key SKODA 120 LS 1980 Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 120 LS, Model: SKODA 120 LS 1980Pages: 238, PDF Size: 47.09 MB

Page 14 of 238

--

!

ti

f

I

n

i

Boot lid

up to 1978 -

To open it, press

down

the release on the

right-hand side

underthe facia

oanel. Then

lift

the lid on the right-hand side and

secure it

in its raised position with

the aid of

the

articulated strut. After

lowering the

lid, lock it by

pulling the release as

far as it will go.

'

Sinie 1978

open lid by pulling

handle and

lower as described above.

To

lock press lid above

catches. I

(in

egr

WO

r,nol

pul

T

rem

fore

B

Pus

the

lugs

forn

cusl

Fig.' OT

,4

Fig.1.3111 Controls

1 -

Geor lever

2 -

Hond broke

lever

3 -

Choke n

between Front

Seots

't488

Fig.1.3112 Switching Positions

of

Switchbox

c/w Steering Lock

0 -

All functions of

f, engine stopping

| -

lgnition on -

ignition system ond

oll ports

ol electricol equipment ore

supplied

with

curre nt

ll -

Engine storting -

before repeoting the

stort-

ing procedu,re,

return the key to the "0"

pos-

ition ond only then stort the

engine ogoin

STOP -

Position for

withdrowing the

ignition

key ond engoging the

steering lock (ofter

hoving withdrown the

ignition key,

turn the

steering wheel till

the lotch of the lock

c licks home

) .

lf the key connot be turned

when unlocking

the steering, relieve the stress

of the steering

geor by tuining the

steering wheel slightly-

LUGGAGE AND ENGINE

COMPARTMENTS

The moin luggoge comportment (boot)

is in

the forebody, the interior (inbuilt)

luggoge

comportment behind the

reor seot bockrests. Fig.

1.3/13 lloot Lid Releose

Engine bonnet -

To open it, pull

the lever in

the operture of the left-hond

reor door. To close

the bonnet, press

it down with the hond into

oosition.

For ony work in the engine comportment see

the notice in porogroph 1,

Chopter 2'1.

Fig. 13lM Reor Bonnet Releose Lever

SEATS, ADJUSTMENT AND CONVERSION

To moke the seot slide, unlock it by lifting

the lever ond tilt the bockrest by

rototing the

rosette. Set

Cor

by thr

only r

is pro

The

ofter

lifting

bock,

by its

positir

Ash

tion o

open i

its cos

hold i

inworc

first it

oshtro'

1.4 C,

Jqck

iock is

held in

14

Page 16 of 238

Lifting

the cor with o

Power iock -

When

r-rsing o service

Power iock, let the

cor rest on

the points

shown in Fi1.1.412.

To tow the cor, hook the towing rope on

to

the brocket under

the cor nose. Threod the pin

through the loop of the rope

ond the brocket

lugs ond secure the pin

with o cotter pin (both

thL pin

ond the cotter pin

ore included in the

cor occessories).

1.5 SPARE WHEEL

AND FUEL TANK

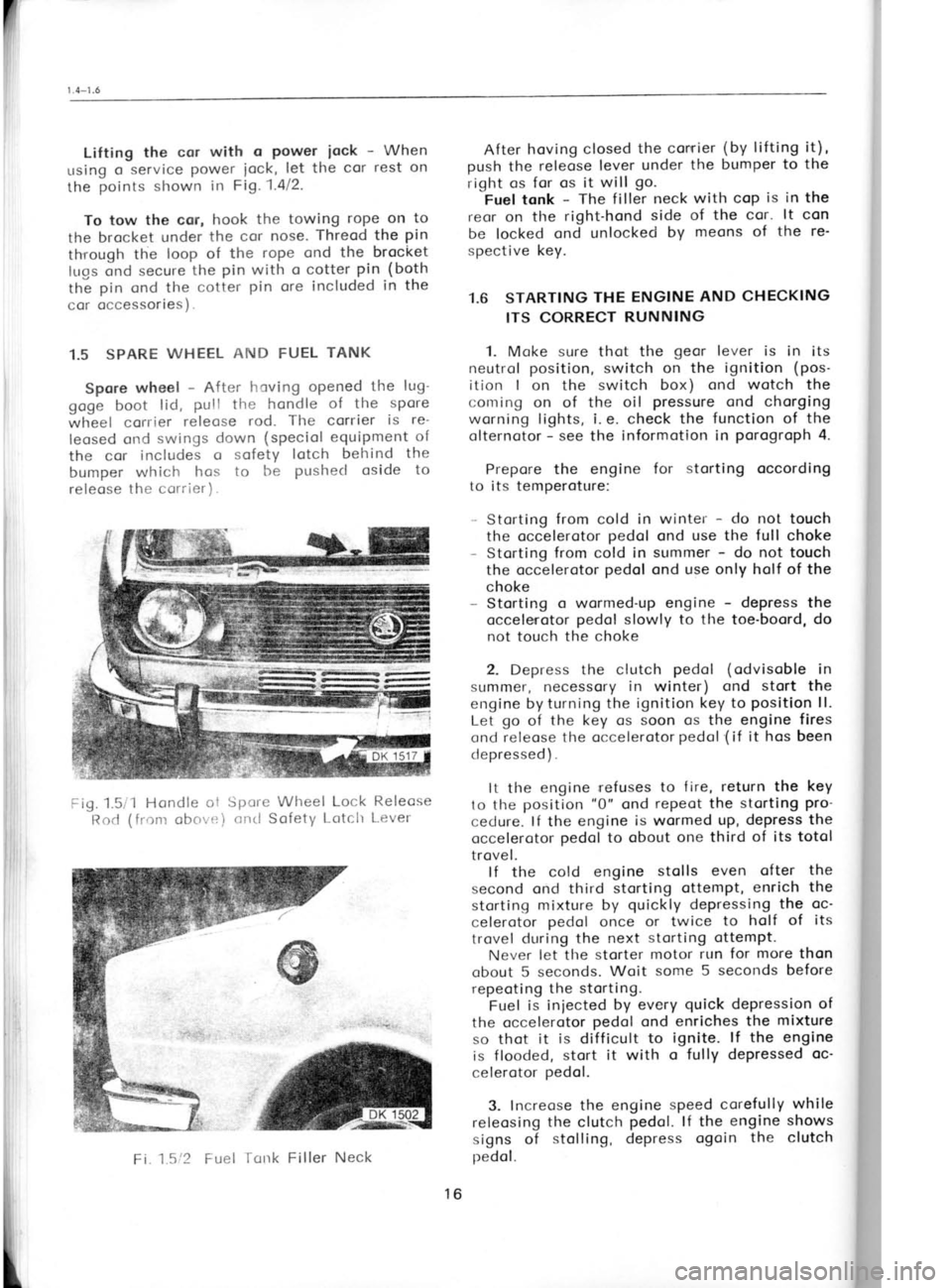

Spore wheel -

After having opened the

lug-

goge boot lid, pull the hondle of the spore

wheel corrier releose

rod.

The corrier is

re-

leosed ond swings

down (speciol equipment of

the cor includes

o sofety lotch behind the

bumper which hos to be pushecl

oside to

releose the corrier

) . After

hoving closed the corrier (by

lifting it),

push the releose lever under

the bumper to the

right os for os it will go.

Fuel tonk -

The filler neck with cop is in the

reor on the right-hond

side of the cor- lt con

be locked ond unlocked by meons of

the re'

spective key.

1.6 STARTING THE

ENGINE AND CHECKING

ITS CORRECT RUNNING

1. Moke sure thot the geor

lever is in its

neutrol position,

switch on the ignition (pos-

ition I on the switch box) ond wotch the

coming on of the oil pressure ond chorging

worning lights, i.

e. check the function of the

olternotor -

see the informotion in porogroph

4.

Prepore the engine

to its temperoture:

- Storting from cold in

the occelerotor pedol

- Storting from cold in

the occelerotor pedol

choke for

storting occording

winter -

do not touch

ond use the full choke

summer -

do not touch

ond use only holf of the

Fig. 1.5/1 Hondle ot

Rod (f ronr obove )Spcre

Wheel Lock

crnrl Safety Lotch -

Storting o wormed-up engine -

depress the

occelerotor pedol

slowly to tlre

toe-boord, do

not touch the choke

2. Depress the clutch pedol

(odvisoble

in

summer, necessory in

winter) ond stort

the

engine by turning the ignition key to position

ll.

Let go

of the key os soon os the engine fires

ond releose the occelerotor pedol

{if it hos

been

clepressed).

It the engine ,refuses

to fire, return the key

to the position "0"

ond rePeot the

storting

Pro-

cedure. lf the engine is wormed up, depress the

occelerotor pedol

to obout one third of its totol

trovel. lf the cold engine stolls even

ofter the

second ond third storting ottemPt, enrich the

storting mixture by quickly

depressing the

oc-

celerotor pedol

once or twice to holf of its

trovel during the next storting ottemPt.

Never let tlre storter motor run for more

thon

obout 5 seconds. Woit

some 5 seconds before

repeoting the storting.

Fuel is injected

by every quick

depression of

the occelerotor pedol

ond enriches the mixture

so thot it is difficult to ignite. lf the engine

is flooded, stort

it

with o fully depressed oc-

celerotor pedol.

3. Increose the engine speed corefully while

releosing the clutch pedol. lf the

engine shows

signs of stolling, depress

ogoin the clutch

pedol.

Relecse

L.ever

Fi.1.5t2 Fuel Tcrtrk Filler

Neck

16

Page 52 of 238

Alternoting

cylinder No. 1

cylinder No.3

cylinder No.4

cylinder No. 2 Adjust cleoronce

on

cylinder No.4

cylinder No.2

cylinder No. 1

cylinder No.3

Fi1.2.1312

-

Volve Cleoronce Adjustment link from the choin

front side ond fit the clip

from the reor with its open end pointing in

the

direction opposite to the choin movement.

Before storting work on the volve geor,

re-

move the oil sump (engine

bottom cover to

which the timing geor

cover is bolted, the suc-

tion stroiner being ottoched to the cronkshoft

centre beoring cover) ond lock

the cronkshoft

in position

in the oxiol direction by depressing

the clutch pedol,

if removol of the entire engine

is not intended for onother purpose.

For speciol

points of the removol refer to

Chopter 2.4.

2.14 WATER PUMP

Disossembly 1. Unlock the wosher of the belt pulley

nut,

remove the nut ond pull

off the belt pulley

using

the MP 1-120 puller (o

fixturre for

Skodo MB 1000

cors) or o universol puller,

for the bolts of which

it is necessory to

cut threods M 8 in the belt

pulley holes.

By pulling

off the belt pulley,

occess will be

goined to the nuts fostening the pump

to the

engine. The some procedure

holds good

when

dismontling the pump

ofter it hos been removed

from the engine.

2. Withdrow the keyfrom

the shoft ond, using

the drift MP 1-121, drive

or press

out the shoft.

Then lift owoy the

housing plote

from the

seoting foce of the pump.

3. Remove the circlip locking the outer boll

beoring in position.

Proceeding from the reor

side of the pump

housing, drive out the boll

beorings with their spocer tube, ond remove

the

rubber seoling rring

from the housing.

Reossembly 1. Smeor the rubber seoling ring with greose

ond insert it into the pump

housing.

Use the

MP 1-123 drift to drive home the inner boll

beoring (without

sheet guord) pocked

with

greose. When opplying the drift,

fit its guide

ring into the bore for the

oute,r boll beoring.

2. Fit the gosket

on the pump

seoting foce

ond ploce

the pump plote

with its cemented-on

gosket (focing outwords from the pump)

over it.

Fosten the plote

to the pump provisionolly

with

one bolt to prevent

the gosket

from being dom-

oged during the following ossembly

iobs.

Insert the rubber seol,

wosher, ond conicol

spring into the speciol (bokelite)

seoling ring

of the pocking glond.

Instoll the spring

with

its nose

into the hole in

the bokelite pocking.

Slip the ossembled pocking glond

on the shoft

with the spring toword the shoft geor,

ond drive

the shoft home into the pump

beoring, while

supporting the beoring with the MP 1-123 drift. Fig.2

4. Fit t

shoft ond

stolling th

in positior

it with gre

sheet guor

5. Top

t

lieve the r

@@@@

DK 1240

Fig.2.1313 -

Volve Arrongement in Cylinderr Heod

Block disks -

exhoust volves

White disks -

intoke volves

Timing Choin ond Timing

Geors

Modified chain and gears

fitted since October

1979 recognised by

squared gearteeth

and chain

with split rollers.

The timing choin hos no slock odiuster (ten-

sioner). A slock choin does not substontiolly

offect the volve geor

occurocy but its operotion

is noisy. Therefore

its correct length should

be

ensured either

o) by selecting o suitoble choin from o number

of choins ovoiloble -

try it on the timing

geors, o1r

b) by replocing the stondord comshoft geor

with on oversize geor

(with greoter

toler-

onces). The comshoft geors

ore groded

in

keeping with their progressive

size (tol-

eronces) into closses A, B ond C. With the

exception of

closs A, the closs morking

letters ore stomped next

to the punch

mork.

For trying, the choin con be disconnected

to ovoid removing ond refitting of the timing

geors. To recouple the choin, insert the coupling Fig.2.1t

52

Page 84 of 238

Remove the clip of

the

clutch throwout beor-

ing guide,

insert the MP 3-102

iig into

the guide,

open its iows, ond withdrow the

guide.

After

hcving renewed the seol ring, drive home the

guide using the MP 3-103 drift. The droin hole

in the guide

must foce

downword.

The lotest desing of the extrocting

iig hos

the type dcsiqnotion MP 3-112. Screw the

iig

bolt into

the

iig nut

inserted into the mech-

onism through the hole cleored by the removol

of the clutch releose cylinder. Jerk the

iig to

drive the guide

out of the housing.

Dismontling the Power Pock

For complete dismontling of the power pock,

remove it from the cor -

see Chopter 4.-1,

"Rernovol of Power Pock from the Cor". Then

proceed os follows:

1. Remove the front cover ond the cover of

the pinion boll beoring, the clutch releose

mechonism, ond the clip of the guide

of the

clutch throwout sleeve, i. e., oll component

ports ottoched

to both holves of the housing.

2. Remove the connecting bolts of the flon-

ges. Force oport the f longes using o screwdriverr

inserted into the chombers of the flonge feet

(lugs). Lifting owoy oll component ports

one

by one is the usuol procedure

of dismontling.

Toking oport of lorger units (pinion,

etc.) is

described individuolly

in the following

chopters.

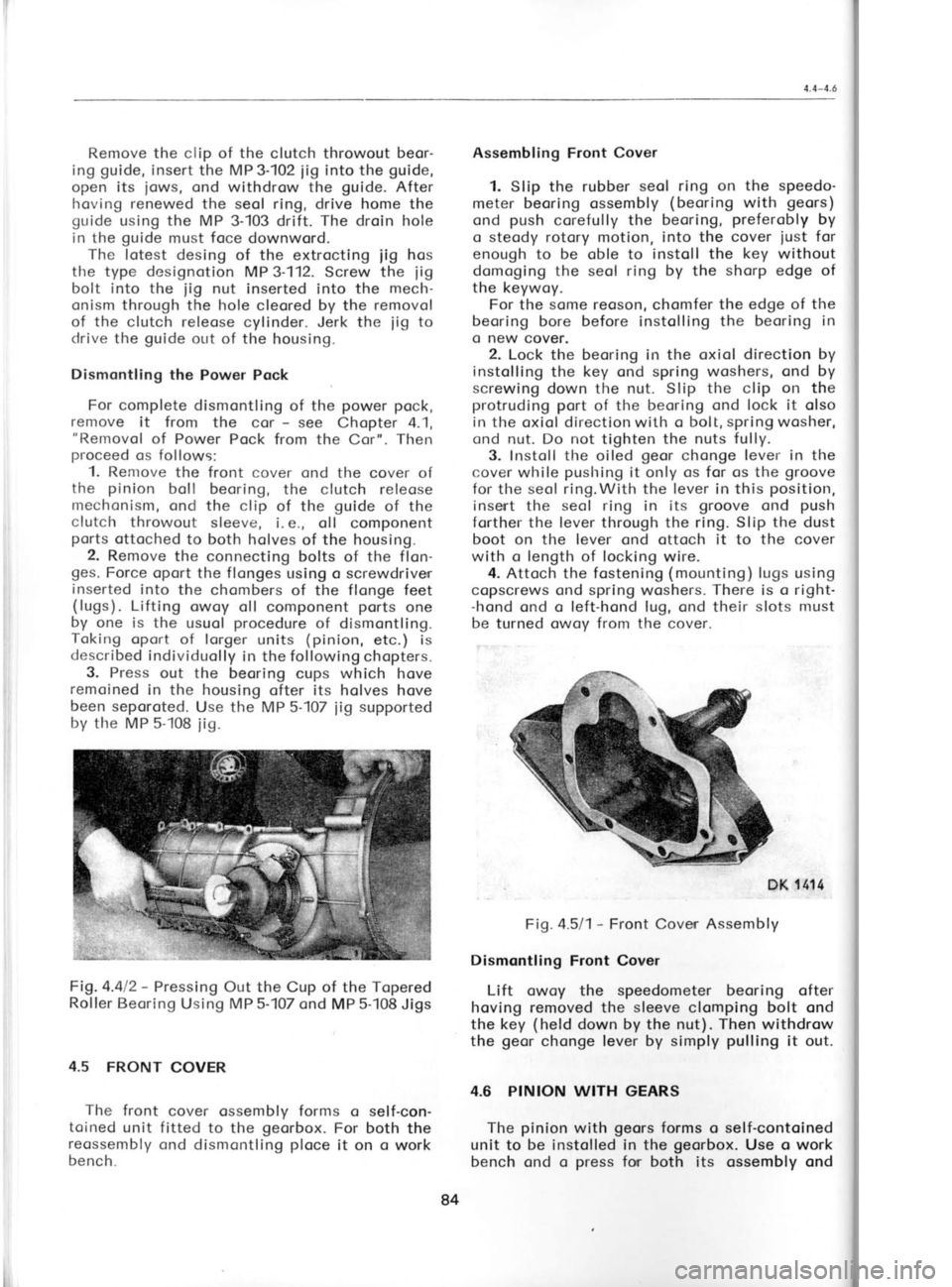

3. Press out the beoring cups which hove

remoined in the housing ofter its holves hove

been seporoted.

Use the MP 5-107

iig supported

by the MP 5-108

iig.

Fig.4.al2 -

Pressing Out the Cup of the Topered

Roller Beoring

Using MP 5-107 ond MP 5-108

Jigs

4.5 FRONT COVER

The front cover ossembly forms

o self-con-

toined unit fitted to the georbox.

For both the

reossembly ond dismontling ploce

it on o work

bench. Assembling

Front Cover

1. Slip the rubber seol ring on the speedo-

meter beoring ossembly (beoring

with geors)

ond push

corefully the beoring, preferobly

by

o steody rotory motion, into the cover

iust for

enough to be oble to instoll the key

without

domoging the seol ring by the shorp edge of

the keywoy. For the some reoson, chomfer the edge of the

beoring bore before

instolling the beoring in

o new cover.

2. Lock the beoring in the oxiol direction by

instolling the key

ond spring woshers, ond by

screwing down the nut.

Slip the clip on

the

protruding pcrt of the beoring ond lock it olso

in the oxiol direction with o bolt, spring

wosher,

ond nut. Do not

tighten the nuts fully.

3. Instoll the oiled geor

chonge lever in the

cover while pushing

it only os for os the groove

for the seol

ring.With the lever in this position,

insent the seol ring

in its groove

ond push

forther the lever through the ring. Slip the

dust

boot on the lever ond ottoch it to the cover

with o length

of locking wire.

4. Attoch the fostening (mounting)

lugs using

copscrews ond spring woshers. There

is o right-

-hond ond o left-hond lug, ond their slots must

be turned owov from the cover.

FK 1t't4

Fig.4.5l1- Front

Cove'r Assembly

Dismontling Front Cover

Lift owoy the speedometer

beoring ofter

hoving removed the sleeve

clomping bolt ond

the key (held

down by the nut). Then

withdrow

the geor

chonge lever by simply pulling

it out.

4.6 PINION WITH GEARS The pinion

with geors

forms o self-contoined

unit to be instolled in the georbox.

Use o work

bench ond o press

fon both its ossembly onddismor

wheel sure t

Only c

wheel

m itted

drive.

4.8.

Whe

olso tl

o new

one is

Assem 1.P

the pi

the or" thrust

toworc

3-104 p

ground

the be, must t

meosul

2.S

collor I

ring ir

the grr

The rir

3.5 to I

th ickes

ond pu

speed

3.H

it the '

selecte

toword

dismor (by tol

itinp

free to

Clon

MP 3.1

Note

inner b

toining

either r

-speed

ports.

4. Tr

groovir

pinion.

friction

groover

groove!

5. On

ond fit

the nex sizes 3

84

Page 86 of 238

1-

in the

other groove.

Chose the ring olso with

regord to toleronces cvoiloble

in one closs of

the rings os mentioned in the previous

Pqro-

groph. Check the cleoronce of the geor with

the oid of o diol indicotor.

Then remove the geor

including the friction

ring in the second groove

of the shoft.

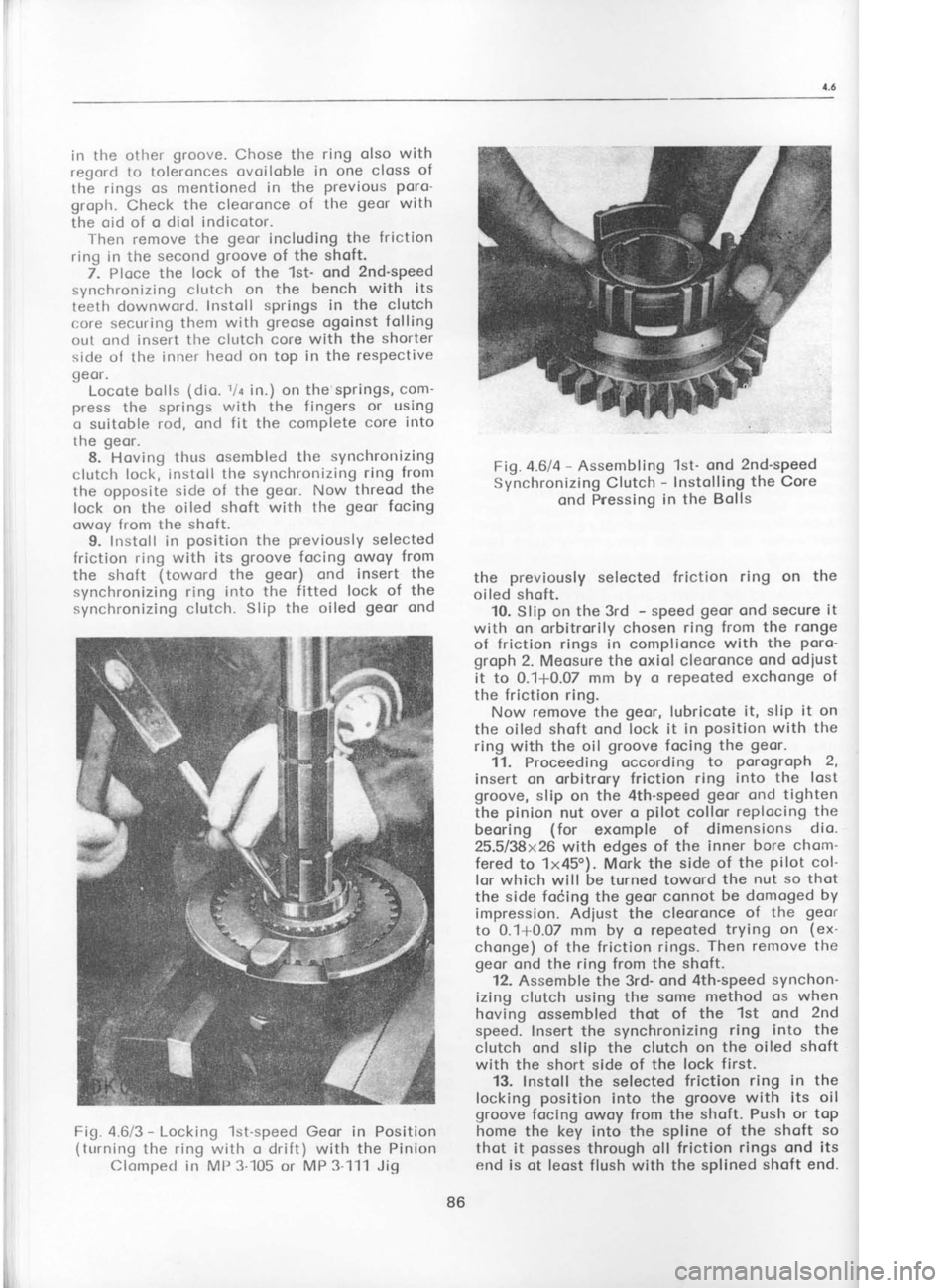

7. Ploce the lock of the 1st' ond 2nd'speed

synchron izing clutch on the bench with

its

teeth downword. lnstoll

springs in the clutch

core securing them with greose

ogoinst folling

out ond insert the clutclr core with the shorter

side of the inner heod on

top in the respective

geor. Locote bclls (dio. 1ir

in.) on the springs, com-

p,ress the springs with

the fingers or using

o suitoble rod, cnd fit

the complete core

itrto

the geor.

8. Hoving thus osembled the synchronizing

clutch lock, instoll the synchronizing ring

fronr

the opposite side of the geor.

Now threod the

lock on the oiled shoft

with the geor focing

owoy from the shoft.

9. Instoll in position the

previously selected

friction ring with its groove

focing owoy from

the shoft (toword

the geor)

ond insert the

synchronizing ring into the fitted lock of the

synchronizing clutch. Slip the oiled geor ond Fig.4.6la

-

Assembling 1st' ond 2nd-speed

Synchronizing Clutch -

lnstolling the Core

ond Pnessing in the Bolls

the previously

selected friction ring on

the

oiled shoft. 10. Slip on the 3rd -

speed geor

ond secure it

with on

orbitrorily chosen ring from the ronge

of friction rings in complionce with the poro-

groph 2. Meosure the oxiol cleoronce ond odiust

it to 0.1*0.07 mm by o repeoted exchonge of

the friction ring. Now remove the geor,

lubricote it,

slip it on

the oiled shoft ond lock it in position with the

ring with the oil groove

focing the geor.

11. Proceeding occording to porogroph 2,

insert on orbitrory friction ring into the lost

groove, slip on the 4th-speed geor

ond tighten

the pinion

nut over o pilot

collor replocing the

beoring (for

exomple of dimensions dio.

25.5/38x26 with edges of the inner

bore chom-

fered to 1x45o). Mork the side of

the pilot

col-

lor which will be

turned toword the

nut so thot

the side focing the geor

connot be domoged by

impression. Adiust the cleoronce of the geor

to 0.1+0.07 mm by o repeoted trying

on (ex-

chonge) of the friction rings. Then remove the

geor ond the ring from the shoft.

12. Assemble the 3rd- ond 4th-speed synchon-

izing clutch using the some method os when

hoving ossembled thot of the 1st ond 2nd

speed. lnsert the synchronizing ring

into the

clutch ond slip the clutch on the oiled shoft

with the short side of the lock first.

13. Instoll the selected friction

ring in the

locking position

into the groove with its

oil

groove focing owoy from the shoft. Push or top

home the key into the spline of the shoft so

thot it posses

through oll friction rings ond its

end is ot leost flush with the splined shoft end.

Fig.

4.6/3 -

Locking 1st-speed Geor in Position

(turning the ring with o drift) with the Pinion

Clompecl in MP 3-105 or MP 3111 Jig

86 Fig.

4.(

Page 97 of 238

5.:

pr

stl

bc

5-t

bo

thr

u*,

on

dit

on arI

ioi

sPl

SW

I

gor

:

wo

bol

cyl

del

\

mo

th€ hot

WO

F

clo

POS +:

nec

wol

reo

toe

wit

T

o)

b)

Alil 1.

con

sloc

seo'

int

Fig.5.2l5

-

Pressing Boll Beoring

on Shoft

Using MP 5-112 Jig ond

lts Liner (smoller)

Fig.5.216 -

Connection of

Holf-oxles

with Rodius Arms

lorger ond one smoller, ond the forked plote),

screw down the

iig on the threod

of the shoft,

ond use

nuts to ottoch it

to the holf-oxle socketf

longe. The

iig of

the lotest design permits

its

simple fostening by engogement with

the holf-

oxle flonge (fit

the

iig ond

rotote

it to lock it

in position).

Instoll the lorger liner between the boll

beor-

irrg ond the

iig heod, ond

press

the boll

beorirrg

on the shoft by turning the iig wrench.

3. Reploce the lorger liner with the smoller

one (rest it ogoinst the

iig bolt heod), ond turn

the wrench in the opposite direction to press

the beoring into the holf-oxle socket.

Fitting Broke Mechonism ond Wheel Hub

4. Instoll the broke bocking plote

complete

with the broke

mechonism on the holf-oxle

socket, slip on the "O"

seoling ring ond the

cop with the seoling ring (with

the tightening

f in focing toword the holf-oxle), ond fosten

oll

the porrts

with bolts, spring woshers, ond

nuts.

The seoling ring should be driven or pressed

into the cop so thot the tightening lip foces the

beoring ond

iust so thot there

remoins

o gop

of

1 to 2 mm between the pocking

ond the cop

f longe.

5. lnsert the key in

the shoftwith its bevelled

end into the runout of the keywoy, smeor

the

hub neck with oil so

thot it does not

drog in

the seoling ring, ond fit the hub with the broke

drum in position.

Moke sure thot the key did

not move further olong the shoft (its

lifted end

in the keywoy would couse the hub to burst)

ond tighten

lightly the nut. Since o high

torque

is required

for finol tightening of the nut, put

off the tightening ond locking of the nut till

ofter instollotion in the cor. Then

tighten the

nut with full torque (see

Chopter 1.8),

top on

the hub to relieve

the possive

stress of the

toper, retighten to the specified torque, ond

lock the nut with o cotter pin.

Fitting Rodius Arms

6. Instoll

the spocer into the rodius

orm, fit

the knurled

woshers (with

the knurling toword

the orm)

to either side of the ellipticol holes of

the rodius

orm, ond fosten them with bolts ond

nuts not

forgetting the spring woshers. Do not

tighten the connection fully. Threod

the bolts

through the bolt holes so thot their nuts foce

into the cor ofter fitting the rodius orm to the

holf-oxle.

Fit the rodius

arm on the protruding

holf-oxle

pin ond threod

the bolt through the hole

of the

secrt. Slip

spocing tubes on the bolt ond pin

together with sheet shims with rubber liners

ond fosten

lightly (without tightening)

the

rodius orm to the holf-oxle using nuts

ond lock

woshers. Tighten

fully the connection

ofter fit-

ting the ossembly

in the cor when odiusting

the

reor wheel

olignment (geometry).

il

i

ii

I

I

I

I

lr

il

H, DK

?EI

98

Page 121 of 238

(

t

t

s r

1

S

t S

n

o

fl

p

t\

e

g

tl

St

T

o

e

ir

h,

el

r€

re

5. Ploce

the steering

box with its bottom

boll

beoring resting on the MP 7-102 jig

ond press

the steering screw

with both beorings into the

iig. Extroct the

bottom beoring using

the MP

6-111 king pin

socket remover

ond push

the

steening screw with the top beoring oert of the

steering box. Support the beoring by the Mp

7-102 iig crnd

press

it out.

7.3 REASSEMBLING STEERING BOX

1. Press the dust cup with its seoling

ring

into the steering

box with the pressed-in

bush

ofter hoving thorouchly

cleorred the box. Now

pf oce the box on the MP 7-102

iig oncl

press-in

the bottom boll beorinct

using tlrei pressing

mandrel MP 7-103.

2. Fit the lower beoring

cop seoled

off with

o poper

gcsket

ond seoling compound, slip

lpring woshers

on to the bolts,

ond tighten the

bolts with o torque os per

Chopter t.6. f it the

wosher on the steering screw

with its deflec-

tion focing

the screw threod ond press

the

top beoring on the screw

using the Mp Z-103

pressing mondrel.

3. Then ploce

ogoin the steering box on the

MP7-102 iig ond

press

into it ond into the bot-

tom beoring the steering

screw with the pnessed-

-on top boll beoring,

using ogoin

the Mp7-103

pressing mondrel. For further ossembly, use the

vice ond the dummy brocket.

Fig. 7.311 -

Pressing-in Bottom

Beoring

on MP 7-102

Jig (support

plote)

Using

MP 7-103 Piressinq

Mondrel 4.

Meosure the height of the beoring pro-

truding from the steering box ond odiust it by

fitting shims interspoced with poper goskets

cooted with o seoling

compound.

Fosten down

the cop by tightening the bolts. Check the

steering screw for free rototion

ond the obsence

of ploy.

The beoring should be without o cleor-

once or there hos

to be o prestress

of up to

0.07 mm.

5. Remove the bolts of the cop, slip the rub-

ber seoling ring dipped in oil on to the shoft,

ond fit the dust cup on the cop. lnstoll spring

woshers on the bolts. Should the cup be over-

stroined due to the toleronce

of the recess for

the seoling ring or the ring itself

, instoll

o poper

gosket under it os under tlre ccrp.

6. Locote the steering nut on the screw fol-

lowecl by the rocker shoft with pin, spring,

spring pin, ond the licl gosket

cooted with

o seoling compound, ond fit the lid with bush

in position to close the steering

box. Instoll

spring woshers under the bolts orrd tighten the

bolts with o torque os per

Chopter 1.8. Screw

the set screw into the lid ond rnove

the steer-

ing geor

so thot the drop orrn is swivelled

through obout one holf of its trovel from the one

or the other extreme lock position.

Witlr the

drop ornr in this position,

screw down the set

screw os for os it will go

ond then bock it off

through obout 95 to '120'.

This will provide

for

on odequote cleoronce of the steering geor.

[.ock the set screw in position

with the re-

spective nut.

7. Drive the key on to the rocker shoft cone,

fit the drop orm ond hold it down lightly with

the nut. Clomp the drop orm in o vice, tighten

fully the nut (for

the tightening torque see

Chopter 1.8), ond secure tlre nut with o cotter

pi n.

8. Clomp ogoin the steering box by meons of

the dummy brocket ond moke sure

thot the dnop

orm con swivel from one extreme lock position

to the other. A certoin

resistonce should olwoys

be present,

but if the resistonce is too greot,

decreose it by o slight slockening of the set

screw in the lid. The

rototing resistonce of the

shaft should not exceed 20 Nm (O.2

kpm). Refer to

page 117/118 for testing

procedure.

9. Set the ossembled steering box in its fit-

ting position

(inclined

by obout 40o) ond pour

in oil through the hole in the bbx lid (cover)

till the oil level reoches the bottom edge of the

filling hole. Then

screw down the topered plug.

7.4 RELAY (TDLER)

LEVER

For its instollotion (ond

removing in reverse

order) ond ony pertinent porticulors

see the

Chopter 6.5, porogrophs

2 ond 3.

122

Page 169 of 238

L

i g)

Excitotion of the olternotor by o current

supply outside the cor is not permitted.

Agoin the semiconductors would suffer.

h) A blown chorging worning lomp must be

reploced immediotely with o new

one. Other-

wise correct excitotion of the olternotor is

not ensured. Use o new lomp of

the some

roting (or input), i.

e., 1.5

to 2 W.

i) Be sure thot there is

o perfect

electricol

connection on the connecting terminols ond

thot the olternotor

ond regulotor

ore properly

eorthed.

i) The

olternotor is oeroted, open. Therefore

toke core when woshing the cor thot woter

or cleoning ogents do not get

into it through

the venting holes.

Removing the Alternqtor

1. Disconnect the bottery.

2. Disconnect the olternotor leods. lt will be

helpful to remember the colour of one conductor

ond its connection for reinstollotion.

3. Remove oll ports

holding the olternotor on

the engine, ond lift owoy the olternotor.

Reinstolling the Alternotor

1. Cleon oll mounting surfoces.

For the olter-

notor mounting, see Chopter 2.3, por.42.

2. With the bottery

disconnected, insert the

conductors into the respective

connectors "M,,

ond "R"

(the conductors beor the some sym-

bols), ond fosten the remoining leod with o nut.

3. Reconnect the botterv. Alternotor

Disossembly -

Repoirs

1. Screw off the belt pulley

nut ond remove

the belt pulley

ond fon.

2. Lift the brushes with o hook proceeding

through the holes in the

commutotor end

shield

ond hold them in the lifted position

by wires

inserted into the shield through dio. 3 mm holes

under the terminols uM'

ond "Ru.

3. Mork the mutuol (relotive) position

of the

commutotor ond drive end shields ond seporote

the qlternotor

ofter hoving removed its clomping

bolts. The drive end shield remoins connected

with the stotor.

This disossembly will give

occess to the

brushes ond some

of the diodes. All other

iobs,

with the exception of the renewol of the beor-

ing, should be done by experts in speciolized

repcir shops -

see the note supplementing the

following porogrophs.

Alternotor Reossembly

1. Insert the circlip into the becring bore

in

the commutotor end shield.

2. Fit the drive end shield with beoring on

the rotor shoft.

3. Assemble the stotor with the rotor ond the

commutotor end shield. 4" Tighten the olternoior with clomping bolts

ond check the rotor for free rototion while

tightening the bolts.

5. Slip the spocer on to tlre shoft,

top the

key in position,

fit the fon ond belt pulley,

ond

tighten the entire ossembly using the nut with

spring wosher.

6. Pull out wires from the commutotor end

shield which hove been used to hold

brushes

in their lifted position.

Replocement of Beorings

The used beorings ore fullyclosed ond seoled,

ond they hove been filled in the foctory

with

lubricont to lost through their entire service life.

1. Pull the beoring off the rotor

using o suit-

oble puller.

When ref itting the beoring, press

it

on to beor on the shoft

collor-

2. Before removing the drive end shield

beor-

ing, f irst drill off the heods

of the flonge rivets

ond then drive the beoring out from

the outer

side of the drive end shield using o suitoble

mondrel (drift).

On reossembly,

close the beoring with the

flonge ond rivet the flonge to the shield.

Replocement of Diodes

The use of the removoble

diode block with

the individuol

corriers of the so-colled positive,

negotive, ond ouxiliory diodes, focilitotes con-

siderobly the replccement of ony defective

176

Fig.133la

-

Alternotor -

Sectionol View

Page 171 of 238

junction

with the olternoto,r occording to

Chop-

ier 13.3 ond mointoining

o constont voltoge of

tlre power

supply set within the

entire ronge

of

service speeds.

Tlre voltoge regulotor

is instolled orr the body

cross beorer, to

the right of the engine ond

beside the ignition coil.

To focilitote hondling

of its leods' especiolly

the occess to their

connections, it

is recom-

rrrended to remove the regulotor fostening

screws. For disconnecting procedures,

see

Chopter 13.3 "Alternotor

lnstollotion ond Gen-

erol lnstructions".

DK 1565

Fig.13.411- Internol

Wiring Diogrom of

Alternotol with

Voltoge Regulotor ond

Outer

Connections

Altenrotor: B, R, M -

olternotor outlets

f -

olternotor phose

windings

m -

olternotor field winding

D1,2,3, 4, 5, 6 -

moin diodes

D7, 8,9 -

olternotor ouxiliory diodes

D10 -

olternotor choking diode

Voltoge regulotor:

R, M, 15/54 -

regulotor outlets

reg -

regulotor tension winding

Rk -

boloncing resistor

Ro -

protective resistor

Rr -

odiustoble resistor

Kr -

regulotor contocts

Outer connections: K -

worning lomp (1.5

W)

S -

switch (switch

box)

B -

bottery

Checking Voltoge Regulotor

on Cor

The regulotor operotion con be offected by

loosened connections ond on imperfect eorth- ing.

lf the wsrning lomp does not go

o.ut when

driving, i. e., if it glows

ot increosed engine

speed brightly or dimly,

or if it does not stort

glowing ofter stopping

the engine ond

o new

iurning of the ignition key in

the switch box,

the voitoge regulotor

is probobly

foulty. Another

symptom of o regulotor

foilure is

o poor

chorg-

irrg of tlre bottery or its

overchorging.. lf there

is nothing wrong with the regulotor, check the

reguloted voltoge over the regulotor which

slrould reod 13.2 volts ot the

minimum ond 14.8

volts ot the moximunr. This check

in the

cor

is only tentotive ond only

o check on

the test

bench'con be considered os definite ond

bind'

i ng.

Electricol Adiustment

The voltoge regulotot- should be tested

ond

odjusted only on o test bench

in o connection

slrown in Fig. 13.412.

At o lood of some

2

onrperes, the checked

voltoge should correspond to

volues specified

in the column "Checking".

lf the checked volt-

oge is within the specified ronge, do

not odiust

the regulotor. Othenwise odiust it to the volues

specified in the column "Adiustment".

lf woter

evoporotes obnormolly from the bottery, odiust

the voltoge regulotor to the bosic volues of

"Adiustment" utilizing the lower section of

the

toleronce zone.

Fig.13.al2 -

Wiring Diogrom of

Regulotor Tested

ond Adiusted on

o

G -

olternotor

REG -

voltoge regulotor

A -

ommeter

V -

voltmeter

S -

switch

R -

lood resistor

B -

bottery DK

1566

Voltoge Test Bench

178

Page 179 of 238

(

1

z

Strike the

slip-over ring off the circlip

(towords the motor windlng). Open the circlip

ond pull

it off the shoft together with the re-

leosed ports.

8. lf necessory, re-turn the commutotor ond

scrope or mill out the insulotion between the

lominotions. "Mikonit"

should be 0.4 to 0.8 mm

below the octive surfoce.

Note: The

switch connot be further token

opat. lf

defective, lt hcs to be reploced with

o new one. When cleoning ports

of the storter

motor, do not dip the ormoture or the pinion

with the idler into petrol

or onother degreosing

ogent.The some opplles to the end shieldswith

beorings. By dipping them in o degreosing

ogent, the beorings become procticolly

worth-

less"

Storter Motor Reossembly 1. Lubricote the hellx of the ormoture shoft

with greose -

see Chopter 15.2 'Lubriconts

of

foreing mokeu ond fit the pinion

with the idler

ond the slip-over ring in posltion.

Fit the

circlip

into the groove

in the shoft, ond drive the slip-

on ring over it. The pinion

with the idler must

move freely olong the shoft.

2. Slip the respective

woshers on the shoft in

their originol sequence (corrier

ring, distonce

ring, fibre ring, distonce ring) ond insert the

ormoture with the engoging lever

into the drive

end shield. 3. Suspend the switch

ormoture into the

pre-engoging lever ond bolt down the switch

lightly. Fit the lever pin

into the drive

end

shield ond lock it in position

with the retoiner.

4. Tighten the copscrews of the switch

ond

fit the stotor on the drive

end shield.

5. Instoll the respective

woshers into

the

commutotor end shield in

their originol se-

quence (the dished wosher with its centre

focing the shield, then the ploin

wosher, the

toothed wosher, ond the drive wosher).

6. Fit the commutotor end shield with lifted

brushes on the shoft (in

the position

occording

to the recess

for the excitotion outlet ond the

notch) ond screw in the clomping bolts.

7. Instoll the brush interconnecting strip ond

bolt it down together with the field winding

outlets to the positive

brush holders, lower the

brushes. 8. Fit the Insuloting strip in position

ond bolt

down the cover. 9. Test the storter mottr.

Diognosing Storter Motor Defects in Cor

o) lf the storter motor refuses

to operote, look

first for on interrupted connection between

the bottery ond

the storter

motor, the engine

eorthing ond the storter

motor, or the engine

eorthing ond the bottery. lf these connec-

tions ore in order (current

flows to the ter' DK

1575

Fig. 13.10/3 -

Storter Motor Testlng Connection

minols u30"

ond "50"

with switched on

ignition), stort looking for o foilure of the

storter motor switch. Even in this instonce,

the couse con be o fully dischorged or foulty

bottery.

b) lf the storter motor

continues running

even

ofter the ignition key hos been switched in

the switch box from the position "START",

it hos to be stopped without ony deloy by

disconnecting the bottery (using

its eorthed

pole).

c) lf the storter motor hos no power

to cronk

the engine, stort with switched-on heod-

lights. A

morked dimming indicotes c poorly

chorged bottery.

Tentotive Checking of

Storter Motor

Outside Cor

Connect the terminol "30'of

the storter

motor to o properly

chorged bottery ond incor'

porote on ommeter with o wide

meosuring ronge

into the circuit -

see Fig. 13.10/3.

Stort the

engine (feed

current to the terminol "50").

The

volue of the current ot idling speed must

not

exceed 65 omperes (not

considering the peok

ot

the first momentous deflection).

The storter motor must run noiselessly,

smoothly, ond the pinion

must move smoothly

into ond out of the rest position

(engoge

ond

diesengoge). The engoged pinion

must not ro-

tote direct on the foce of the slip-on ring. The

run-out of the storter motor must not lost longer

thon 8 seconds ofter the disconnection of the

switch from the current supply.

Inspect the brush pressure

springs. The

brushes must

beor on the commutotor by ot

leost two thirds of their surfoce ond they must

move freely in their cells.

The ormoture should hove o noticeoble oxiol

cleoronce (ploy)

not exceeding 0.7 mm.

At

o slight rototion of the pinion

in the direction

of the storter motor rototion,

the idlor must

slip

freely.

186