checking oil SKODA 105S 1980 User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 105S, Model: SKODA 105S 1980Pages: 238, PDF Size: 47.09 MB

Page 179 of 238

(

1

z

Strike the

slip-over ring off the circlip

(towords the motor windlng). Open the circlip

ond pull

it off the shoft together with the re-

leosed ports.

8. lf necessory, re-turn the commutotor ond

scrope or mill out the insulotion between the

lominotions. "Mikonit"

should be 0.4 to 0.8 mm

below the octive surfoce.

Note: The

switch connot be further token

opat. lf

defective, lt hcs to be reploced with

o new one. When cleoning ports

of the storter

motor, do not dip the ormoture or the pinion

with the idler into petrol

or onother degreosing

ogent.The some opplles to the end shieldswith

beorings. By dipping them in o degreosing

ogent, the beorings become procticolly

worth-

less"

Storter Motor Reossembly 1. Lubricote the hellx of the ormoture shoft

with greose -

see Chopter 15.2 'Lubriconts

of

foreing mokeu ond fit the pinion

with the idler

ond the slip-over ring in posltion.

Fit the

circlip

into the groove

in the shoft, ond drive the slip-

on ring over it. The pinion

with the idler must

move freely olong the shoft.

2. Slip the respective

woshers on the shoft in

their originol sequence (corrier

ring, distonce

ring, fibre ring, distonce ring) ond insert the

ormoture with the engoging lever

into the drive

end shield. 3. Suspend the switch

ormoture into the

pre-engoging lever ond bolt down the switch

lightly. Fit the lever pin

into the drive

end

shield ond lock it in position

with the retoiner.

4. Tighten the copscrews of the switch

ond

fit the stotor on the drive

end shield.

5. Instoll the respective

woshers into

the

commutotor end shield in

their originol se-

quence (the dished wosher with its centre

focing the shield, then the ploin

wosher, the

toothed wosher, ond the drive wosher).

6. Fit the commutotor end shield with lifted

brushes on the shoft (in

the position

occording

to the recess

for the excitotion outlet ond the

notch) ond screw in the clomping bolts.

7. Instoll the brush interconnecting strip ond

bolt it down together with the field winding

outlets to the positive

brush holders, lower the

brushes. 8. Fit the Insuloting strip in position

ond bolt

down the cover. 9. Test the storter mottr.

Diognosing Storter Motor Defects in Cor

o) lf the storter motor refuses

to operote, look

first for on interrupted connection between

the bottery ond

the storter

motor, the engine

eorthing ond the storter

motor, or the engine

eorthing ond the bottery. lf these connec-

tions ore in order (current

flows to the ter' DK

1575

Fig. 13.10/3 -

Storter Motor Testlng Connection

minols u30"

ond "50"

with switched on

ignition), stort looking for o foilure of the

storter motor switch. Even in this instonce,

the couse con be o fully dischorged or foulty

bottery.

b) lf the storter motor

continues running

even

ofter the ignition key hos been switched in

the switch box from the position "START",

it hos to be stopped without ony deloy by

disconnecting the bottery (using

its eorthed

pole).

c) lf the storter motor hos no power

to cronk

the engine, stort with switched-on heod-

lights. A

morked dimming indicotes c poorly

chorged bottery.

Tentotive Checking of

Storter Motor

Outside Cor

Connect the terminol "30'of

the storter

motor to o properly

chorged bottery ond incor'

porote on ommeter with o wide

meosuring ronge

into the circuit -

see Fig. 13.10/3.

Stort the

engine (feed

current to the terminol "50").

The

volue of the current ot idling speed must

not

exceed 65 omperes (not

considering the peok

ot

the first momentous deflection).

The storter motor must run noiselessly,

smoothly, ond the pinion

must move smoothly

into ond out of the rest position

(engoge

ond

diesengoge). The engoged pinion

must not ro-

tote direct on the foce of the slip-on ring. The

run-out of the storter motor must not lost longer

thon 8 seconds ofter the disconnection of the

switch from the current supply.

Inspect the brush pressure

springs. The

brushes must

beor on the commutotor by ot

leost two thirds of their surfoce ond they must

move freely in their cells.

The ormoture should hove o noticeoble oxiol

cleoronce (ploy)

not exceeding 0.7 mm.

At

o slight rototion of the pinion

in the direction

of the storter motor rototion,

the idlor must

slip

freely.

186

Page 212 of 238

I-

.'t Fig.

15.3/3 -

Oil Filter

oil f ilter bowl

witlr f ilter

element

centre-boll oil pressure

switclr pressure

oir. When driving often

on dusty roods,

ihe cleoning intervols

should

be shortened by

holf. For oir cleoner mointenonce in tropicol

re'

gions refer to

ChoPter 16.2.

Air Cleoner -

winter oPerotion

Remove the rubber

cop from

the cover exten-

sion orm ond

use it to stop the mouth of

the

orm. Fit o guide extension into

the cleored hole

in the ornr ond

insert the

corrugoted poper hose

(included in the

cor equipment) into

the

ex-

iension ond

the holder on the

intoke ond

ex-

houst monifold.

Give the

hose the required shope by

bending

it slowly ond corefully. Above

oll, ploce

it into

the holcier so thot

there is

o suff icient distonce

(wide enough to

insert o

finger) between it

crnd the exhot-tst monifold.

Tightening of

cYlinder heod bolts

The cylinder heod

bolts should be tightened

in the running-in period before

the gosket gets

settled ond then

ofter every replocement of the

gosket, i.e., ofter

obout 1,000

kilometres' For

itre tightening procedure,

s9e

Chopter

-2'16'

Check'ilg of vilve

cleoronce ofter

every tighten'

ing of tlie

cylinder heod

is o

routine procedure

which must not be omitted.

Volve Cleoronce

For checking procedures

ond odiusting volues,

refer to ChoPter 2.13.

Alternotor V'belt

Tensioning

Loosen the

nuts of the bolts

in the olternotor

f longe (fostening

it to

the engine ond

the strut)

ond'of itre

bottJ holding down

the strut on

the

olternotor, ond

swing

oside (tip)

the olternotor'

Adiust the

belt so

thot it gives

woy 10- to

15 mm midwoy between the

belt pulleys

when

depressed lightly (ot

if o- weight of obout

2 kg were opplieal with

the

finger ot this point'

LoCk the

olternotor in

this position

by tighten-

ing properlY

oll the nuts.

Belt dimensions: 9x9.5x1,0O0 mm.

To Cleon the

Distributor

The contoct breoker points, the

cover, ond

the rotor orm

of the distributor must never

be

greosy or dirty. Scrope off

ony burns on the

distributor cover.

lf you hove

cleoned the

distributor with

oetrol, do

not ref it the cover till ofter

the petrol

hos comPletelY evoPoroted.

222

oll

the greose

into the beorings. Tighten

the

cop thoioughly so

thot it connot be worked

loose by vibrotion.

Air Cleoner -

cleoning ond

replocing of

filter

element

Unclosp the cover

fostening clips

and lift

owoy the lid. Depress the

cross broce in

the

1ock6t, rotote

it

slightly to disengoge it, ond

withdrow the filter

element. Wipe

cleon the

inside of the

iocket, cleon

the filter

element or

reploce it with o new

one, ond reclose the oir

cleoner proceeding

in reverse order.

Shoke ond

top the filtet element to

rid it of

clirt porticles, oncl

blow it off ond through with

Fiq.15314

-

Lubricotor of

Woter Pump Beorings

Page 216 of 238

friction focing. lnodequote

ploy

results irr o too

short free trovel of the clutch pedol

ond on

olmost immediote clutch disengogement. Access

to the releose

cylinder con be goined

os de-

scribed in the previous porogroph

on clutch

lubricotion. Hold the rod protruding from

the

relose cylinder ond force

from it corefully the

releose lever, ogoinst which it is restingi

the

lever con be relieved by disengoging the ten-

sion (pull-off

) springs.

ln service, the forcing-off

must be ot leost

2 mm. Adiust it to 4

to 5 mm by odiusting the

length of the rod. After hoving

loosened the nut

on the rod

of the releose cylinder, rotote

the

releose finger to obtoin the correct rod

length.

Then retighten the nut, thus locking the releose

f inger in its position

on the rod.

lf the ploy

is correctly od justed,

the f ree

trovel of the

clutch pedol

pod should ronge

from 40 to 50 mm. lt should not be ollowed to

drop below '!0

to 15 mm. lf the described od-

justing procedure foils to bring the required

result, it is necessory to odjust the clutch

mech-

onism in occordonce with

informotion con

toined in Chopter 3.2.

Bleeding the Glutch Hydroulic System

The movement of the clutch pedol

is trons-

mitted hydroulicolly to the clutch releose cylin-

der. The couses ond symptoms of penetrotion

of oir into the hydroulic

system (similor

to the

broke hydroulic system) ore described in detoil

in the section deoling with brokes. The pro-

cedure of bleeding the clutch is the some os

wherr bleeding the brokes -

see Chopter 15.8.

Fig. 15.411-

Adiusting Elements of

Clutch

Control Mechonism

I -

releose cylinder rod, 2 -

releose cylinder,

3 -

releose lever, 4 -

bleed screw 15.5 GEARBOX

AND FINAL DRIVE UNIT

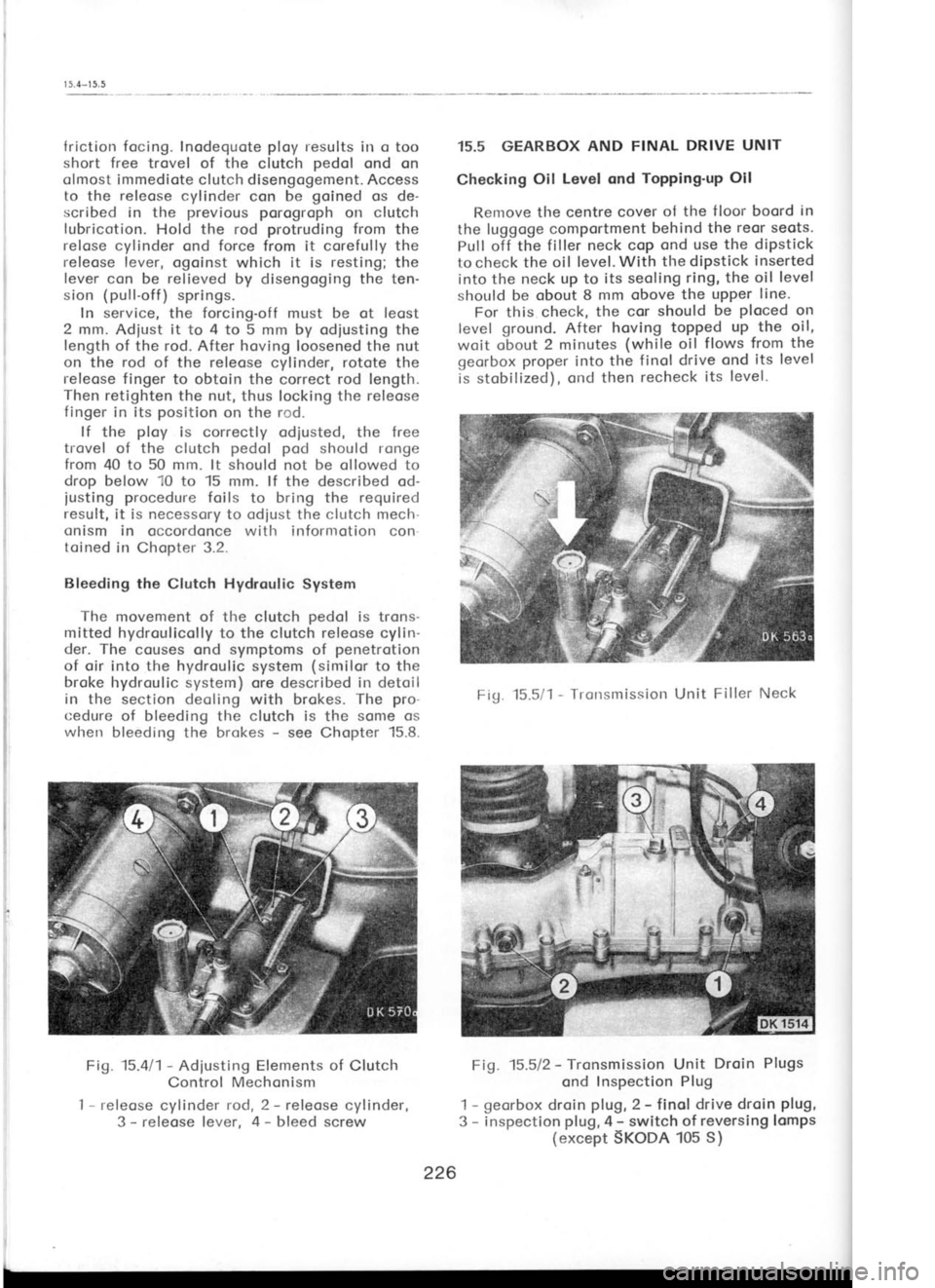

Checking Oil

Level ond Topping'up

Oil

Renrove the centre cover ol the

f loor boord in

the luggoge comportment behind the

reor seots.

Pull off the filler neck cop ond use

the dipstick

to check the oil level. With the diPstick inserted

into the neck up to its seoling ring, the oil level

should be obout 8 mm obove the upper line'

For this check, the cor

should be ploced

on

level ground.

After hoving topped up the oil,

woit obout 2 minutes (while

oil flows from the

georbox proper

into the finol drive ond its level

is stobilized), ond then recheck

its level-

Fig. 15.5/1 -

Tronsmission Unit Filler Neck

Fig. 15.512 -

Tronsmission Unit Droin

Plugs

ond Inspection Plug

1 -

georbox droin plug,

2 -

finol drive droin plug,

3 -

inspection plug,

4 -

switch of reversing lcmps

(except SKoDA 105 S)

ffi

;rt'i,*

tiiffi

ii.! i;

br'ill

226

Page 220 of 238

r

5.9-15. r

2

Dismontle the housing, remove

old greose,

cleon the individuol ports,

opply fresh greose,

ond reossemble the housing. Sook the felt rings

on the links (pull-rods)

in engine oil.

15.10 WHEELS AND TYRES, SNOW

CHAINS

Tyre Inflotion, Boloncing

ond lnterchonge

of Wheels

The procedures ore outlined in

Chopters 10.1

through 10.3. Snow

choins ond their use ore

deolt with in Chopter 10.6.

Wheel Toe-in -

see Chopter 16.1.

Shock Absorbers -

see Chopter 8.3 "Shock

Absorbers ".

15.11 ELECTRTCAL EQUTPMENT

Checking electrolyte level ond topping up --

see Chopter 13.2.

Sporking plugs -

electrode gop

odiustment,

etc. -

see Chopter 13.7.

Stqrter motor -

exqminqtion ond renewol of

brushes, etc. -

see Chopters 13.11 through 13.14.

lgnition timing, odiustment of contoct breoker

point gop, distributor lubricotion -

see Chop-

ter 15.3.

15.12 BODYWORK -

UNDERBODY

Woshing ond Mointenonce

The visible ports

of the body qre

f inislred in

o hord synthetic boking vornish, the remoining

ports in synthetic vornish.

The underbody is sproy-cooted

with o plostic

compound -

for detoiled informotion, see Chop-

ter '14.9.

Follow the

usuol procedures

when

woshing, cleoning ond polishing

the cor, ond

observe the specific instructions for

the use of

woshing ond cleoning preporotions,

issued by

their monufocturers.

All lights with the exception

of heodlomps

hove cosings of plostic

moteriols qnd

they

should be cleoned onlywith woteror shompoos.

When hosing down the corr

cover the voltoge

regulotor of the olternotor ond

the ignition coil

to protect

them ogoinst sploshing with woter,

ond do not

sproy woter direct on

the door lock

ond the lid covering the fuel

tonk filler neck.

Woshing ond Core of Underbody

Mechonisms

The underbody mechonisms

ore protected

with o synthetic vornish which stonds

well the

usuol woshing procedures.

Protect oll rubberports

ogoinst direct contoct with speciol chemi-

col solvLnts or limit the durotion of this

contoct

to o minimum before

o complete woshing off of

the solvents with woter (by

hosing down, etc.)'

Keep the oil cooler, if fitted on

the cor, in

cleon'condition. Hose

it down when woshing

the cor, ond if dirt still

sticks to the cooling

surfoces, use some of the detergents.

Bodywork Lubricotion

Routine mointenonce includes the

lubricotion

of door hinges ond limiters, hinges

ond releose

mechonismi of the engine bonnet ond boot lid,

the releose mechonism of

the spore wheel,

ond

the leveroge of windscreen wipers. Lubricotion

of inner dolor mechonisms is

included in

speciol

mqintenonce. Lubricote oll occessible mechcnisms

with

high-quolity greoses which

do not

dry, do not

oxldize, ond protect

the mechonisms ogoinst

corrosion for o long time. Oil is

not suitoble due

to its short-time efJect. Any greose con

be used

to lubricqte the

door limiters ond

the front

seot

slide roils.

Lubricotion of SporeWheel Corrier

Bearings-

Remove the spore wheel,

cleon the hinges, ond

opply oil on iheit

upper sides. In oddition, rub

in greose of ony brond.

Lubricotion of Windscreen Wiper

Leveroge -

Remove the cover of the

ioint (o

plostic cup),

f ill it with greose, lubricote the

ioint, ond

rein-

stoll tlre cover.

The Lubricotion of

Inner Door Mechonisms

is possible only

ofter removing the

door ponel

ond the inner 'door

mechonism. Use

only re-

commended greose brcnds.

Lubricote

the bowden

coble of thJwindow wind-up mechonism

with

Fig.15.1211- Lubricotion

of Windscreen Wiper

Leveroge Joint -

ioint cover

230