SKODA 105S 1980 Owner's Manual

Manufacturer: SKODA, Model Year: 1980, Model line: 105S, Model: SKODA 105S 1980Pages: 238, PDF Size: 47.09 MB

Page 21 of 238

tz

8Z-tZ 8 tl '

leeqtlrrAll u!

6ulsnoq t{clnlc 6u1ualso;

1;og

1ocldc

uaqM se

(1ro 6ugD

uoll Jelt

I

a6o66n1

Jol luaul

Apoq

6uttul SI

Slt

1 jztl

1 jztl

sJnoq-3Ji

qllM per

esoelD t

JOU!r

llotl

(;up

enbrol

6u ruelqDql uo!lceuuoc

HCrnlC

' 6n1d 6u1>1rodg

' qollms a.rnssald

116

' tlclltvrs arnssard

lro lo leloos

enlD^ lerloi arnssard

po

lo llog

e.oatd 6u;1cod dLund

len; lo llog

' 6n1d uto.t6

Marcs duns

116

'

lloq duns

p1g

' Aellnd ]loq tlDqsluDrc

lo llog

0c-02

9Z -OZ

99- 0S 9Z-ZZ 0L-8

st-0t suorsueulc

sz'LxvL L XOL

9'L X9L

9'L:X'L 8

9'LXZZ r^t

IAIA

IA

ll

tA

6-l

ozL -

001

99-99

9C-0e

s9-0s

8Z -92

zt -'92

9-t

9L-ZL 9L-ZL

8Z-92 9V-OV 9U\|

g'Lxoz 1l

.flxoL lN

.i 0L tl

,f

OL IA

8tA

8tA

, g

[,1

,.". 8 hl

8 tl

Lx8 tl

0L ll 11oq

1aaqmAl1

' roa6 UoLlsutDO lo llog

- slloq poaq

:aputll3

' '

lloq pDeq

repullAc

1o 1ng

lloq )solqlualls ,o lnN

lloq ra^o3

pDeq

rapu!1Ac

;o 1n5

' duund lenl ,o lnN

Aelqnd lleq dund ratDtvr

+o ]nN

' lloq por

Durlcauuoc

lo lnN

11oq 6ulroaq

llDLlsluoro lo lnN

(rup enbjdi

6u1u3fq611

8e0

gLZ

ttL

g',61

6e

9'08

9'6e 9'91 suo!susullc

r.rorlcauuoc

:lN19Nl

L8Z

081 VLL

99

9'ZE 661

8ZL

L8

LN

tz 6rt

96

L9

9t

9'tL

9'9t

9'LL t'l 9'LxgL

ht

9'L xtl

W

g'L xzl

t

gz'L xOL

l l

LX8 IA

0L ll

8W thl

I

I

i

I

I

L9

et

9'tL 9'tv

9'tz

t'6 0t

t'v

)zL )01

lD!ratDlA

- - -

(inrNt anTtol 6-uruaiq6ir urnurxon C9

pDe-rq1

-uoc pauelqDrl eqt roqlaqM

luD^elarr! s!

ll 'z

'qslu!t ecDlrns D

lno

-qllnt slrod qcns

ol puD 'slloq

puD slnu peztuD^

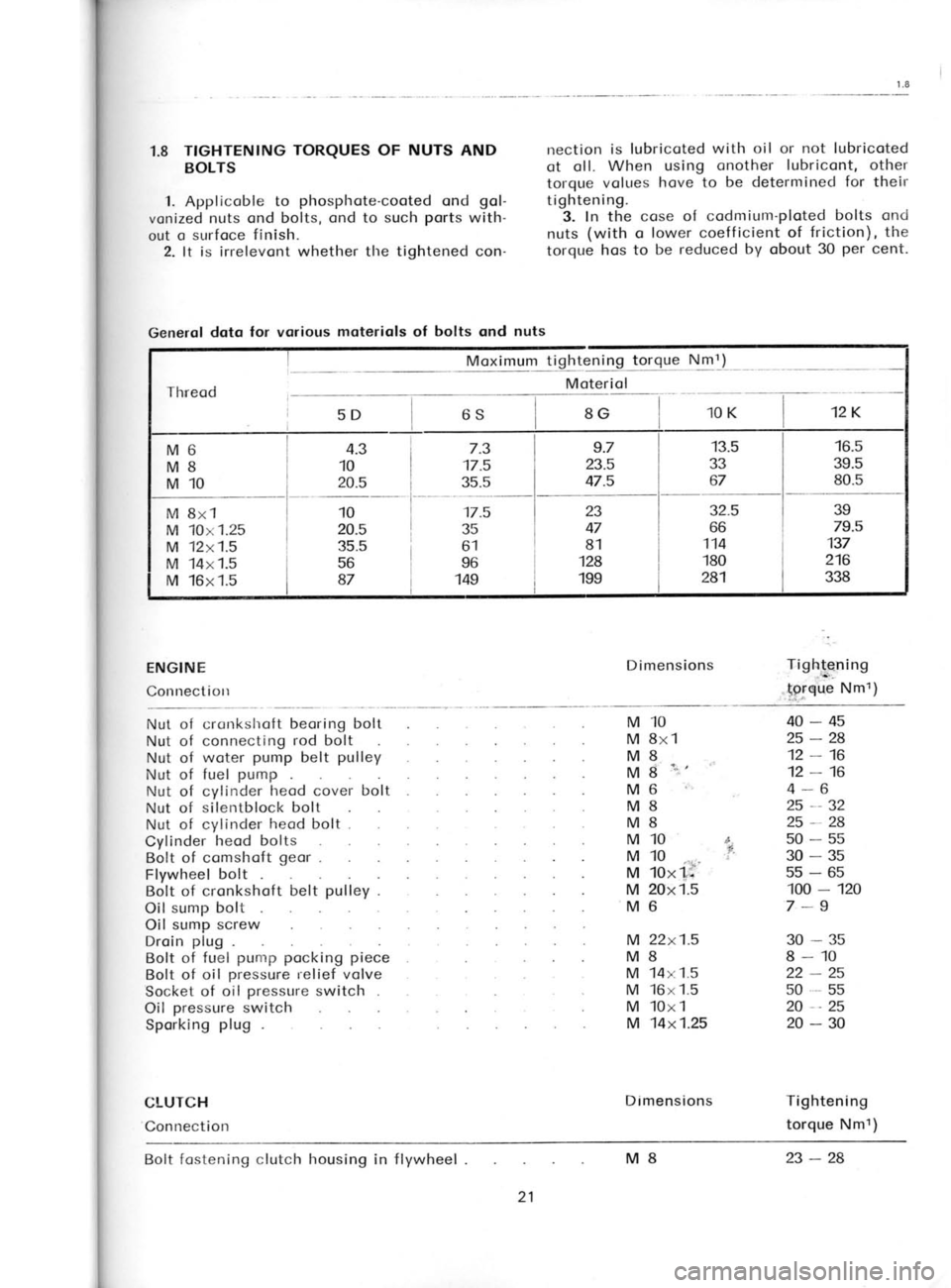

-1oD puo pelooc-eloqdsoqd o1 alqoctlddy '1

s1108

oNv srnN Jo

s:rnbuor eNlNsrHglr 8'l

_1

'luac rad 0t lnoqD itq

pacnpa.r

eq ol sDq anb:ol

aq1 '(uo11c!r]

lo luelcrlleoc rarnrrol D

Ulltvt) stnu

puD sltoq pelo;d-runlupoc

lo "to,

?;l,,ljrq%,,

J'!aq] Jo] peu!LuJalap

aq ol a^oq sat.llDn anblol

loqlo 'luoc!lqnl

leqlouD 6u1sn ueqM 'llo

}D

polDcrJqnl lou Jo

llo q]!M

palDclJqnl sl uollceLlslnu

PUD slloq

lo slDljelDtu

snolJDA Jol DIDP

loJeueo

Page 22 of 238

il

tli

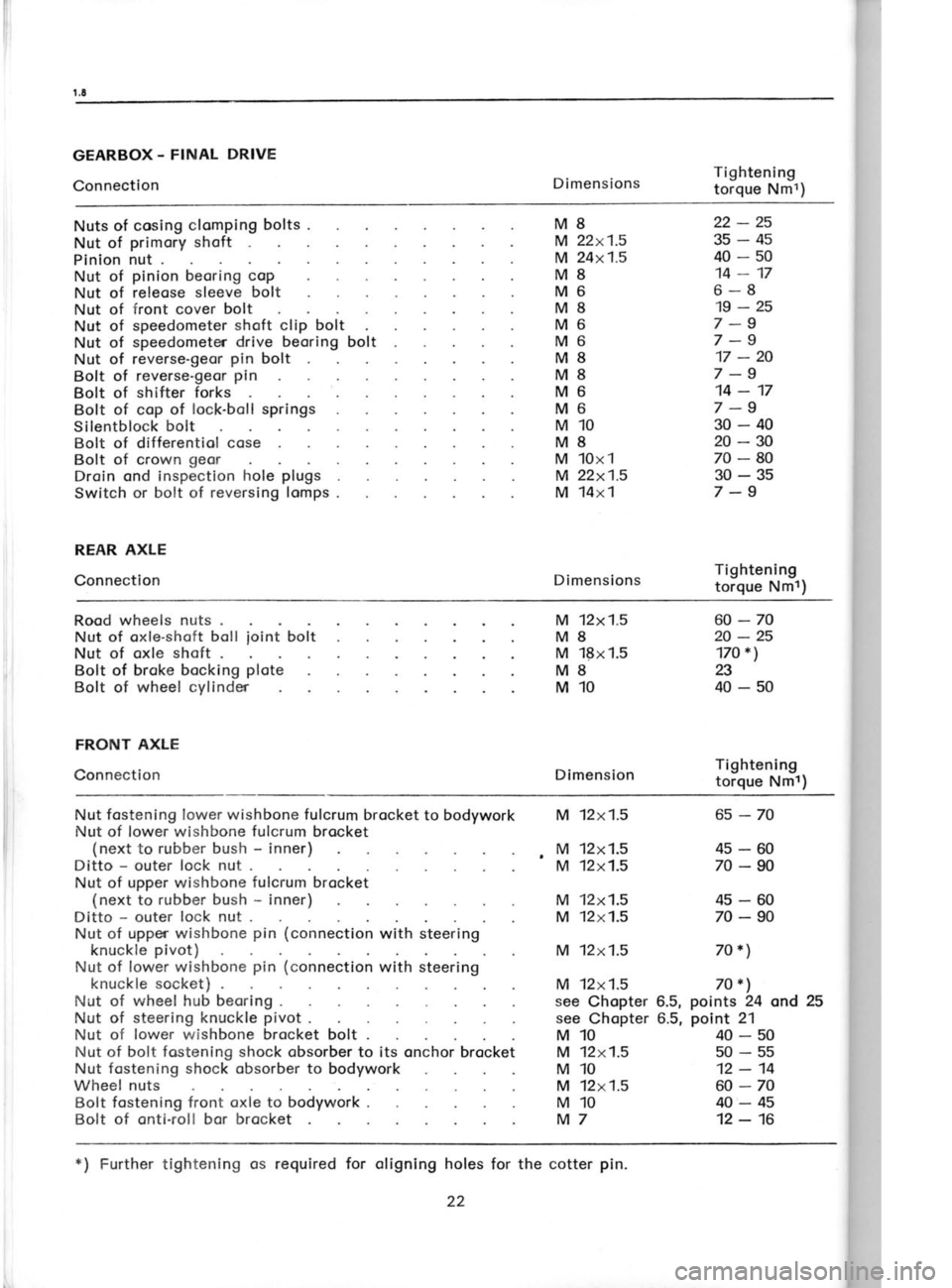

GEARBOX. FINAL

DRIVE

Connection DimensionsTightening

torque Nmt)

Nuts of cosing clomping bolts .

Nut of primory shoft

Plnlon nut .

Nut of pinion

beoring coP

Nut of releose sleeve

bol

Nut of front cover bolt

Nut of speedometer shoft clip bolt

Nut of speedometer drive beoring

bolt

Nut of reverse-geor pin

bolt

Bolt of reverse-geor pin

Bolt of shifter forks

Bolt of cop of lock-boll springs

Silentblock bolt

Bolt of differentiol cose

Bolt of crown geor

Droin ond inspection hole plugs

Switch or bolt of reversing lomps .

REAR AXLE

Connection M8

M 22x1.5

M 24x1.5

M8

M6 M8

M 22x1.5

M 14x1

Dimensions 40-50

14-17

6-8 19-25

7-9

7-9 17 -20

7 -9

14-17

7 -9

30-40 22-25

35-45

20-30

70-80

M6

M6

M8

M8

M6

M6

M10

M8

M 10x1 30-35

7 -9

Tightening torque Nmr)

Rood wheels nuts .

Nut of oxle-shoft boll

Nut of oxle shoft

.ioin;

boit M 12x1.5

M8 M 18x1.5

M8

M10

Dimension 60-70

20-25

17O *)

a

40-50

Bolt of broke

bocking plote

Bolt of wheel cylinder

FRONT AXIE

Connection Tightening

torque Nml)

Nut fostening lower wishbone fulcrum

brocket to bodywork

Nut of lower wishbone fulcrum

brocket

(next to rubber bush -

inner)

Ditto -

outer lock nut .

Nut of upper wishbone fulcrum

brocket

(next to rubber bush -

inner)

Ditto -

outer lock nut .

Nut of upper wishbone pin (connection

with steering

knuckle pivot)

Nut of lower wishbone pin (connection

with steering

knuckle socket)

Nut of wheel

hub beoring .

Nut of steering knuckle pivot

.

Nut of lower

wishbone brocket bolt .

Nut of bolt fostening shock obsorber to its onchor brocket

Nut fostening shock

obsorber to

bodywork

Wheel nuts

Bolt fostening

front oxle to bodywork .

Bolt of

onti-roll bor brocket see

Chopter 6.5, points

24 ond 25

see Chopter 6.5, point

21

M

,M M

M

M

M 12x1.5

12x1.5

12x1.5

12x1.5

12x1.5

12x1.5 6s-70

45-60

70-90

45-60

70-90

70*)

70 *l

40-50 50-55 12-14

60-70

40-45

12-16

M

12x1.5

M10

M 12x1.5

M10

M 12x1.5

M10

M7

*) Further tightening os

required for olignlng holes

for the cotter pin.

22

Page 23 of 238

ez

-tuDr6olll Jo e.qieupuodop;1) ru161

1o urdl lau

-rol or{t seco;der (erleuuolmeu) .,tup, (anbrol)

eorol lDuolsrot lo lueuou atll

lo 11un eq1

(c

'alqoclgddo s1 (suoyrneu)

N 908'6:6>l -ro d>t

I lo uollDler

aqt puD'(uo.r6

-ol!l) 6I .ro (puodol!))

dl rorurol eql secoldal

(uoyrteu) "N, (pool)

ocrol

lo lgun eq1

(q

'sorlaul!lllru u! ero A;uo sa.rn6;l u! pepclpu!

stuo.t6olp puD

suo!lDllsnll! u! suo!suoru!C (D 'lDnuDu

aql

u! esn r!aq] qllrvr

A11tu.ro;uoc ul souo plo

eql ol

sllun rrtau eql lo suollDlal

puo

sa6uoqc oql

lo

Aenrns lelJq D eng6 em 'uol1o1ueglo

elollllool ot

'seuo pesnun oueql!q 'Mau

q]!/vl sllun eql

lo

euos peluolddns

soq (s11un

6ul.rnsoeu) s1lun

loclslqd tro ualsAs

lDuollourelu! lS rvrou aql

srtNn lvcls^Hd 6'l

'r-rrd ra1loc oql roj saloq 6u1u6;1o ro; pa.rlnbar

so 6u1ua1q6rl .raqllnJ (*g

I

0

,t I

0

gz Puo

(rtuN 6ugt

(rutlr 6ul

(rtut 6q

:

oL tl

0LW 8lN

OL IA

8ll

OL U\I

oLW

OL U\|

ot,

-

oz

zt, -

vz

tz-oz

09-0t EZ

VLoz

7Z --

8L >l.mnnlpoq ol Jaroaq

ssolc

xoqrDe6 6ullcauuoo

llog

' la)cDlq 1:orvrApoq u!

ruJD snlpDl

lo lloS

(6u1rds ;o dol

p)

l.ronnlpoq ur

6u11unou

luerl!seJ alxD

JDaJ

to llog

oll!c

(esoc ergrp

lourl ol au;6ua)

tloq 6ullcauuoo

o]

lnN

.raddn -

reMol -

roqrosqo

)coqs ol

lnN

(le.roaq sso.tc

puD xoqroaB uaamlaq)

lcolqluells ol

lnN

' lloq 1e43Drq rasuells

ol

uN

oll!c

lloq urD

snlpDl ol

lnN

lloq rolotu

leljDls

lo lnN

W

1A

tA

W

8Z-OZ

09-09

ol-09

0r-0e 8

9'LXZL

9'L X'L

OL

(1up anbrc1

6ugue1q6r1

09-st

LL_9L L

0t' sz

0t-sz

09 -09

09-09 GoL

(* 0?

(* 03

(* 09

(* 0L

0t-92 suo!suaur!(l

oL llLIN

I lt

81l

g.LXZL tA

LXgA W

g'Lxzl l t

9'LXZL W

L XOL

IAI

0L tl

9'LX'L IN

9'L x8L

t l

9'LXtL W uo!l3auuoc

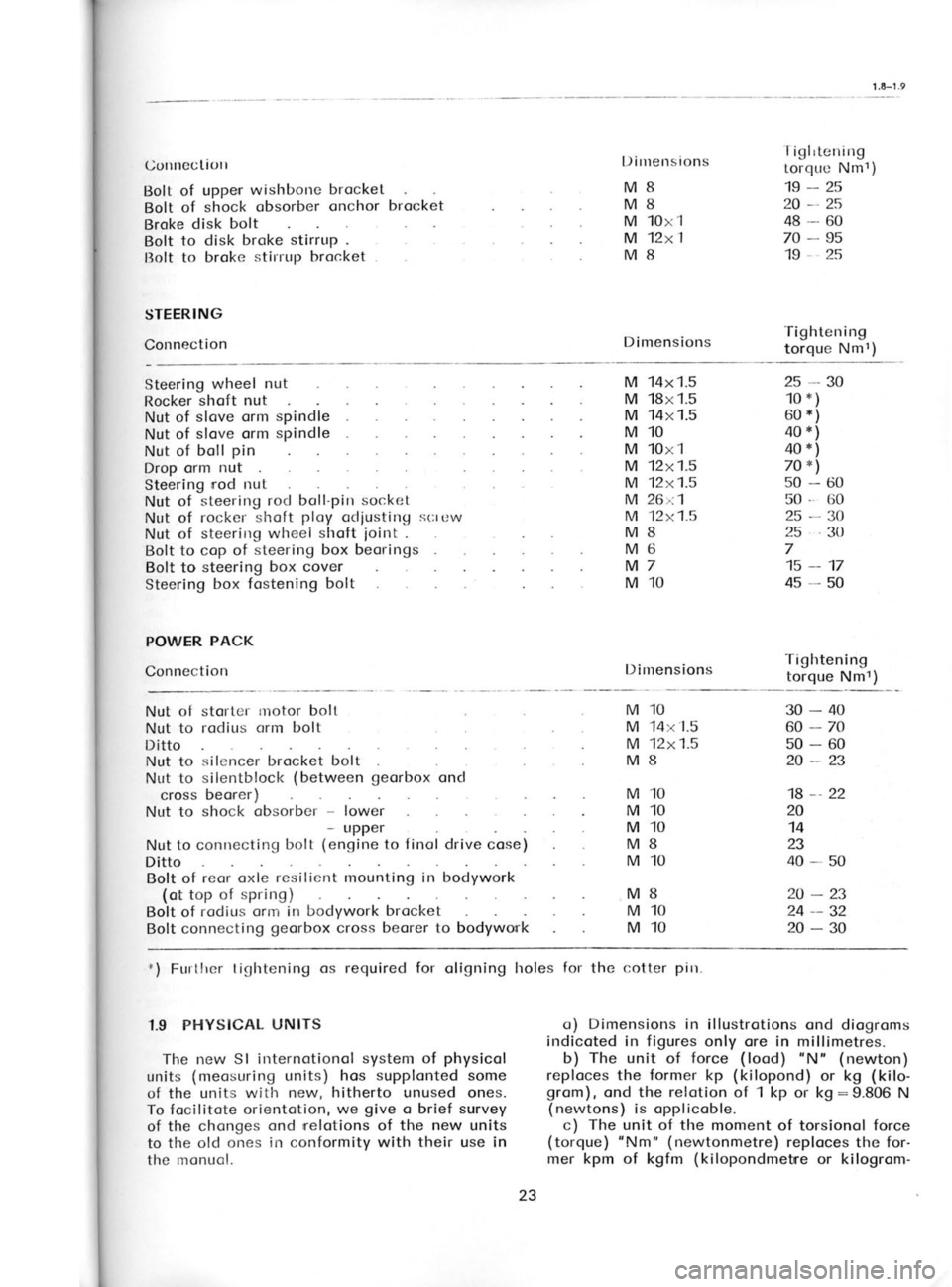

)cvd u]/nod

lloq 6uluelsDl

xog 6u!.raels

JoAoJ xoq 6u;.raels ol

llog

' s6ul.roeq xoq 6u;.raa1s

;o doc ol

llog

' lulo! UDqs leaqm 6u1:ae1s

lo lnN

Marl)s 6urlsnlpo lold 1;oqs Jelcor

lo lnN

. lnrlr:" u1d-lgoq

po.r

6u1lee1s^lo

nN

' lnu por

6u1:ee1g

' ]nu tu.ro

do.t6

ugd 11oq lo rnN

egpu;ds turD e^ols

lo lnN

alpu;ds urJD aADls

lo uN

lnu uor{s relcou

lnu lseqm 6u;lee1g

(rurp anbrol

6u1ue1q611 suo!suau!c

9Z .6L

9G-Ol

09-8t 9Z --

OZ

9Z-6L

(stup anbrol 6uruay16t1 8ll

L XZL

IAI

lxol l l

8n 8 tl uo!lceuuoc

9NlU33lS

leloo.rq dn-r-r1gs

oloJq ol

llotl

' iloq )s!P elor€

lelcorq roqcuo

raqJosqD

lcot{s lo llo8

lelcDlq auoqqslM rcddn

lo llog

6'r-c'l suorsusurlcl

lro!lcauuoo

Page 24 of 238

metre), ond the

relotion of 1

kpm :9.806

Nm is'

opplicoble. When opplied to tightening

torques

of bolts ond nuts, use the relotion

10 Nm :

: 1 kpm.

d) The unit of power (output) tW'

(wott)

reploces the former "h.p."

(horsepower) ond

the relotion

of t h. p.:

735.499 W is opplicoble.

For procticol purposes,

o multiple of kW (kilo-

wott :

1,000 wotts) is used, i. e., t h. p. :

:0.736 kW.

e) The

unit of pressure "Po"

(poscol) or, in

proctice, MPo (megoposcol :

1,000,000 poscols)

or kPo (kiloposcol :

1,000 poscols)

reploces the

former "bor"

ond "kglcmz",

ond the following

relation is opplicoble: 1 MPo: 10 bors :1O.2

kg/cm2 (kp/cm2).

For current meosuring

of tyre

pressure etc., use the relotion: 100 kPo :

1 bor:

:1kglcm2 (kp/cm,) :1

otm.

1.10 GENERAL INSTRUCTIONS

With the exception of o few

speciol pro-

cedures or ossembly techniques

mentioned in

the respective section of

this monuol,

every

removol ond refitting (disossembly

ond re-

ossembly) should be governed

by the following

generol principles:

o) Use suitoble tools ond especiolly tubulor

box sponners which couse the leost domoge

to nuts ond bolt heods.

b) During disossembly note corefully how

the ports

hove been ossembled. This knowledge

is involuoble for correct reossembly.

c) Cleon ports

in trichloroethylene or tech-

nicol petrol.

They do not contoin substonces

(esoeciolly leod) which horm

the skin os motor

petrol does. Current bronds of seoling com-

pounds con be removed with denoturoted

ol-

cohol or scroped off. For o speciol

seoling

compound see the note ot the end of this

chopter.

Avoid contominotion of self-lubricoting

metol

beorings with ony degreosing

ogent os this

would unfovourobly offect their self-lubricoting

properties.

Cleon ports

of the broke ond clutch hydroulic

system with olcohor.

d) Lubricote

oll ports

moving on or in

eoch

other before their ossembly. Operoting lubri-

conts do not spreod eosily on dry surfoces,

the

ports ore not properly

lubricoted, ond friction

oreos ore opt to get

domoged. Coot the os-

sembled ports with the lubricont which is used

to lubricote them in operotion. When lubricoted

with oil, dip

the ports

in motor oil, the f luidity of which mokes

it

especiolly suitoble for

this

purpose. Use greoses

ond hydroulic f luid bronds

specified in the Toble

of Recommended Lubri-

conts.

e) Use new cotter pins

ond metol lock

woshers if you

ore not convinced of the perfect

condition of the old ones which could breok

ond leove the joints

unsecured. Moreover, there

is o risk

of the broken ports

domoging other

functionol ports.

f) Cleon new ontifriction beorings (boll,

rol-

ler, ond topered roller beorings) of preserving

greose using kerosene.

Preserving greose is not

suitoble for lubricotion ond it mixes bodly with

I ubriconts.

g) Some of the joints

hove to be tightened

with o moximum occurocy to the specified

tor-

ques listed in the previous

chopter.

h ) 'Ihe

permissible rototion unbolonce is spe-

cified for some of

the rototing ports,

usuolly in

gcm (gromcentimetres). A well boloqced port

con be stopped in

ony position

if it is

instolled

so thot no rototion resistonce

octs on it. With

the exception of dynomic boloncing, the ports

ore usuolly tested on on ouxiliory shoft ploced

on the

edges. The

unbolonced port

moves from

the deflected position

with its heoviest (i.

e.

unbolonced) port

downword. The

volue of un-

bolonce con be determined

when fostening

o weight corresponding to the permissible

un-

bolonce to the opposite side

of the unbolonced

port. lf the port

does not move when deflected

or if it moves with this weight downword; the

unbolonce is within the recommended limits.

The weight of the testing weight sholl be

de-

termined by dividing the volue of the permis-

sible unbolonce by the distonce of the weight

from the rototion

centre of the port.

i) Even slightly domoged seols ond pockings

must be reploced with new ones

Note: In the foctory,

the speciol seoling

compound

of the "Velvonton

C" brond is used for seoling

the engine reor

cover on the cylinder block, the

moting surfoces of the georbox housing holves,

ond the guide

of the clutch releose beoring.

This seoling compound is mode

on the bose

of o polyurethone

plostic ond it

corresponds to

"Hykemor", "Reineplost", "Curil

K" ond similor

compounds. lt con be removed from the ports

by scroping ond woshing with ocetone, butyl-

ocetone or chlorinoted solvents, for exomple

chloroform (trichloromethone)

ond corbon tetro-

ch loride.

24

Page 25 of 238

9Z

89

99

dun6

1an3 67'7

69 rollarnqrDc

6L'z

dun6 pg -

re^oC roag 6u1urL gL'Z

dlung lO t;Z

s6ulrdg puD

se^lDn 'poeH

lapu11l3 g1'7

sJelcou Puo llDr.ls relcou

gL'z

dun6 La1o4n y;'7

u!DqC 6ugtu;g -

rDae e^lDn

CL'Z

09 suolsld

puD 'spou

6urlceuuo3's.rapur;A3 7;'7

pog 6ullcauuoC

LL'Z

LT s6u1X uolsrd

puo

urd uoe6png M/c uolstd

OL'Z

rapulqI3 6'Z

1aaqmll1 g'Z

z? l+DqsIuDrC

l'Z

Icolg :apur1I3

9'Z

8t tuo.r6or6

uo!loclrqn'l au16u3 puD

lsef elDrg

g'Z

au;6u3 6u111uor.usr6 V'Z

0t aul6u3

6u1;quassoag

tZ

rDC ur

au16u3 6u11111a9

Z'Z

roC tuoJl aug6u3 6ut,roueX

L'Z

6Z

a6o6 uol1dlrcsa6

lDcrut{ce1

lNl9N7'Z

89

t9

v9

z9 t9

6n 9t w

LN

LE

6Z

6Z -Dllel

\loq

elduoxe

-gA1nq 'eu

spod eqt

rDllLu!s Pl

ol sPuodl

esoq aql

'6u1:ot

'senloq 6

eql'lcolr 6u11oes r,

punodtuo

s6u1>1cod

1q61am e

-sFu:ad i

-aP eq

ll

'sllur!l

P

aql IPJD'

Pelcellet pacuoloq

-un alq!s

6u 1ue1so

-un lo e

'o 'l) tsr

u^roJl so^

pacold 1

syod eq

qllM'l!

pellolsu!

pod pec

u! Allons

-eds s1 e

-rol Pelll

paue1q6l

qllM llp

lou s! o!

6ugn:ese

-lor 'lloq

raqlo 6t

areql 'J0

lDarq P

1celled i

{col lol

-lrqnl pl

sPuDlq I

s!t{l ro}

Page 26 of 238

ENGIN

e

/\ e

.=

i

c)

-

'=

-

IJJ

3

.9

c

;

(n I

r

;

ir

33

46_

o

32. 5'

3t-

4/

ENGINE

Page 27 of 238

LZ

cc\ 9C

,/'

,/ ,,9

,---'cE

tr L---__

-p

t t,_ I

t.I \

gt LE- ot

t

/''<.

,'' , t'

6Z

ld 8

./t

Ppq

//'tl

r'r/l

8t Er sulNrl oNV

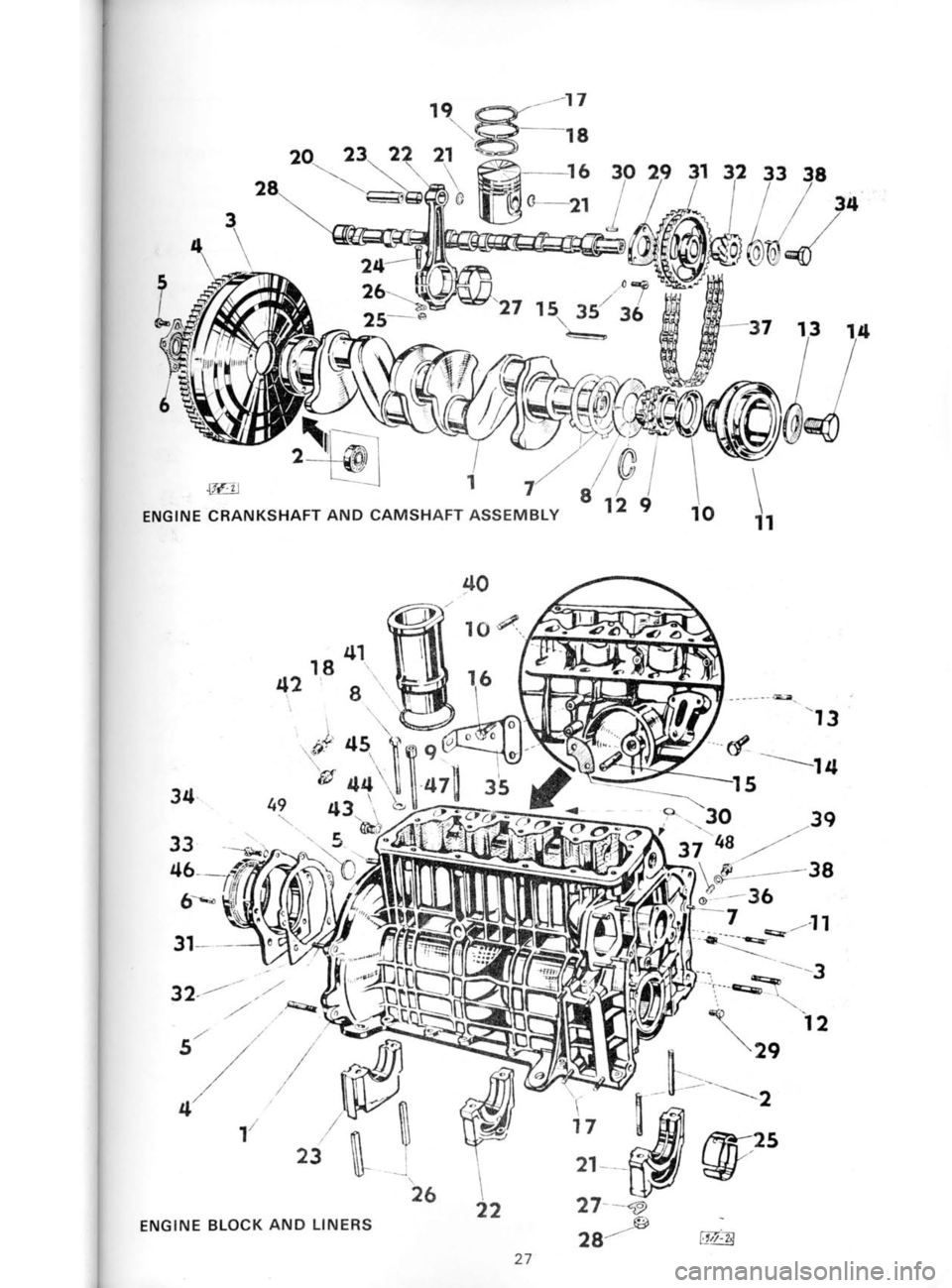

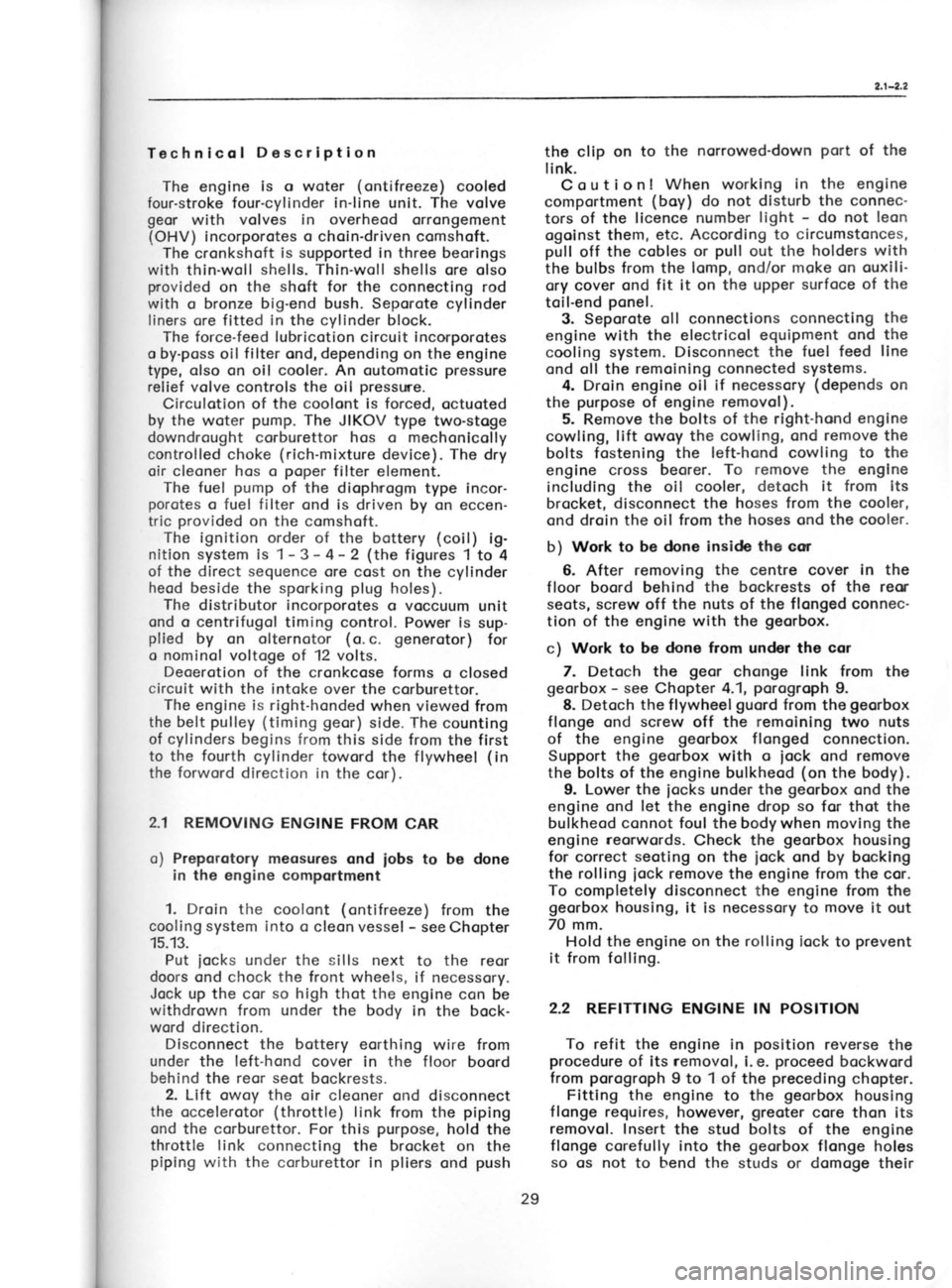

)co-18 3Nl9Nl

e(,

,,L

E!/ Lt

q=9 -9tt

tt

'trt

eI u,

'€ oL

0tt

A'IghI]SSV IJVHSU\IVC ONV IIVHS)NVUC ]NION3

,.L I

F----- Y48

//'lzsl T1

N

J

T.

o

:

m

:.

-

*

T

Page 28 of 238

ENGINE

CYLINDER HEAD ASSEMBLY

Gr__53a- @ -54

a--&J

3oa

"3q;' 25

2t

66

/62

:> €}\

8- -60

)^\ 0-cl

I

38---\

64 ow,,, l\ '39

|

l2

Page 29 of 238

6Z

Jleql aoDuop Jo spnls

eql pueq

ol

lou sD os

setoq ebuDll xoqrDe6 oqt olur 11;n;a.roc

e6uo1l

au16ue eql

lo slloq

pnls

aql

uesul 'lolouar

slr uor{l eJDc JalooJD 'rener*oq

'sellnbe:

abuol;

Bugsnoq xoq.roe6 eql ol au16ue aqt 6u!p!J

'reldoqc Dugpacard eq] lo L o1

6 qdo.r6o.rod

uro.r;

pJDMloDq paaco.rd 'a'!

'lDAoueJ

sl! ,o elnpeco:d

eql esra^el uo;1;sod ug au16ue aql

lller oI

NOr[SOd Nt 3Nr9N3 eNrrlrjfu Z'Z

.6ug1go1 urorl l!

luene:d ol

lcot 6u1g1o.r eql uo eu16ua eql

ploH

'urru 0l

]no l! elour

o1 l:ossecau

s!

l! '6u1snoq

xoq:oe6

eql uoJl eu;6ua aql lceuuocs;p Alelelduoc

ol

'Joc alll tuor;

eu16ua eql enoure.r >1col 6u;11o.r aqt

6u1>1coq Aq puo

1co! eq1

uo 6ugloes

lcarroc Jol

6ulsnoq xoq.roe6 aql lceqC 'sprDMroar

eu16ue

eq1 6ulnour ueqnn

lpoq oql

Inol louuDc pDaqllnq

aql lorll rol

os do.rp eu16ue aqt

lol puo

eu16ua

eql puo

xoqroa6 eql Japun slco!

aq1 reMol '6

'(Apoq eql uo) pDaqllnq

eu16ue eql

lo stloq

oql

enoueJ puo

>1co! o qlltvr

xoq:oe6 aqt

t.roddng

'uo!loauuoc paDuoll xoqloa6 eug6ua eql

lo

slnu oml 6u;u1or.ue:

aqt

llo Mercs

puo

e6uol;

xoq.roeb oql uorl pron6

leeqmA1l aqt

qcolec '8

'6 qdo.r6o.rod 'L'V.re1doq9

aes -

xoq:oa6

sql urorl {u!l a6uoqc

roe6

eql qcDle6 'l

roc orll Jopun tuorl

auop eq o1

1ro41 (c

'xoq.roeb etl] qllM

au16ue eql

lo uoll

-ceuuoc pe6uoll aq]

lo slnu eql

llo i!\eJcs 'slDes

rDar aql

lo slserlcoq eqr

Pulqeq piooq

rooll

orll u! Jonoc erluoc eql Dullourar raUV 'g

roo oql aplsu! euoP oq o1

1ro6 (q

'lelooc et{l puo

sesoq aq} tuorl

l!o eq} u!DJP

puD

'Jelooc aql uojl sosoq

aql

lcauuocslP 'lolcDlq

sl! ruoJl l! r{cDlep'Jelooc

l!o eq} 6ulpn;cu1

au;6ua eql elotual oI 'Jerooq

sso:c aug6ue

eql ol 6u;1r'roc puoq-Ual

aqt 6u;ualsol slloq

oql a^oueJ puo '6u11r*oc

eq1 ,tor"ro

U!l '6u!l/v\oc

eu16ue puoq-1q61:

aql

lo slloq

aql

a^oureu 'g

'(1onouel eu16ue 1o esodlnd

eql

uo spuedep) A.rossecau

;g 1;o au16ua

u1016 't

'sualsr(s pelsauuoc 6u1u1oua.r eql

llo puo

au1 pael

lenl eql

lceuuocslq 'tua1s{s

6ug;ooc

eql puD

lueudlnba loclrlcale eql

qllm

au16ue

aql 6ullceuuoc suo!lcauuoc

;1o elo.rodag 'g

'1euod pue-llDl

or{t lo ecorrns

.reddn aql uo

l! }l} puD

lenoc Ajo

-!llxno uD aloru rolpuo 'duJDl

eql uorl sqlnq eq]

qllM sreploLl oql

lno 11nd .ro

salqDc aq1

1;o 11nd

'secuolsurncJ!o ol 6ulp.roccy 'cle

'usql

lsu1o6o

!.rDol lou op -

rq6!l requnu acuacll

ot{1

}o sJo}

-oeuuoc aqt qrnlslp

lou op

(loq)

rueul.rodtuoc

au16ua eql ul 6u11:ornn uaq6

lu o

I l n o

C

'lu!l

eql lo 1.rod ualop-peMorrou

aql ol uo d11c eq1 qsnd puo

sla;1d u! rollernqroc eql qlrr*

6u1dgd

aql uo

lelcDrq aql

6ullceuuoc

lu!l sluoJrll

aql ploq 'esodrnd

srql JoJ 'Jollernqroc

eql puD

6urdrd eql uorl

1ur1 (a111o.rgl)

.rolo.ralaceo eql

lcauuocslp puo

reuoelc rlD eql Aor*o

1y1-1 '7

'slssrlcDq loss rosr

srll

Pu!qaq

prooq rooll eql u! Ja^oc puDq-uel

eql Jepun

ruorl srM 6u1q1:oa A:eltoq aql

lcauuocs!C

'uollcej!p prDM

-lcDq aql u; Ipoq sql repun LuoJl

urvroJpr{}lM

aq uDc eug6ua oql

lDql q61q

os rDc aql dn

1co1.

'fuossaceu

,! 'slaeLlM

luorl eql

lcoqc puD

sloop

lDer eql ol

lxau sllls

aql rapun slco!

1n6

'01'91

:aldoqg ees -

lesse^ uoalc D

olug ualsAs

6u11ooc

eql uor, (ezeeryguo) luDlooc eql ul016'L

luaurgroduoc aug6ue eql

u!

auop eq o1

sqo! puD

selnsoau ,trolo.roder6 (o

uvc l touJ 3Nt9N3

9NtnOWSd L'Z

'(:oc aq1 ur uo!]oor!p piDMroj

eql

u;) leaqmAll or{}

prDMo}

rapurlic

t{Unot erl} ol

lsrll eql

urorl

ep!s stql uoi+

sugBeq s.repullAc

1o

6ul1unoc eql 'ep!s

(.roeb 6urrugl) Iallnd

lleq eql

urorl peMell

uoLlM papuoq-1q61.r

s1 eug6ua eq1

'JouojnqJoc aql ra^o s)olu!

eql qll/v

llncj|c

Pasolc D

suIJo, esDcluoJc oql

lo uo!lDleDscl

'sllo^ ZL ;o e6o11on

lDu!urou o

rol (.roloreuaB 'c'o)

rolourello uD Iq pslld

-dns sg JoMod 'loJluoo

6urru11 1oBn1;.r1uec D

puD

llun unnccDl

o selDJod.rocul JolnqlJlslp aqf

'(se1oq 6n1d 6u11.rods a{} ap!seq pDeq

:apurlAc eql uo

]sDc eJD acuanbss

]coJlp oql

lo

t ol

L sa.rn6;;

eql)

Z -V

-t -

L s!

tustsls uog11u

-61 (11oc) i.ranoq oql

Io repro

uo11;u61 aq1

'UDqsuDc aql uo peplno.rd

c;.r1

-uecco uo Aq ue^lJp s! puD

rallll

lenl o salo.rod

-rocu! adAl urDo.rqdolp

eql

1o drund

len, oqt

'lueuale re1;t1 redod D sDr.l reuDalc JID

l:p eq1 '(ecgnap

arnlx!ur-qclr) eloqc pellortuoc

Allocguoqcatrl D soq ropaJnqJoc

lq6norpurvrop

e6o1s-om1 edll

ng;11. aq1 'dund

rolDM aql Aq

pepnlco 'PecJol

s! luolooc eql

,o uolplncJrc

'e.msseld l!o eql sloJluoc

e^lD^

la!leJ

arnsserd c!lDruolno uV 'Jaloog

llo uo

oslo 'edrt1

eu16ue eql uo 6urpuadep'puo rall!l 11o ssod-rtq o

selolodrccu! llncJlo uo!toc!Jqnl

peal-e3ro'

eql

'lcolq :epuggAc aq] ul pa]lll

ero srau!l

:apu1llc elolodag 'qsnq

pua-6!q ezuorq D qllM

pol Bullcauuoc aql Jol

UDqs aql

uo papr,rod

oslD ero sllaqs

lloM-u!rlf 'sllaqs

lloM-u!ql qltM

s6u;roaq eerql u! payoddns

s!

llor.lsluDrc aql

'UDqsuDc uo^!rp-ulDl.lc o salolod.rocu; (npg)

luatua6uo.r.rD poeLlJaAo

u! ssllol r{l!M .roa6

enloA eql 'l!un

au!l-u; lapugl{c-lno} aloJls-Jno}

pelooc (ezee.r;g1uo) .ra1or,r o

s; eugbua eql

uo;1d!rcseO tDc!uqcaI 0!

19

6

L9

tn

trt

Z-

l- t9

6.-t

0g_

6Z-.. 1t-c

OZ-' zz/ ,/l

CZF

e(

Ltt-

t9--

ts-

Page 30 of 238

2.2-2.3

threods. Fill the etrgine with oil ond the cooling

systenr with on ontifreeze, ond

bleed them.

2.3 REASSEMBLING THE ENGINE

The reossembly procedure depends

on the

extent to which the engine hos been

dis-

rnontled. For better understonditrg, o

reossembly

of o conrpletely disnrontled

engine is described

in the following

porogrophs.

lnspection of

Cylinder Block

1. Clomp the thoroughly cleoned

cylinder

block into the MP 9-101 stond with the engine

corrier type MP 1-101 ond check it for complete-

ness -

see Chopter 2.6. Fit the

block with its

lugs on the engine corrier pins

ond use the side

bolt for ltolding it down.

DK 1188

Fig.2311- Cylinder Block Fostened on the

Assenrbly Stond by lVleons of the MP 1-10-l

Corrier

2. Rernove the pressure

relief volve, moke

sure thot the boll contoct {oces ore cleon,

ond

refit the cleoned volve. Forr

f itting o new volve

see Chopter 2.6.

3. Remove the cronkshoft beoring

covers ond

tlre i;ylinder block reor cover.

To Refit the Cronkshoft

4. Force the beoring shell lrolves with the

fingers into the cronkshoft beoring bores so thot

the shell lip snops home into the slot (cut-out)

in the block ond so thot the shells do not pro'

trude over the beoring surfoces for the beoring

covers, ond lubricote them with engine oil. Be

r;ure to fit shells motching the cronkshoft

i":urnols -

see Chopter 2.7.

5. Slip the oiled guide

ring on the cronkshcft

"vith oil grooves

pointing

toword the cronkshoft

'.veb ond {it the cronkshoft with the pressed-on

boll beoring (see

Chopter 2.7)

into the shell. 6.

Inscrt the

beoring shell

holf ir-rto

the cover

of the beoring No.-l

os described in

porogroph

4,

ond fit the cover with the

recess for the guide

ring turned outword. Proceeding from

the front

of lhe block, slip

on the next guide ring with

the oil grooves pointing

owoy from the block so

thot itJ

lip engoges ogoin into

the slot in the

cover. Coot the ring

with oil ond slip on the

thrust ring. Fit the MP -1'112

thrust collor on the

cronkshofi ond

tighten the

beoring slightly

using the belt

PrrlleY bolt.

7. Instoll the next

two beorirrg covers

corl'l'

plete with beoring shells

ond lightly

tighten l.he

cover nuts.

Press the cork

seol

into the

reo'r

cover moking

sure thot it

f its the groove

snugly

ond slightly bverlops the lower

seoting surfoce'

Before titting the cork seols,

compress them

for

o while in o vice to distort them. Insert the

distorted seols in the grooves

or gops between

the cover qnd

the cylinder block

where they

will expond onci provide

for perfect seoling.

lnsert tob woshers under

the nuts of the

beoring covers

ond while tightening the rruts

check their correct position so os

to enoble

o subsequent correct locking

of the nuts.

Fig.2.312 -

Meosuring Cronkshoft Ploy

1 -

Thrust collor, type

MP 1 112

2 -

Diol indicotor in o

speciolly mode yoke

8. Rotote the cronkshoft severol times ond

using o mollet top the covers ond both shoft

ends to ensure o correct bedding

of the covers

ond cronkshoft guide rings.

9. Tighten the belt pulley nut

to clomp the

thrust ring, ond

rotote ond force

off

the cronk-

shoft to

check its ploy. The

cronkshoft must

be

free to rotote but

without ony

noticeoble ploy.

lf there is o noticeoble ploy, recheck

its volue

ond odiust it by replocing the guide ring with

o new one. The

moximum ploy

should not ex-

ceed 0.10 mm, the recommended minimum ploy

being 0.04 mm. 10.

F

speciol

end onr Drive

suchr o

be turnr

cover. I

ever, tf

the cyl

speciol note in

11. Ti

the tigh

in the

covers. hoving

does no

must ro

Then lo,

woshers

ond nut

To Refil

12. R

greose i

it with i

o flywhr

engine,

with rec

under tt

Chopter

bending

shoft og

powl ins

For flyw

Fig.2.3l3

Using thr

Screw

holes, for

con be ur

further o1

the hondr

30