tire type SKODA 120 LS 1980 Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 120 LS, Model: SKODA 120 LS 1980Pages: 238, PDF Size: 47.09 MB

Page 34 of 238

primory

feed to the distributor coincides with

the connecting line of the

distributor centre

line ond the first cylinder

heod

bolt os

per

Fig.2.3l10. Secure the distributor in this pos-

ition by lightly tightenning the tie-bolt ond

remove the timing geor

cover from the cylinder

block. The used type of distributor is described

in Chopter 13.5.

Fig.2.3l10 -

Position of Distributor on Engine

-l - screw of primory power

feed

2 -

cylinder heod bolt

3 -

index line rnorking the position

of the

distributor ornr when cvlinder No. 1 f ires

24. Coot with oil the moting

surfoces of the

timing geor cover ond the cylinder

block, locote

the cover gosket

on the block,

oil the timing

choin ond the comshott worm geor.

Remove the

f lywheel powl

ond rotote the

cronkshoft through

360o so

os to bring tlre pistons

of the cylinders

No. 1 ond 4 to their TDC position

ogoin. This

position corresponds opproximotely

to the volve

geor position

when the cylinder No. 1 f ires (the

tips of the coms of

cylinder No. 1 ore turned

downword, owoy from

the engine). Lock the

cronkshoft in position by refitting ond tight-

ening the flywheel powl.

25. Turn

the distributor orm in the direction

of the

screw (1) in occordonce with Fig. 2.3110,

hold it down with the

finger in this position,

ond ref it the timing geor

cover on the cylinder

block. By sliding the worm geor

of the distribu-

tor drive into the comshoft worm geor,

the orm

is turned to coincide with the timing

mork for

cylinder No. 1

on the distributor housing. lf

there is no coincidence of the orm ond timing

mork, od just

the position

of the orm by

slightly

rototing the distributor.

lf the

misolignment of the distributor

ornr

ond the timinq

mork of the

cvlinder

No'1 is so greot

thot it connot be corrected

by rototing

the distributor, remove

the timing geor

cover,

rotote the distributor slightly ond repeot

the

entire procedure

of refitting the timing geor

cover. 26. Smeor the protruding

end of the cronk-

shoft ond the outer shoft end (stem)

of the

belt

pulley with oil, f

it the belt pulley,

the nespective

wosher, ond tighten the bolt. Bolt the

PumP

suction stroiner tothe cronkshoft centre beoring

ond use o spring

wosher under the bolt heod.

27. Bolt down the timing geor

cover using

spring woshers ond

cheese-heod bolts

(exclus-

ively) cnd f inolly fosten the timing geor

cover

in such o position

thot the contoct breoker

points open before the crronkshoft with

the con-

necting rod ond piston

hos ottoined the top

deod centre (TDC)

position (see

the lgnition

Timing Toble in Chopter 15.3).

For checking the ignition odvonce, on electric

power supply is required with o bulb connected

in o circuit with the distributor. this

circuit

being interrupted by the oction of the contoct

breoker. An odopted conventionol torch with o

metol

iocket con be

used with odvontoge for this

purpose. Remove the flywheel powl ond

set the re-

quired ignition odvonce by turning the cronk-

shoft with o screw'driver inserted into

the geor

ring ond propped ogoinst the cylinder block

f longe. Rotote the shof t onticlockwise o bit

more thon necessory ond

bock it off so os to

odiust the bocklosh of the timing geors

ond the

distributor drive geors.

oK 6ls

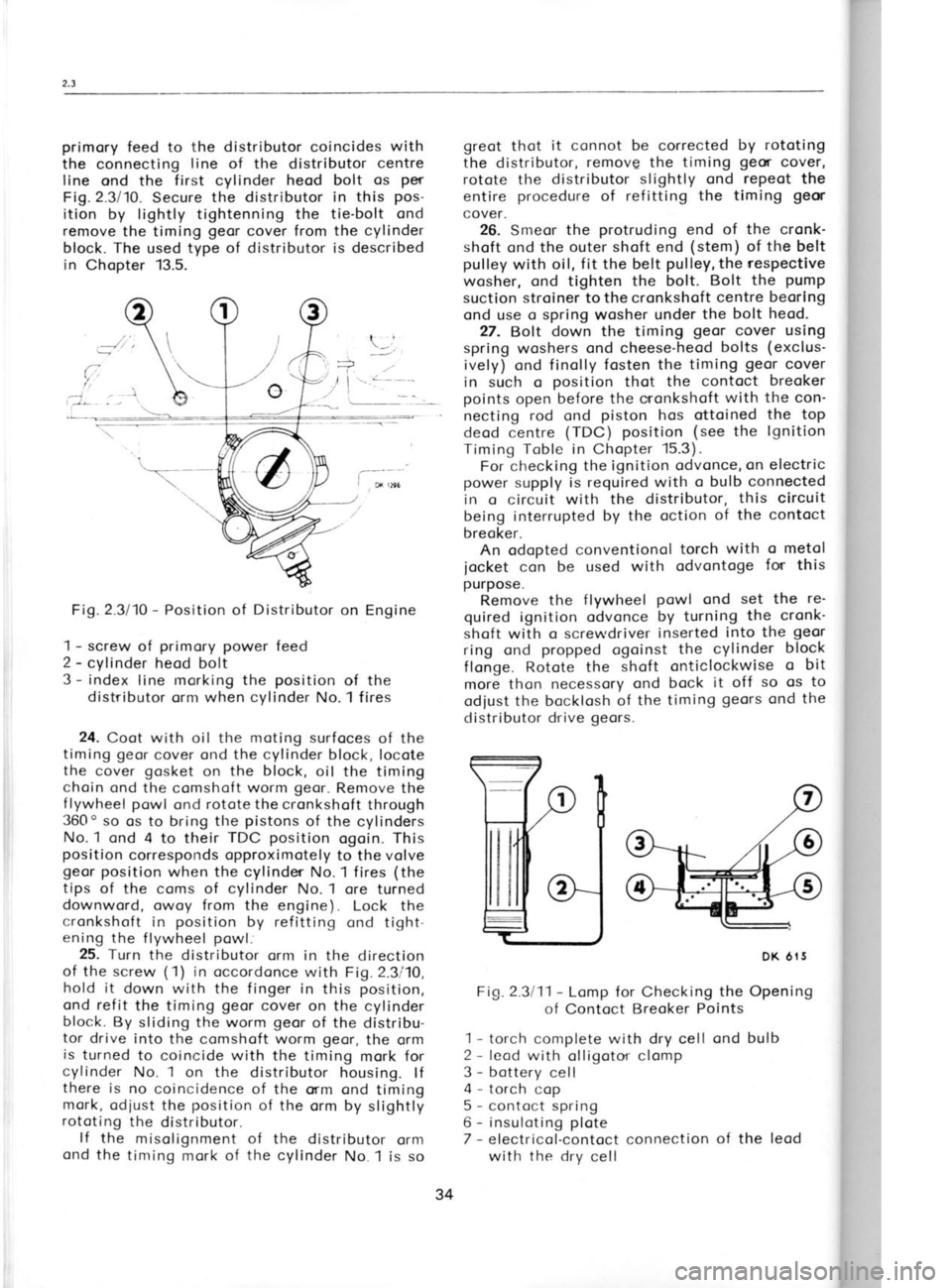

Fi9.2.3111- Lomp for Checking the Opening

of Contoct Breoker Points

-1 - torch complete with dry cell ond bulb

2 -

leod with olligotor clomp

3 -

botterv cell

4 -

torch coo

5 -

contoct spring

6 -

insuloting plote

7 -

electricol-contoct connection of the leod

with the

drv cell Con

using

torch.

the br

slowly

indico

A corr

is not

timing 28.L

beorin

Then f

while

oil sun

the thr

the tyl

see Cl.

shri n ks

of the

woter

move i

ively.

To Fit

Toppetr

25. r

remove

positior

sure thr

cylinder

cylinder nuts. F<

first bo

woteir p

oir clec

finol ti1

2.16.

Ploin

heod bo

which t

woshers

no wosl

heod bo

cy I i nder

the outs

hove to

of the rc

Tighte

broce or,

30. Sc

thermom

into the

cosing o

ofter ho

Use spri

thermost

cooted g

with the

with the

The th

should br

34

Page 183 of 238

t 3.t

r*r 3.1 2

1. lf the wiper moves with the switch in the

OFF position

ofter its

connection to the electric

power supply, tighten (screw

down) the screw

till it begins to be litfed by the geor

com ond

till the wiper begins to be

switched off ond

broked. Screw down the screw from this po'

sition by onother holf turn.

2. Press the lid into

the cover ond seol it

with point.

WIPER ARM DRIVE

This drive consists of thewiper beoringswith

cronks, the tie-rod of the

cronks, ond

the driv-

ing tie-rod. The

drive is instolled in the cor os

o unit.

Tie-rods The tie-rods should be slipepd on

the cronk

pins in the

following sequence:

o springwosher

with its centre comber focing outword (owoy

from the pin),

o flot

wosher, the tie-rod, o flot

wosher, ond o lock

ring.

lf necessory, lubricote the ioints with

greose

- see the following section deoling with beor-

ings. Fill the cover at the point

of the tie-rod

motor cronk connection with greose

(of ony

brond) ond slip it on the tie-rod.

Beorings On one side, the beoring

is inserted into the

wiper brocket from inside the body, on the

other side, it is fitted into o speciol wosher in-

serted with its nose foremost

into the re-

spective hole in the body. Locote o seoling

wosher with corefully smoothed-out edges ond

o flot

wosher from outside, ond secure the

entire unit with the respective

nut. The

unit is

seoled off by

o rubber pocking.

Fill the unit

with greose (see

Chopter 15.3 for recommended

foreign bronds or Czechoslovok Lrronds SP 4 or

A 4) ond press

it down into the neck of the

bush.

lf it is necessory to remove

or disossemble

the beoring, prise

the lock ring out of the pin

groove under the rubber pocking.

On reossembly,

insert o spring wosher under

the bush with its

combered centre

toword the bush. Lubricote

with the specified greose.

Wiper Arms

The wiper orms fitted with o rubber

blode

con be swung owoy from

the windscreen. They

ore held down by nuts

on the grooved

topers of

the beoring pins.

After hoving fitted

the wiper orms, sproy

woter on the windscreen

ond test the run

of the

wipers. lf necessory, turn the wiper cms

on the pins.

The wipers must wipe

the lorgest

possible oreo of the windscreen without, how'

ever, touching the windscreen glozing

mould-

i ng.

13.12 RADIATOR FAN

Technicol Description

The fon is on ossembly of the fon motor ond

impeller. The

impeller is pressed

on to the

motor shoft. The motor hos permonent mognets ond

o rotor running in self-lubricoting beorlngs. The

impeller is mode of plostic.

Motor type

Roted voltoge Roted current

Roted output

Direction

of rototion PAL 443.132

-

O97.O45

12 volts

7.5 omperes

55 wotts

clockwise (right-hond) when

viewing the front end of the

shoft

Coble poles

coble with lug (blue) -

negotive pole

coble with femole connector

(red) -

positive pole

Removol ond Refitting

The fon is

occessible ofter

removing the

rodiotor to which it is fostened by meons of

o rim held down by copscrews ond sprlng

woshers. The motor rests on resilient bushes in

the rim. When refitting the fon moke sure thot

there is o spocer tube in the bush, locote the

flot ond the spring woshers, ond tighten

the

nut.

Cleoning ond

Repoirs

Refer to porogrophs

1 to 3 deoling with

cleoning ond repoirs in Chopter 13.11.

Dismontling Motor ond lmpeller

The motor con be removed (ond

dismontled)

only ofter removing the impeller. Use the puller

MP 8-102

to pull

off the fon or support the fon

hub in three points

on its circumference ond

press out the motor by opplying

Pressure on

the motor shoft. No topping or blows on the

shoft ore permitted.

1. Remove the nuts of the clomping bolts,

hold the shoft

by its grooved

end, ond lift

owoy the

commutotor end shield ond stotor.

190