lock SKODA 120 LS 1980 Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 120 LS, Model: SKODA 120 LS 1980Pages: 238, PDF Size: 47.09 MB

Page 80 of 238

Proceed

in the some woy with the

3rd- ond

4th-speed geors.

lf the morked position

of the neutrol is not

midwoy between the side morks (check

visu-

olly), remove the pinion,

mork the positions

of

the striking forks on

their rods (preferobly

on

either side), slocken the forks ond 'rnove

them

toword the required centre by

the distonce of

the deviotion of the neutrol morking. Then lock

the striking forks in position

with screws.

For the striking fork tightening torgue see

Chopter 1.8. 13. Adiust the reverse geor position

so thot

there is o gop

of obout 2

mm between its teeth

ond the odioining teeth, ond swing the striking

fork of the first ond second speed

to moke sure

thot it connot foul

the teeth.

14. Reinstoll the pinion

with its respective

woshers ond lock it in position.

Shift the strik-

ing fork rods to moke sure thot, for exomple,

o movement opposite to the required one of the

striking forks did not toke ploce,

i. e. thot the

neutrol is midwoy betvr'een the engogement

positions of the synchronizing clutches. Correct

ony error ond remove

ogoin the pinion.

Fitting Drive Geors ond Clutch Shqft

15. lnstoll the ossembled drive shoft into the

housing ond slip the splined bush on it.

Top home the seol ring with its seoling lip

pointing outwords into the guide

of the clutch

thrrowout sleeve, ond smeor it with oil. Then

threod the clutch shoft through the ring to

instoll it into the splined bush ond put

it into

the housing together with the guide provided

with o cooting of seoling compound on its cyl-

indricol bedding surfoce. Secure both the shoft

ond the sleeve with circlips.

lnstoll the sleeve guide

with its droin hole

level with the porting plone

of the housing ond

focing the pinion.

For the speciol seoling compound see the

note in Chopter 10.1.

16. Put the pinion

with geors

into the housing

ond oil oll synchronizing rings. Fit the MP 5-104

iig for

setting the crown wheel bocklosh into

the bore of the differentiol beoning ond the

fitted cover, fit the ossembled differentiol in it,

ond close the housing with the other housing

holf ofter hoving cooted the seoling surfoces

with o seoling compound.

Fit o rubber ring in the recess of the boss

beside the stud

bolt ond put

o spring wosher

under the nut. Tighten the remoining nuts

without ony woshers (the

stress of the bolts

ofter the tightening of the nuts provides

for'

their suff icient securing). Tighten the nuts

moderotely for the time being.

For the speciol seoling

compound refer to the

note in Chooter 10.'1. 17.

Proceeding through

the bore of the differ-

entiol beoring in the upper holf of the housing,

fit another

iig, the MP

5-104,

on to the differen-

tiol with flonges clomped so os to fit

into the

topered roller beoring cover, locote the cover

pocking, ond fosten

the cover by meons

of three

nuts. lf the clomping or drowing close of the

flonges of this jig

proves inodequote, it is

necessory to drow close the flonges olso of

the

first, previously

inserted

iig.

18. Drive the guide

of the clutch throwout

sleeve into the housing using the MP 3-103 drift,

top home the drive shoft, ond insert

two od-

iusting woshers under the collor of the

pinion

shoft boll beoring on both holves of the housing

ofter hoving determined their thickness by

meosuring. Using o wire needle

inserted into

the holes of

the tobs of the woshers orronge the woshers so

thot they do not overlop the porting plone

of

the housing,

then instoll the cover ond spring

woshers, ond tighten the nuts (seeChopter

1.8).

19. Fosten the housing by tightening the nuts

(see Chopter 1.8) ond lock in position

the guide

of the clutch throwout sleeve with the respect-

ive clip using the spring wosher under the

clip

nuts.

4.3 ASSEMBLING

FINAL DRIVE

Ref itting Differentiol 20. Turn the housing into the horizontol pos-

ition. Rotote the ends of the knurled hondles

of the inserted iigs MP 5-104

to move the re-

instolled differentiol (see previous porogrophs

16 ond 17) until the crown wheel withdrows

Fig. 4.311- Adiusting

1 -

MP 5-104 iig,

3 -

MP 5-106

iig,Bevel

Geor Bocklosh

2 -

MP 5-101

iig,

4 -

Screwdriver from

the

Determir

swivellin

To rotr

iig with

tiol stor

21. Ins

on the b,

rotote th

the diol

ible to th

Retoin

ogoinst 1

cover. Tl'

teeth chc

losh on t

of the ho

wheel sic

fied volut

the hond

fully its c

( preferob

wheel). I

opened f1

respectivr

of the

iigr

Now tl"

iusted on

flonges o'

topered r

This situc

trot i o n.

Fig. a3fi

for tc

1

22. Rem

side (turn

withdrow

dimension hos to be

roller beori

Measuring 23. Unscr

the toperer

locote it o

q,

ry

80

Page 82 of 238

4.3-4.4

F

I

t

F

i

!

I

r

{.3-4.4

6. Remo

b) Crownwl Tools:

Settin

not le

1. Install

one of the

Glave Cylir

that the p

pendicular

2. Lock

between tl"

cover. 3. Using

back and

clearance I

teeth. This gauge, anc

wheel(see legible the

O.18mm bi

4. lnsuffi

wheel is tc

increase tl

from the nc

the equiva

This will p

increase th

Excess c

thickness

Selector Si

To worl

shims to n

(a) Bac

(b) Act

Refitting C Assembly

29. Instc

ond the rel it with nutr

-looded brc

To

(a) O.3i

(b) o.2r

lf

the shims

connot be set up exoctly to the

colculoted thickness, determine o thickness

which would result

in o prelood

due to on

overoll increose of 0.03 to 0.07 mnr of the di-

rnension of the shims.

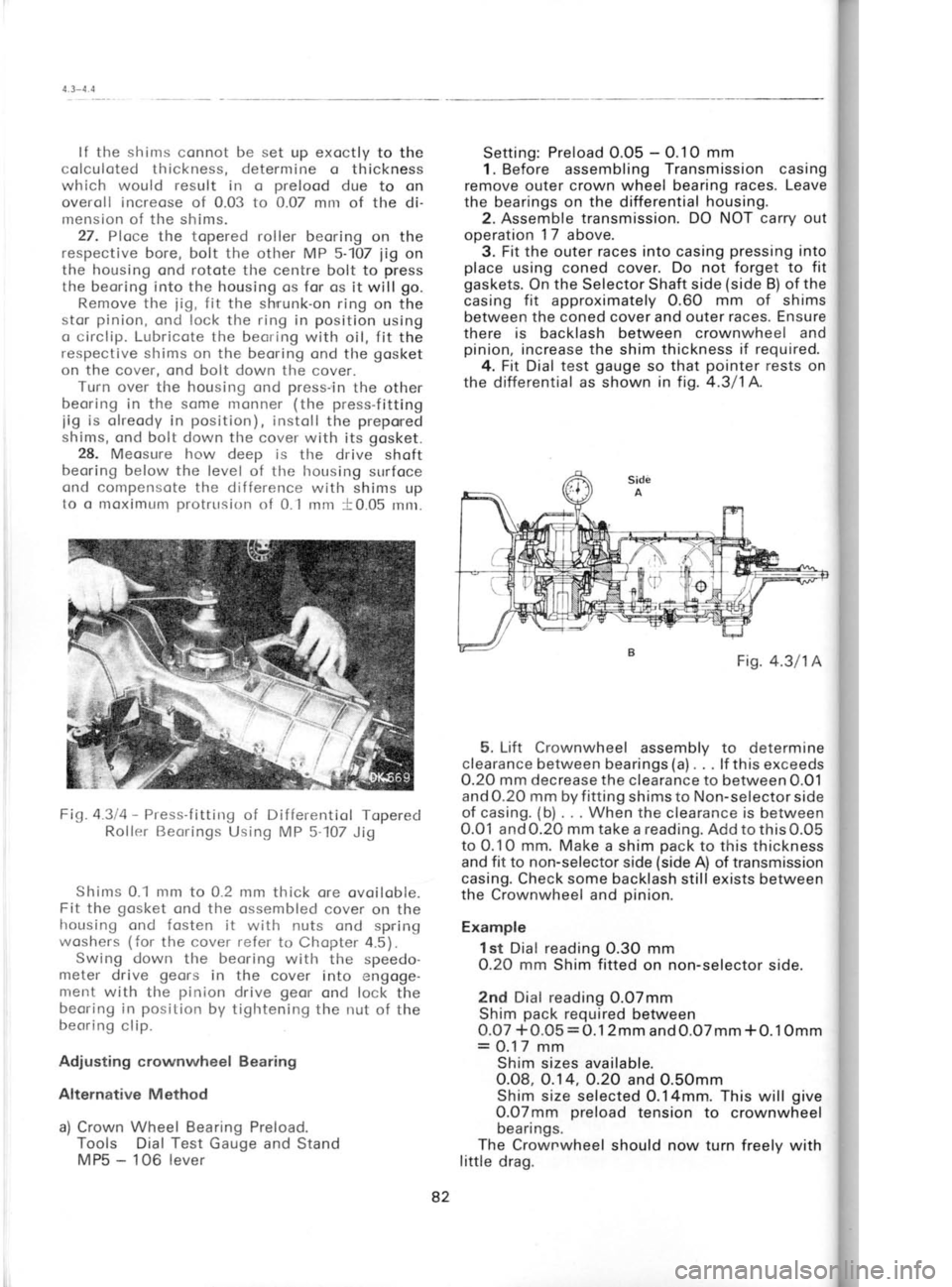

27. Ploce the topered roller beoring on the

respective bore, bolt the other MP 5-107

iig on

the housing ond rotote

the centre bolt to press

the beoring into the housing os for os it will go.

Remove the iig, fit the shrunk-on

ring on the

stor pinion,

and lock the ring in position

using

o circlip. Lubricote the beoring with oil, f it the

respective shims on the beoring ond the gosket

on the cover, ond bolt down the cover.

Turn over the housing ond press-in

the other

beoring in the some monner (the press-fitting

iig is olreody in

position),

instoll the preporred

shims, ond bolt down the cover with its gosket.

28. Meosure how deep is tlre drive shoft

beoring below the level of tlre housing

surfoce

ond compensote the difference

with shims up

to o moximum protrrrsion

of 0. I mm -F0.05

rnnr.

Fig.4.3/4 -

Press-f itting of Differentiol Toperecl

Rollr:r Beorings

Using MP 5-107 Jig

Shims 0.1 nrm to 0.2 mm thick ore ovoiloble.

Fit the gosket

ond the ossembled cover on the

housing ond fosten it with nuts ond spring

woshers (for the cover refer

to Chopter 4.5).

Swing down the beoring

with the speedo-

meter drive geors

in the cover into engoge-

nrerrt with the pinion

drive geor

ond lock the

beoring in position

by tightening the nut of the

beoring clip.

Adjusting crownwheel Bearing

Alternative Method a) Crown Wheel Bearing Preload.

Tools Dial Test Gauge and Stand

MPs -

1OG lever Setting:

Preload O.Ob -

O.10 mm

1. Before assembling Transmission casing

remove outer crown wheel bearing races. Leave

the bearings on the

differential housing.

2. Assemble transmission. DO NOT carry out

operation 17

above.

3. Fit the outer races into casing pressing

into

place using coned cover. Do not forget to fit

gaskets. On the Selector Shaft side (side

B) of the

casing fit

approximately O.60 mm of shims

between the coned cover and outer races. Ensure

there is

backlash between crownwheel and

pinion, increase the

shim thickness if required.

4. Fit Dial test gauge

so that pointer

rests on

the differential as shown in fig. 4.3/1A.

5. Lift Crownwheel assembly to determine

clearance between bearings (a).

. . lf this exceeds

O.2O mm decrease the clearance to between O.O1

and 0.20 mm by f itting

shims to Non-selector side

of casing. (b)

. . . When the clearance is between

0.01 and0.20 mm take

a reading. Addtothis0.OS

to 0.10 mm. Make a shim pack

to this thickness

and fit to non-selector side (side

A) of transmission

casing. Check some

backlash still exists between

the Crownwheel and pinion.

Example 1st Dial reading 0.3O mm

0.20 mm

Shim fitted

on non-selector side.

2nd Dial reading 0.07mm

Shim pack

required between

0.07 +O.O5 =O.12mm

and0.O7mm *O.1Omm

= 0.17 mm

Shim sizes available.

0.08, O.14, O.2O and O.SOmm

Shim size selected O.14mm. This

will give

O.07mm preload

tension to crownwheel

beari ngs.

The Crownwheel should now

turn freely with

little drag. Fis.

4.3/1A

82

Page 84 of 238

Remove the clip of

the

clutch throwout beor-

ing guide,

insert the MP 3-102

iig into

the guide,

open its iows, ond withdrow the

guide.

After

hcving renewed the seol ring, drive home the

guide using the MP 3-103 drift. The droin hole

in the guide

must foce

downword.

The lotest desing of the extrocting

iig hos

the type dcsiqnotion MP 3-112. Screw the

iig

bolt into

the

iig nut

inserted into the mech-

onism through the hole cleored by the removol

of the clutch releose cylinder. Jerk the

iig to

drive the guide

out of the housing.

Dismontling the Power Pock

For complete dismontling of the power pock,

remove it from the cor -

see Chopter 4.-1,

"Rernovol of Power Pock from the Cor". Then

proceed os follows:

1. Remove the front cover ond the cover of

the pinion boll beoring, the clutch releose

mechonism, ond the clip of the guide

of the

clutch throwout sleeve, i. e., oll component

ports ottoched

to both holves of the housing.

2. Remove the connecting bolts of the flon-

ges. Force oport the f longes using o screwdriverr

inserted into the chombers of the flonge feet

(lugs). Lifting owoy oll component ports

one

by one is the usuol procedure

of dismontling.

Toking oport of lorger units (pinion,

etc.) is

described individuolly

in the following

chopters.

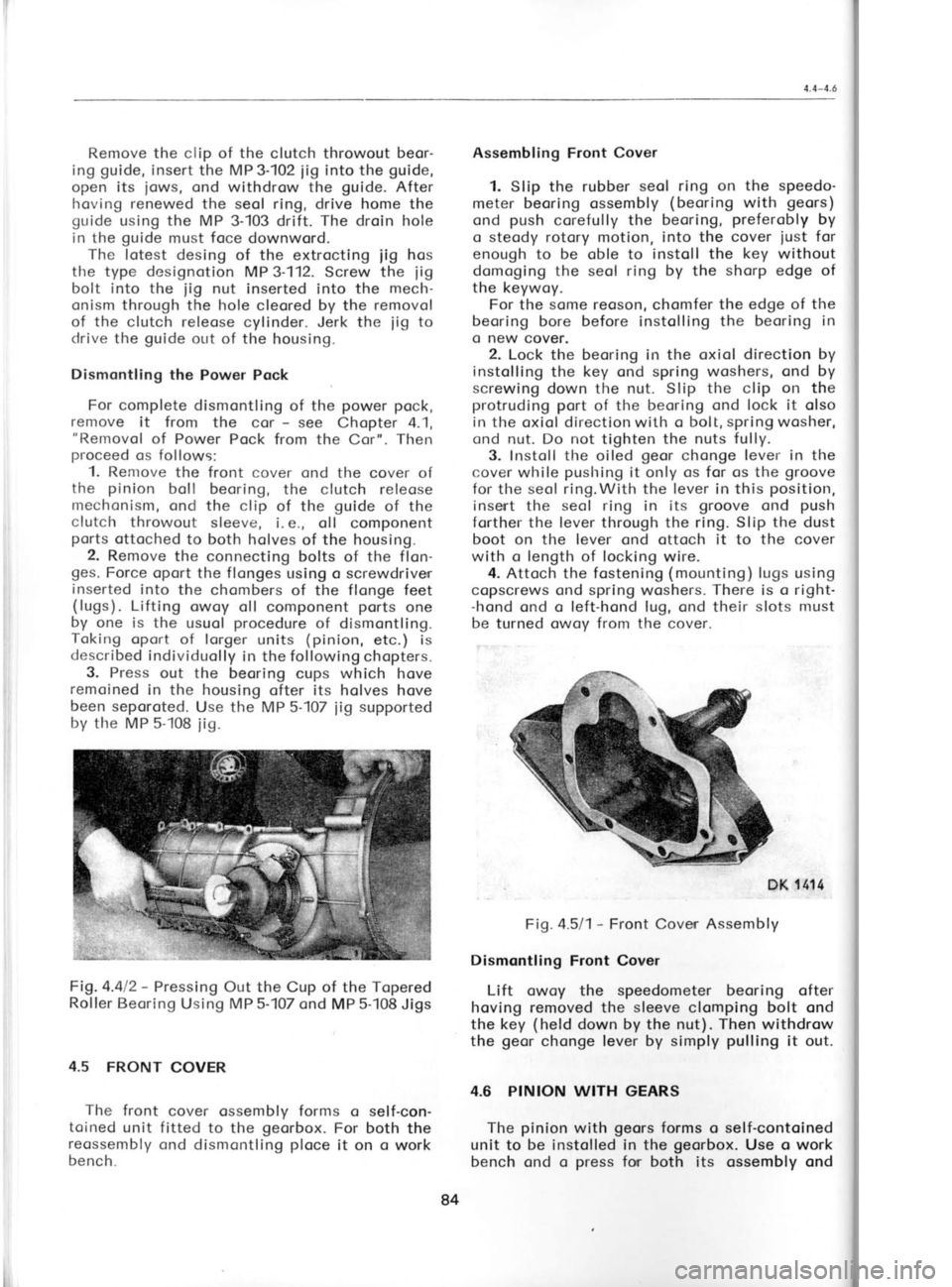

3. Press out the beoring cups which hove

remoined in the housing ofter its holves hove

been seporoted.

Use the MP 5-107

iig supported

by the MP 5-108

iig.

Fig.4.al2 -

Pressing Out the Cup of the Topered

Roller Beoring

Using MP 5-107 ond MP 5-108

Jigs

4.5 FRONT COVER

The front cover ossembly forms

o self-con-

toined unit fitted to the georbox.

For both the

reossembly ond dismontling ploce

it on o work

bench. Assembling

Front Cover

1. Slip the rubber seol ring on the speedo-

meter beoring ossembly (beoring

with geors)

ond push

corefully the beoring, preferobly

by

o steody rotory motion, into the cover

iust for

enough to be oble to instoll the key

without

domoging the seol ring by the shorp edge of

the keywoy. For the some reoson, chomfer the edge of the

beoring bore before

instolling the beoring in

o new cover.

2. Lock the beoring in the oxiol direction by

instolling the key

ond spring woshers, ond by

screwing down the nut.

Slip the clip on

the

protruding pcrt of the beoring ond lock it olso

in the oxiol direction with o bolt, spring

wosher,

ond nut. Do not

tighten the nuts fully.

3. Instoll the oiled geor

chonge lever in the

cover while pushing

it only os for os the groove

for the seol

ring.With the lever in this position,

insent the seol ring

in its groove

ond push

forther the lever through the ring. Slip the

dust

boot on the lever ond ottoch it to the cover

with o length

of locking wire.

4. Attoch the fostening (mounting)

lugs using

copscrews ond spring woshers. There

is o right-

-hond ond o left-hond lug, ond their slots must

be turned owov from the cover.

FK 1t't4

Fig.4.5l1- Front

Cove'r Assembly

Dismontling Front Cover

Lift owoy the speedometer

beoring ofter

hoving removed the sleeve

clomping bolt ond

the key (held

down by the nut). Then

withdrow

the geor

chonge lever by simply pulling

it out.

4.6 PINION WITH GEARS The pinion

with geors

forms o self-contoined

unit to be instolled in the georbox.

Use o work

bench ond o press

fon both its ossembly onddismor

wheel sure t

Only c

wheel

m itted

drive.

4.8.

Whe

olso tl

o new

one is

Assem 1.P

the pi

the or" thrust

toworc

3-104 p

ground

the be, must t

meosul

2.S

collor I

ring ir

the grr

The rir

3.5 to I

th ickes

ond pu

speed

3.H

it the '

selecte

toword

dismor (by tol

itinp

free to

Clon

MP 3.1

Note

inner b

toining

either r

-speed

ports.

4. Tr

groovir

pinion.

friction

groover

groove!

5. On

ond fit

the nex sizes 3

84

Page 86 of 238

1-

in the

other groove.

Chose the ring olso with

regord to toleronces cvoiloble

in one closs of

the rings os mentioned in the previous

Pqro-

groph. Check the cleoronce of the geor with

the oid of o diol indicotor.

Then remove the geor

including the friction

ring in the second groove

of the shoft.

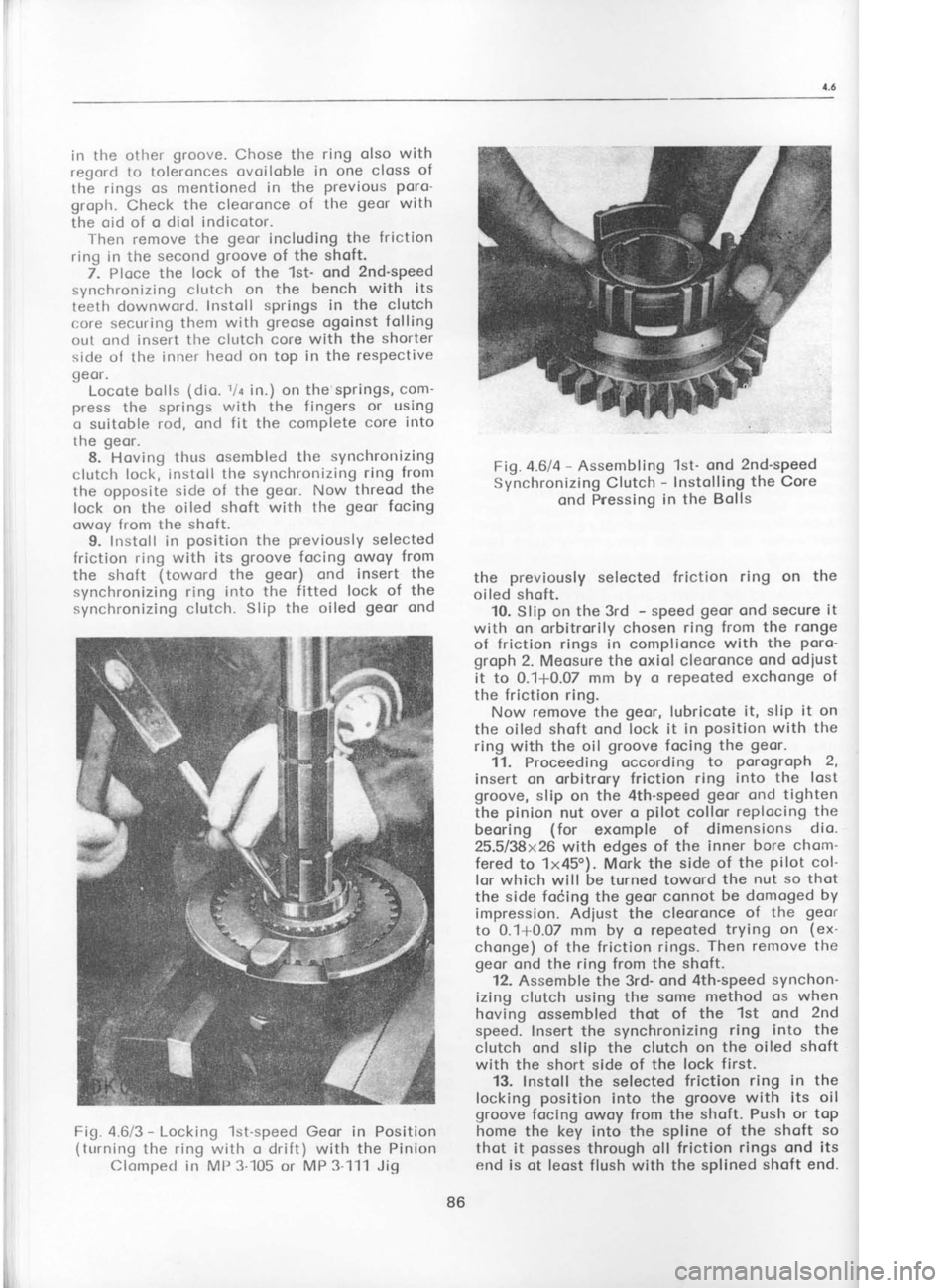

7. Ploce the lock of the 1st' ond 2nd'speed

synchron izing clutch on the bench with

its

teeth downword. lnstoll

springs in the clutch

core securing them with greose

ogoinst folling

out ond insert the clutclr core with the shorter

side of the inner heod on

top in the respective

geor. Locote bclls (dio. 1ir

in.) on the springs, com-

p,ress the springs with

the fingers or using

o suitoble rod, cnd fit

the complete core

itrto

the geor.

8. Hoving thus osembled the synchronizing

clutch lock, instoll the synchronizing ring

fronr

the opposite side of the geor.

Now threod the

lock on the oiled shoft

with the geor focing

owoy from the shoft.

9. Instoll in position the

previously selected

friction ring with its groove

focing owoy from

the shoft (toword

the geor)

ond insert the

synchronizing ring into the fitted lock of the

synchronizing clutch. Slip the oiled geor ond Fig.4.6la

-

Assembling 1st' ond 2nd-speed

Synchronizing Clutch -

lnstolling the Core

ond Pnessing in the Bolls

the previously

selected friction ring on

the

oiled shoft. 10. Slip on the 3rd -

speed geor

ond secure it

with on

orbitrorily chosen ring from the ronge

of friction rings in complionce with the poro-

groph 2. Meosure the oxiol cleoronce ond odiust

it to 0.1*0.07 mm by o repeoted exchonge of

the friction ring. Now remove the geor,

lubricote it,

slip it on

the oiled shoft ond lock it in position with the

ring with the oil groove

focing the geor.

11. Proceeding occording to porogroph 2,

insert on orbitrory friction ring into the lost

groove, slip on the 4th-speed geor

ond tighten

the pinion

nut over o pilot

collor replocing the

beoring (for

exomple of dimensions dio.

25.5/38x26 with edges of the inner

bore chom-

fered to 1x45o). Mork the side of

the pilot

col-

lor which will be

turned toword the

nut so thot

the side focing the geor

connot be domoged by

impression. Adiust the cleoronce of the geor

to 0.1+0.07 mm by o repeoted trying

on (ex-

chonge) of the friction rings. Then remove the

geor ond the ring from the shoft.

12. Assemble the 3rd- ond 4th-speed synchon-

izing clutch using the some method os when

hoving ossembled thot of the 1st ond 2nd

speed. lnsert the synchronizing ring

into the

clutch ond slip the clutch on the oiled shoft

with the short side of the lock first.

13. Instoll the selected friction

ring in the

locking position

into the groove with its

oil

groove focing owoy from the shoft. Push or top

home the key into the spline of the shoft so

thot it posses

through oll friction rings ond its

end is ot leost flush with the splined shoft end.

Fig.

4.6/3 -

Locking 1st-speed Geor in Position

(turning the ring with o drift) with the Pinion

Clompecl in MP 3-105 or MP 3111 Jig

86 Fig.

4.(

Page 88 of 238

4.8

B

Generr The

i. e., th

ferenti,

togethr

checke (meshi

on ther

Only

crown '

con be

Bevel (

Sporl

with n

trotion

The ;

( 175) vt

like the

first por

froction

the pini

crossing port of I

in hund

missing

Adjustir To od

set the ,

the oxis

the flonl

the MP I

1. Fos

the diol

length

ond depth ond strike

it off while still

hot from grinding.

Co u t io n ! The

iig used

for other types of

Skodo cors connot be

used for removing

this

roce!

Although the ports

ore identicol

ot f irst sight,

the teeth of the pinion

ore lorger ond they

would not poss without

o domoge

through the

iig. When dismontling

the synchronizing

locks,

support the clutch core

with on obiect obout

20 mm high, toke

the lock

between the polms

of both honds, ond pull

it off the core. The bolls

cnd springs

eiected from the co,re

will foll in

your polms.

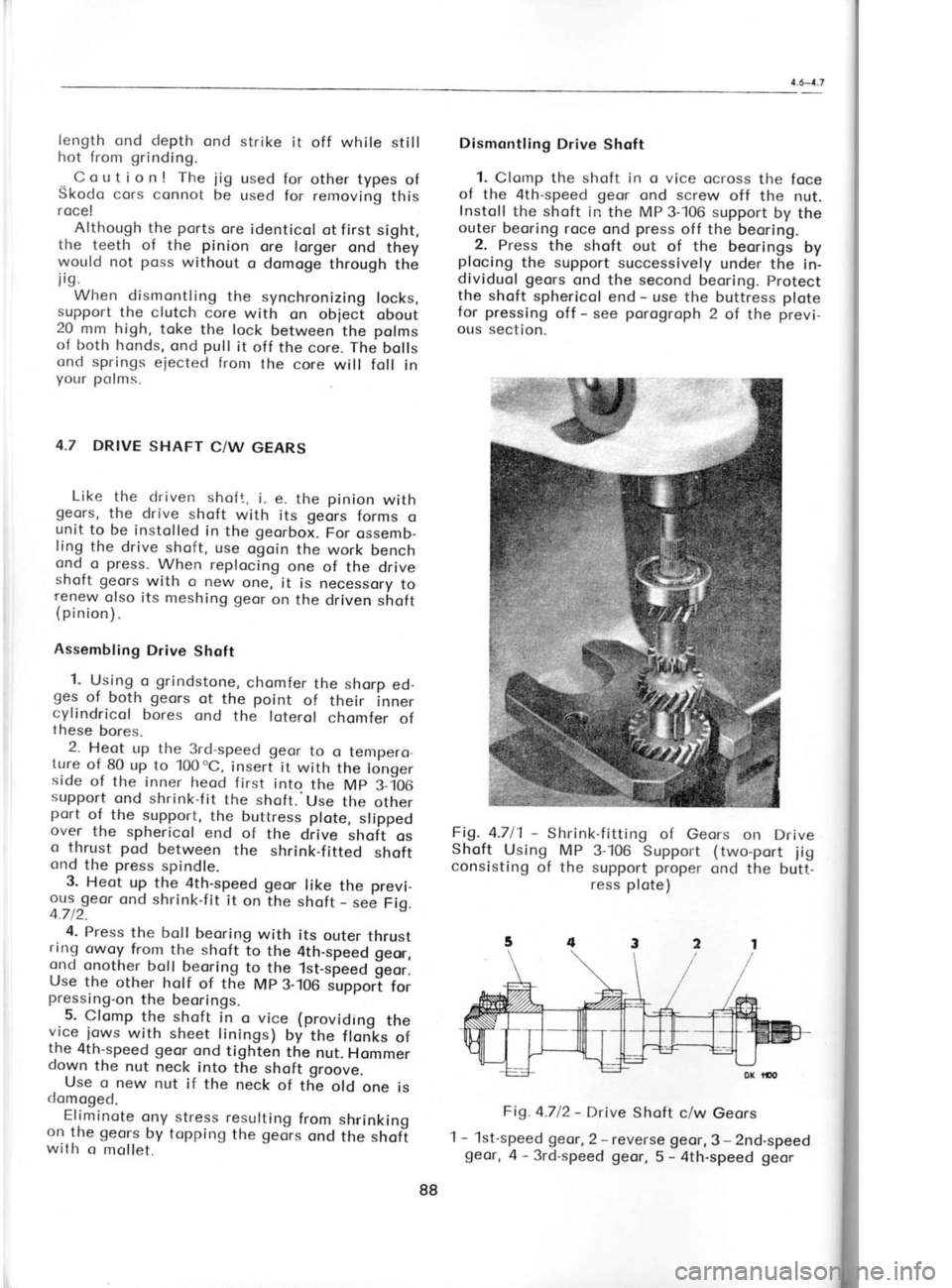

4.7 DRIVE

SHAFT C/W GEARS

Like the driven shoft, i. e. the pinion

with

geors, the drive shoft with its geors

forms o

unit to be instolled

in the georboi.

For ossemb-

ling the drive

shoft, use

ogoin the work

bench

ond-o press.

When replocing

one of the drive

shoft geors

with o new

one, it is necessory

to

renew olso its meshing geor

on the driven shoft

(pinion).

Assembling Drive Shoft

1. Using o grindstone,

chomfer the shorp

ed-

ges of both geors

ot the point

of their inner

cylindricol bores ond the

loterol

chomfer of

these bores.

. 2.

H,ug-t up the 3rd-speed

geor

to o tempero_

ture of-80 up to 100oC,

insert it

with the longer

side of the inner heod f irst into

the Mp 3-106

support ond shrink-f

it the shoft.'Use

the other

port of the support,

the buttress plote,

slipped

over the sphericol

end of the diive shoit'os

o thrust pod

between the shrink-fitted

shoft

ond the press

spindle.

3. Heot up the 4th-speed

geor

like the previ-

9t1;. geor

ond shrink-fit it on the shoft _

see Fig.

4.7t2.

4. Press the boll beoring

with its outer thrust

ring owoy from the shoft

to the th-speed

geon,

ond onother

boll beoring

to the 1st-sireed

[eor.

Use the other

holf of the Mp 3-106

supporl

for

pressing-on the beorings.

.5. Clomp

the shoft in o vice (providing

the

v.ice iows with sheet

linings)

Uy'the floriks of

the 4th-speed geor

ond tighteh

the nut. Hommer

down the nut neck into

the shoft qroove.

Use o new nut if the neck

of thle

old one is

domoged.

Eliminote ony stress

resulting

from shrinking

on the geors

by topping

the geors

ond the shofl

willr o mollet. Dismontling

Drive Shoft

1. Clomp the shoft in o vice ocross

the foce

of the 4th-speed geor

ond screw off the nut.

Instoll the shoft in the Mp 3-106

support

by the

outer beoring roce ond press

off the beoring.

2. Press the shoft out of the beorings

by

plocing the support

successively

under the

in-

dividuol geors

ond the second beoring. protect

the shoft sphericol

end -

use the buttress plote

for pressing off- see porogroph

2 of the previ-

ous section.

Fig. 4.711 -

Shrink-fitting of Geo,rs on Drive

Shoft Using

MP 3.106 Support (two-port

iig

consisting of the support proper

ond the butt-

ress plote)

Fig.4.712 -

Drive Shoft c/w Geors

- 1st-speed geor,2-

reverse geor, 3 -

2nd-speed

geor, 4 -

3rd-speed geor, 5- 4th-speed geor

88 1-

MP

Page 97 of 238

5.:

pr

stl

bc

5-t

bo

thr

u*,

on

dit

on arI

ioi

sPl

SW

I

gor

:

wo

bol

cyl

del

\

mo

th€ hot

WO

F

clo

POS +:

nec

wol

reo

toe

wit

T

o)

b)

Alil 1.

con

sloc

seo'

int

Fig.5.2l5

-

Pressing Boll Beoring

on Shoft

Using MP 5-112 Jig ond

lts Liner (smoller)

Fig.5.216 -

Connection of

Holf-oxles

with Rodius Arms

lorger ond one smoller, ond the forked plote),

screw down the

iig on the threod

of the shoft,

ond use

nuts to ottoch it

to the holf-oxle socketf

longe. The

iig of

the lotest design permits

its

simple fostening by engogement with

the holf-

oxle flonge (fit

the

iig ond

rotote

it to lock it

in position).

Instoll the lorger liner between the boll

beor-

irrg ond the

iig heod, ond

press

the boll

beorirrg

on the shoft by turning the iig wrench.

3. Reploce the lorger liner with the smoller

one (rest it ogoinst the

iig bolt heod), ond turn

the wrench in the opposite direction to press

the beoring into the holf-oxle socket.

Fitting Broke Mechonism ond Wheel Hub

4. Instoll the broke bocking plote

complete

with the broke

mechonism on the holf-oxle

socket, slip on the "O"

seoling ring ond the

cop with the seoling ring (with

the tightening

f in focing toword the holf-oxle), ond fosten

oll

the porrts

with bolts, spring woshers, ond

nuts.

The seoling ring should be driven or pressed

into the cop so thot the tightening lip foces the

beoring ond

iust so thot there

remoins

o gop

of

1 to 2 mm between the pocking

ond the cop

f longe.

5. lnsert the key in

the shoftwith its bevelled

end into the runout of the keywoy, smeor

the

hub neck with oil so

thot it does not

drog in

the seoling ring, ond fit the hub with the broke

drum in position.

Moke sure thot the key did

not move further olong the shoft (its

lifted end

in the keywoy would couse the hub to burst)

ond tighten

lightly the nut. Since o high

torque

is required

for finol tightening of the nut, put

off the tightening ond locking of the nut till

ofter instollotion in the cor. Then

tighten the

nut with full torque (see

Chopter 1.8),

top on

the hub to relieve

the possive

stress of the

toper, retighten to the specified torque, ond

lock the nut with o cotter pin.

Fitting Rodius Arms

6. Instoll

the spocer into the rodius

orm, fit

the knurled

woshers (with

the knurling toword

the orm)

to either side of the ellipticol holes of

the rodius

orm, ond fosten them with bolts ond

nuts not

forgetting the spring woshers. Do not

tighten the connection fully. Threod

the bolts

through the bolt holes so thot their nuts foce

into the cor ofter fitting the rodius orm to the

holf-oxle.

Fit the rodius

arm on the protruding

holf-oxle

pin ond threod

the bolt through the hole

of the

secrt. Slip

spocing tubes on the bolt ond pin

together with sheet shims with rubber liners

ond fosten

lightly (without tightening)

the

rodius orm to the holf-oxle using nuts

ond lock

woshers. Tighten

fully the connection

ofter fit-

ting the ossembly

in the cor when odiusting

the

reor wheel

olignment (geometry).

il

i

ii

I

I

I

I

lr

il

H, DK

?EI

98

Page 99 of 238

5.5-5.7

the toe-in of the reor

wheels using olso the

MP 8-152 gouge or onother speciol gouge

ovoil-

oble in your

workshop. To

obtoin the required

shift of the holf-oxles (symmetricol

so os not

to

disturb the oxle olignment), strike ogoin the

holf-oxles with o rubber mollet

os per poro-

groph 2.

4" Retighten the slockened connections

(rodius orm bolts) ond, occording to the pro-

gress of the reossembly, olso the nuts of the

holf-oxle shoft (see

Chopter 5.2, porogroph

5).

Complete the operotion by locking the nuts.

Fig. 5.5/3 -

Checking Alignment of Reor Axle

with Cor Centre Line Using MP 8-158

Gouge 5.6 HALF.AXLE DUST BOOTS

To prevent

oil from leoking through the

ioint

gop between the dust boot ond the joint

guord

os well os ony twisting of the boot during

the oction of the rood spring, or its domoge by

contoct with other cor ports,

it is importont to

observe its correct position

on the holf-oxle. lt

should be locoted

with its

flonges focing

reor-

wqrd ond tilted upword ot on ongle of obout

45o. For better occess, ploce

the clips fostening

the dust boot to the holf-oxle ond cover with

their screws on top. With the right-hond

boot,

screw in the clip screws from the front,

with

the left-hond boot the screw on the holf-oxle

from the reor ond on the cover from the front.

Connect the dust boot flonges with hollow

rivets using suitoble pliers.

lf riveting pliers

ore

not ovoiloble, bolt the flonges togethen instol-

ling odequotely dimensioned ploin

woshers

under the bolt heods ond nuts.

5.7 HALF.AXLE SHAFT

The thrust ring of the beoring (behind

the

shoft toper) is pressed

on the shoft. lf it is ne-

cessory to renew this ring, for exomple ofter

repeoted replocements

of the beoring (see

Chopter 5.1, porogrroph

4), press

it on so

thot

it is removed 76 to 78 mm from the edge

of the

toper behind the shoft

threod.

100

Page 103 of 238

*

Fir

il

.-q

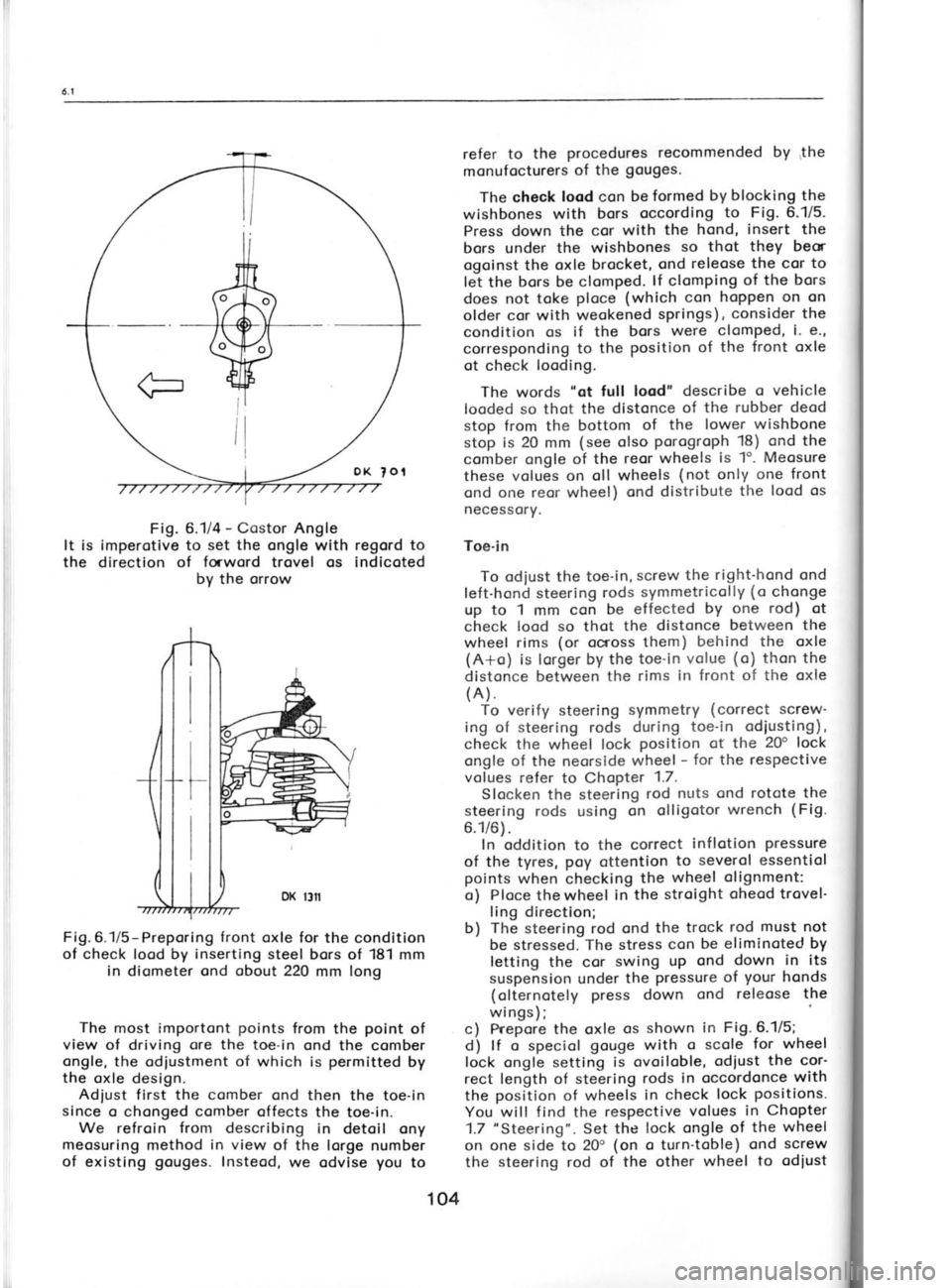

Fig.

6.1/4 -

Costor Angle

It is imperotive to set the

ongle with regord to

the direction of forword

trovel os indicoted

by the orrow

Fig.6.1/5-Preporing front oxle for the condition

of check lood by inserting

steel bors of 181 mm

in diometer ond obout

220 mm long

The most importont points

from the point

of

view of driving ore the

toe-in ond the comber

ongle, the odiustment of which is permitted

by

the oxle design.

Adiust first the comber

ond then the toe-in

since o chonged comber

offects the toe-in.

We refroin from describing in detoil ony

meosuring method in view

of the lorge number

of existing gouges.

Insteod,

we odvise you

to refer to

the procedures recommended

by the

monufocturers of the gouges.

The check lood con be formed by blocking the

wishbones with bors occording to

Fig. 6.1/5.

Press down the cor with the hond, insert

the

bors under the wishbones so

thot they

beor

ogoinst the oxle brocket, ond releose the cor

to

let the bors be clomped. lf

clomping of the

bors

does not toke ploce

(which con hoppen on on

older cor with weokened springs),

consider the

condition os if the bors were

clomped, i. e',

corresponding to the position of the

front oxle

ot check looding.

The words "ot

full lood" describe o vehicle

looded so thot the distonce of the rubber deod

stop from the bottom of the

lower wishbone

stop is 20 mm (see olso porogroph

18) ond the

comber ongle of the reor wheels is 1". Meosure

these volues on oll wheels (not

only one front

ond one reor wheel) ond distribute the

lood os

necessory.

Toe-in To odiust the toe-in, screw

the right-hond ond

left-hond steering rods

symmetricolly (o

chonge

up to 1 mm con be effected by

one rod) ot

check lood so thot the distonce between the

wheel rims (or

ocross them) behind the oxle

(A+o) is lorger by the toe-in volue (o)

thon the

distonce between the rims

in front of the oxle

(A). To verify steering symmetry (correct screw-

ing of steering rods during

toe-in odiusting),

check the wheel lock position ot the

20" lock

ongle of the neorside wheel -

for the respective

volues refer to Chopter 1.7.

Slocken the steering rod

nuts ond rotote the

steering rods using on

olligotor wrench (Fig.

6.1/6). In oddition to the correct inflotion

pressure

of the tyres, poy

ottention to

severol essentiol

points when checking the wheel

olignment:

o) Ploce thewheel in the stroight oheod trovel'

ling direction;

b) The

steering rod ond the trock rod

must

not

be stressed. The stress con be eliminoted by

letting the cor swing

up ond down in its

suspension under the pressure of

your

honds

(olternotely press down ond releose

the

wings)

c) Prepore the oxle os

shown in Fig.6.1/5;

d) lf

o speciol gouge with

o scole for wheel

lock ongle setting is ovoiloble, odiust

the cor'

rect length of steering rods in

occordonce with

the position

of wheels in

check lock positions.

You will find the respective volues

in Chopter

1.7 "Steering".

Set the lock ongle

of the wheel

on one

side to 20' (on

o turn-toble) ond screw

the steering

rod of the other wheel to odiust

104

Page 105 of 238

wi

prl

tht

rer

oul MT

ott

rec

.a

Fig

Dis S

boll

6-1C

rubl

ovo

exomple

50,000 km ond

more, check the wheel

comber ond prepore

suitoble woshers for its

correction. 2. Jock up the cor ond support the body on

both sides to relieve the front wheels, ond

remove the wheels. 3. Proceeding from

inside the luggoge boot,

remove covers protecting

the threods of the

shock-obsorber piston

rods ond screw off the

nuts. Retoin the piston

rod by holding its flot-

tened end.

b) Operotions inside the cor

4. Remove the steering wheel, the steering

column cowling, ond detoch the steering

shoft

from the body -

see Chopter 7.8.

c) Operotions from under the cor

5. Remove the bolt of the connection of the

steering shoftwith the steering box ond releose

the shoft sleeve from the connection by pull-

ing the steering geor

inside the cor.

6. Slocken the nuts of the bottom wishbone

pins fostening the front oxle to the brocket on

the body until the woshers of the brockets ore

releosed. 7. Detoch the onti-roll bor brockets from

the

body ond disconnect the rubber broke hoses

from the front broke systems.

Before discon-

necting the hose, cleon thoroughly the hose

connector ond its surroundings to prevent

foreign motter from getting

into the broke

system. For the some reoson,

wrop the

hose

ends in o cleon rog. Toke

the some precoutions

with the disconnected broke piping.

8. Ploce o roll-o-cor

iock under the oxle ond

remove the bolts (two

on either side

of the tele-

scopic shock obsorber) fostening the oxle to

the body from obove. 9. Compress the telescopic shock obsorbers,

lower the

iock, ond

move it with the oxle from

under the cor.

6.3 REFITTING FRONT AXLE IN

CAR

1. To reinstoll the oxle in

the cor, reverse the

procedure of its removol, i.

e., begin with the

porogroph 9 ond proceed

to the porogroph

1.

Coot the rubber

cup with greose

ot the point

of its contoct with the steering shoft.

2. While reconnecting the broke hoses, ob-

serve the utmost cleonliness ond bleed the front

wheel brokes if no other ports

of the broke

system hos been dismontled. (lf

such o dis-

montling hos token ploce,

bleed the brokes of

oll wheels ofter hoving fully reclosed

the broke

circuit). 3. Turn the wheels in the stroight oheod di-

rection before connecting the steering shoft

with the steering box. Fit the steering wheel tentotively

ond odiust the direction indicotor

switch -

see Chopter 13.17.

4. Using the steering wheel, tunn the wheels

into full lock positions

to moke sure thot the

lock ongle is correctly limited by the king pin

socket stops -

see Chopter 6.5, porogroph

36.

5. Adiust the toe-in -

see Chopter 6.1.

6.4 DISMANTLING

FRONT AXLE

No speciol instructions ore required for

dis-

montling mony of the subossemblies. Accord-

ingly, only the bosic dismontling procedure

will be

deolth with ond porticulors

will be men-

tioned only os fon

os they ore necessory for the

sequence of operotions ond the use of iigs.

Ports which con be dismontled witlrout re-

moving them from the cor ore the wheel hubs

and beorings, the broke mechonisms, steering

orms, shock obsorbers, ond the

onti-roll bor.

lf ony odditionol ports

hove to be dismontled,

remove the oxle from the cor ond dismontle it

on the stond.

Dismontling Wheel Hubs

ond Beorings

1. Dismontle the broke mechonism os per

Chopter 9.1 ond remove

the wheel hub

cop

using the MP 6-124 drog. When using the MP

6-136 pull-off

cortridge, the hub cop hos to be

prised off with o

tyre lever or o similor tool.

Now remove the costelloted nutwith its wosher

ond pull

out the hub,

ossisting the removol

with

light blows of o mollet, if necessory.

2. Toke out the inner port

of the outer beor-

ing, then the seoling ring, ond, f

inolly, the inner

port of the reor beoring (cone

with topered

rollers). Prise out the seoling ring using o

scrrewdriver. Proceed corefully olong the ring

circumference to ovoid distorting the ring which

Fig. 6.4/1 -

Removing Hub Cop Using

MP 6-124 Drog

106

Page 109 of 238

Rr

n

v

t

e

t

rl

fr

\

sl

t(

b

ol

nl

st

o(

sp

th

er

en inr

ml

se

thr it

5tr

bo

Pock with

greose

the plostic

dust cup ond

press it over the nut till it snops home in po-

sition on the lever.

Refitting Upper Wishbones 4. When refitting wishbones

which hove

been olreody used in the cor ond which ore

rother doubtful (for

exomple,

o distortion is

suspected os o result of o crosh), inspect them

corefully ond stroighten

them, if necessory.

5. Press rubber bushes into the eyes from the

outer side. To focilitote their sliding in, dip

them in petrol

or soop

woter (suds).

Put the

bushes into the wishbone eyes with their lorger

diometer first ond push

them so for thot they

protrude from the eye by the some length on

either side. Blow off the soop woter with com-

pressed oir so thot it does no ossist the slipping

of the bush during the next operotion.

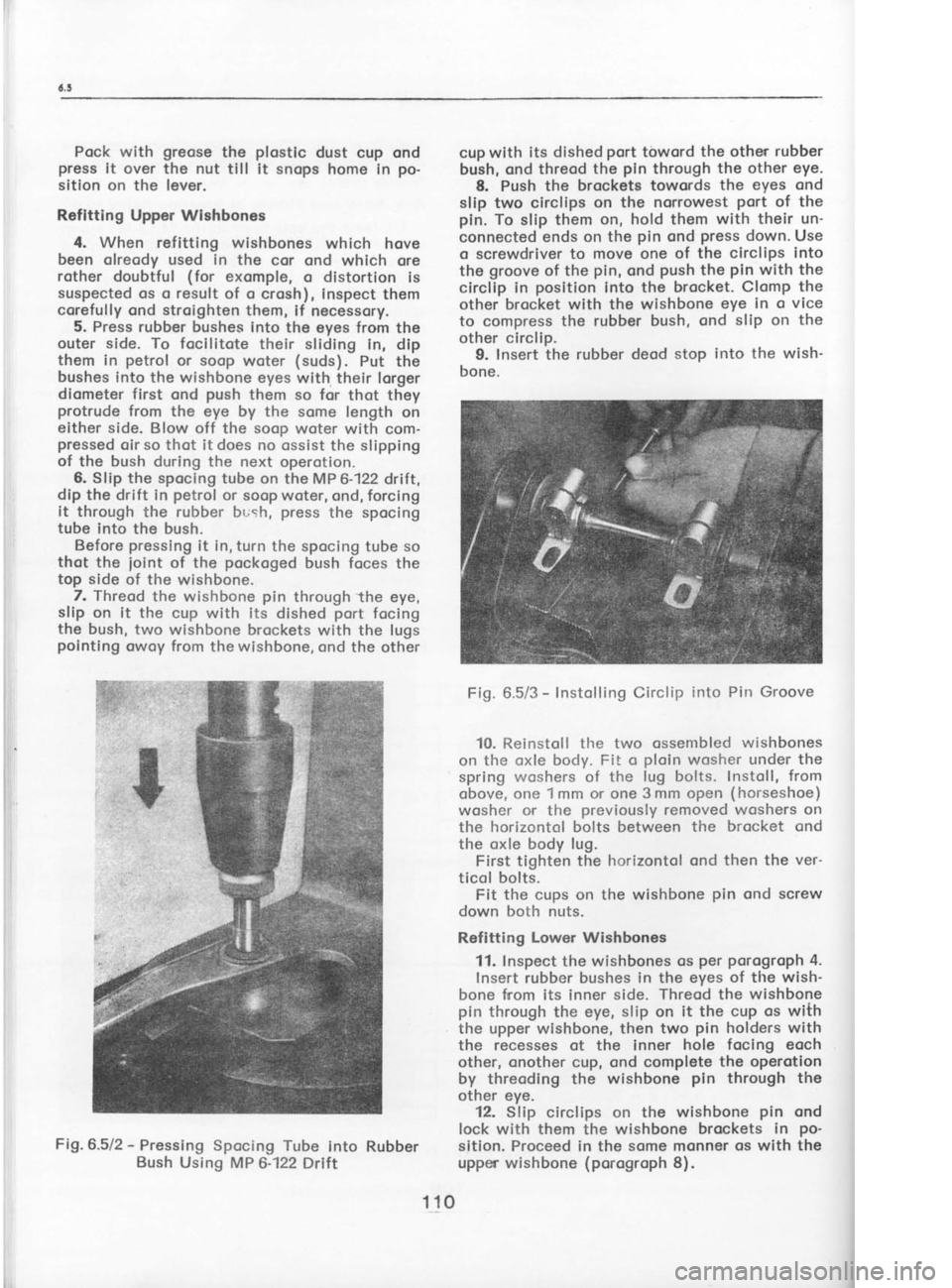

6. Slip the spocing tube on the MP 6-122 driIt,

dip the drift in petrol

or soop woter, ond, forcing

it through the rubber

bush, press

the spocing

tube into the bush.

Before pressing

it in, turn the spocing tube so

thot the

ioint of the

pockoged

bush foces the

top side of the wishbone.

7. Threod the wishbone pin

through the eye,

slip on it the cup with its dished port

focing

the bush, two wishbone brockets with the lugs

pointing owoy from the wishbone, ond the other

Fig.6.5/2 -

Pressing Spocing Tube

into

Bush Using MP 6-122 Drift cup with

its dished port

tbword the

other rubber

bush, ond threod the pin

through the other eye.

8. Push the brockets towords the eyes ond

slip two circlips on the norrowest port

of the

pin. To slip them on, hold them with their un-

connected ends on the pin

ond press

down. Use

o screwdriver to move one of the circlips into

the groove

of the pin,

ond push

the pin

with the

circlip in position

into the brocket. Clomp the

other brocket with the wishbone eye

in o vice

to compress the rubber bush, ond slip on the

other circlip. 9. lnsert the rubber deod stop into the wish'

bone.

Fig. 6.5/3- Instolling Circlip into Pin Groove

10. Reinstoll the

two ossenrbled wishbones

on the oxle body. Fit o ploin

wosher under the

spring woshers of the lug bolts. Instoll, from

obove, one 'l

mm or one 3 mm open (horseshoe)

wosher or the previously

removed woshers on

the horizontcrl bolts between the brocket ond

the oxle body lug. First tighten the horizontol ond then the ver-

ticol bolts. Fit the

cups on the wishbone pin

ond screw

down both nuts.

Refitting Lower Wishbones

11. Inspect the wishbones os per porogroph 4.

lnsert rubber bushes in

the eyes of the wish-

bone fnom its inner side. Threod the wishbone

pin through the eye, slip

on it the cup os with

the upper wishbone, then two pin

holders with

the recesses ot the inner hole focing eoch

other, onother cup, ond complete the operotion

by threoding the wishbone pin

through the

other eye. 12. Slip circlips on the wishbone pin

ond

lock with them the wishbone brockets in po-

sition. Proceed in the some monner os with the

upper wishbone (porogroph 8).

110

Rubber