lock Seat Toledo 2016 Manual PDF

[x] Cancel search | Manufacturer: SEAT, Model Year: 2016, Model line: Toledo, Model: Seat Toledo 2016Pages: 248, PDF Size: 5.82 MB

Page 162 of 248

Operation

lock is only applied if the brake is not press-

ed and the sel ect

or l

ever is moved to position

N for more than 2 seconds.

The selector lever only locks when the is vehi-

cle stationary or driving at a speed lower

than 5 km/h (3 mph). At a higher speed, it

automatically disconnects in the N position.

Interlock button

The interlock button on the selector lever

knob prevents the driver from inadvertently

engaging a gear. Press the button to unlock

the selector lever.

Safety interlock for ignition key 1)

After switching off the ignition, you can only

remove the ignition key if the selector lever is

in position P. When the ignition key is re-

moved, the selector lever is locked in posi-

tion P.

Driving programmes Your vehicle is equipped with an electronical-

ly

-c

ontr

olled automatic gearbox. Shifting up

or down depends on the programme selec-

ted.

For a calm driving style, the gearbox uses the

most economic programme. The gearbox shifts up as quickly as possible and shifts

down as

late as possible, thus increasing

driving economy.

With a sporty driving style , characterised by

sudden acceleration, heavy acceleration,

speeds that often increase and decrease and

maximum speed, the gearbox adapts to this

driving style when the accelerator is pressed

down fully (kick-down) by shifting down as

quickly as possible and can even shift down

by several gears at once.

Selecting the best driving programmes is an

endless job. Regardless of this, the driver can

also make the gearbox switch to a more dy-

namic gear shift programme by pressing the

accelerator quickly. This makes the automatic

gearbox shift down into a lower gear than the

one that would normally apply to the current

speed, allowing for more rapid acceleration

(e.g. to overtake another vehicle) without

having to press the accelerator until the kick-

down position. On shifting up in a corre-

sponding driving style, the gearbox returns to

the original programme.

When driving along mountain roads, the

gearbox adapts to the gradients. This avoids

having to frequently change gears when driv-

ing uphill. In Tiptronic mode, it is possible to

shift down manually when driving downhill to

use the braking effect of the engine. Backup programme A back-up programme exists in case of faults.

In the event

of

a fault in the gearbox electron-

ics, it will continue to work in one of the cor-

responding back-up programmes. All seg-

ments of the screen are lit up or switched off.

The fault can be seen as follows:

● The gearbox only engages certain gears

● Reverse gear R cannot be en

gaged

● The manual gearbox switches off in the

bac k

-up programme Note

If the gearbox switches to the back-up pro-

gramme, v

isit an Authorised Service as soon

as possible to solve the problem. Gearbox malfunctions

Gearbox: Fault! Stop the ve-

hicle and place the lever in the

position P.

There i s

a fault in the gearbox. Stop the vehi-

cle in a safe place and do not continue driv-

ing. Seek specialist assistance. 1)

Valid only for certain countries.

160

Page 187 of 248

Towing bracket device

Driving with a trailer Exterior mirrors

Check

whether

you can see enough of the

road behind the trailer with the standard rear

vision mirrors. If this is not the case, you

should have additional exterior mirrors fitted.

Observe the relevant statutory requirements

of the country you are in.

Headlights

Before starting a journey, also check the

headlight beam settings with the trailer

hitched up. Adjust the headlight range set-

tings if necessary ›››

page 117, Main light

range control .

Driving speed

For your own safety do not drive faster than

the maximum permitted speed indicated on

the trailer.

At all times, immediately reduce speed if you

detect the slightest swaying movement of the

trailer. Never try to “return the trailer to a

straight position” by accelerating.

Brakes

Brake in due course! If the trailer has an over-

run brake, apply the brakes gently at first and

then, firmly. This will prevent the jerking that

can be caused by locking of trailer wheels.

Change to a lower gear in good time before descending a slope in order to take advant-

age of

the en

gine brake.

The trailer is incorporated into the vehicle's

anti-theft alarm system:

● When the vehicle has a factory-fitted anti-

theft al

arm and a towing bracket.

● When the trailer is electrically connected to

the vehic

le via the towing bracket socket.

● When the vehicle electrical device and the

tow

ing bracket are operational.

● When the vehicle is locked and the vehi-

cle's

anti-theft alarm device is activated.

Once the electrical connection is interrupted

with the vehicle trailer locked, the alarm

sounds.

Always switch off the vehicle anti-theft alarm

device before connecting or disconnecting a

trailer. The vehicle anti-theft alarm device

could cause the alarm to sound ››› page 112,

Anti-theft alarm system*.

Engine overheating

In the event that the coolant temperature

gauge needle moves to the right section of

the scale or to the red area, immediately re-

duce speed. If the control lamp flashes on

the general instrument panel, stop the vehi-

cle and switch off the engine. Wait several

minutes and check the coolant level in the

tank ››› page 208. Please observe the following indications

›››

page 208, Control lamp .

The coolant temperature can be reduced by

switching on the heating. WARNING

● Adjus t

your speed to suit the road and traf-

fic conditions.

● An electrical installation that is connected

incorrectly

or by non-specialised personnel

can prevent the connection of the current to

the trailer and cause faults in the operation of

the electrical system throughout the entire

vehicle, leading to accidents and serious in-

jury.

● All electrical work must be carried out only

by s

pecialised services.

● Never directly connect the trailer electrical

device t

o the electrical sockets of the reverse

driving lights or other sources of electrical

current. CAUTION

● Av oid c

orners, and sudden and sharp brak-

ing.

● Once the trailing arm has been removed,

plac

e the corresponding cover on the hole of

the fastening point. This prevents dirt from

entering the hole – see the trailer system as-

sembly manual. » 185

Technical data

Advice

Operation

Emergencies

Safety

Page 189 of 248

Towing bracket device

Clamping bush

C l

ampin

g bush cap

Ball head cover

Ball-headed bar

Locking balls

Centred

Red marking on the manual regulator

Manual regulator

Key

Key slot cover

Red marking on the manual regulator

White marking on the ball-headed bar Note

Contact an Authorised Service Partner if you

lose y

our key. 3

4

5

6

7

8

9

10

11

12

13

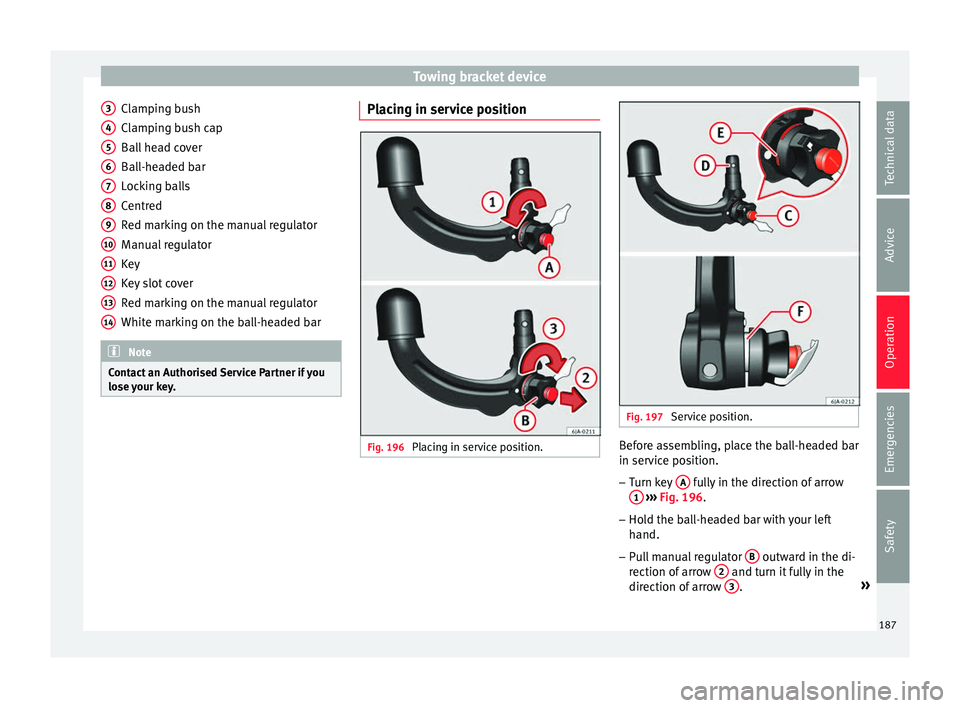

14 Placing in service position

Fig. 196

Placing in service position. Fig. 197

Service position. Before assembling, place the ball-headed bar

in ser

v

ic

e position.

– Turn key A fully in the direction of arrow

1

› ›

› Fig. 196

.

– Hold the ball-headed bar with your left

hand.

– Pu

ll manual regulator B outward in the di-

r ection of

arr

ow 2 and turn it fully in the

dir ection of

arr

ow 3 .

»

187

Technical data

Advice

Operation

Emergencies

Safety

Page 190 of 248

Operation

The manual regulator will remain in this posi-

tion.

Ser v

ic

e position ››› Fig. 197

● Key C is in an open position – the key ar-

r o

w points

to the “unlocked” symbol. The key

cannot be removed from the key slot.

● The D locking balls may be fully inserted

int o the body

of

the ball-headed bar by ap-

plying some pressure.

● The red E marking on the manual regula-

t or points

t

owards the white marking on the

ball-headed bar.

● Between the manual regulator and the

body of the b

all-headed bar there is a clearly

visible space of approximately 4 mm F .

Onc e the b

al

l-headed bar has been posi-

tioned like this, it will be ready to be placed

in the clamping bush. WARNING

Do not use the ball-headed bar if it cannot be

corr ectly

placed in the service position. CAUTION

The key cannot be removed from the manual

re gu

lator key slot when it is in the service po-

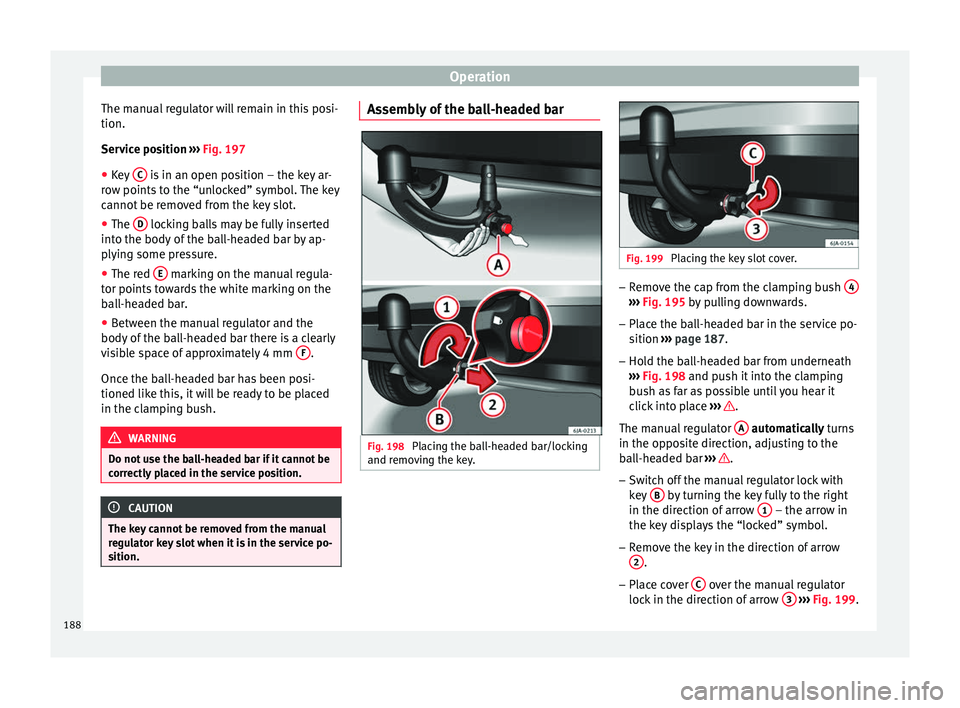

sition. Assembly of the ball-headed bar

Fig. 198

Placing the ball-headed bar/locking

and r emo

v

ing the key. Fig. 199

Placing the key slot cover. –

Remove the cap from the clamping bush 4 ›››

Fig. 195 by p

ulling downwards.

– Place the ball-headed bar in the service po-

sition ››

› page 187.

– Hold the ball-headed bar from underneath

›››

Fig. 198 and push it into the clamping

bush as far as possible until you hear it

click into place ››› .

The m anual

r

egulator A aut

omatically turns

in the op po

site direction, adjusting to the

ball-headed bar ››› .

– Switch off the manual regulator lock with

key

B by turning the key fully to the right

in the dir ection of

arr

ow 1 – the arrow in

the k ey

di

splays the “locked” symbol.

– Remove the key in the direction of arrow

2 .

– Place cover C over the manual regulator

loc k

in the dir

ection of arrow 3

› ›

› Fig. 199 .

188

Page 191 of 248

Towing bracket device

– Verif

y

the correct placement of the ball-

headed bar ››› page 189. WARNING

● Do not ho l

d the manual regulator with your

hand when fitting the ball-headed bar since

you could sustain injuries to your fingers.

● When mounting the ball-headed bar, al-

way

s lock it with a key and remove the key

from the slot.

● The ball-headed bar must not be in the

servic

e position with the key in the key slot.

● If the ball-headed bar is not placed in the

servic

e position you will not be able to place

it in the clamping bush. CAUTION

When removing the key, always place the

co v

er over the key slot of the manual regula-

tor to prevent dirt from entering. Note

Once removed, place the clamping bush cap

in an appr opri

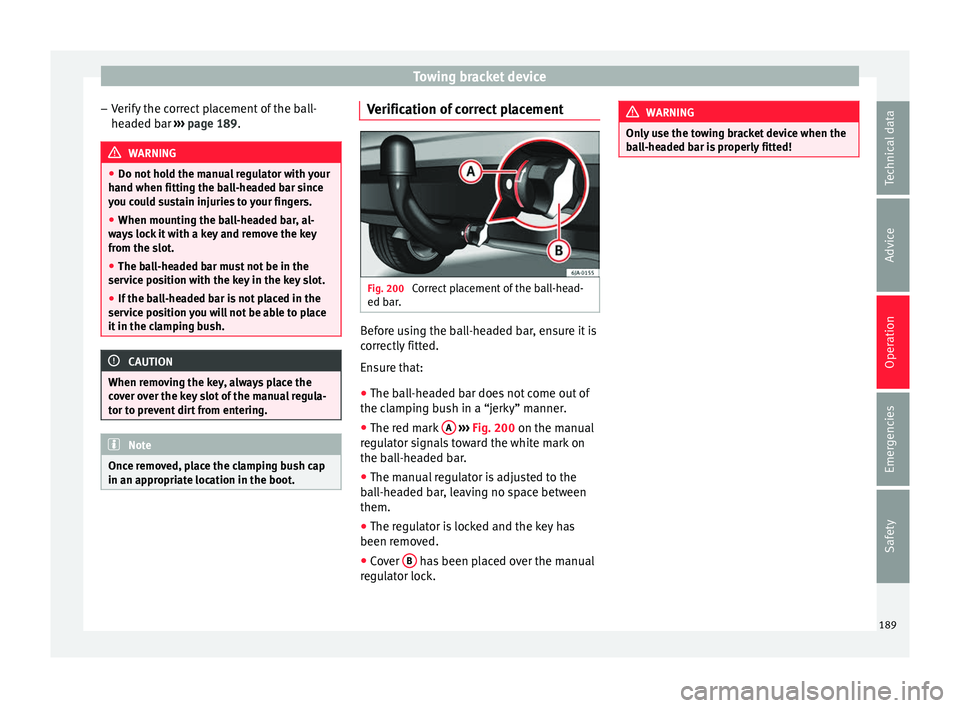

ate location in the boot. Verification of correct placement

Fig. 200

Correct placement of the ball-head-

ed b ar

. Before using the ball-headed bar, ensure it is

c

orr

ectly

fitted.

Ensure that:

● The ball-headed bar does not come out of

the clampin

g bush in a “jerky” manner.

● The red mark A

› ›

› Fig. 200

on the manual

regulator signals toward the white mark on

the ball-headed bar.

● The manual regulator is adjusted to the

ball-he

aded bar, leaving no space between

them.

● The regulator is locked and the key has

been remov

ed.

● Cover B has been placed over the manual

r e gu

lator lock. WARNING

Only use the towing bracket device when the

ba l

l-headed bar is properly fitted! 189

Technical data

Advice

Operation

Emergencies

Safety

Page 192 of 248

Operation

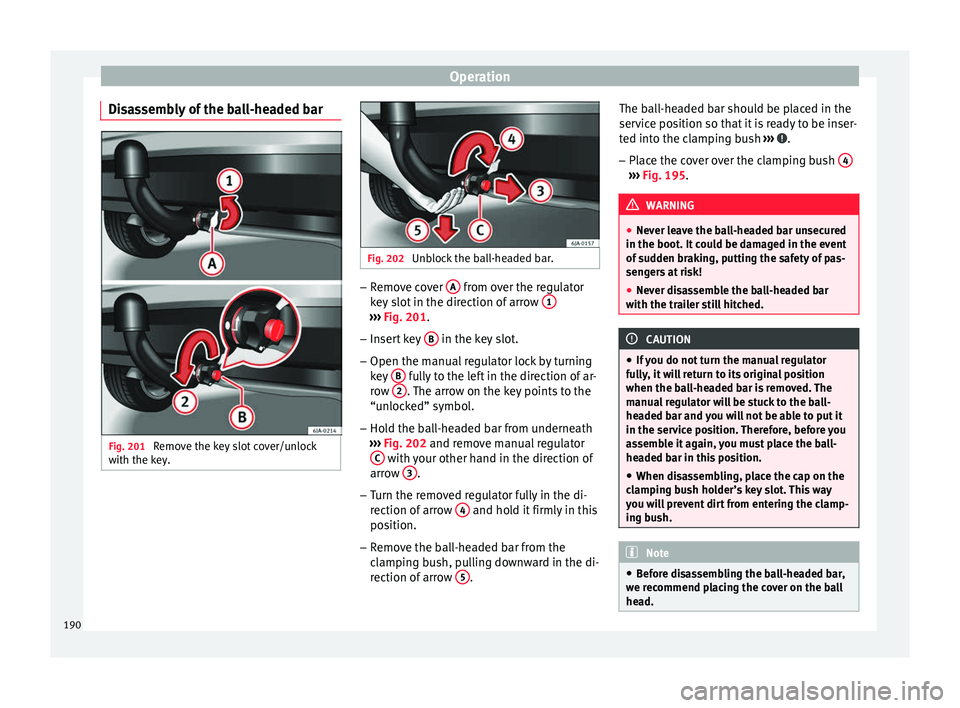

Disassembly of the ball-headed bar Fig. 201

Remove the key slot cover/unlock

w ith the k

ey

. Fig. 202

Unblock the ball-headed bar. –

Remove cover A from over the regulator

k ey

s

lot in the direction of arrow 1 ›››

Fig. 201.

– Insert key B in the key slot.

– Open the manual regulator lock by turning

key

B fully to the left in the direction of ar-

r o

w 2 . The arrow on the key points to the

“u n

loc

ked” symbol.

– Hold the ball-headed bar from underneath

›››

Fig. 202 and remove manual regulator

C with your other hand in the direction of

arr o

w 3 .

– Turn the removed regulator fully in the di-

rection of

arr

ow 4 and hold it firmly in this

po s

ition.

– R

emove the ball-headed bar from the

clampin

g bush, pulling downward in the di-

rection of arrow 5 .The ball-headed bar should be placed in the

ser

v

ic

e position so that it is ready to be inser-

ted into the clamping bush ››› .

– Place the cover over the clamping bush 4 ›››

Fig. 195. WARNING

● Never leave the ball-headed bar unsecured

in the boot. It c

ould be damaged in the event

of sudden braking, putting the safety of pas-

sengers at risk!

● Never disassemble the ball-headed bar

with the trai

ler still hitched. CAUTION

● If y

ou do not turn the manual regulator

fully, it will return to its original position

when the ball-headed bar is removed. The

manual regulator will be stuck to the ball-

headed bar and you will not be able to put it

in the service position. Therefore, before you

assemble it again, you must place the ball-

headed bar in this position.

● When disassembling, place the cap on the

clampin

g bush holder’s key slot. This way

you will prevent dirt from entering the clamp-

ing bush. Note

● Bef or

e disassembling the ball-headed bar,

we recommend placing the cover on the ball

head. 190

Page 195 of 248

Care and maintenance

●

The modification of the s

uspension of the

vehicle wheels, including the use of non-per-

mitted combinations of tyres and rims can al-

ter the operation of the airbag system and in-

crease the risk of serious or fatal injuries in

an accident.

● During all jobs on the airbag system, in ad-

dition to the remo

val and fitting of parts of

the system in the course of other repair jobs,

parts of the airbag system can be damaged.

Therefore in the event of an accident, this

may cause the airbags to activate incorrectly

or not activate at all. Radio and aerial reception

In vehicles factory-fitted with an audio or

n

av

ig

ation system, the aerial may be instal-

led in different places:

● inside the rear window next to the heating

elements,

● on the roof

of the vehicle.

Care and cleaning Introduction Regular and suitable care helps to

m

aint ain

the u

seful life of your vehicle. This may also

be one of the requirements for upholding any warranty claims in the event of corrosion or

paint def

ects.

We recommend you use cleaning products

from the SEAT Original Accessories pro-

gramme available in SEAT dealers. Please fol-

low the instructions for use on the packag-

ing. WARNING

● Cle

aning products and other materials used

for car care can damage the health if mis-

used.

● Always keep car care materials in a safe

plac

e out of the reach of children. Risk of poi-

soning!

● When washing the car during the winter

season: Moi

sture and ice on the brakes may

affect braking efficiency. Risk of accident!

● The ignition must always be switched off

when the car is

washed. Risk of accident!

● Do not clean the underside of the car or in-

side the wheel ar

ches without protecting your

hands and arms. You may cut yourself on

sharp metal parts!

● Perfumes and air fresheners inside the ve-

hicle m

ay be harmful to health at high tem-

peratures in the interior. CAUTION

● Check the c

olour-fastness of your clothing

to avoid damaging or visibly staining the fab-

ric (leather), upholstery and fabric trim. ●

Cle

aning products containing solvents may

damage the material being cleaned.

● Do not wash the vehicle in direct sunlight.

Risk of

damage to paintwork.

● If washing the vehicle with a hose in win-

ter, do not

direct the jet of water directly at

the locks or at the door seals or bonnet. Risk

of freezing.

● Do not use sponges for removing insects or

abras

ive household sponges, etc. on painted

surfaces. Risk of damage to the painted sur-

face!

● Do not put stickers on the inner side of the

rear w

indow in areas where heating elements

or the aerial are located. This could cause

damage and, in the case of the aerial, radio

and navigation system reception faults.

● Do not clean the inside of the window with

sharp ob

jects or corrosive or acidic cleaning

products. Risk of damaging the heating ele-

ments or the aerial.

● Do not attach any fragrance or air freshener

to the da

sh panel. Risk of damage to the

dash panel!

● To avoid damaging the parking aid system

sensors, s

pray them only briefly at a mini-

mum distance of 10 cm when cleaning the ve-

hicle with a high-pressure or steam cleaner.

● Do not clean the roof panel with a brush.

Risk of

damage to the panel surface! » 193

Technical data

Advice

Operation

Emergencies

Safety

Page 198 of 248

Advice

Damage to the paint Minor damage to the paint, such as scratches

or st

one c

hips, should be touched up without

delay using paint.

Suitable touch-up brushes or sprays for the

colour of your vehicle can be purchased from

authorised SEAT dealers. Note

We recommend you leave paint damage re-

pair s

to a SEAT Authorised Service. Plastic parts

Exterior plastic parts will come clean using a

d

amp c

loth. If

this is not sufficient, plastic

parts can also be treated with special sol-

vent-free plastic cleaning detergents .

Do not use paint cleaners, polishes or wax on

plastic parts.

Windows and mirrors Remove snow and ice from windows and rear

v

i

s

ion mirrors with a plastic scraper only. To

avoid damaging the surface of the glass, the

scraper should only be pushed in one direc-

tion and not moved to and fro. The windows should also be cleaned on the

inside at

regular intervals.

Use a separate cloth or chamois to dry the

windows and rear vision mirrors.

Do not use the chamois used to polish the

bodywork to dry the windows. Waxing and

polishing residues could cause smears on

the glass and hinder visibility. CAUTION

● Never u se hot

or boiling water to remove

snow and ice from the windows. Risk of crack-

ing glass!

● Make sure you do not damage the paint-

work on the

vehicle on removing snow and

ice from the windows and rear vision mirrors.

● Do not remove the snow or ice dirty with

thick p

articles, e.g. gravel, sand or road salt,

from windows and mirrors. Risk of damage to

the glass and mirror surfaces. Headlights

Use soap and clean, hot water to clean the

fr

ont

he

adlights. CAUTION

● Never rub the he a

dlights to dry them and

do not use sharp objects to clean the plastic

glass material. These could damage the pro- tective paint and cause the headlights to

cr

ac

k.

● Do not use aggressive cleaning products or

chemica

l solvents to clean the glass. This

could damage the headlights. Caring for rubber seals

The weatherstrips on doors and windows will

rem

ain p

liable and last longer if they are oc-

casionally treated with a suitable rubber care

product. This will prevent premature ageing

and leaks. If they are properly cared for, the

seals will be less likely to freeze up in the

winter.

Door lock cylinder Special products must be used to defrost

loc

k

cylinder

s. Note

● Mak e s

ure, when washing the vehicle, that

the least amount of water possible enters the

lock cylinders.

● We recommend the use of products from

the selection of

SEAT Original Accessories to

care for the door lock cylinder. 196

Page 200 of 248

Advice

The dye used in many garments, for example

d ark

j

eans, is not always sufficiently colour-

fast. Seat upholstery (fabric and leather), es-

pecially when light-coloured, may visibly dis-

colour if the dye comes out of clothing, even

in normal conditions. This is not an uphols-

tery defect but indicates that the dye in the

item of clothing is not solid enough.

Heated seat upholstery Do not clean the seat upholstery with

damp

pr oduct

s, as this could damage the seat

heating system.

Clean the upholstery with special products,

e.g. dry foam, etc.

Natural leather Leather should be looked after from time to

time, dependin

g on its

u

se.

Normal cleaning

Moisten a cotton or woollen cloth with water

and wipe over the leather surfaces.

More stubborn dirt

Do not let water soak through the leather or

penetrate the seams.

Dry it with a soft, dry cloth. Removing stains

Remov

e fresh water-based stains such as cof-

fee, tea, juices, blood, etc. with an absorbent

cloth or kitchen roll. Use the special deter-

gent to clean dried-on stains.

Remove fresh fat-based stains such as but-

ter, mayonnaise, chocolate, etc. with an ab-

sorbent cloth or paper towel or use the spe-

cial detergent if the stain has not yet soaked

through the surface.

Use a grease-dissolving product to treat

dried-in, fat-based stains.

Treat less common stains such as ball-pen

and other inks, felt-tip pens, nail polish,

emulsion paint, shoe cream etc. with a spe-

cial leather stain remover.

Leather care

The leather should be treated regularly

(about twice a year) with a leather-care prod-

uct.

Apply the protective product very sparingly.

Dry the leather with a soft, dry cloth. CAUTION

● Av oid e

xposing leather to direct sunlight

for long periods so that it does not lose its

colour. If the car is left for a prolonged period

outdoors, cover the leather so that it does

not lose its colour. ●

Sharp-edg ed o

bjects on clothing, such as

zips, rivets or belts can leave permanent

scratches and rough marks on the surface of

the leather.

● Use of a mechanical steering wheel lock

can dam

age the leather surface of the steer-

ing wheel. Note

● Use a s uit

able impregnating cream with ul-

tra-violet protection at regular intervals and

after cleaning. The cream will nourish and

moisturise the leather, keep it supple and

able to breathe. In addition, it will also help

to protect the surface of the leather.

● Clean the leather every 2 to 3 months and

remov

e fresh dirt as necessary.

● Preserve the colour of the leather. A special

colour

ed cream for leather will renew the col-

our of more heavily worn areas as required.

● Leather is a natural material with specific

propertie

s. During vehicle use, the appear-

ance of parts of the leather covers may

change; folds or wrinkles may appear as a re-

sult of their use. Seat belts

Keep the seat belts clean!

W

a

sh soi

led seat belts with mild, soapy wa-

ter, removing any heavier dirt with a soft

brush.

198

Page 201 of 248

Checking and refilling levels

Check the condition of all seat belts at regu-

l ar int

er

vals.

Very soiled belts may not retract properly. WARNING

● The seat belt

s should never be removed

from the vehicle for cleaning.

● Never clean using chemical products, as

chemica

l detergents destroy the fabric. En-

sure that the seat belts do not come into con-

tact with corrosive fluids such as acids, etc.

● If you find any damage to the belt webbing,

belt fitting

s, the belt retractor or the buckle,

the belt in question must be replaced by an

Official Service.

● Make sure that the inertia reel seat belts

are comp

letely dry before allowing them to

retract. Checking and refilling levels

F uel

R ef

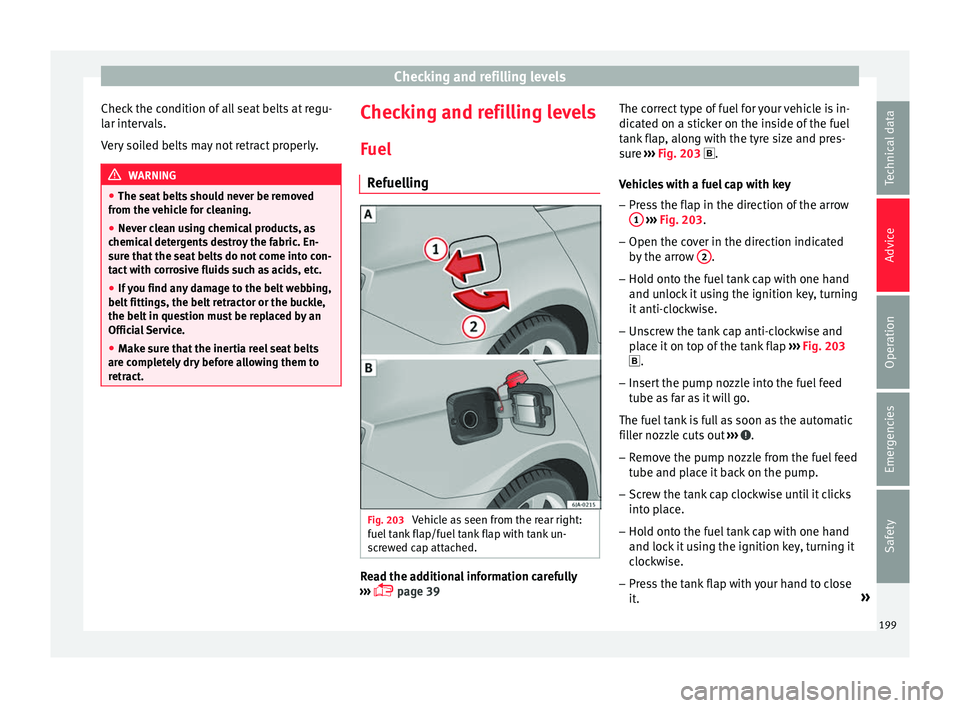

uelling Fig. 203

Vehicle as seen from the rear right:

f uel t

ank flap/fuel tank flap with tank un-

screwed cap attached. Read the additional information carefully

› ›

›

page 39 The correct type of fuel for your vehicle is in-

dicated on a s

ticker on the inside of the fuel

tank flap, along with the tyre size and pres-

sure ››› Fig. 203 .

Vehicles with a fuel cap with key

– Press the flap in the direction of the arrow

1

› ››

Fig. 203

.

– Open the c

over in the direction indicated

by the arr

ow 2 .

– Hold onto the fuel tank cap with one hand

and u n

loc

k it using the ignition key, turning

it anti-clockwise.

– Unscrew the tank cap anti-clockwise and

plac

e it on top of the tank flap ››› Fig. 203

.

– Insert the pump nozzle into the fuel feed

tube as

far as it will go.

The fuel tank is full as soon as the automatic

filler nozzle cuts out ››› .

– Remove the pump nozzle from the fuel feed

tube and p

l

ace it back on the pump.

– Screw the tank cap clockwise until it clicks

into pl

ace.

– Hold onto the fuel tank cap with one hand

and lock it

using the ignition key, turning it

clockwise.

– Press the tank flap with your hand to close

it. »

199

Technical data

Advice

Operation

Emergencies

Safety