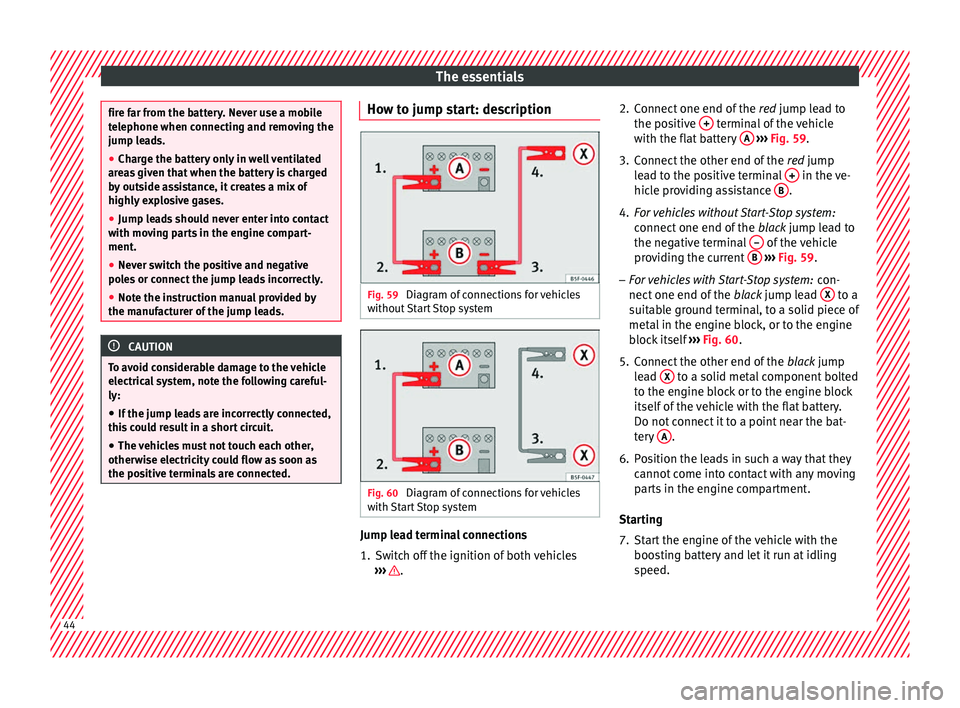

the positive terminals are connected. How to jump start: description

Fig. 59

Diagram of connections for vehicles

w ithout

Start Stop system Fig. 60

Diagram of connections for vehicles

w ith

St

art Stop system Jump lead terminal connections

1. Switch off the ignition of both vehicles

››

›

.2. Connect one end of the

re

d

jump lead to

the positive + terminal of the vehicle

w ith the fl

at

battery A

› ››

Fig. 59

.

3.

Connect the other end of the red

jump

lead to the positive terminal + in the ve-

hic l

e pr

oviding assistance B .

4. For vehicles without Start-Stop system:

connect

one end of

the black jump lead to

the negative terminal – of the vehicle

pr o

v

iding the current B

› ››

Fig. 59

.

– F

or vehicles with Start-Stop system: con-

nect one end of

the black jump lead X to a

s uit

ab

le ground terminal, to a solid piece of

metal in the engine block, or to the engine

block itself ››› Fig. 60.

5. Connect the other end of the black

jump

lead X to a solid metal component bolted

t o the en

gine b

lock or to the engine block

itself of the vehicle with the flat battery.

Do not connect it to a point near the bat-

tery A .

6. Position the leads in such a way that they cannot

c

ome into contact with any moving

parts in the engine compartment.

Starting

7. Start the engine of the vehicle with the boostin

g battery and let it run at idling

speed. 44

Page 51 of 232

Safe driving

● Adju s

t

the seat so that there is a distance

of at least 25 cm between the steering wheel

and your chest ››› Fig. 64 and so that you can

hold the steering wheel with both hands on

the outside of the ring at the 9 o'clock and 3

o'clock positions with your arms slightly

bent.

● The adjusted steering wheel must face your

ches

t and not your face.

● Adjust the driver seat forwards or back-

ward

s so that you are able to press the accel-

erator, brake and clutch pedals to the floor

with your knees slightly angled and the dis-

tance between your knees and the dash pan-

el is at least 10 cm ››› Fig. 64.

● Adjust the height of the driver seat so that

you can e

asily reach the top of the steering

wheel.

● Keep both feet in the footwell so that you

have the

vehicle under control at all times.

● Adjust and fasten your seat belt correctly

›››

page 52.

Valid for the passenger:

● Adjust the seat backrest to an upright posi-

tion so that

your back rests completely

against it.

● Move the front passenger seat back as far

as po

ssible for optimum protection should

the airbag deploy.

● Always keep your feet in the footwell while

the vehic

le is in motion. ●

Adjust

and fasten your seat belt correctly

››› page 52.

Valid for the passengers in the rear section:

● Adjust the head restraint so that its upper

edge is

at the same level as the top of your

head, or as close as possible to the same lev-

el as the top of your head and under no cir-

cumstances below eye level. Keep the back

of your neck as close as possible to the head

restraint ››› Fig. 64 and ››› Fig. 65.

● Short people must lower the head restraint

to the firs

t anchorage position, even if your

head is below its upper edge.

● Tall people must raise the head restraint

compl

etely.

● Always keep your feet in the footwell while

the vehic

le is in motion.

● Adjust and fasten your seat belt correctly

›››

page 52.

Adjusting the steering wheel position Read the additional information carefully

› ›

›

page 14.

Adjust the steering wheel before your trip

and only when the vehicle is stationary.

Adjust the correct distance between the driv-

er and the steering wheel ›››

Fig. 64 using the

controls on the driver seat ›››

page 12. WARNING

Incorrect use of the steering wheel adjust-

ment f u

nction and an incorrect adjustment of

the steering wheel can result in severe or fa-

tal injury.

● After adjusting the steering column, push

the lever firm

ly upwards to ensure the steer-

ing wheel does not accidentally change posi-

tion while driving.

● Never adjust the steering wheel while the

vehicl

e is in motion. If you need to adjust the

steering wheel while the vehicle is in motion,

stop safely and make the proper adjustment.

● The adjusted steering wheel should be fac-

ing y

our chest and not your face so as not to

hinder the driver's front airbag protection in

the event of an accident.

● When driving, always hold the steering

wheel with both h

ands on the outside of the

ring at the 9 o'clock and 3 o'clock positions

to reduce injuries when the driver's front air-

bag deploys.

● Never hold the steering wheel at the 12

o'clock

position or in any other manner (e.g.

in the centre of the steering wheel). In such

cases, if the driver's airbag deploys, you may

sustain injuries to your arms, hands and

head. 49

Technical data

Advice

Operation

Emergencies

Safety