ESP SKODA 105S 1980 Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 105S, Model: SKODA 105S 1980Pages: 238, PDF Size: 47.09 MB

Page 199 of 238

Reverse

the

dismontling procedure

to rein'

stoll tl-re window ond its winder. The

loterol

ploy con be odiusted by odiusting (swinging

out) the centre post

ofter hoving loosened the

respective bolts ond nuts -

see Fig. '14.6/6

ond/

or 14.617.

Use this occosion to lubricote inner door

mechonisms -

see Chopter 15.12.

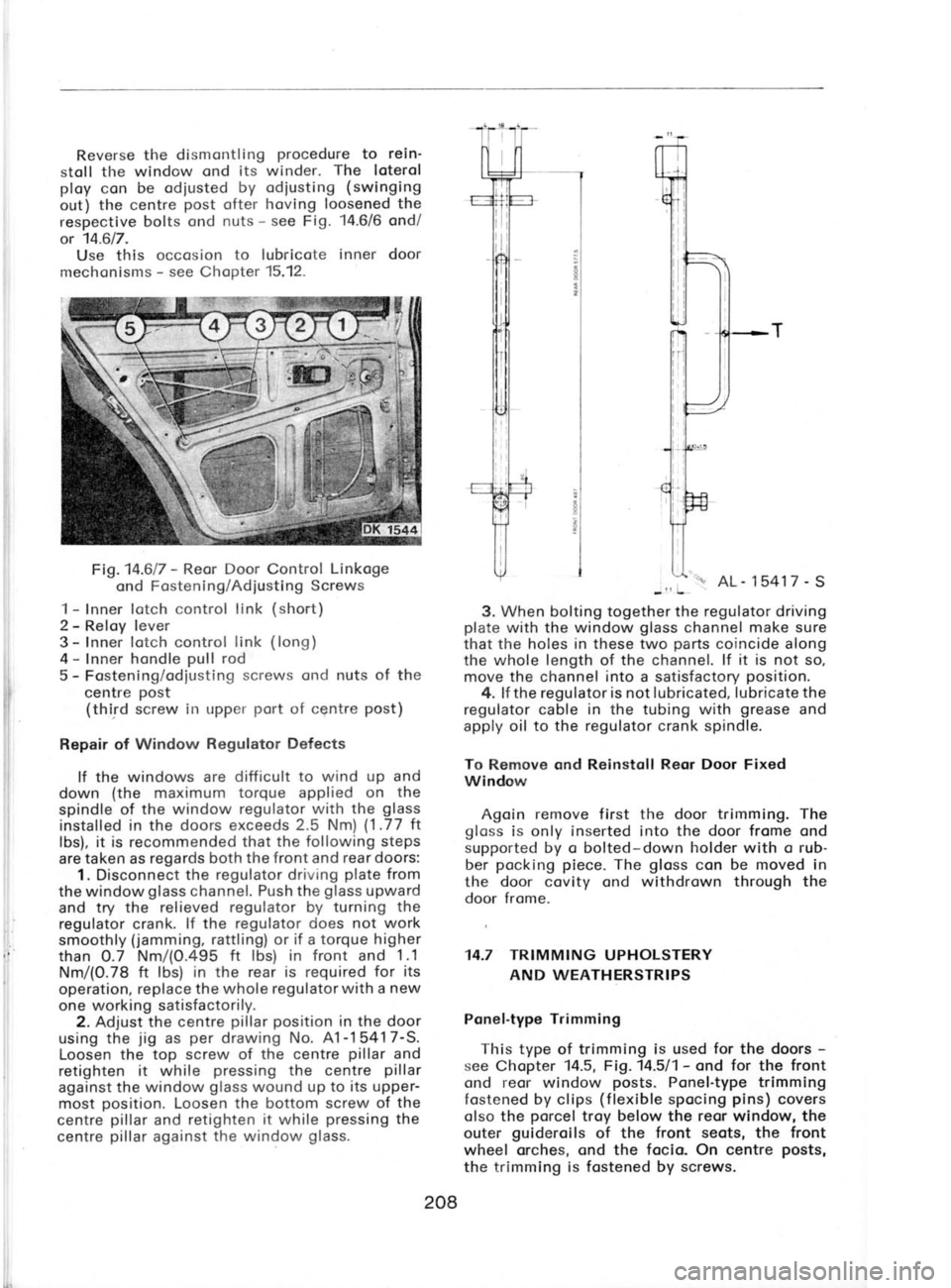

Fig.14.617 -

Reor Door Control Linkoge

ond Fostening/Adiusting Screws

1 -

Inner lotch control link (short)

2 -

Reloy lever

3 -

lnner lotch control link

(long)

4 -

Inner hondle pull

rod

5 -

Fostening/odiusting screws ond nuts

of

the

centre post

(third screw in upper port

of centre post)

Repair of Window Regulator Defects

lf the windows are difficult to wind up and

down (the

maximum torque applied on the

spindle of the window regulator with the glass

installed in the doors exceeds 2.5 Nm) (1.77

tt

lbs), it is recommended that the following steps

are taken as regards both the front

and rear doors:

1. Disconnect the regulator driving plate

from

the window glass

channel. Push the glass

upward

and try the relieved regulator by turning the

regulator crank. lf the regulator does not work

smoothly (jamming,

rattling) or if

a torque higher

than O.7 Nm/(O.495 ft lbs) in front and 1.1

Nm/(0.78 ft lbs) in the rear is required for its

operation, replace the whole regulator with a new

one working satisfactorily.

2. Adjust the centre pillar position

in the door

using the jig

as per

drawing No. A1-1 5417-S.

Loosen the top screw of the centre pillar

and

retighten it while pressing

the centre pillar

against the window glass

wound up to its upper-

most position.

Loosen the bottom screw of the

centre pillar

and retighten it while pressing

the

centre pillar

against the

window glass. 5417

-

S

-l! L

3. When bolting together the regulator driving

plate with the window glass

channel make sure

that the holes in these two parts

coincide along

the whole length of the channel. lf it is not so,

move the

channel into a satisfactory position.

4. lf the regulator is

not lubricated, lubricate the

regulator cable in the

tubing with grease

and

apply oil to the regulator

crank spindle.

To Remove ond Reinstoll Reor Door Fixed

Window

Agoin remove first the door trimming. The

gloss is only inserted

into the door frome ond

supported by o bolted-down holder with o rub-

ber pocking piece.

The gloss

con be moved in

the door

covity ond withdrown through the

door frome.

14.7 TRIMMING UPHOLSTERY AND WEATHERSTRIPS

Ponel-type Trimming

This type of trimming is used for

the doors -

see Chopter 14.5, Fig.14.511- ond for

the front

ond reor window posts.

Ponel-type trimming

fostened by clips (flexible

spocing pins)

covers

olso the porcel

troy below the reor window, the

outer guideroils

of the front seots, the front

wheel orches, ond the focia. On centre posts,

the trimming is fostened by screws.

208

Page 201 of 238

I

x

li

I

I

.t

the

ploces

from which you

hove removed the

sticking dirt ogoin, ond wipe

the entire body-

work diy, including chromium'ploted ports,

with

chomois leother. Wosh ond

wlpe dry the vor'

nished surfoces with uniform strokes in one

direction, i. e.

not

by circulor movements.

After hoving wiped oll vornished ports

of the

bodywork dry, polish

them with o soft (flonnel)

duster. Do not use polish

of ony kind.

lf the bodywork is so dirty thot it connot be

woshed cleon with woter, use cor

shompoo.

lf it is necessory to refreshen the gloss

of the

finish, use o cor polish

occording to instructions

of its monufocturer. To wosh the underbody,

use o hose ond

running woter, worm or cold; never use petrol,

kerosene, diesel oil, etc.

Remove greose

spots with o cloth, dry or

sooked in petrol

if necessory. To

remove tor, dip

the cloth in kerosene or o speciol

tor removing

preporotion, ond rub the spots. Then

immediotely

wosh owoy oll troces of

kerosene or the tor

removing solution, ond repolish the spots with

o cor polish.

TOUCHING.UP VARNISH

Preporotion:

Removol of Polishes etc.

When touching up o repoired bodywork (dom-

oged surfoce

finish), it is

importont to olso

cleon the surrounding vornish

to prevent

the

touching-up point

from floking off loter on in

ploces of overlopping.

Remove cor polishes

with o shompoo. Silicone

oil, contoined in some bronds

of polishes

ond

preventing the odhesion of the touching-up

point, con be woshed owoy only with o speciol

preporotion. !n Czechoslovokio, this is

for

exomple VENEDIN. Rub with this preporotion

olso vornished oreos which will be roughened

by grinding

where the bore ploces

poss

into

ground ond cemented oreos.

Removol of Rust

Remove rust mechonicolly by grinding

or

rubbing with emery poper

ond woshing with

c derusting ogent (for

exomple SK 2,

which is

bosicolly o 300/s phosphoric

ocid).

Procedure: f irst cleon the rusty spot with

emery poper

No.80 ond 100

or using o grinder.

Then rub the spot with o 15 0/6

solution of

phosphoric ocid (SK 2 deruSter)

heoted up to

40oC. When using o cold solution,

its concen-

trotion must be obout 300/e (undiluted

SK 2

deruster). Work in rubber gloves.

After hoving removed the rust, wosh

the spot

twice. First

with tepid or cold woter,

soft or softened

by odding 2

to 2.501s of sodo,

then

with o solution of chromium trioxide (1 gr.

to

1 litre of soft

woter) heoted

up

to 80oC (thls

is

the so-colled possivoting

rinse). Now let the

spot dry.

Degreosing Degreose the spot to be touched up by rub-

bing it down with trichloroethylene or technicol

petrol.

1. Touching-up with low-boking points -

the most perfect procedure

o) Cleon the touched-up spot, derust

ond

degreose it (see

the previous

porogrophs

on

preporotion)

b) Sproy over with priming point

c) Let the priming point

dry ot 80oC to 110oC

for o period

of 50

or 15 minutes (50 minutes

ot 85oC, 15

minutes ot 110oC)

d) Coot over with synthetic cement or poly-

ester cement

e) Let the cement dry ot 85oC or 110oC for

o period

of 50 or 15 minutes respectively;

when using polyester

cement, the drying

period con be shortened -

this cement dries

of normol temperoture

f ) Grind under

woter with emery poper

No.280

to320till the spot is perfectly

flot ond even,

ond let it dry

g) Sproy with top-coot vornish

h) Let it dry ot 80oC to 110oC for

o period

of

15 or 50 minutes respectively; ofter boking,

the vornish hos

o high gloss

ond it is not

necessory to polish

it

i) Use o polish

to remove

ony visible troces of

tronsition between the originol ond the

new

vornish.

2. Touching-up with

nitro-combinotion vornish

o) Cleon, grind,

derust, ond degreose the spot

to be touched up

b) Apply priming

point with o brush or o

sproy-gun

c) Level up, if

necessory, with on oil-bose

cement (once

or twice)

d) Let

it dry lor 24 hours ond then grind

with

emery poper

No.220

e) Sproy

the entire touched-up oreo with

sproying cement ond let it dry for 24 hours

f) Grind with

emery poper

No. 280 ond 320

under woter till the oreo is perfectly

smooth

ond flot, ond let it dry

g) Sproy the touched-up spot with o vornish

prepored by mixing low-boking

,vornish

(Toolol ond touching-up vornish (300/e);

use

exclusively o

nitro-thinner for diluting the

vornish

210

Page 214 of 238

Fig.

15.3/8 -

Distributor Adiusting Elements

1 -

contoct holder, 2 -

rotor orm, 3- com,

4 -

distributor brocket, 5 -

distributor brocket

clomping bolt

Alwoys turn the engine clockwise to eliminote ony ploy

in the distributor drive geor

ond to

ovoid loosening of the bolt. To relieve the

com-

pression resistonce, it

is recommended to bock

off the sporking plugs.

b) Stroboscopic method:

When using this method, the volues of the

bosic ignition timing ond

the odvonce con-

trolled by the centrifugol timing control (for

its

diogrom refer to Chopter 13.5) should be odded

upwhile multiplying bytwo

the odded upvolues

occording to the diogrom. Any effect of the

vocuum control must be

eliminoted by discorr-

necting the respective hose (connecting

the

distributor vocuum unit with the corburettor).

The meosuring procedure

is indicoted by the

diognostic equipment itself.

To Adiust ldling Speed

Use the oir-correction screw (speed

cor-

rection screw). The speed decreoses when ro-

toting the screw clockwise ond increoses when

rototing it onticlockwise.

Adiust the idling speed in occordonce with

the tochometer ond within the limits specified

in the following porogroph "To

Adiust ldle

Run". The engine must be wormed-up

before

storting the odjusting procedure (see

olso the

following porogrophs) ond its ignition must be

in perfect

condition (distributor

contoct-breoker

points, sporking plug

electrodes, ond ignition

odvonce).

N o t e : For the bosic position

of the odiusting

screw refer to Chopter 2.19 - "Mointenonce

ond

Adiusting". Fig.

15.3/9 -

Air-correction Screw -

idling speed

correction screw

To Adiust ldle

Run

Acljust the contoct-breoker point

gop,

the gop

of the sporking plug

electrodes, ond

the ig-

nition odvonce. Then check

the

volve cleoronce

(if there is no cleoronce, odiust

the

volves),

cleon the oir intoke filter

element, ond moke

sure thot the occelerotor pedol link hos

the re'

quired free trovel -

see Chopter 12.2-

Use o needle to remove the plug

covering

the fost-idling screw

ond let the engine run ot

obout 2,000 r. p.

m. to ottoin on oil temperoture

of 70oC. Insert the probe

of the thermonreter

into the hole for the oil diPstick'

Now connect the

speed indicotor (tocho-

meter) ond the onolyzer of

corbon

.monoxide

(contoined in exhoust fumes). Use

the oir'cor-

iection screw (Fig.

15.3/9) to set the

speed

-r-?n

at 800 l;; t.

p. ni. cnd the fost-idling screw

(Fiq. 15.3/10) to odiust the

content of corbon

moioxide to 2*0.50/s or the oir-fuel proportion-

by-weight mixing rotio,

comporoble with

the

specif ied corbon monoxide content, to

1+.2 +$.t.

After about one minute of

the continued idle

running recheck the odiustment ond

correct it,

if necelsory. Close the hole

with the

fost-idling

screw by driving in o

new plug with

its bottom

outword.

Note: For the bosic position of

odiusting

screws refer to Chopter 2.19 - "Mointenonce

ond Adjustment".

To Lubricote Accelerotor Mechonism

Pour severol drops of oil into

the end of the

bowden coble tubing ond lubricote both

ioints

(on top ond below)- of the corburettor pull-rod

itself with obout one drop of oil. Then

depress

224