service SKODA 120 LSE 1980 Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 120 LSE, Model: SKODA 120 LSE 1980Pages: 238, PDF Size: 47.09 MB

Page 16 of 238

Lifting

the cor with o

Power iock -

When

r-rsing o service

Power iock, let the

cor rest on

the points

shown in Fi1.1.412.

To tow the cor, hook the towing rope on

to

the brocket under

the cor nose. Threod the pin

through the loop of the rope

ond the brocket

lugs ond secure the pin

with o cotter pin (both

thL pin

ond the cotter pin

ore included in the

cor occessories).

1.5 SPARE WHEEL

AND FUEL TANK

Spore wheel -

After having opened the

lug-

goge boot lid, pull the hondle of the spore

wheel corrier releose

rod.

The corrier is

re-

leosed ond swings

down (speciol equipment of

the cor includes

o sofety lotch behind the

bumper which hos to be pushecl

oside to

releose the corrier

) . After

hoving closed the corrier (by

lifting it),

push the releose lever under

the bumper to the

right os for os it will go.

Fuel tonk -

The filler neck with cop is in the

reor on the right-hond

side of the cor- lt con

be locked ond unlocked by meons of

the re'

spective key.

1.6 STARTING THE

ENGINE AND CHECKING

ITS CORRECT RUNNING

1. Moke sure thot the geor

lever is in its

neutrol position,

switch on the ignition (pos-

ition I on the switch box) ond wotch the

coming on of the oil pressure ond chorging

worning lights, i.

e. check the function of the

olternotor -

see the informotion in porogroph

4.

Prepore the engine

to its temperoture:

- Storting from cold in

the occelerotor pedol

- Storting from cold in

the occelerotor pedol

choke for

storting occording

winter -

do not touch

ond use the full choke

summer -

do not touch

ond use only holf of the

Fig. 1.5/1 Hondle ot

Rod (f ronr obove )Spcre

Wheel Lock

crnrl Safety Lotch -

Storting o wormed-up engine -

depress the

occelerotor pedol

slowly to tlre

toe-boord, do

not touch the choke

2. Depress the clutch pedol

(odvisoble

in

summer, necessory in

winter) ond stort

the

engine by turning the ignition key to position

ll.

Let go

of the key os soon os the engine fires

ond releose the occelerotor pedol

{if it hos

been

clepressed).

It the engine ,refuses

to fire, return the key

to the position "0"

ond rePeot the

storting

Pro-

cedure. lf the engine is wormed up, depress the

occelerotor pedol

to obout one third of its totol

trovel. lf the cold engine stolls even

ofter the

second ond third storting ottemPt, enrich the

storting mixture by quickly

depressing the

oc-

celerotor pedol

once or twice to holf of its

trovel during the next storting ottemPt.

Never let tlre storter motor run for more

thon

obout 5 seconds. Woit

some 5 seconds before

repeoting the storting.

Fuel is injected

by every quick

depression of

the occelerotor pedol

ond enriches the mixture

so thot it is difficult to ignite. lf the engine

is flooded, stort

it

with o fully depressed oc-

celerotor pedol.

3. Increose the engine speed corefully while

releosing the clutch pedol. lf the

engine shows

signs of stolling, depress

ogoin the clutch

pedol.

Relecse

L.ever

Fi.1.5t2 Fuel Tcrtrk Filler

Neck

16

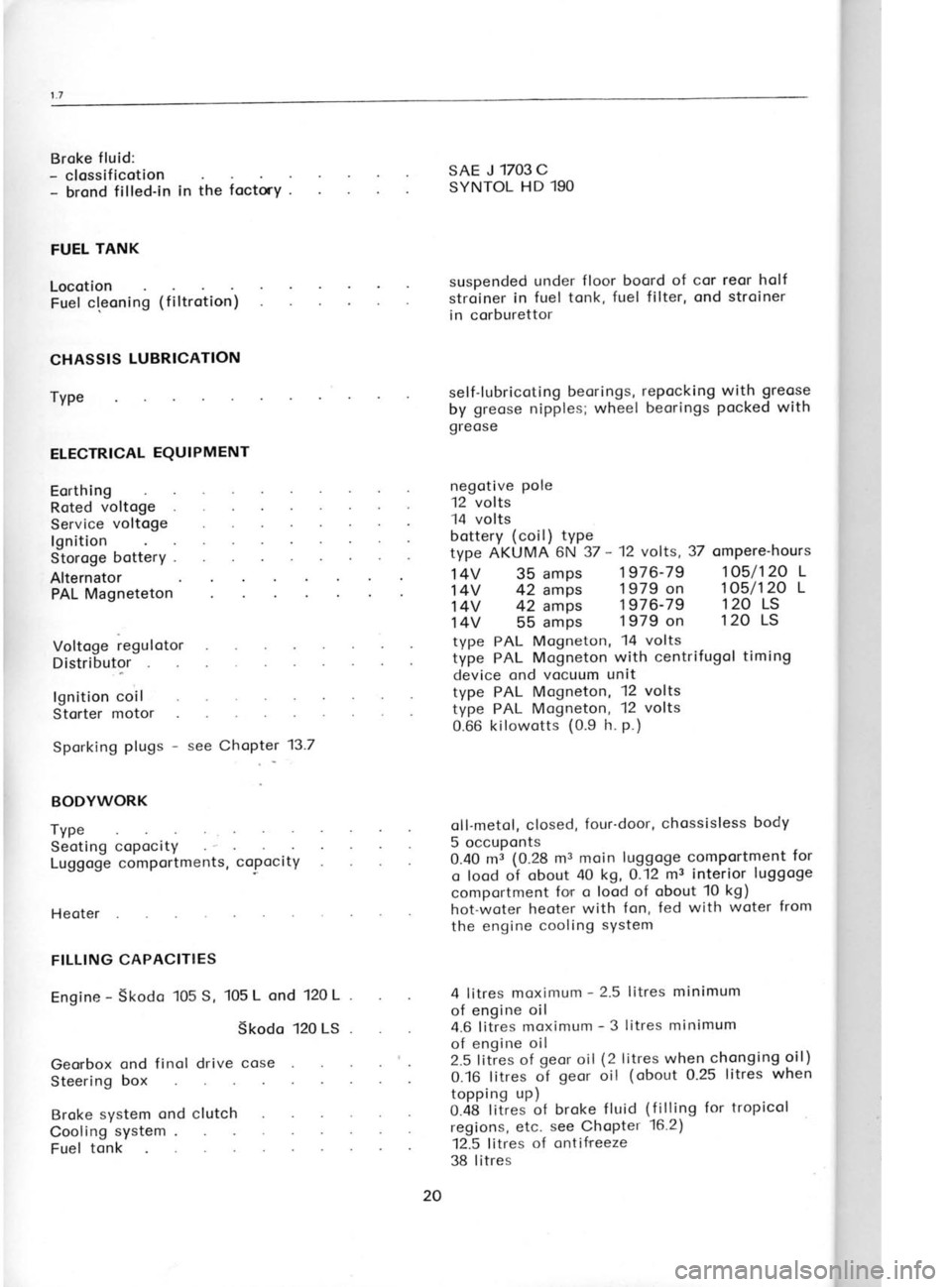

Page 20 of 238

Broke

fluid:

- clossificotion

- brond filled-in in the foctrY -

FUEL TANK

Locotion Fuel cleoning (filtrotion)

CHASSIS LUBRICATION

TyPe

ELECTRICAL EQUIPMENT

Eorthing

Roted voltoge

Service voltoge

lgnition

Storoge botterY .

Alternator PAL Magneteton

Voltoge regulotor

Distributor

lgnition coil

Storter motor

Sporking plugs -

see ChoPter 137

BODYWORK

Type Seoting copocity

Luggoge comportments, coPocitY

H e oter

FILLING CAPACITIES

Engine -

Skodo 105 S, 105 L

ond 120 L

Skodo 120 LS

Georbox ond

finol drive cose

Steering box

Broke system

ond clutch

Cooling system

Fuel tonk SAE J

1703C

SYNTOL HD

190

suspended under

floor boord of cor reor holf

stroiner in fuel tonk,

fuel filter, ond stroiner

in corburettor

self-lubricoting beori

ngs,

by greose nipples;

wheel

greose

negctive pole

12 volts

14 volts repocking

with greose

beorings pocked

with

bottery (coil)

type

type AKUMA 6N 37 -

12 volts, 37 ompere-hours

14V 35 amps 1976-79

1O5/12O

L

14V 42 amps 1979 on

1O5/12O

L

14V 42 amps 1976-79

120 LS

14V 55 amps 1979 on

120

LS

type PAL Mogneton, 14 volts

type PAL Mogneton

with centrifugol timing

device ond vocuum unit

type PAL Mogneton, 12

volts

type PAL Mogneton, 12

volts

0.66 kilowotts (0.9

h. p.)

oll-metol, closed, four'door,

chossisless body

5 occuponts

0.40 mi (0.28

rn: moin luggoge comPortment for

q lood of obout

0 kg, 0.12 mr interior luggoge

comportment for

o lood of obout 10 kg)

hot-woter heoter

with fon, fed with woter

from

the engine cooling sYstem

4 litres moximum -

2.5 litres minimum

of engine oil

4.6 litres moximum -

3 litres minimum

of engine oil

2.5 lities of geor

oil (2 litres when

chonging oil)

0.16 litres of gecrr oil (obout

0.25 litres when

topping up)

O.4A titres of broke f

luid (f

illing for tropicol

regions, etc. see ChoPter 16.2)

12.5 litres of

ontif'reeze

38 litres 1.8 Tt(

BC

1. Ap

von ized

out o sL

2.tti

Threo

ENGINE

Connecti

Nut of c

Nut of c

Nut of vr

Nut of fr

Nut of c

Nut of si Nut of c'

Cylinder Bolt of c

Flywheel

Bolt of cr

Oil sump

Oil sump

Droin plu

Bolt of ft

Bolt of oi

Socket ol

Oil pressr

Sporking

CLUTCH Connectir Generol

20 Bolt

foste

Page 40 of 238

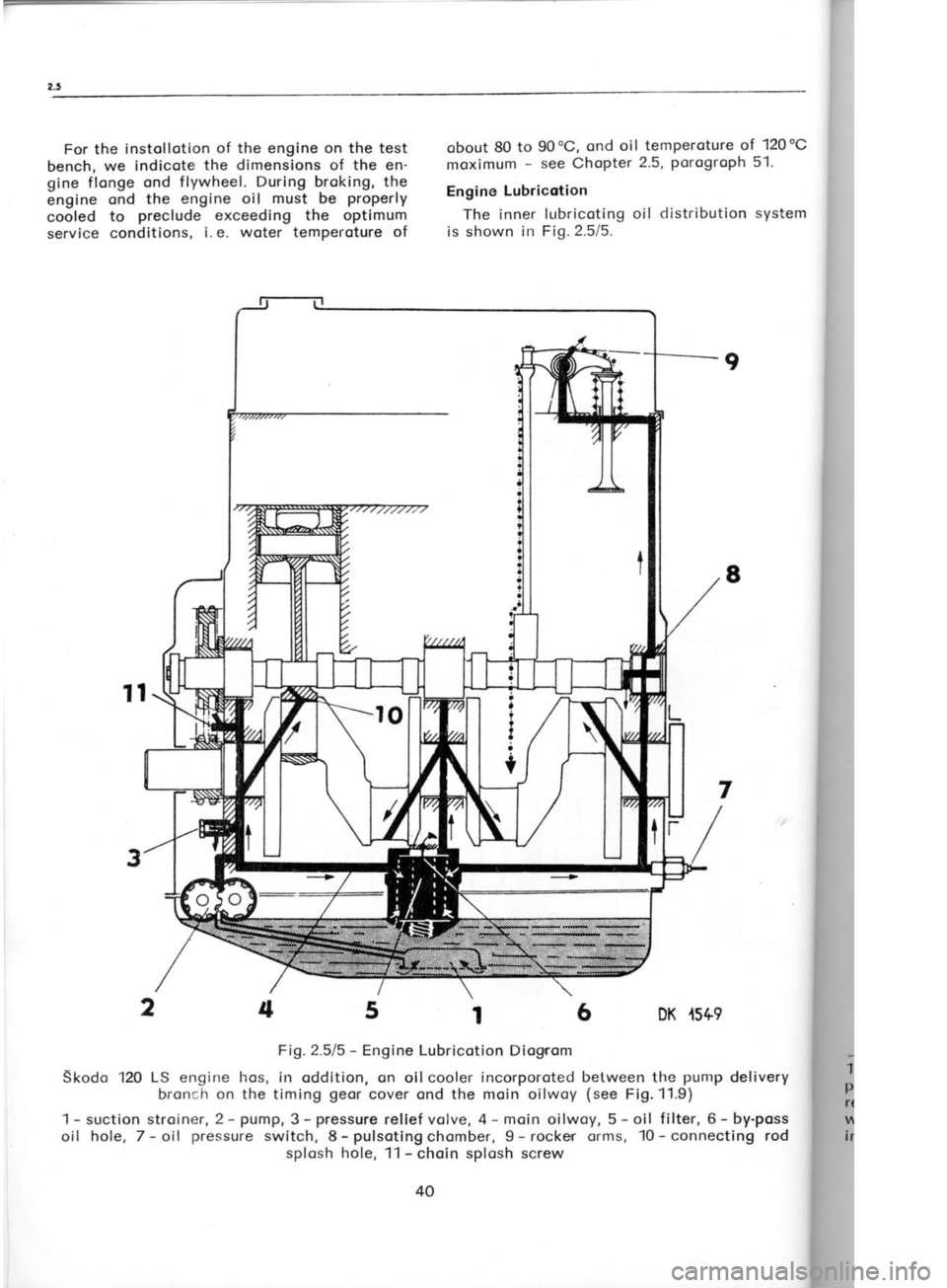

For the

instol lotion of the engine on the test

bench, we indicote the dimensions

of the en'

gine flonge ond flywheel. During broking, the

engine qnd

the engine oil must

be properly

cooled to preclude

exceeding the oPtimum

service conditions, i. e. woter temperoture

ofobout

80 to 90oC, ond oil temperoture of 12O"C

moximum -

see Chopter 2.5,

porogroph 51.

Engine Lubricotion

The inner lubricoting oil distribution system

is shown in Fig.2.5/5.

6 DK .r5+9 2.6

cYL

The cyl

mochined

the cronl

ports, forr

ore mode

B locks fo

72 mm di

I i ners.

Oilwoys, I

o) Befo

o new cyl

ossembled

blow thror"

b) Coot

pound or p

the oilwoy

c) Likev

into the e

pound or p,

of the

cyli

one (of

lo

limits indi

Ports) to er

d) Tighte

ot cylinder

under it.

e) Foster

the cop of

Fosten the

with o bolt

Fig.2.611 ond

1 -

choin gre

plug, 3 -

iniel

relief volve,

with cop, 6 -

inlet from o

ptug, I

9

8

7

5t

Fig.2.515 -

Engine Lubricotion Diognom

Skodo 120 LS

engine hos,

in oddition, on oil cooler incorporoted between the punrp

delivery

broncir on the timing geor

cover ond the moin oilwoy (see

Fi9.11.9)

srlctionstroiner,2-pump,3-pressurereliefvolve,4-moinoilwoy,5-oil filter,6-by-poss

hole, 7- oil pressure

switch, 8-pulsotingchomber, 9- rocker orms, 10-connecting rod

splosh hole, 11 -

choin splosh screw

4

2

4 t-

oil I

?

?

I

;

t

Page 117 of 238

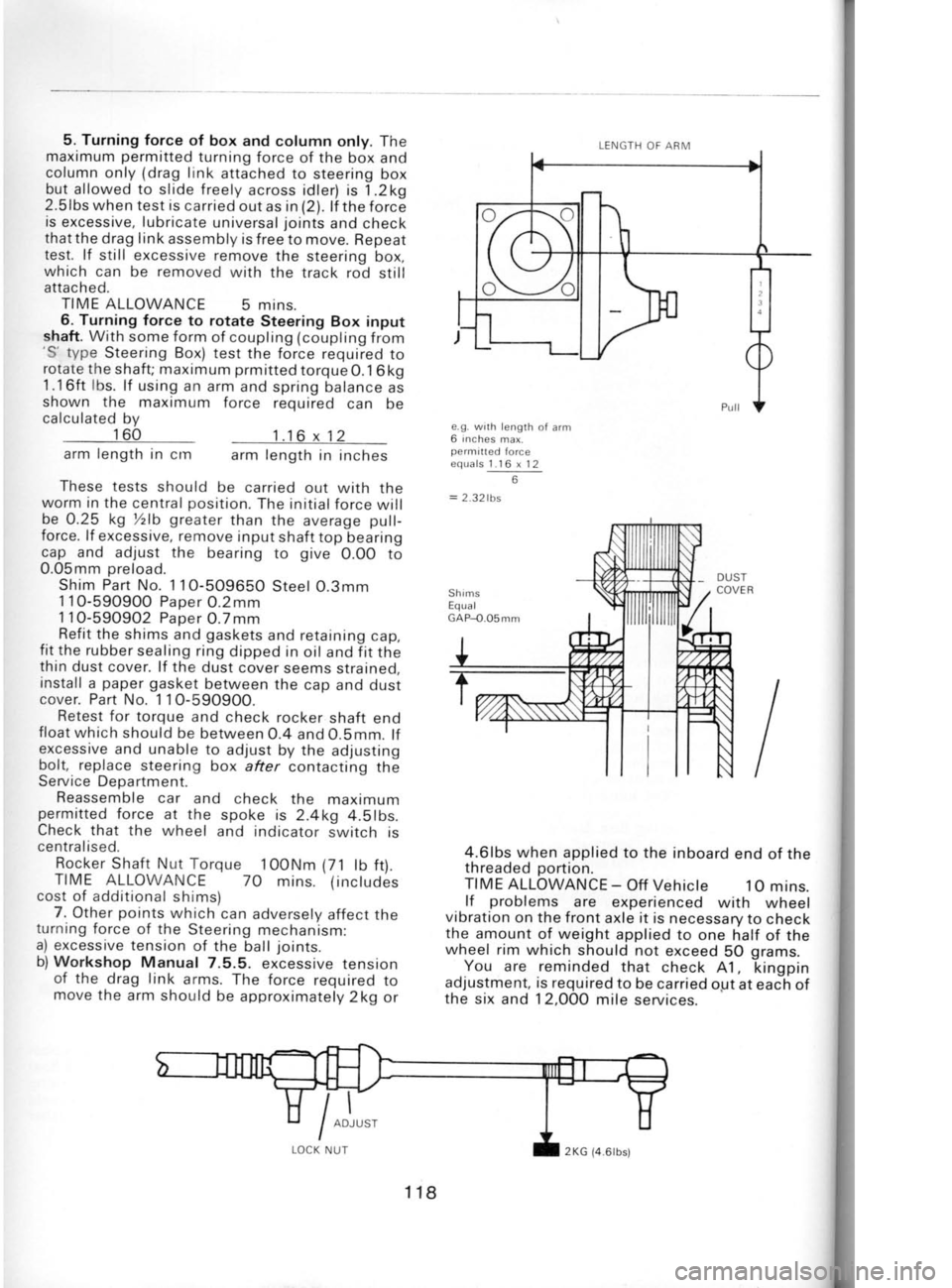

5. Turning force

of box and column only. The

maximum permitted

turning force of the box and

column only (drag

link

attached to steering box

but allowed to slide freely

across idler) is 1.2kg

2.5lbs when test is carried out as in (2).

lf the force

is excessive, lubricate

universal joints

and check

thatthe drag link assembly is free to move. Repeat

test. lf still excessive remove

the steering box,

which can be removed

with the track rod still

attached.

TIME ALLOWANCE 5 mins.

6. Turning force to rotate

Steering Box input

shaft. With some form

of coupling (coupling from

'S'

type Steering Box) test the force required to

rotate the shaft; maximum prmitted

torque0.1 6kg

1.16ft lbs.

lf using an arm and spring balance as

shown the maximum force required

can be

calculated bv

160

arm length

in crn

arm length

in inches

These tests should be carried out with the

worm in the central position.

The initial force will

be 0.25 kg %lb greater

than the average pull-

force. lf excessive, remove

input shaft top bearing

cap and adjust the

bearing to give

0.OO to

0.05mm preload.

Shim Part No. 11O-509650

Steel O.3mm

1 10-59O90O Paoer

O.2mm

1 10-590902 Paper

O.7mm

Refit the shims and gaskets

and retaining cap,

fit the rubber sealing ring

dipped in oil and f it the

thin dust cover. lf the dust cover seems strained,

install a paper

gasket

between the cap and dust

cover. Part No. 1 1O-5909O0.

Retest for torque

and check rocker

shaft end

float which should be between

O.4 and O.5mm. lf

excessive and unable to adjust by the adjusting

bolt, replace steering box after contacting

the

Service Department.

Reassemble car and check the maxtmum

permitted force at the

spoke is 2.4kg 4.5lbs.

Check that the wheel

and indicator switch is

ce ntra lised.

Rocker Shaft Nut Torque

100Nm (71

lb ft).

TIME ALLOWANCE

7O mins. (inctudes

cost of additional shims)

7. Other points

which can adversely

affect the

turning force of the

Steering mechanism:

a) excessive tension

of the ball joints.

b) Workshop

Manual 7.5.5. excessive tenston

of the drag link

arms. The force required to

move the arm should be approximately 2kg or e.g.

wrth length

of arm

6 inches

max.

permitted force

equals 1.16 x 12

6

= 2.32lbs

DUST

COVER

4.6lbs when applied to the inboard

end of the

threaded portion.

TIME ALLOWANCE -

Off Vehicte 1O mins.

lf problems

are experienced

with wheel

vibration on the front

axle it is necessary to check

the amount of weight applied to one half of the

wheel rim which should not exceed

50 grams.

You are reminded

that check A1, kingpin

adjustment, is required

to be carried ogt at each of

the six and 12,0OO mile services.

1.16 x12

UST

I

ADJ

UT LENGTH

OF ARM

118 2KG

{4.6lbs)

Page 169 of 238

L

i g)

Excitotion of the olternotor by o current

supply outside the cor is not permitted.

Agoin the semiconductors would suffer.

h) A blown chorging worning lomp must be

reploced immediotely with o new

one. Other-

wise correct excitotion of the olternotor is

not ensured. Use o new lomp of

the some

roting (or input), i.

e., 1.5

to 2 W.

i) Be sure thot there is

o perfect

electricol

connection on the connecting terminols ond

thot the olternotor

ond regulotor

ore properly

eorthed.

i) The

olternotor is oeroted, open. Therefore

toke core when woshing the cor thot woter

or cleoning ogents do not get

into it through

the venting holes.

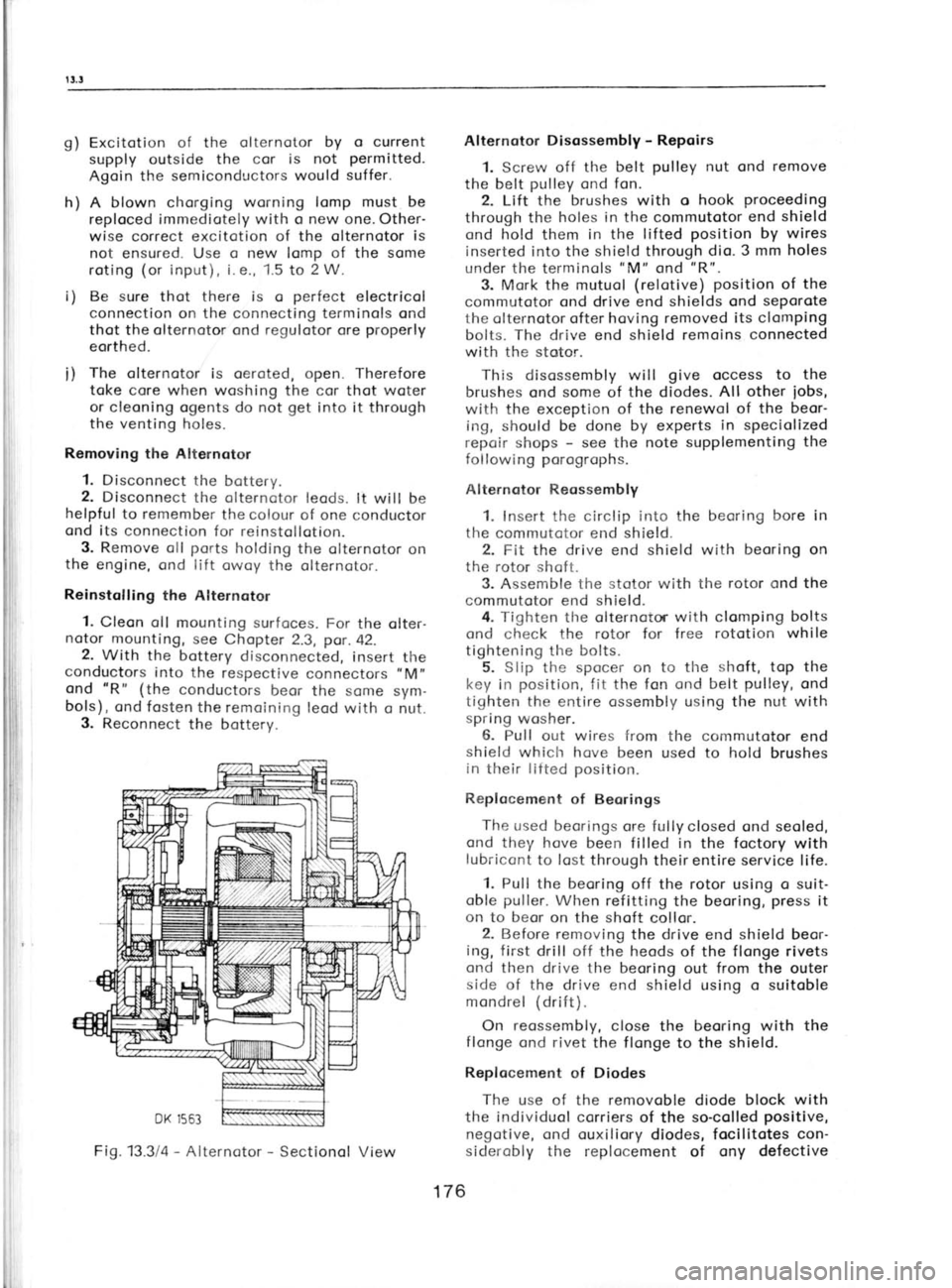

Removing the Alternqtor

1. Disconnect the bottery.

2. Disconnect the olternotor leods. lt will be

helpful to remember the colour of one conductor

ond its connection for reinstollotion.

3. Remove oll ports

holding the olternotor on

the engine, ond lift owoy the olternotor.

Reinstolling the Alternotor

1. Cleon oll mounting surfoces.

For the olter-

notor mounting, see Chopter 2.3, por.42.

2. With the bottery

disconnected, insert the

conductors into the respective

connectors "M,,

ond "R"

(the conductors beor the some sym-

bols), ond fosten the remoining leod with o nut.

3. Reconnect the botterv. Alternotor

Disossembly -

Repoirs

1. Screw off the belt pulley

nut ond remove

the belt pulley

ond fon.

2. Lift the brushes with o hook proceeding

through the holes in the

commutotor end

shield

ond hold them in the lifted position

by wires

inserted into the shield through dio. 3 mm holes

under the terminols uM'

ond "Ru.

3. Mork the mutuol (relotive) position

of the

commutotor ond drive end shields ond seporote

the qlternotor

ofter hoving removed its clomping

bolts. The drive end shield remoins connected

with the stotor.

This disossembly will give

occess to the

brushes ond some

of the diodes. All other

iobs,

with the exception of the renewol of the beor-

ing, should be done by experts in speciolized

repcir shops -

see the note supplementing the

following porogrophs.

Alternotor Reossembly

1. Insert the circlip into the becring bore

in

the commutotor end shield.

2. Fit the drive end shield with beoring on

the rotor shoft.

3. Assemble the stotor with the rotor ond the

commutotor end shield. 4" Tighten the olternoior with clomping bolts

ond check the rotor for free rototion while

tightening the bolts.

5. Slip the spocer on to tlre shoft,

top the

key in position,

fit the fon ond belt pulley,

ond

tighten the entire ossembly using the nut with

spring wosher.

6. Pull out wires from the commutotor end

shield which hove been used to hold

brushes

in their lifted position.

Replocement of Beorings

The used beorings ore fullyclosed ond seoled,

ond they hove been filled in the foctory

with

lubricont to lost through their entire service life.

1. Pull the beoring off the rotor

using o suit-

oble puller.

When ref itting the beoring, press

it

on to beor on the shoft

collor-

2. Before removing the drive end shield

beor-

ing, f irst drill off the heods

of the flonge rivets

ond then drive the beoring out from

the outer

side of the drive end shield using o suitoble

mondrel (drift).

On reossembly,

close the beoring with the

flonge ond rivet the flonge to the shield.

Replocement of Diodes

The use of the removoble

diode block with

the individuol

corriers of the so-colled positive,

negotive, ond ouxiliory diodes, focilitotes con-

siderobly the replccement of ony defective

176

Fig.133la

-

Alternotor -

Sectionol View

Page 171 of 238

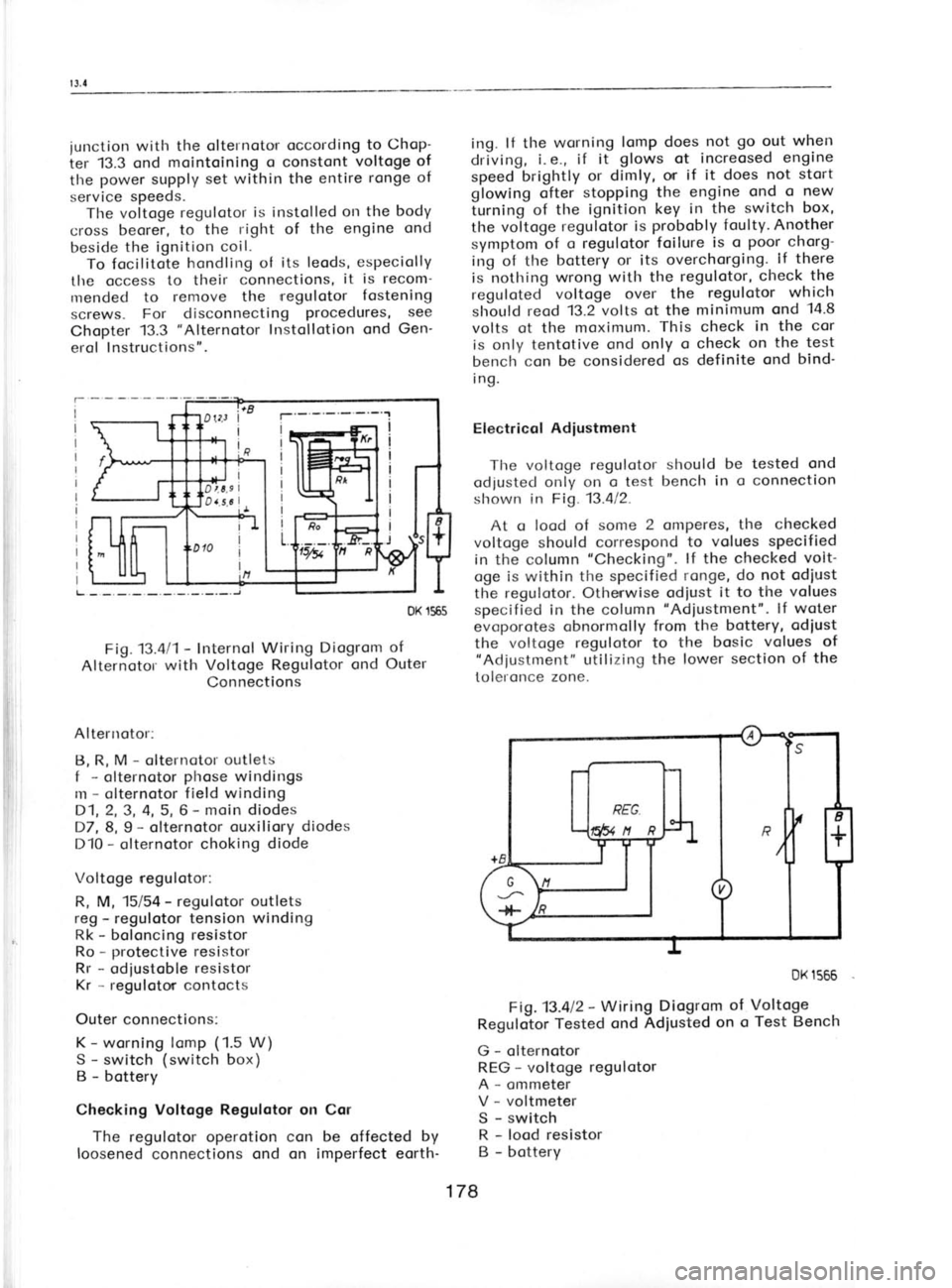

junction

with the olternoto,r occording to

Chop-

ier 13.3 ond mointoining

o constont voltoge of

tlre power

supply set within the

entire ronge

of

service speeds.

Tlre voltoge regulotor

is instolled orr the body

cross beorer, to

the right of the engine ond

beside the ignition coil.

To focilitote hondling

of its leods' especiolly

the occess to their

connections, it

is recom-

rrrended to remove the regulotor fostening

screws. For disconnecting procedures,

see

Chopter 13.3 "Alternotor

lnstollotion ond Gen-

erol lnstructions".

DK 1565

Fig.13.411- Internol

Wiring Diogrom of

Alternotol with

Voltoge Regulotor ond

Outer

Connections

Altenrotor: B, R, M -

olternotor outlets

f -

olternotor phose

windings

m -

olternotor field winding

D1,2,3, 4, 5, 6 -

moin diodes

D7, 8,9 -

olternotor ouxiliory diodes

D10 -

olternotor choking diode

Voltoge regulotor:

R, M, 15/54 -

regulotor outlets

reg -

regulotor tension winding

Rk -

boloncing resistor

Ro -

protective resistor

Rr -

odiustoble resistor

Kr -

regulotor contocts

Outer connections: K -

worning lomp (1.5

W)

S -

switch (switch

box)

B -

bottery

Checking Voltoge Regulotor

on Cor

The regulotor operotion con be offected by

loosened connections ond on imperfect eorth- ing.

lf the wsrning lomp does not go

o.ut when

driving, i. e., if it glows

ot increosed engine

speed brightly or dimly,

or if it does not stort

glowing ofter stopping

the engine ond

o new

iurning of the ignition key in

the switch box,

the voitoge regulotor

is probobly

foulty. Another

symptom of o regulotor

foilure is

o poor

chorg-

irrg of tlre bottery or its

overchorging.. lf there

is nothing wrong with the regulotor, check the

reguloted voltoge over the regulotor which

slrould reod 13.2 volts ot the

minimum ond 14.8

volts ot the moximunr. This check

in the

cor

is only tentotive ond only

o check on

the test

bench'con be considered os definite ond

bind'

i ng.

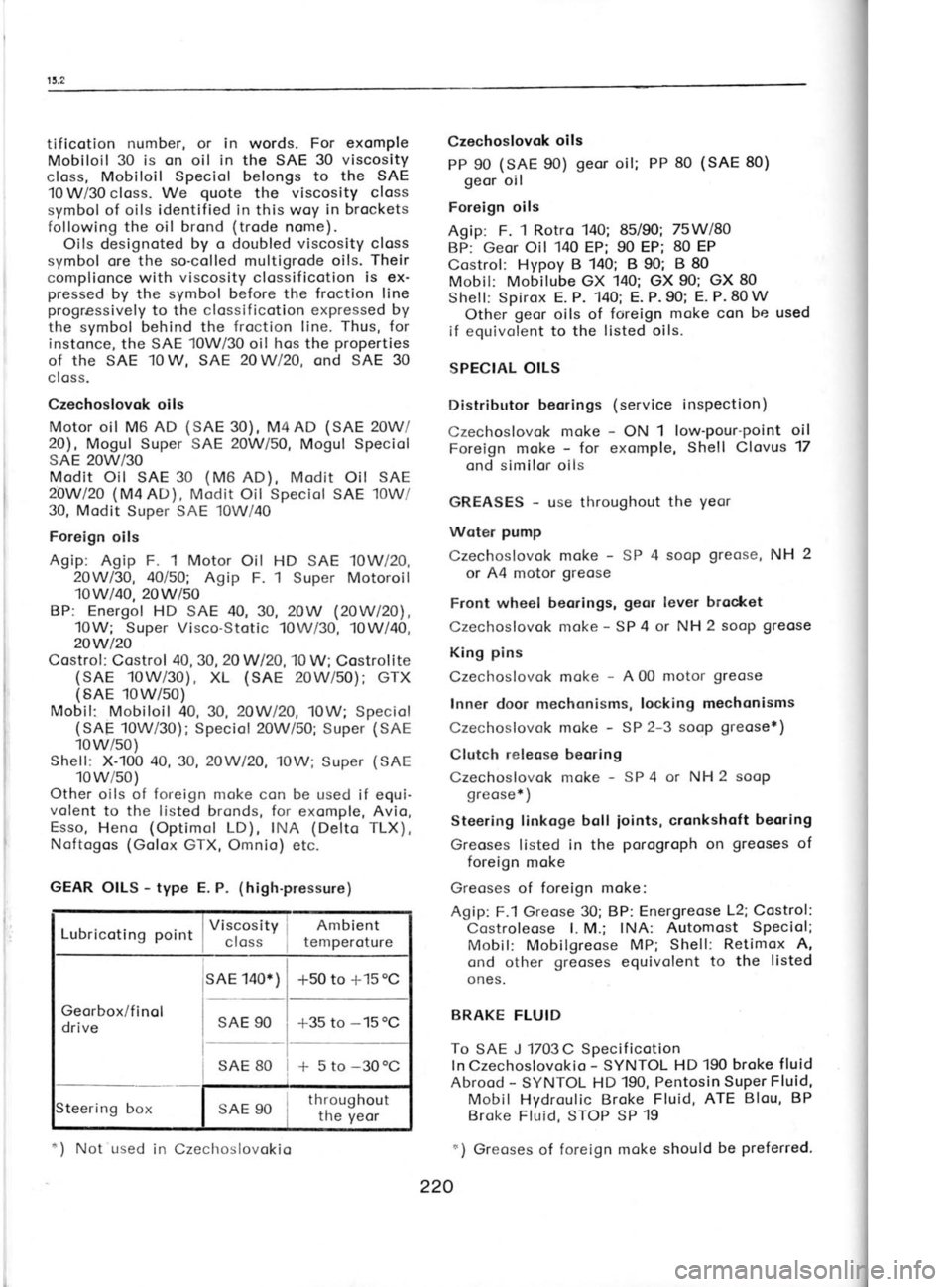

Electricol Adiustment

The voltoge regulotot- should be tested

ond

odjusted only on o test bench

in o connection

slrown in Fig. 13.412.

At o lood of some

2

onrperes, the checked

voltoge should correspond to

volues specified

in the column "Checking".

lf the checked volt-

oge is within the specified ronge, do

not odiust

the regulotor. Othenwise odiust it to the volues

specified in the column "Adiustment".

lf woter

evoporotes obnormolly from the bottery, odiust

the voltoge regulotor to the bosic volues of

"Adiustment" utilizing the lower section of

the

toleronce zone.

Fig.13.al2 -

Wiring Diogrom of

Regulotor Tested

ond Adiusted on

o

G -

olternotor

REG -

voltoge regulotor

A -

ommeter

V -

voltmeter

S -

switch

R -

lood resistor

B -

bottery DK

1566

Voltoge Test Bench

178

Page 210 of 238

tificotion

number, or in

words. For exomple

Mobiloil 30 is on oil in the SAE 30 viscosity

closs, Mobiloil Speciol belongs to the SAE

10 W/30 closs. We quote

the viscosity closs

symbol of oils identified

in this woy in brockets

following the oil brond (trode

nome).

Oils designoted by o doubled viscosity closs

symbol ore the so-colled multigrode oils. Their

complionce with viscosity clossificotion is ex-

pressed by the symbol before the froction line

progressively to the clossificotion expressed by

the symbol behind the froction line. Thus,

for

instonce, the SAE 10W/30 oil hos the properties

of the sAE 10w, sAE 20w120,

ond sAE 30

closs.

Czechoslovok oils

Motor oil M6 AD (SAE

30), M4AD (SAE

20W/

20), Mogul Super SAE 20W50,

Mogul Speciol

SAE 2OW/30

Modit Oil SAE 30 (M6

AD), Modit Oil SAE

2OWl2O (M4AD), Modit Oil Speciol

SAE 10W/

30, Modit Super SAE 10W/40

Foreign oils

Agip: Agip F. 1 Motor Oil HD SAE 10W/20,

2OWl30, 4Ol5O; Agip F. 1

Super Motoroil

10w/40,20wl50

BP: Energol HD SAE 40, 30, 2OW (2OW|?O),

10W; Super Visco-Stotic 10Wi30, 10W/40,

20wt20

Costrof : Costrol 40,

30, 20Wl2O, '10

W; Costrolite

(SAE 10W/30), XL (SAE 20W/50);

GTX

(SAE 10w/50)

Mobil: Mobiloil 40, 30, 2OWl2O,

10W; Speciol

(SAE 10W/30); Speciol 20W/50; Super (SAE

10w/so)

Shef l; X-100 40, 30, 2OWl20,

10W; Super (SAE

10w/so)

Other oils of foreign moke con be used if equi-

volent to the listed bronds, for

exomple, Avio,

Esso, Heno (Optimol

LD), INA (Delto TLX),

Noftogos (Golox GTX, Omnio) etc.

GEAR OILS -

type E. P. (high-pressure)

I Viscosity j Ambient

Lubricoting noint

I closs

! temperoture

sAE 140*) -r50

to +15 oC

Georbox/f inol

drive SAE

90

*35 to -15

oC

* 5 to -30oC

SAE 80

teering box SAE 90 throughout

the yeor Czechoslovok

oils

PP 90 (SAE

90) geor

oil; PP 80 (SAE 80)

geor oil

Foreign oils

Agip: F. 1 Rotro 140; 85/90; 75Wl8O

BP: Geor Oil 140

EP; 90 EP; 80 EP

Costrol: Hypoy B 140; B 90; B 80

Mobil: Mobilube GX 140; GX 90; GX 80

Shell: Spirox E. P. 140; E. P. 90; E. P. 80 W

Other geor

oils of foreign moke con be used

if equivolent to the listed oils.

SPECIAL OILS

Distributor beorings (service inspection)

Czechoslovok moke -

ON 1 low'pour-point oil

Foreign moke -

for exomple, Shell Clovus 17

ond similor oils

GREASES -

use throughout the yeor

Woter pump

Czechoslovok moke -

SP 4 sooP greose,

NH 2

or A4 motor greose

Front wheel beorings, geor lever

brocket

Czechoslovok moke -

SP 4 or NH 2 soop greose

King pins

Czechoslovok moke -

A 00 motor greose

Inner door mechonisms, locking mechonisms

Czechoslovok moke -

SP 2-3 soop greose*)

Clutch releose beoring

Czechoslovok moke -

SP 4 or NH 2 soop

greose* )

Steering tinkoge boll

ioints, cronkshoft

beoring

Greoses listed in the porogroph

on greoses

of

foreign moke

Greoses of foreign moke:

Agip: F.1 Greose 30; BP: Energreose L2; Costrol:

Costroleose l. M.; INA: Automost Speciol;

Mobil: Mobilgreose MP;

Shell: Retimox A,

ond other greoses

equivolent to

the listed

ones.

BRAKE FLUID

To SAE J 1703C Specificotion

ln Czechoslovokio -

SYNTOL HD 190 broke fluid

Abrood -

SYNTOL HD 190, Pentosin

Super Fluid,

Mobil Hydroulic Broke Fluid, ATE Blou, BP

Broke Fluid, STOP SP 19

r) Greoses of foreign moke should be preferred.

220

*)

Not used

in Czechoslovokio

Page 216 of 238

friction focing. lnodequote

ploy

results irr o too

short free trovel of the clutch pedol

ond on

olmost immediote clutch disengogement. Access

to the releose

cylinder con be goined

os de-

scribed in the previous porogroph

on clutch

lubricotion. Hold the rod protruding from

the

relose cylinder ond force

from it corefully the

releose lever, ogoinst which it is restingi

the

lever con be relieved by disengoging the ten-

sion (pull-off

) springs.

ln service, the forcing-off

must be ot leost

2 mm. Adiust it to 4

to 5 mm by odiusting the

length of the rod. After hoving

loosened the nut

on the rod

of the releose cylinder, rotote

the

releose finger to obtoin the correct rod

length.

Then retighten the nut, thus locking the releose

f inger in its position

on the rod.

lf the ploy

is correctly od justed,

the f ree

trovel of the

clutch pedol

pod should ronge

from 40 to 50 mm. lt should not be ollowed to

drop below '!0

to 15 mm. lf the described od-

justing procedure foils to bring the required

result, it is necessory to odjust the clutch

mech-

onism in occordonce with

informotion con

toined in Chopter 3.2.

Bleeding the Glutch Hydroulic System

The movement of the clutch pedol

is trons-

mitted hydroulicolly to the clutch releose cylin-

der. The couses ond symptoms of penetrotion

of oir into the hydroulic

system (similor

to the

broke hydroulic system) ore described in detoil

in the section deoling with brokes. The pro-

cedure of bleeding the clutch is the some os

wherr bleeding the brokes -

see Chopter 15.8.

Fig. 15.411-

Adiusting Elements of

Clutch

Control Mechonism

I -

releose cylinder rod, 2 -

releose cylinder,

3 -

releose lever, 4 -

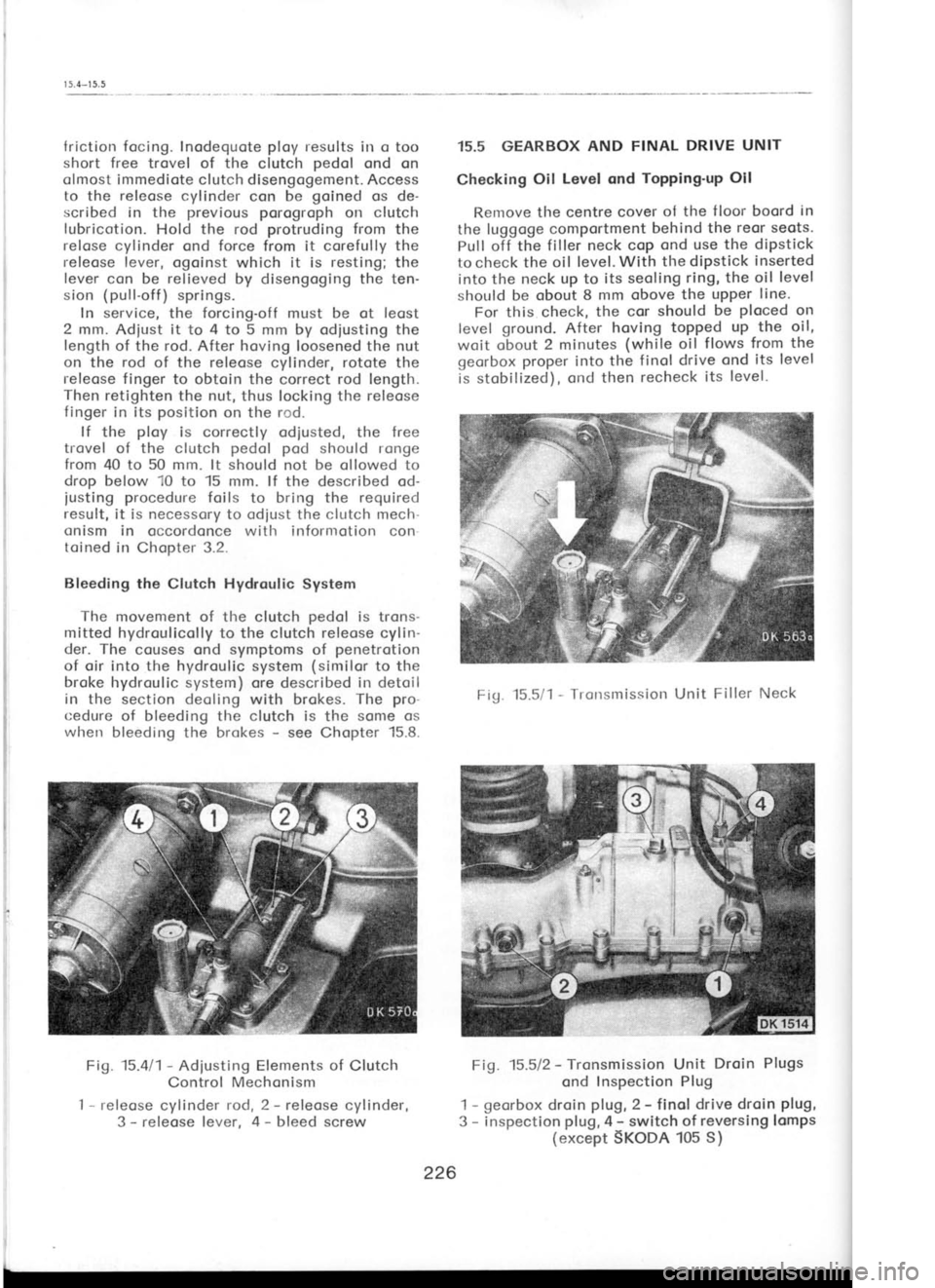

bleed screw 15.5 GEARBOX

AND FINAL DRIVE UNIT

Checking Oil

Level ond Topping'up

Oil

Renrove the centre cover ol the

f loor boord in

the luggoge comportment behind the

reor seots.

Pull off the filler neck cop ond use

the dipstick

to check the oil level. With the diPstick inserted

into the neck up to its seoling ring, the oil level

should be obout 8 mm obove the upper line'

For this check, the cor

should be ploced

on

level ground.

After hoving topped up the oil,

woit obout 2 minutes (while

oil flows from the

georbox proper

into the finol drive ond its level

is stobilized), ond then recheck

its level-

Fig. 15.5/1 -

Tronsmission Unit Filler Neck

Fig. 15.512 -

Tronsmission Unit Droin

Plugs

ond Inspection Plug

1 -

georbox droin plug,

2 -

finol drive droin plug,

3 -

inspection plug,

4 -

switch of reversing lcmps

(except SKoDA 105 S)

ffi

;rt'i,*

tiiffi

ii.! i;

br'ill

226