wipers SKODA 120 LS 1980 Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 120 LS, Model: SKODA 120 LS 1980Pages: 238, PDF Size: 47.09 MB

Page 12 of 238

Worrring

lights:

5 -

left-hond direction indicotors, green

6 -

oil pressure,

red

7 -

right-hond direction indicotors, green

8 -

broke system, red

9 -

chorging, red

10 -

fuel reserve, omber

11 -

high beom, blue

The thermometer indicotes the temperoture

of the coolont with the ignition switched on.

The optimum operoting temperoture ronge is

from 75 to 105oC. In

SfOon 105 S, this

ronge

is identified by

the green

zone of the scole.

The fuel gouge

indicotes the level

of the fuel

with the ignition switched on. The scole is

provided with divisions 0 -

r/2

-

1, i. e., empty,

holf full,

ond full

tonk.

The driver is worned by the red worning light

when thene ore less thon 5litres of fuel in the

fuel tonk.

The tochometer indicotes the speed (revol-

utions) of the engine. The

speed should

never

rise to the red zone. When chonging the geors,

on increose of speed within the ronge

of the

yellow zone is permissible.

The porking

lights come on when the switch

is thrown to the first

right-hond position.

The

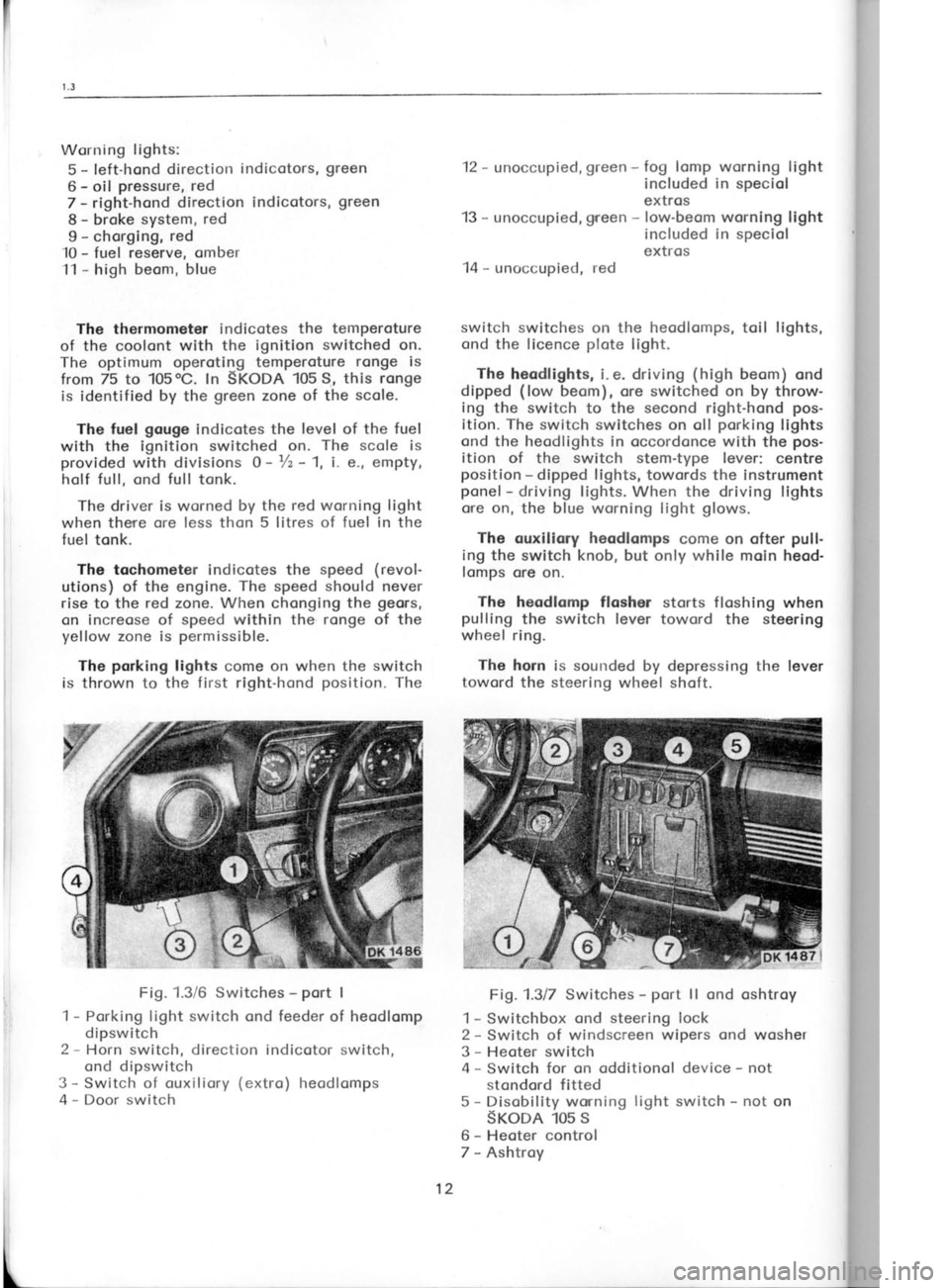

Fig. 1.3/6 Switches -

port I

1 -

Porking light switch ond feeder of heodlomp

dipswitch

2 -

Horn switch, direction indicotor switch,

ond dipswitch

3 -

Switch of ouxiliory (extro)

heodlomps

4 -

Door switch 12

-

unoccupied, green -

fog lomp worning light

included in speciol

extros

13 -

unoccupied, green -

low-beom worning light

included in speciol

extros

14 -

unoccupied, red

switch switches on the heodlomps, toil lights,

ond the licence plote

light.

The heodlights, i. e. driving (high

beom) ond

dipped (low

beom), ore switched on by throw-

ing the switch to the second

right-hond pos-

ition. The switch switches on oll porking

lights

ond the heodlights

in occordonce with the pos-

ition of the switch stem-type lever: centre

position -

dipped lights,

towords the instrument

ponel -

driving lights. When the

driving lights

ore on, the blue worning light glows.

The ouxiliory heodlomps

come on ofter pull.

ing the switch knob, but only while moin

heod-

lomps ore on.

heodlomp flasher storts floshing

when

the switch lever

toword the steering

ring.

horn is sounded by depressing

the lever

the steering wheel shoft.

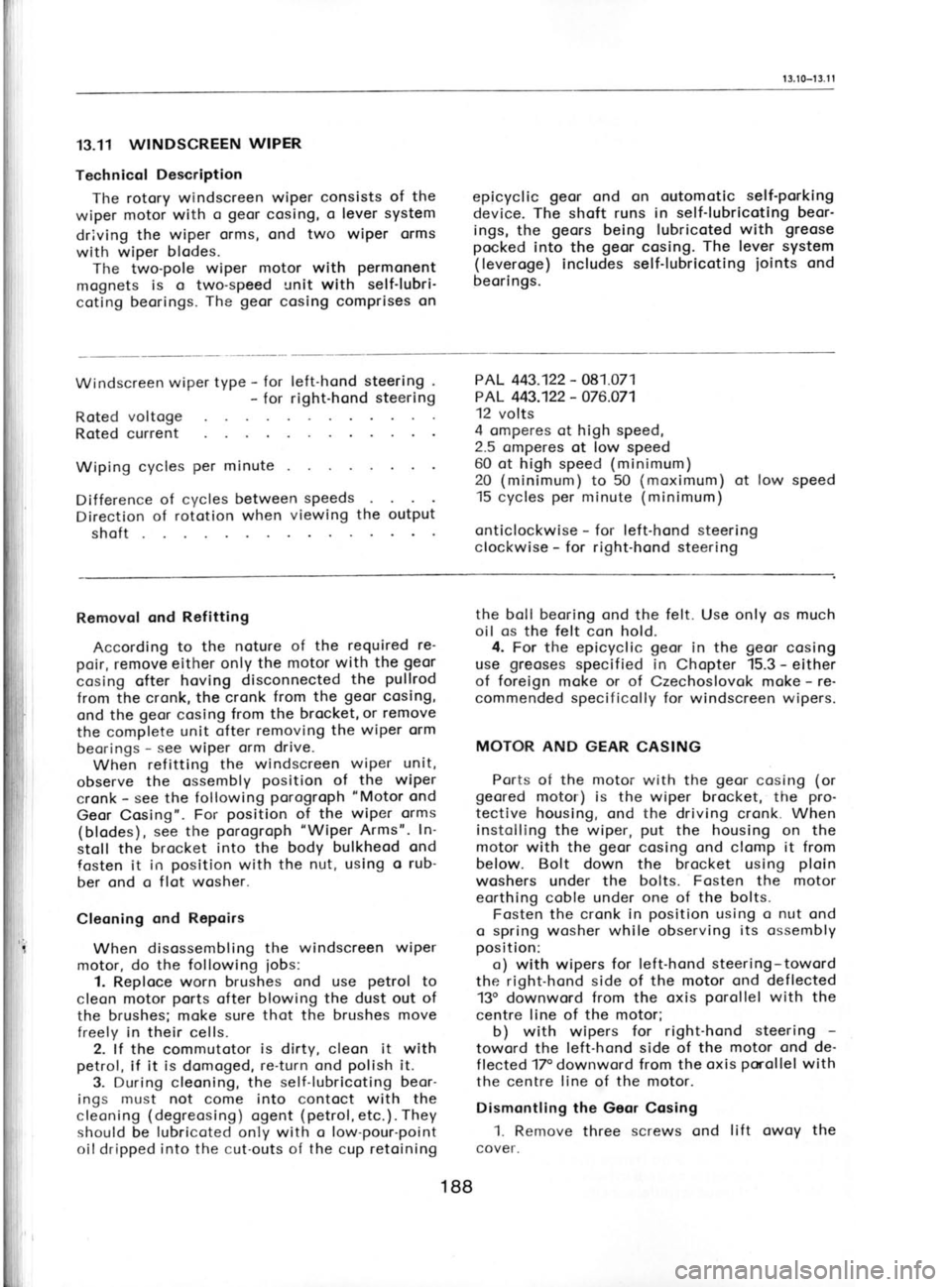

Fig.1.317 Switches -

port ll ond oshtroy

1 -

Switchbox ond steering lock

2 -

Switch of windscreen wipers ond

wosher

3 -

Heoter switch

4 -

Switch for on odditionol device -

not

stondord fitted

5 -

Disobility worrning light

switch -

not on

SKoDA 105 s

6 -

Heoter control

7 -

Ashtroy

The

pulling

wheel

The

toword

i

I

L 12

Page 181 of 238

1 3.10-t

3.1 1

13.11 WINDSCREEN WIPER

Technicol Description

The rotory windscreen wiper consists of the

wiper motor

with o geor

cosing, o lever system

driving the wiper orms, ond two wiper orms

with wiper blodes.

The two-pole wiper motor

with permonent

mognets is o two-speed

unit with self'lubri'

coting beorings. The geor

cosing comprises onepicyclic

geor

ond on outomotic self-porking

device. The shoft runs in self'lubricoting beor'

ings, the geors

being lubricoted with greose

pocked into the geor

cosing. The lever system

(leveroge) includes self-lubricoting

ioints ond

beorings.

Windscreen wiper

tyPe -

for left-hond steering .

- for right-hond steering

Roted voltoge

Roted current PAL 443.122

-

081.071

PAL 443.122 -

076.071

-12

volts

4 omperes ot high speed,

2.5 omperes ot low speed

60 ot high speed (minimum)

20 (minimum)

to 50 (moximum)

ot low speed

15 cycles per

minute (minimum)

onticlockwise -

for left-hond steering

clockwise -

for right-hond steering

Wiping

cycles per

minute

Difference of cycles between speeds

Direction of

rototion when viewing

the output

shoft

I

i

f1

llr

fi.,

il

lr

l Removol

ond

Refitting

According to the

noture of the required re-

poir, remove either only the motor with the geor

cosing after hoving disconnected the pullrod

from the cronk, the cronk from the geor

cosing,

ond the geor

cosing from the brocket, or remove

the complete unit

ofter removing the wiper orm

beorings -

see wiper orm drive.

When ref itting

the windscreen wiper unit,

observe the

ossembly position of the

wiper

cronk -

see the following porogroph "Motor

ond

Geor Cosing". For position

of the wiper

orms

(blodes), see the porogroph 'Wiper

Arms". ln-

stoll the brocket into the body bulkheod ond

fosten it in position

with the nut, using o rub-

ber ond o flot wosher.

Cleoning ond Repoirs

When disossembling the windscreen wiper

motor, do the following jobs:

1. Reploce worn brushes ond use petrol

to

cleon motor ports

ofter blowing the dust out of

the brushes; moke sure thot the brushes move

freely in their cells. 2. lf the commutotor is

dirty, cleon it

with

petrol, if it is domoged, re-turn ond polish

it.

3. During cleoning, the self-lubricoting beor-

ings must not come into contoct with the

cleoning (degreosing)

ogent (petrol,

etc.). They

should be lubricoted

only with o low-pour-point

oil dripped into the cut-outs of the

cup retoining the boll beoring ond

the felt. Use only os much

oil os the felt con hold.

4. For the epicyclic geor

in the geor

cosing

use greoses

specif ied in Chopter 15.3 -

either

of foreign

moke or of

Czechoslovok moke -

re-

commended specificolly

for windscreen wipers.

MOTOR AND GEAR CASING

Ports of the motor

with the geor

cosing (or

geored motor) is the wiper brocket,

the pro.

tective housing, ond the driving cronk. When

instolling the wiper, put

the housing

on the

motor with the geor

cosing ond clomp it from

below. Bolt down the brocket using ploin

woshers under the bolts. Fosten the motor

eorthing coble under one

of the bolts.

Fosten the cronk in position

using o nut

ond

o spring wosher while observing its ossembly

position:

o) with wipers for left-hond steering-toword

the right-hond side

of the motor ond deflected

13o downword from

the oxis porollel

with the

centre line

of the motor;

b) with wipers for right-hond steering

toword the left-hond side of the motor ond de-

f lected 17" downword from the oxis porollel

with

the centre line

of the motor.

Dismontling the Geor Cosing 1. Remove three screws ond lift owoy the

cover.

188

Page 183 of 238

t 3.t

r*r 3.1 2

1. lf the wiper moves with the switch in the

OFF position

ofter its

connection to the electric

power supply, tighten (screw

down) the screw

till it begins to be litfed by the geor

com ond

till the wiper begins to be

switched off ond

broked. Screw down the screw from this po'

sition by onother holf turn.

2. Press the lid into

the cover ond seol it

with point.

WIPER ARM DRIVE

This drive consists of thewiper beoringswith

cronks, the tie-rod of the

cronks, ond

the driv-

ing tie-rod. The

drive is instolled in the cor os

o unit.

Tie-rods The tie-rods should be slipepd on

the cronk

pins in the

following sequence:

o springwosher

with its centre comber focing outword (owoy

from the pin),

o flot

wosher, the tie-rod, o flot

wosher, ond o lock

ring.

lf necessory, lubricote the ioints with

greose

- see the following section deoling with beor-

ings. Fill the cover at the point

of the tie-rod

motor cronk connection with greose

(of ony

brond) ond slip it on the tie-rod.

Beorings On one side, the beoring

is inserted into the

wiper brocket from inside the body, on the

other side, it is fitted into o speciol wosher in-

serted with its nose foremost

into the re-

spective hole in the body. Locote o seoling

wosher with corefully smoothed-out edges ond

o flot

wosher from outside, ond secure the

entire unit with the respective

nut. The

unit is

seoled off by

o rubber pocking.

Fill the unit

with greose (see

Chopter 15.3 for recommended

foreign bronds or Czechoslovok Lrronds SP 4 or

A 4) ond press

it down into the neck of the

bush.

lf it is necessory to remove

or disossemble

the beoring, prise

the lock ring out of the pin

groove under the rubber pocking.

On reossembly,

insert o spring wosher under

the bush with its

combered centre

toword the bush. Lubricote

with the specified greose.

Wiper Arms

The wiper orms fitted with o rubber

blode

con be swung owoy from

the windscreen. They

ore held down by nuts

on the grooved

topers of

the beoring pins.

After hoving fitted

the wiper orms, sproy

woter on the windscreen

ond test the run

of the

wipers. lf necessory, turn the wiper cms

on the pins.

The wipers must wipe

the lorgest

possible oreo of the windscreen without, how'

ever, touching the windscreen glozing

mould-

i ng.

13.12 RADIATOR FAN

Technicol Description

The fon is on ossembly of the fon motor ond

impeller. The

impeller is pressed

on to the

motor shoft. The motor hos permonent mognets ond

o rotor running in self-lubricoting beorlngs. The

impeller is mode of plostic.

Motor type

Roted voltoge Roted current

Roted output

Direction

of rototion PAL 443.132

-

O97.O45

12 volts

7.5 omperes

55 wotts

clockwise (right-hond) when

viewing the front end of the

shoft

Coble poles

coble with lug (blue) -

negotive pole

coble with femole connector

(red) -

positive pole

Removol ond Refitting

The fon is

occessible ofter

removing the

rodiotor to which it is fostened by meons of

o rim held down by copscrews ond sprlng

woshers. The motor rests on resilient bushes in

the rim. When refitting the fon moke sure thot

there is o spocer tube in the bush, locote the

flot ond the spring woshers, ond tighten

the

nut.

Cleoning ond

Repoirs

Refer to porogrophs

1 to 3 deoling with

cleoning ond repoirs in Chopter 13.11.

Dismontling Motor ond lmpeller

The motor con be removed (ond

dismontled)

only ofter removing the impeller. Use the puller

MP 8-102

to pull

off the fon or support the fon

hub in three points

on its circumference ond

press out the motor by opplying

Pressure on

the motor shoft. No topping or blows on the

shoft ore permitted.

1. Remove the nuts of the clomping bolts,

hold the shoft

by its grooved

end, ond lift

owoy the

commutotor end shield ond stotor.

190

Page 220 of 238

r

5.9-15. r

2

Dismontle the housing, remove

old greose,

cleon the individuol ports,

opply fresh greose,

ond reossemble the housing. Sook the felt rings

on the links (pull-rods)

in engine oil.

15.10 WHEELS AND TYRES, SNOW

CHAINS

Tyre Inflotion, Boloncing

ond lnterchonge

of Wheels

The procedures ore outlined in

Chopters 10.1

through 10.3. Snow

choins ond their use ore

deolt with in Chopter 10.6.

Wheel Toe-in -

see Chopter 16.1.

Shock Absorbers -

see Chopter 8.3 "Shock

Absorbers ".

15.11 ELECTRTCAL EQUTPMENT

Checking electrolyte level ond topping up --

see Chopter 13.2.

Sporking plugs -

electrode gop

odiustment,

etc. -

see Chopter 13.7.

Stqrter motor -

exqminqtion ond renewol of

brushes, etc. -

see Chopters 13.11 through 13.14.

lgnition timing, odiustment of contoct breoker

point gop, distributor lubricotion -

see Chop-

ter 15.3.

15.12 BODYWORK -

UNDERBODY

Woshing ond Mointenonce

The visible ports

of the body qre

f inislred in

o hord synthetic boking vornish, the remoining

ports in synthetic vornish.

The underbody is sproy-cooted

with o plostic

compound -

for detoiled informotion, see Chop-

ter '14.9.

Follow the

usuol procedures

when

woshing, cleoning ond polishing

the cor, ond

observe the specific instructions for

the use of

woshing ond cleoning preporotions,

issued by

their monufocturers.

All lights with the exception

of heodlomps

hove cosings of plostic

moteriols qnd

they

should be cleoned onlywith woteror shompoos.

When hosing down the corr

cover the voltoge

regulotor of the olternotor ond

the ignition coil

to protect

them ogoinst sploshing with woter,

ond do not

sproy woter direct on

the door lock

ond the lid covering the fuel

tonk filler neck.

Woshing ond Core of Underbody

Mechonisms

The underbody mechonisms

ore protected

with o synthetic vornish which stonds

well the

usuol woshing procedures.

Protect oll rubberports

ogoinst direct contoct with speciol chemi-

col solvLnts or limit the durotion of this

contoct

to o minimum before

o complete woshing off of

the solvents with woter (by

hosing down, etc.)'

Keep the oil cooler, if fitted on

the cor, in

cleon'condition. Hose

it down when woshing

the cor, ond if dirt still

sticks to the cooling

surfoces, use some of the detergents.

Bodywork Lubricotion

Routine mointenonce includes the

lubricotion

of door hinges ond limiters, hinges

ond releose

mechonismi of the engine bonnet ond boot lid,

the releose mechonism of

the spore wheel,

ond

the leveroge of windscreen wipers. Lubricotion

of inner dolor mechonisms is

included in

speciol

mqintenonce. Lubricote oll occessible mechcnisms

with

high-quolity greoses which

do not

dry, do not

oxldize, ond protect

the mechonisms ogoinst

corrosion for o long time. Oil is

not suitoble due

to its short-time efJect. Any greose con

be used

to lubricqte the

door limiters ond

the front

seot

slide roils.

Lubricotion of SporeWheel Corrier

Bearings-

Remove the spore wheel,

cleon the hinges, ond

opply oil on iheit

upper sides. In oddition, rub

in greose of ony brond.

Lubricotion of Windscreen Wiper

Leveroge -

Remove the cover of the

ioint (o

plostic cup),

f ill it with greose, lubricote the

ioint, ond

rein-

stoll tlre cover.

The Lubricotion of

Inner Door Mechonisms

is possible only

ofter removing the

door ponel

ond the inner 'door

mechonism. Use

only re-

commended greose brcnds.

Lubricote

the bowden

coble of thJwindow wind-up mechonism

with

Fig.15.1211- Lubricotion

of Windscreen Wiper

Leveroge Joint -

ioint cover

230