stop start Seat Toledo 2013 Owner's Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Toledo, Model: Seat Toledo 2013Pages: 258, PDF Size: 3.94 MB

Page 164 of 258

162Driving and the environment

Note

You will receive information about the modification of the headlights at an

authorised SEAT dealer.

Preventing damage to the vehicle

In order to prevent damage to the vehicle, take special care:

● on roads in poor condition

● when mounting the kerb

● when approaching very steep ramps, etc.

● with the parts of the vehicle situated on the lower part of the vehicle, i.e.

the spoiler, the exhaust pipe,

This applies especially to vehicles with a very low suspension (sport) and

when the vehicle is fully loaded.

Driving through water

Fig. 113 Driving through

water To prevent the vehicle from being damaged when driving through water (i.e.

flooded roads), please observe the following:

●

Determine the depth of the water before entering. The water can reach a

maximum height of below the door sill ⇒ Fig. 113.

● Drive at a maximum pace of walking speed. Driving at a higher speed

can cause a wave in front of the vehicle, which can cause water to enter the

engine air intake system or other parts of the vehicle.

● Never stop in the water, never reverse and never stop the engine.

● Before driving through water deactivate the START-STOP system

⇒ page 154.

WARNING

● Driving through water, dirt and mud can reduce braking capability

and prolong the braking distance – Risk of accident!

● Do not carry out any sudden or strong braking manoeuvres after driv-

ing through water.

● Clean and dry the brakes as soon as possible after driving through

water by breaking intermittently. Carry out braking in order to dry the

brakes and clean the brake discs only if traffic so permits. Do not put oth-

er drivers at risk.

CAUTION

● In the event of driving through water the parts of the vehicle can be seri-

ously damaged, such as the engine, gearbox, catalytic converter, suspen-

sion or the electrical system.

● Oncoming vehicles that drive through water can cause waves that ex-

ceed your vehicle's permitted level for driving through water.

● There may be pot-holes mud or rocks under the water that can hinder or

prevent driving through water.

● Do not drive through salt water. The salt can cause rust. All components

that are exposed to salt water must be rinsed immediately with fresh water.

Page 167 of 258

165

Driving the vehicle with a trailer

WARNING

● Exceeding the maximum established load per axle and the maximum

towing bracket load in addition to the maximum permitted load or the

load of the vehicle + trailer assembly can cause accidents and serious in-

juries.

● A sliding load could considerably affect the stability and safety of the

vehicle + trailer assembly, resulting in accidents and serious injuries.

Towing a trailer

Exterior mirrors

Check whether you can see enough of the road behind the trailer with the

standard rear vision mirrors. If this is not the case, you should have addi-

tional exterior mirrors fitted. Observe the relevant statutory requirements of

the country you are in.

Headlights

Before starting a journey, also check the headlight beam settings with the

trailer hitched up. Adjust the headlight range settings if necessary

⇒ page 99, Range control of main lights .

Driving speed

For your own safety do not drive faster than the maximum permitted speed

indicated on the trailer.

At all times, immediately reduce speed if you detect the slightest swaying

movement of the trailer. Never try to “return the trailer to a straight posi-

tion” by accelerating.

Brakes

Brake in due course! If the trailer has an overrun brake, apply the brakes

gently at first and then, firmly. This will prevent the jerking that can be caused by locking of trailer wheels. Change to a lower gear in good time be-

fore descending a slope in order to take advantage of the engine brake.

The trailer is incorporated into the vehicle anti-theft alarm system.

●

When the vehicle has a factory-fitted anti-theft alarm and a towing

bracket

● When the trailer is electrically connected to the vehicle via the towing

bracket socket

● When the vehicle electrical device and the towing bracket are operation-

al

● When the vehicle is locked and the vehicle anti-theft alarm device is ac-

tivated

Once the electrical connection is interrupted with the vehicle trailer locked,

the alarm sounds.

Always switch off the vehicle anti-theft alarm device before connecting or

disconnecting a trailer. The vehicle anti-theft alarm device could cause the

alarm to sound ⇒ page 91, Anti-theft alarm system*.

Engine overheating

In the event that the coolant temperature gauge needle moves to the right

section of the scale or to the red area, immediately reduce speed. If the con-

trol lamp flashes on the general instrument panel, stop the vehicle and

switch off the engine. Wait several minutes and check the coolant level in

the tank ⇒ page 188.

Please observe the following indications ⇒ page 72, Coolant level and tem-

perature .

The coolant temperature can be reduced by switching on the heating.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 175 of 258

173

Care of the vehicle and cleaning

Note

● Remove stains from fresh ball-pen and other inks, lipstick, shoe cream

and similar stains on the fabric (leather), upholstery and fabric trim as soon

as possible.

● We recommend that you visit an authorised SEAT dealer to clean and

care for the interior of your vehicle, due to the problems that may arise

when cleaning and caring for the interior of your vehicle and to the utensils

and knowledge required.

Washing the vehicle

The best protection of the vehicle from the harmful influences of the envi-

ronment involves frequent washing and waxing. The frequency with which

the vehicle is washed depends on many different factors, such as:

● Frequency of use

● Type of parking (garage, underneath trees, etc.)

● Time of year

● Weather conditions

● Environmental conditions

The longer substances such as insects, bird droppings, resinous tree sap,

road dirt, industrial deposits, tar, soot or road salt and other aggressive ma-

terials remain on the paintwork, the more damage they do. High tempera-

tures (for instance in strong sunlight) further intensify the corrosive effect.

After the winter season, it is important to have the underside of the vehicle

washed thoroughly. Automatic car washes

Your vehicle can be washed in an automatic car wash.

Before going through a car wash, be sure to take the usual precautions such

as closing the windows, etc.

If the vehicle has special accessories such as spoilers or a roof carrier or

two-way radio aerial, etc., it is advisable to consult the car wash operator

beforehand.

The windscreen wiper rubbers must be degreased after going after the car

wash and waxing.

Washing by hand

When washing the car by hand, use plenty of water to soften the dirt first

and rinse off as well as possible.

Then clean the vehicle with a sponge, glove or brush. Start on the roof and

work down. Use only slight pressure when cleaning the painted surfaces of

the vehicle. A car shampoo should only be used for very persistent dirt.

Rinse the sponge or glove thoroughly and often.

Wheels, sills and underside should be cleaned last. Use a second sponge

for this.

After washing, rinse the vehicle thoroughly and then dry with a chamois.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 183 of 258

181

Checking and refilling levels

will help to prevent corrosion, keep the fuel system clean and prevent de-

posits from building up in the engine.

If good quality petrol with metal-free additives is not available or engine

problems arise, the necessary additives must be added when refuelling

⇒

.

Not all petrol additives have been shown to be effective. The use of unsuita-

ble petrol additives may cause significant damage to the engine and the

catalytic converter. Metal additives should never be used. Metal additives

may also be contained in petrol additives for improving anti-detonation rat-

ings or octane ratings ⇒

.

SEAT recommends “genuine Volkswagen Group fuel additives for petrol en-

gines”. These additives can be bought at SEAT Authorised Services, where

information on how to use them can also be obtained.

CAUTION

● Do not refuel if the filler indicates that the fuel contains metal. LRP (lead

replacement petrol) fuels contain high concentrations of metal additives.

Using them may damage the engine!

● All SEAT vehicles with petrol engines can only run on unleaded petrol.

Refuelling just once with leaded petrol disables the exhaust system!

● Use of petrol with a lower RON to that prescribed could damage the en-

gine components.

● Fuels marked as containing metal on the garage fuel pump cannot be

used. Risk of damage to most engine parts or the exhaust system!

● The use of unsuitable additives in petrol can cause damage to most en-

gine parts or the exhaust system. Diesel fuel

Your vehicle can only run on

diesel fuel that complies with the Standard EN

590 (in Germany, also DIN 51628, in Austria also ÖNORM C 1590 , in Russia

also GOST R 52368-2005/EN 590:2004 ).

Winter driving – winter-grade diesel

In winter use diesel fuel that complies with the Standard EN 590 (in Germa-

ny, also DIN 51628, in Austria also ÖNORM C 1590, in Russia also GOST R

52368-2005/EN 590:2004). “Winter-grade diesel” still performs well at

-20 °C (-4 °F).

In countries with other weather conditions, diesel is often available that be-

haves differently with regards to the temperature. The authorised SEAT deal-

ers and petrol stations in each country will inform you on the normal diesel

fuel of the country in question.

Preheating the fuel filter

The vehicle is fitted with a glow plug system for the fuel filter. Therefore, the

reliability of the diesel is ensured at ambient temperatures of down to ap-

prox. -25 °C (-13 °F).

Fuel additives

Fuel additives, known as “thinners” (petrol or similar substances) should

not be mixed with the diesel fuel.

CAUTION

● Even one tankful of diesel fuel that does not comply with the standard

could damage engine parts, the fuel system and the exhaust system!

● If fuel different to the prescribed diesel fuel (e.g. petrol) is used by mis-

take, never start the engine or switch on the ignition! Risk of serious dam-

age to the engine! Contact an authorised SEAT dealer to clean the engine

fuel system.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 184 of 258

182Checking and refilling levels

● Water allowed to collect in the fuel filter can cause engine faults.

● Your vehicle is not prepared for use of biofuel (RME) and, therefore, this

fuel must not be used for refuelling or driving. The use of biofuel (RME)

could cause serious damage to the engine or the fuel system.

Engine compartment

Introduction

Always be aware of the danger of injury and scalding as well as the risk of

accident or fire when working in the engine compartment, e.g. when check-

ing and refilling fluids. Therefore, always observe the warnings and follow

all general safety precautions. The engine compartment of any motor vehi-

cle is a potentially hazardous area .

WARNING

● Never open the bonnet if you see steam, smoke or coolant escaping

from the engine compartment. Risk of scalding! Wait until no steam or

coolant can be seen before opening the bonnet.

● Switch off the engine and remove the key from the ignition.

● Engage neutral in vehicles with manual gearbox and move the selec-

tor lever to position P in vehicles with automatic gearbox.

● Apply the handbrake firmly.

● Wait for the engine to cool down.

● For safety reasons, the bonnet must always be closed when the vehi-

cle is moving. Therefore, after closing the bonnet always check that it is

properly secured.

WARNING (Continued)

● Should you notice that the bonnet is not safely secured when the ve-

hicle is moving, stop the vehicle immediately and close the bonnet prop-

erly. Risk of accident!

● Keep children away from the engine compartment.

● Do not touch hot engine parts. Risk of burns!

● Never spill fluids on hot engine compartments. These fluids can

cause a fire (e.g. antifreeze in coolant).

● Take care not to cause short circuits in the electrical system, especial-

ly when working on the battery.

● Never touch the radiator fan when the engine is hot. The fan may start

running suddenly!

● Do not unscrew the cap on the coolant expansion tank when the en-

gine is hot. The cooling system is under pressure!

● Protect face, hands and arms from any hot steam or hot coolant re-

leased by covering the cap with a large, thick rag when opening the ex-

pansion tank.

● Do not leave any objects, such as cloths and tools, in the engine com-

partment.

● When working underneath the vehicle, secure it so that it cannot roll

away and support it safely on suitable supports. The hydraulic jack is not

sufficient for this purpose. Risk of injuries!

● If any tests have to be performed with the engine running, there is an

extra safety risk from rotating parts, such as the drive belt, alternator

and radiator fan, etc., and from the high-voltage ignition system. You

should also note the following:

–Never touch the electrical wiring of the ignition system.

– Keep away from moving engine parts when wearing jewellery,

loose clothing or long hair. Risk of fatal injuries! All jewellery must be

removed, hair tied back and close-fitting clothing worn.

● Observe the following additional warnings if work on the fuel system

or the electrical system is necessary.

–Always disconnect the battery from the on-board network.

– Do not smoke.

Page 195 of 258

193

Checking and refilling levels

– The positive terminal (+) of the battery is connected in reverse

order.

Checking battery acid level

Fig. 130 Battery: Acid

level indicator

We recommend you have the acid level regularly checked at an official tech-

nical service, particularly in the following cases.

● At high outside temperatures.

● On long daily trips.

● Whenever the vehicle is loaded ⇒ page 193, Charging the battery.

In vehicles equipped with a battery with colour indicator, the so-called mag-

ic eye ⇒ Fig. 130 changes colour to indicate the acid level.

Air bubbles can influence the colour of the indicator. Therefore, carefully

knock the indicator before checking the acid level.

● Black – the acid level is correct.

● Colourless or light yellow – acid level too low, battery must be changed.

Note

● The battery acid level is also regularly checked during servicing at au-

thorised SEAT dealers.

● The acid level on “AGM” vehicle batteries cannot be checked for techni-

cal reasons.

● Vehicles equipped with the “START-STOP” system include a battery con-

trol unit to control the battery level for repeat engine starting.

Winter service

At low temperatures the battery provides only a fraction of the starting pow-

er it has at normal temperatures.

A flat battery can also freeze at temperatures slightly below 0 °C (32 °F).

We therefore recommend you have the battery checked and, if necessary,

charged at an official SEAT technical service before the start of winter.

Charging the battery

A fully-charged battery is essential for reliable starting.

– Switch off the ignition and all electrical equipment.

– For “fast-charging” only: disconnect both battery connection ca-

bles (first the “negative” terminal and then the “positive”).

– Connect the charger cables to the battery terminals (red = “pos-

itive”, black = “negative”).

– Plug in the battery charger and switch on.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 196 of 258

194Checking and refilling levels

–After charging the battery: Switch off the battery charger and

disconnect the cable.

– Remove the charger cables.

– If necessary, reconnect both battery cables to the battery (first

the “positive” cable, then the “negative” cable).

When charging with a low current (e.g. with a small battery charger), the

battery does not have to be disconnected. The instructions of the battery

charger manufacturer must be followed.

Use a current equivalent to or lower than 10% of the battery capacity to fully

charge the battery.

Before “fast-charging” the battery however, both battery cables must be

disconnected.

“Fast-charging” a battery is dangerous and requires a battery charger and

special knowledge. Fast charges should be performed by an official techni-

cal service.

The battery caps should not be opened while the battery is being charged.

CAUTION

In vehicles fitted with the “START-STOP” system, the charger cable cannot

be directly connected to the negative terminal of the vehicle battery but

must be attached to the engine earthing point ⇒ page 216.

Disconnecting and connecting the battery

The following functions will either be inoperative or will not work properly

after disconnecting and reconnecting the battery:

effectInstallationSetting the clock⇒ page 60The multifunction display data is deleted⇒ page 61

Note

We recommend having the vehicle checked by an authorised SEAT dealer to

guarantee the correct working order of all electrical systems.

Changing the battery

A replacement battery must have the same capacity, voltage, current rating

and size as the original. The appropriate types of battery can be acquired

from authorised SEAT dealers.

We recommend having the battery changed by an authorised SEAT dealer,

where the new battery will be correctly installed and the original disposed

of in line with regulations.

Automatic disconnection of electrical equipment

When heavily-charging a battery, the programme selected by the electrical

system control unit prevents the battery from automatically discharging.

This may result in the following:

● Increase in idling speed so that the alternator can supply more current

to the electrical system.

● The performance of certain electrical components could be limited or

some may switch off temporarily, e.g. the heated seats, the heated rear win-

dow, the 12V power socket.

Page 210 of 258

208Self-help

WARNING (Continued)

● Always raise the vehicle with the doors closed.

● Never place parts of your body, e.g. arms and legs, underneath the

vehicle when supported only by the jack.

● Secure the base of the jack with suitable supports so that it cannot

slip. The jack could slide if the ground below it is soft and slippery and

the vehicle could slip off it. Therefore, place the jack on a firm surface or

use a large, stable base. On a slippery surface, e.g. tiles, use a non-slip

base such as a rubber mat.

● Never start the engine when the vehicle is raised. Risk of injury.

● The jack should only be used in the correct jacking points.

CAUTION

● The prescribed tightening torque for wheel bolts on steel and alloy

wheels is 120 Nm.

● If the anti-theft wheel bolt is overly tightened, this could damage the

bolt and the adapter

Note

● The set of anti-theft wheel bolts or the adapter are available from au-

thorised SEAT dealers.

● Please observe the relevant local legal regulations when changing the

wheel.

Preparation work

Some preparation is required before changing a wheel:

– If you have a flat tyre, stop the vehicle as far away as possible

from moving traffic. The surface must be horizontal.–

All vehicle occupants should leave the vehicle . Vehicle occu-

pants should waiting in a safe place, e.g. behind the roadside

crash barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral or move the selector

lever on the automatic gearbox to position P.

– Apply the handbrake firmly.

– If towing a trailer, unhitch it.

– Take the vehicle tool kit ⇒ page 207 and the spare wheel

⇒ page 207 out of the luggage compartment.

Changing a wheel

If possible, change the wheel on a level surface.

– Pull off the hub cap ⇒ page 200 or the wheel bolt covers

⇒ page 200.

– First loosen the anti-theft wheel bolts and then the other wheel

bolts ⇒ page 209.

– Raise the vehicle until the wheel to be changed is no longer

touching the ground ⇒ page 210.

– Remove the wheel bolts and place them on a clean surface

(cloth, paper, etc.).

– Take off the wheel.

– Lift the spare wheel into position and tighten the wheel bolts

lightly.

Page 215 of 258

213

Self-help

Before using the tyre repair kit

The following jobs must be performed before using the tyre repair

kit:

– If you have a flat tyre, stop the vehicle well away from moving

traffic. Stop on flat, solid ground.

– All vehicle occupants should leave the vehicle. Vehicle occu-

pants should waiting in a safe place, e.g. behind the roadside

crash barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral or move the selector

lever on the automatic gearbox to position P.

– Apply the handbrake firmly.

– Check whether the tyre can be repaired using the tyre repair kit

⇒ page 211.

– If towing a trailer, unhitch it.

– Take the tyre repair kit out of the luggage compartment.

– Fix the sticker 2

⇒ Fig. 142 ⇒

page 212 onto the dash panel

where the driver will see it.

– Do not remove the foreign body, e.g. bolts or nails, from the

tyre.

– Unscrew the tyre valve cap.

– Using the valve extractor 1

, unscrew the valve insert and place

it onto a clean surface (cloth, paper, etc.) Filling and inflating the tyre

Filling the tyre

–

Shake the tyre sealant can 10

⇒ Fig. 142 ⇒ page 212 thorough-

ly several times.

– Attach the flexible filling hose 3

onto the can 10. The foil seal-

ing the can will be automatically pierced.

– Remove the cap from the flexible filling hose 3

and insert the

open end as far as it will go into the tyre valve.

– Hold the can 10

upside down and fill the complete contents of

the can into the tyre.

– Remove the empty can from the tyre.

– Screw the valve insert back into the tyre valve using the valve

extractor 1

.

Inflating the tyre

– Screw the tyre filling hose 5

⇒ Fig. 142 ⇒ page 212 firmly onto

the tyre valve.

– Make sure that the bleed screw 7

is closed.

– Start the vehicle engine and leave it running.

– Plug the connector 9

into the 12-volt power socket.

– Turn the air compressor on with the switch 8

.

– Leave the air compressor running until the tyre pressure has

reached 2.0-2.5 bar (29-36 psi / 200-250 kPa). Max. operating

time for the compressor is 8 minutes ⇒

!

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 217 of 258

215

Self-help

Both batteries must be rated at 12 Volts. The capacity (Ah) of the booster

battery should not be significantly lower than that of the discharged battery.

Jump leads

The jump leads must be heavy enough to carry the starter current and must

be fitted with insulated battery clamps. Refer to the instructions given by

the manufacturer.

Positive cable – usually red

Negative cable – usually black

WARNING

● A flat battery can also freeze at temperatures slightly below 0 °C

(32 °F). Do not attempt a jump start with a frozen battery – Explosion

hazard!

● Please note the safety warnings referring to working in the engine

compartment ⇒ page 182.

● The non-insulated parts of the battery clamps must not be allowed to

touch. Additionally, the jump lead attached to the positive battery termi-

nal must not touch metal parts of the vehicle. Risk of short circuit!

● Do not connect the negative lead to the negative terminal of the dis-

charged battery. In the event of sparks when starting the engine, the ex-

plosive gas given off by the battery could catch fire.

● Position the jump leads in such a way that they cannot come into con-

tact with any moving parts in the engine compartment.

● Do not bend over the battery. Risk of acid burns!

● The screw plugs on the battery cells must be screwed in firmly.

● Keep sources of fire (flames, lit cigarettes, etc.) away from the bat-

tery. Risk of explosion!

● Never use the jump leads on batteries in which the electrolyte level is

too low. Risk of explosion and acid burns.

Note

● The vehicles must not touch each other, as electricity could flow as soon

as the positive terminals are connected.

● The discharged battery must be properly connected to the vehicle elec-

trical system.

● The jump leads should be checked in a specialist vehicle battery shop.

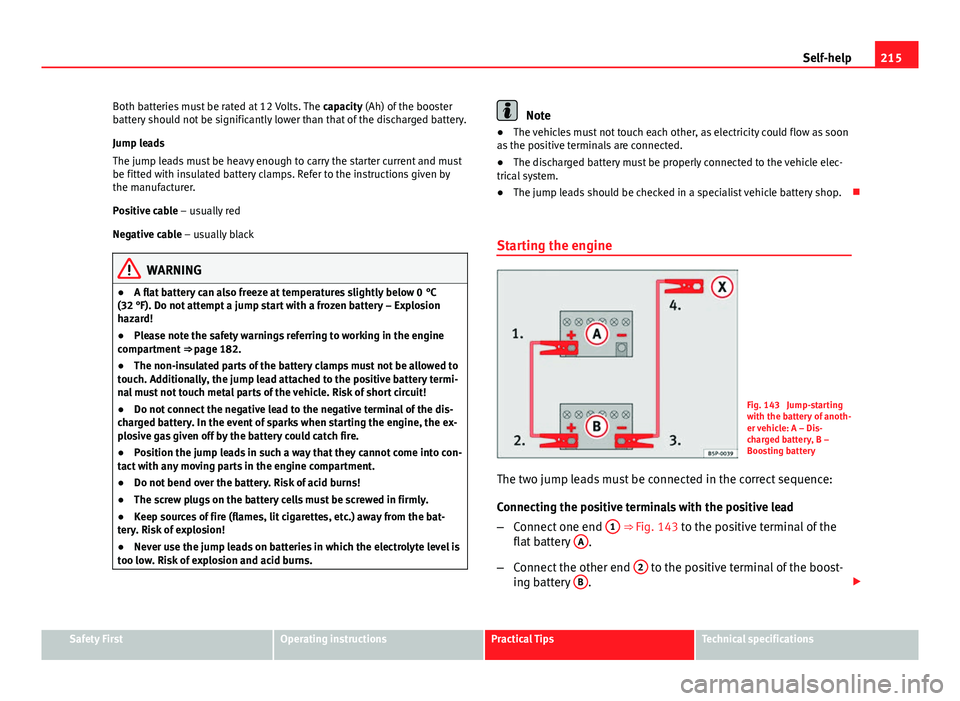

Starting the engine

Fig. 143 Jump-starting

with the battery of anoth-

er vehicle: A – Dis-

charged battery, B –

Boosting battery

The two jump leads must be connected in the correct sequence:

Connecting the positive terminals with the positive lead

– Connect one end 1

⇒ Fig. 143 to the positive terminal of the

flat battery A.

– Connect the other end 2

to the positive terminal of the boost-

ing battery B.

Safety FirstOperating instructionsPractical TipsTechnical specifications