towing Seat Toledo 2013 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Toledo, Model: Seat Toledo 2013Pages: 258, PDF Size: 3.94 MB

Page 160 of 258

158Driving and the environment

Fuel consumption also depends on factors that cannot be influenced by the

driver. It is normal for consumption to be greater in winter or in difficult con-

ditions, on roads in poor condition, when towing a trailer, etc.

Fuel consumption can also vary considerably from that stated by the manu-

facturer due to the outside temperature, the weather and driving style.

The vehicle has factory-fitted technical conditions in order to save fuel and

to operate in economic mode. SEAT pays special attention to minimize the

environmental impact. Take the following indications in this chapter into ac-

count in order to conserve and to take advantage of these qualities:

The engine speed must be maintained at the maximum in order to prevent

vehicle resonance and high fuel consumption.

Foresighted driving

The vehicle consumes the majority of fuel when accelerating, therefore

avoid unnecessary acceleration and braking. If you think ahead when driv-

ing, you will need to brake less and thus accelerate less. For example, when

approaching a red traffic light, allow the vehicle to decelerate freely or use

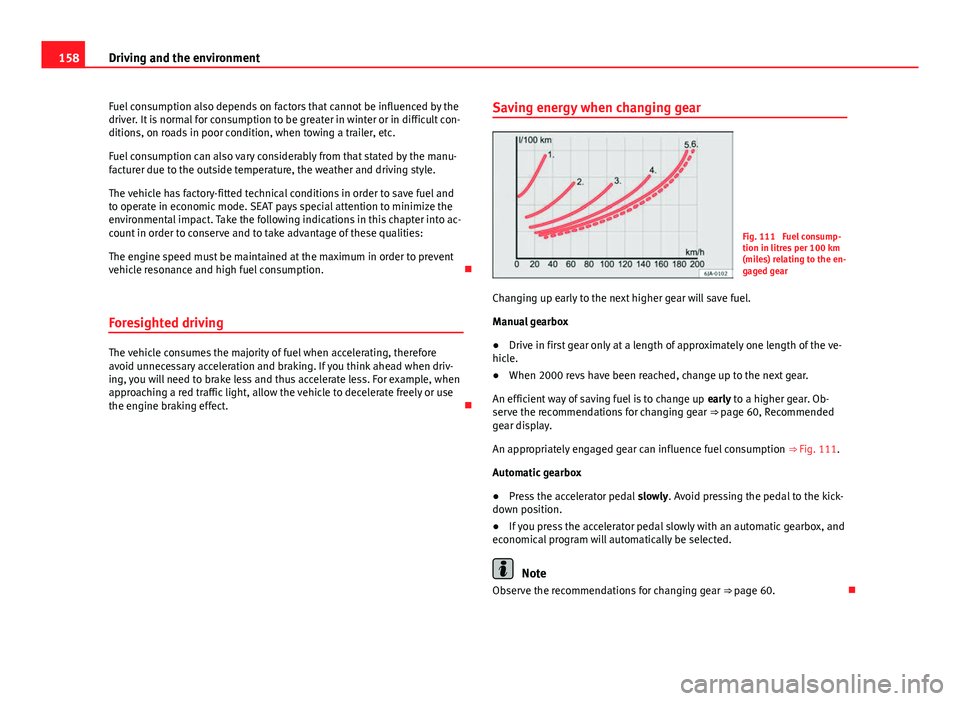

the engine braking effect. Saving energy when changing gear

Fig. 111 Fuel consump-

tion in litres per 100 km

(miles) relating to the en-

gaged gear

Changing up early to the next higher gear will save fuel.

Manual gearbox

● Drive in first gear only at a length of approximately one length of the ve-

hicle.

● When 2000 revs have been reached, change up to the next gear.

An efficient way of saving fuel is to change up early to a higher gear. Ob-

serve the recommendations for changing gear ⇒ page 60, Recommended

gear display.

An appropriately engaged gear can influence fuel consumption ⇒ Fig. 111.

Automatic gearbox

● Press the accelerator pedal slowly. Avoid pressing the pedal to the kick-

down position.

● If you press the accelerator pedal slowly with an automatic gearbox, and

economical program will automatically be selected.

Note

Observe the recommendations for changing gear ⇒ page 60.

Page 166 of 258

164Driving the vehicle with a trailer

Driving the vehicle with a trailer

Driving the vehicle with a trailer

Technical requirements

If your vehicle has a factory-fitted towing bracket or is equipped with a se-

lection of SEAT Original Accessories, it meets all the relevant technical and

legal requirements.

In vehicles with a towing bracket it is possible to remove the ball joint, situ-

ated (together with the special assembly instructions) in the housing for the

spare wheel in the vehicle luggage compartment ⇒ page 207, Vehicle tool

kit*.

Your vehicle is fitted with a 13-pole power socket for the electrical connec-

tion between the trailer and the vehicle. If the trailer you are going to use

has a 7-pin connector, the corresponding adaptor, acquired from the SEAT

Original Accessories Catalogue, can be used.

If a towing bracket is to be retro-fitted to the car, it must be done according

to the instructions of the towing bracket manufacturer.

Note

Any queries that may arise can be directed to an authorised SEAT dealer.

Trailer weight

Trailer weight

The combined vehicle and trailer must be balanced. To do so use the maxi-

mum permitted towing bracket load. An insufficient weight exerted by the trailer drawbar on the ball joint of the towing bracket will have a negative

impact upon the response of the vehicle-trailer assembly on the road.

Weight distribution

Distribute loads in the trailer so that heavy objects are as near to the axle as

possible. Ensure that the objects do not move.

If the towing vehicle is empty and the trailer loaded then the load distribu-

tion is incorrect. However, if these conditions cannot be avoided, drive very

slowly.

Tyre pressure values

Correct the tyre pressure in your vehicle to “total load” ⇒

page 197, Tyre

useful life.

Trailer weight

Never exceed the authorised trailer weight under any circumstances

⇒ page 233, Description of the data.

The trailer weights listed are only applicable for altitudes up to 1000 m

above sea level. Due to a lower air density the engine power decreases de-

pending on the increase in altitude, this also causes the climbing ability to

decrease, which requires a reduction of the weight of the vehicle with a

trailer by 10 % for every 1000 m increase in altitude. The weight of the as-

sembly is calculated by adding the vehicle weight (loaded) to the trailer

weight (loaded). Always drive with special care when towing a trailer.

The towed load and support load information that is displayed on the tow-

ing bracket manufacturers label are only values for the verification of the

device. The correct figures for your specific vehicle, which are usually lower

than these figures, are given in the documentation of your vehicle.

Page 167 of 258

165

Driving the vehicle with a trailer

WARNING

● Exceeding the maximum established load per axle and the maximum

towing bracket load in addition to the maximum permitted load or the

load of the vehicle + trailer assembly can cause accidents and serious in-

juries.

● A sliding load could considerably affect the stability and safety of the

vehicle + trailer assembly, resulting in accidents and serious injuries.

Towing a trailer

Exterior mirrors

Check whether you can see enough of the road behind the trailer with the

standard rear vision mirrors. If this is not the case, you should have addi-

tional exterior mirrors fitted. Observe the relevant statutory requirements of

the country you are in.

Headlights

Before starting a journey, also check the headlight beam settings with the

trailer hitched up. Adjust the headlight range settings if necessary

⇒ page 99, Range control of main lights .

Driving speed

For your own safety do not drive faster than the maximum permitted speed

indicated on the trailer.

At all times, immediately reduce speed if you detect the slightest swaying

movement of the trailer. Never try to “return the trailer to a straight posi-

tion” by accelerating.

Brakes

Brake in due course! If the trailer has an overrun brake, apply the brakes

gently at first and then, firmly. This will prevent the jerking that can be caused by locking of trailer wheels. Change to a lower gear in good time be-

fore descending a slope in order to take advantage of the engine brake.

The trailer is incorporated into the vehicle anti-theft alarm system.

●

When the vehicle has a factory-fitted anti-theft alarm and a towing

bracket

● When the trailer is electrically connected to the vehicle via the towing

bracket socket

● When the vehicle electrical device and the towing bracket are operation-

al

● When the vehicle is locked and the vehicle anti-theft alarm device is ac-

tivated

Once the electrical connection is interrupted with the vehicle trailer locked,

the alarm sounds.

Always switch off the vehicle anti-theft alarm device before connecting or

disconnecting a trailer. The vehicle anti-theft alarm device could cause the

alarm to sound ⇒ page 91, Anti-theft alarm system*.

Engine overheating

In the event that the coolant temperature gauge needle moves to the right

section of the scale or to the red area, immediately reduce speed. If the con-

trol lamp flashes on the general instrument panel, stop the vehicle and

switch off the engine. Wait several minutes and check the coolant level in

the tank ⇒ page 188.

Please observe the following indications ⇒ page 72, Coolant level and tem-

perature .

The coolant temperature can be reduced by switching on the heating.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 169 of 258

167

Driving the vehicle with a trailer

Towing bracket device Introduction

If the vehicle is equipped with a towing bracket device from the factory or

consisting of genuine SEAT accessories, it meets all the national technical

and legal requirements for towing.

Your vehicle is fitted with a 13-pin power socket for the electrical connection

between the trailer and the vehicle. If the towing bracket is equipped with a

7-pin connector, the corresponding available adaptor may be used as a

genuine SEAT accessory.

The towing device has a maximum vertical load of 50 kg.

WARNING

● Before driving with the ball-headed bar fitted, verify its correct as-

sembly and placement in the clamping bush.

● Do not use the ball-headed bar if it is not correctly placed and fixed in

the clamping bush.

● Do not use the towing device for towing if it is damaged or missing

parts.

● Do not modify or adapt the towing device for towing.

● Never disengage the ball-headed bar with the trailer still hitched.

CAUTION

Be careful not to damage the paint on the bumper when handling the ball-

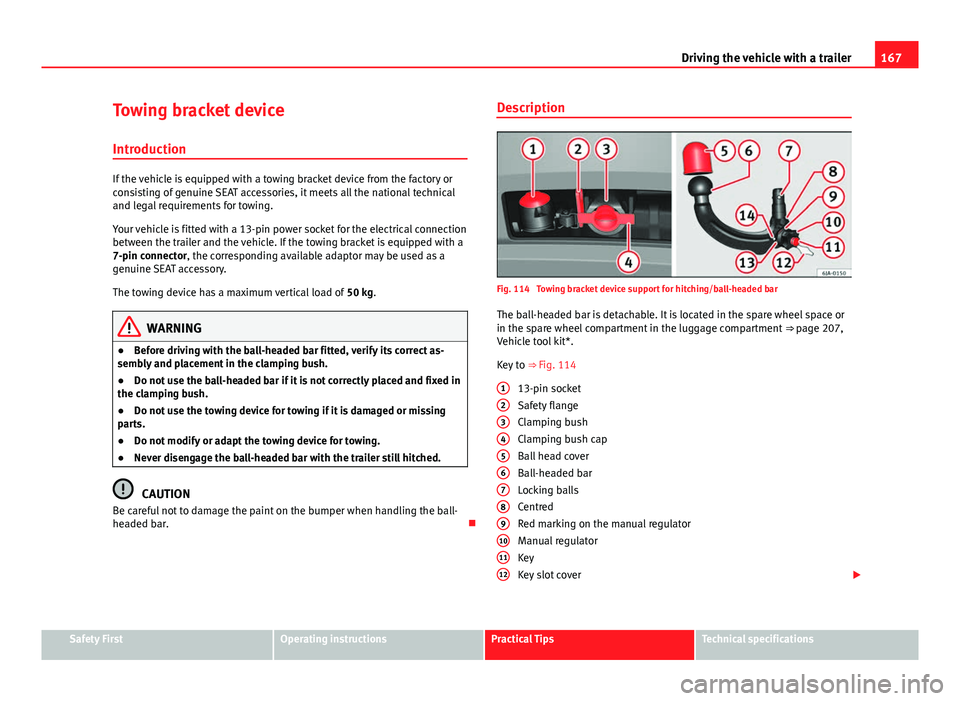

headed bar. Description

Fig. 114 Towing bracket device support for hitching/ball-headed bar

The ball-headed bar is detachable. It is located in the spare wheel space or

in the spare wheel compartment in the luggage compartment ⇒ page 207,

Vehicle tool kit*.

Key to ⇒ Fig. 114

13-pin socket

Safety flange

Clamping bush

Clamping bush cap

Ball head cover

Ball-headed bar

Locking balls

Centred

Red marking on the manual regulator

Manual regulator

Key

Key slot cover

1

23456789101112

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 172 of 258

170Driving the vehicle with a trailer

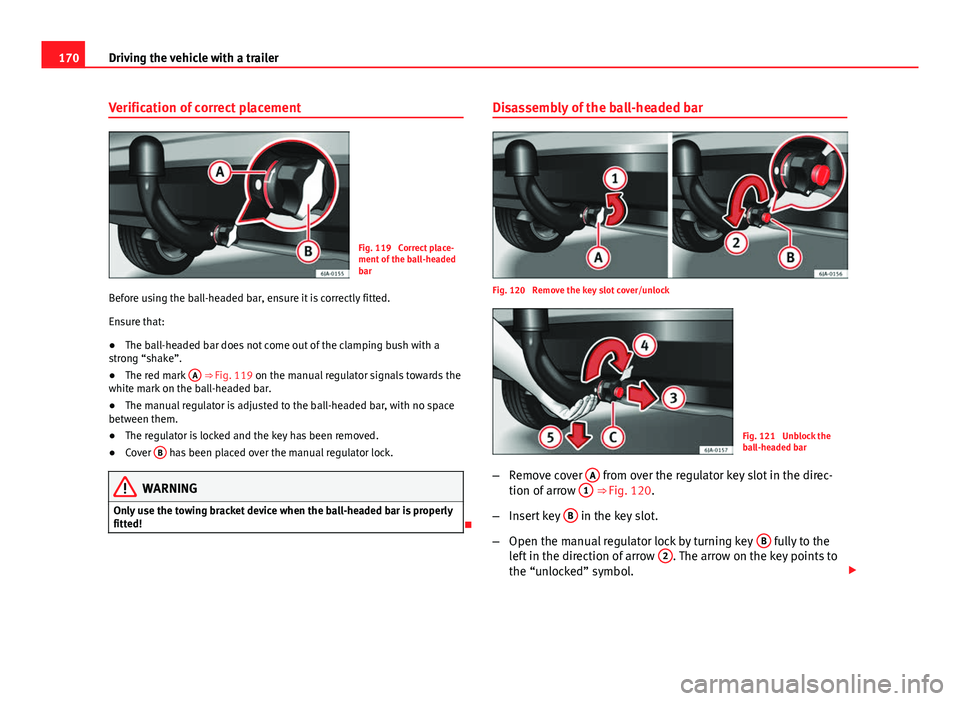

Verification of correct placement

Fig. 119 Correct place-

ment of the ball-headed

bar

Before using the ball-headed bar, ensure it is correctly fitted.

Ensure that:

● The ball-headed bar does not come out of the clamping bush with a

strong “shake”.

● The red mark A

⇒ Fig. 119 on the manual regulator signals towards the

white mark on the ball-headed bar.

● The manual regulator is adjusted to the ball-headed bar, with no space

between them.

● The regulator is locked and the key has been removed.

● Cover B

has been placed over the manual regulator lock.

WARNING

Only use the towing bracket device when the ball-headed bar is properly

fitted!

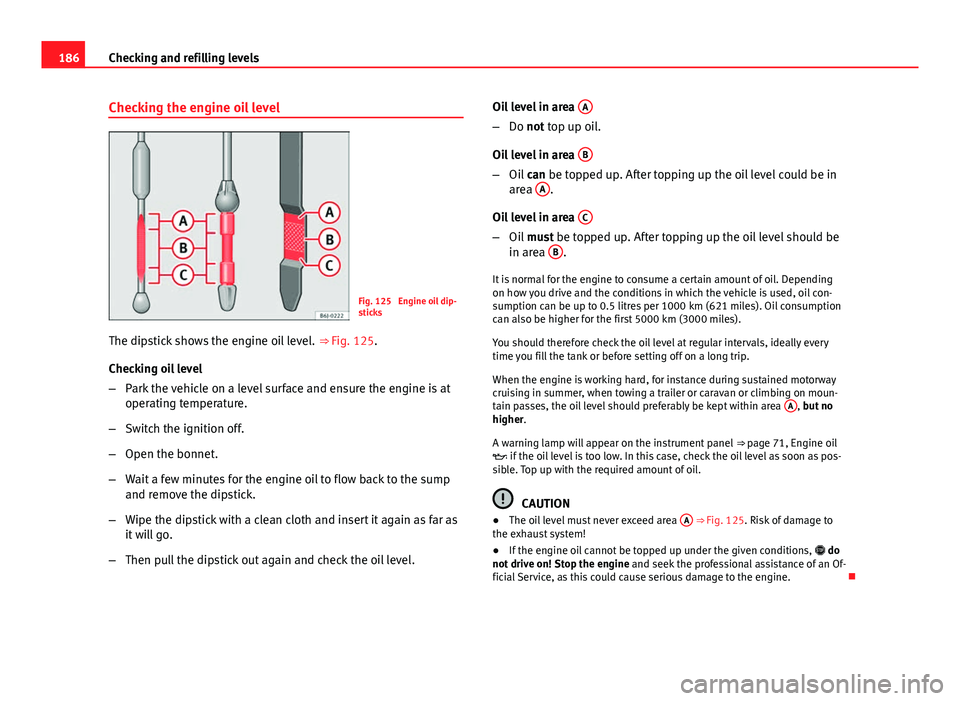

Disassembly of the ball-headed bar

Fig. 120 Remove the key slot cover/unlock

Fig. 121 Unblock the

ball-headed bar

– Remove cover A

from over the regulator key slot in the direc-

tion of arrow 1 ⇒ Fig. 120.

– Insert key B

in the key slot.

– Open the manual regulator lock by turning key B

fully to the

left in the direction of arrow 2. The arrow on the key points to

the “unlocked” symbol.

Page 188 of 258

186Checking and refilling levels

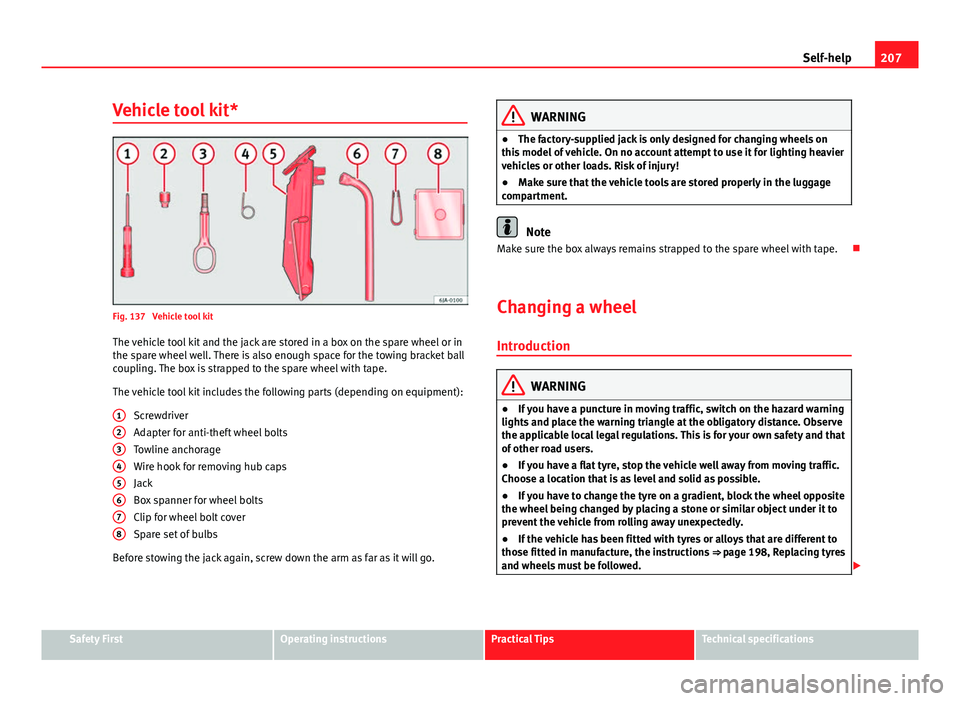

Checking the engine oil level

Fig. 125 Engine oil dip-

sticks

The dipstick shows the engine oil level. ⇒ Fig. 125.

Checking oil level

– Park the vehicle on a level surface and ensure the engine is at

operating temperature.

– Switch the ignition off.

– Open the bonnet.

– Wait a few minutes for the engine oil to flow back to the sump

and remove the dipstick.

– Wipe the dipstick with a clean cloth and insert it again as far as

it will go.

– Then pull the dipstick out again and check the oil level. Oil level in area

A

–

Do not top up oil.

Oil level in area B

–

Oil can be topped up. After topping up the oil level could be in

area A.

Oil level in area C

–

Oil must be topped up. After topping up the oil level should be

in area B.

It is normal for the engine to consume a certain amount of oil. Depending

on how you drive and the conditions in which the vehicle is used, oil con-

sumption can be up to 0.5 litres per 1000 km (621 miles). Oil consumption

can also be higher for the first 5000 km (3000 miles).

You should therefore check the oil level at regular intervals, ideally every

time you fill the tank or before setting off on a long trip.

When the engine is working hard, for instance during sustained motorway

cruising in summer, when towing a trailer or caravan or climbing on moun-

tain passes, the oil level should preferably be kept within area A

, but no

higher.

A warning lamp will appear on the instrument panel ⇒ page 71, Engine oil

if the oil level is too low. In this case, check the oil level as soon as pos-

sible. Top up with the required amount of oil.

CAUTION

● The oil level must never exceed area A ⇒ Fig. 125. Risk of damage to

the exhaust system!

● If the engine oil cannot be topped up under the given conditions, do

not drive on! Stop the engine and seek the professional assistance of an Of-

ficial Service, as this could cause serious damage to the engine.

Page 209 of 258

207

Self-help

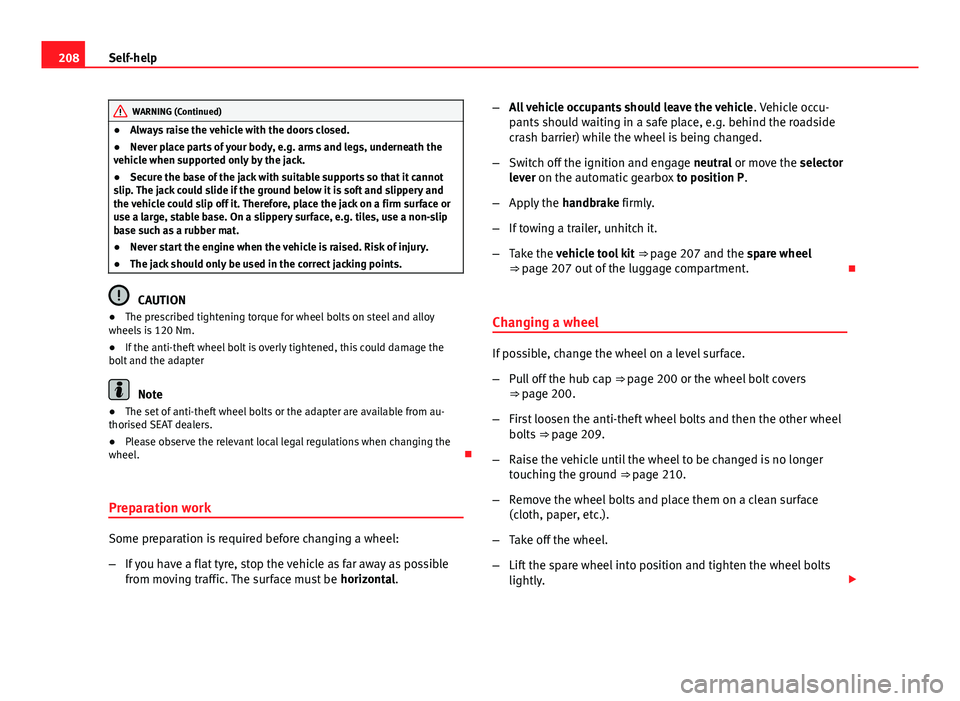

Vehicle tool kit*

Fig. 137 Vehicle tool kit

The vehicle tool kit and the jack are stored in a box on the spare wheel or in

the spare wheel well. There is also enough space for the towing bracket ball

coupling. The box is strapped to the spare wheel with tape.

The vehicle tool kit includes the following parts (depending on equipment): Screwdriver

Adapter for anti-theft wheel bolts

Towline anchorage

Wire hook for removing hub caps

Jack

Box spanner for wheel bolts

Clip for wheel bolt cover

Spare set of bulbs

Before stowing the jack again, screw down the arm as far as it will go. 1

2345678

WARNING

● The factory-supplied jack is only designed for changing wheels on

this model of vehicle. On no account attempt to use it for lighting heavier

vehicles or other loads. Risk of injury!

● Make sure that the vehicle tools are stored properly in the luggage

compartment.

Note

Make sure the box always remains strapped to the spare wheel with tape.

Changing a wheel Introduction

WARNING

● If you have a puncture in moving traffic, switch on the hazard warning

lights and place the warning triangle at the obligatory distance. Observe

the applicable local legal regulations. This is for your own safety and that

of other road users.

● If you have a flat tyre, stop the vehicle well away from moving traffic.

Choose a location that is as level and solid as possible.

● If you have to change the tyre on a gradient, block the wheel opposite

the wheel being changed by placing a stone or similar object under it to

prevent the vehicle from rolling away unexpectedly.

● If the vehicle has been fitted with tyres or alloys that are different to

those fitted in manufacture, the instructions ⇒ page 198, Replacing tyres

and wheels must be followed.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 210 of 258

208Self-help

WARNING (Continued)

● Always raise the vehicle with the doors closed.

● Never place parts of your body, e.g. arms and legs, underneath the

vehicle when supported only by the jack.

● Secure the base of the jack with suitable supports so that it cannot

slip. The jack could slide if the ground below it is soft and slippery and

the vehicle could slip off it. Therefore, place the jack on a firm surface or

use a large, stable base. On a slippery surface, e.g. tiles, use a non-slip

base such as a rubber mat.

● Never start the engine when the vehicle is raised. Risk of injury.

● The jack should only be used in the correct jacking points.

CAUTION

● The prescribed tightening torque for wheel bolts on steel and alloy

wheels is 120 Nm.

● If the anti-theft wheel bolt is overly tightened, this could damage the

bolt and the adapter

Note

● The set of anti-theft wheel bolts or the adapter are available from au-

thorised SEAT dealers.

● Please observe the relevant local legal regulations when changing the

wheel.

Preparation work

Some preparation is required before changing a wheel:

– If you have a flat tyre, stop the vehicle as far away as possible

from moving traffic. The surface must be horizontal.–

All vehicle occupants should leave the vehicle . Vehicle occu-

pants should waiting in a safe place, e.g. behind the roadside

crash barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral or move the selector

lever on the automatic gearbox to position P.

– Apply the handbrake firmly.

– If towing a trailer, unhitch it.

– Take the vehicle tool kit ⇒ page 207 and the spare wheel

⇒ page 207 out of the luggage compartment.

Changing a wheel

If possible, change the wheel on a level surface.

– Pull off the hub cap ⇒ page 200 or the wheel bolt covers

⇒ page 200.

– First loosen the anti-theft wheel bolts and then the other wheel

bolts ⇒ page 209.

– Raise the vehicle until the wheel to be changed is no longer

touching the ground ⇒ page 210.

– Remove the wheel bolts and place them on a clean surface

(cloth, paper, etc.).

– Take off the wheel.

– Lift the spare wheel into position and tighten the wheel bolts

lightly.

Page 215 of 258

213

Self-help

Before using the tyre repair kit

The following jobs must be performed before using the tyre repair

kit:

– If you have a flat tyre, stop the vehicle well away from moving

traffic. Stop on flat, solid ground.

– All vehicle occupants should leave the vehicle. Vehicle occu-

pants should waiting in a safe place, e.g. behind the roadside

crash barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral or move the selector

lever on the automatic gearbox to position P.

– Apply the handbrake firmly.

– Check whether the tyre can be repaired using the tyre repair kit

⇒ page 211.

– If towing a trailer, unhitch it.

– Take the tyre repair kit out of the luggage compartment.

– Fix the sticker 2

⇒ Fig. 142 ⇒

page 212 onto the dash panel

where the driver will see it.

– Do not remove the foreign body, e.g. bolts or nails, from the

tyre.

– Unscrew the tyre valve cap.

– Using the valve extractor 1

, unscrew the valve insert and place

it onto a clean surface (cloth, paper, etc.) Filling and inflating the tyre

Filling the tyre

–

Shake the tyre sealant can 10

⇒ Fig. 142 ⇒ page 212 thorough-

ly several times.

– Attach the flexible filling hose 3

onto the can 10. The foil seal-

ing the can will be automatically pierced.

– Remove the cap from the flexible filling hose 3

and insert the

open end as far as it will go into the tyre valve.

– Hold the can 10

upside down and fill the complete contents of

the can into the tyre.

– Remove the empty can from the tyre.

– Screw the valve insert back into the tyre valve using the valve

extractor 1

.

Inflating the tyre

– Screw the tyre filling hose 5

⇒ Fig. 142 ⇒ page 212 firmly onto

the tyre valve.

– Make sure that the bleed screw 7

is closed.

– Start the vehicle engine and leave it running.

– Plug the connector 9

into the 12-volt power socket.

– Turn the air compressor on with the switch 8

.

– Leave the air compressor running until the tyre pressure has

reached 2.0-2.5 bar (29-36 psi / 200-250 kPa). Max. operating

time for the compressor is 8 minutes ⇒

!

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 218 of 258

216Self-help

Connecting negative terminals with the engine block

–Connect one end 3

⇒ Fig. 143 to the negative terminal of the

boosting battery B.

– Attach the other end 4

to a solid metal part firmly attached to

the engine block or to the engine block itself.

Starting the engine

– Start the engine of the vehicle and let it run at idling speed.

– Now start the engine of the vehicle with the discharged battery.

– If the engine fails to start, do not operate the start for longer

than 10 seconds. Wait for about 30 seconds and try again.

– Remove the jump leads from the engine in exactly the opposite

sequence to that described above. Jump-starting vehicles with the START-STOP system

Fig. 144 Jump-starting

vehicles with the START-

STOP system

In vehicles fitted with the START-STOP system, the booster cable cannot be

directly connected to the negative terminal of the vehicle battery but must

be attached to the engine earthing point.

Towing the vehicle

Introduction

Vehicles with manual gearbox can be towed using a towbar or tow-

rope. They can also be towed with either the front or rear wheels

lifted off the road.

Vehicles with automatic gearbox can be towed using a towbar or

towrope. They can also be towed with the front wheels lifted off the