tow SKODA 120L 1980 User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 120L, Model: SKODA 120L 1980Pages: 238, PDF Size: 47.09 MB

Page 84 of 238

Remove the clip of

the

clutch throwout beor-

ing guide,

insert the MP 3-102

iig into

the guide,

open its iows, ond withdrow the

guide.

After

hcving renewed the seol ring, drive home the

guide using the MP 3-103 drift. The droin hole

in the guide

must foce

downword.

The lotest desing of the extrocting

iig hos

the type dcsiqnotion MP 3-112. Screw the

iig

bolt into

the

iig nut

inserted into the mech-

onism through the hole cleored by the removol

of the clutch releose cylinder. Jerk the

iig to

drive the guide

out of the housing.

Dismontling the Power Pock

For complete dismontling of the power pock,

remove it from the cor -

see Chopter 4.-1,

"Rernovol of Power Pock from the Cor". Then

proceed os follows:

1. Remove the front cover ond the cover of

the pinion boll beoring, the clutch releose

mechonism, ond the clip of the guide

of the

clutch throwout sleeve, i. e., oll component

ports ottoched

to both holves of the housing.

2. Remove the connecting bolts of the flon-

ges. Force oport the f longes using o screwdriverr

inserted into the chombers of the flonge feet

(lugs). Lifting owoy oll component ports

one

by one is the usuol procedure

of dismontling.

Toking oport of lorger units (pinion,

etc.) is

described individuolly

in the following

chopters.

3. Press out the beoring cups which hove

remoined in the housing ofter its holves hove

been seporoted.

Use the MP 5-107

iig supported

by the MP 5-108

iig.

Fig.4.al2 -

Pressing Out the Cup of the Topered

Roller Beoring

Using MP 5-107 ond MP 5-108

Jigs

4.5 FRONT COVER

The front cover ossembly forms

o self-con-

toined unit fitted to the georbox.

For both the

reossembly ond dismontling ploce

it on o work

bench. Assembling

Front Cover

1. Slip the rubber seol ring on the speedo-

meter beoring ossembly (beoring

with geors)

ond push

corefully the beoring, preferobly

by

o steody rotory motion, into the cover

iust for

enough to be oble to instoll the key

without

domoging the seol ring by the shorp edge of

the keywoy. For the some reoson, chomfer the edge of the

beoring bore before

instolling the beoring in

o new cover.

2. Lock the beoring in the oxiol direction by

instolling the key

ond spring woshers, ond by

screwing down the nut.

Slip the clip on

the

protruding pcrt of the beoring ond lock it olso

in the oxiol direction with o bolt, spring

wosher,

ond nut. Do not

tighten the nuts fully.

3. Instoll the oiled geor

chonge lever in the

cover while pushing

it only os for os the groove

for the seol

ring.With the lever in this position,

insent the seol ring

in its groove

ond push

forther the lever through the ring. Slip the

dust

boot on the lever ond ottoch it to the cover

with o length

of locking wire.

4. Attoch the fostening (mounting)

lugs using

copscrews ond spring woshers. There

is o right-

-hond ond o left-hond lug, ond their slots must

be turned owov from the cover.

FK 1t't4

Fig.4.5l1- Front

Cove'r Assembly

Dismontling Front Cover

Lift owoy the speedometer

beoring ofter

hoving removed the sleeve

clomping bolt ond

the key (held

down by the nut). Then

withdrow

the geor

chonge lever by simply pulling

it out.

4.6 PINION WITH GEARS The pinion

with geors

forms o self-contoined

unit to be instolled in the georbox.

Use o work

bench ond o press

fon both its ossembly onddismor

wheel sure t

Only c

wheel

m itted

drive.

4.8.

Whe

olso tl

o new

one is

Assem 1.P

the pi

the or" thrust

toworc

3-104 p

ground

the be, must t

meosul

2.S

collor I

ring ir

the grr

The rir

3.5 to I

th ickes

ond pu

speed

3.H

it the '

selecte

toword

dismor (by tol

itinp

free to

Clon

MP 3.1

Note

inner b

toining

either r

-speed

ports.

4. Tr

groovir

pinion.

friction

groover

groove!

5. On

ond fit

the nex sizes 3

84

Page 86 of 238

1-

in the

other groove.

Chose the ring olso with

regord to toleronces cvoiloble

in one closs of

the rings os mentioned in the previous

Pqro-

groph. Check the cleoronce of the geor with

the oid of o diol indicotor.

Then remove the geor

including the friction

ring in the second groove

of the shoft.

7. Ploce the lock of the 1st' ond 2nd'speed

synchron izing clutch on the bench with

its

teeth downword. lnstoll

springs in the clutch

core securing them with greose

ogoinst folling

out ond insert the clutclr core with the shorter

side of the inner heod on

top in the respective

geor. Locote bclls (dio. 1ir

in.) on the springs, com-

p,ress the springs with

the fingers or using

o suitoble rod, cnd fit

the complete core

itrto

the geor.

8. Hoving thus osembled the synchronizing

clutch lock, instoll the synchronizing ring

fronr

the opposite side of the geor.

Now threod the

lock on the oiled shoft

with the geor focing

owoy from the shoft.

9. Instoll in position the

previously selected

friction ring with its groove

focing owoy from

the shoft (toword

the geor)

ond insert the

synchronizing ring into the fitted lock of the

synchronizing clutch. Slip the oiled geor ond Fig.4.6la

-

Assembling 1st' ond 2nd-speed

Synchronizing Clutch -

lnstolling the Core

ond Pnessing in the Bolls

the previously

selected friction ring on

the

oiled shoft. 10. Slip on the 3rd -

speed geor

ond secure it

with on

orbitrorily chosen ring from the ronge

of friction rings in complionce with the poro-

groph 2. Meosure the oxiol cleoronce ond odiust

it to 0.1*0.07 mm by o repeoted exchonge of

the friction ring. Now remove the geor,

lubricote it,

slip it on

the oiled shoft ond lock it in position with the

ring with the oil groove

focing the geor.

11. Proceeding occording to porogroph 2,

insert on orbitrory friction ring into the lost

groove, slip on the 4th-speed geor

ond tighten

the pinion

nut over o pilot

collor replocing the

beoring (for

exomple of dimensions dio.

25.5/38x26 with edges of the inner

bore chom-

fered to 1x45o). Mork the side of

the pilot

col-

lor which will be

turned toword the

nut so thot

the side focing the geor

connot be domoged by

impression. Adiust the cleoronce of the geor

to 0.1+0.07 mm by o repeoted trying

on (ex-

chonge) of the friction rings. Then remove the

geor ond the ring from the shoft.

12. Assemble the 3rd- ond 4th-speed synchon-

izing clutch using the some method os when

hoving ossembled thot of the 1st ond 2nd

speed. lnsert the synchronizing ring

into the

clutch ond slip the clutch on the oiled shoft

with the short side of the lock first.

13. Instoll the selected friction

ring in the

locking position

into the groove with its

oil

groove focing owoy from the shoft. Push or top

home the key into the spline of the shoft so

thot it posses

through oll friction rings ond its

end is ot leost flush with the splined shoft end.

Fig.

4.6/3 -

Locking 1st-speed Geor in Position

(turning the ring with o drift) with the Pinion

Clompecl in MP 3-105 or MP 3111 Jig

86 Fig.

4.(

Page 97 of 238

5.:

pr

stl

bc

5-t

bo

thr

u*,

on

dit

on arI

ioi

sPl

SW

I

gor

:

wo

bol

cyl

del

\

mo

th€ hot

WO

F

clo

POS +:

nec

wol

reo

toe

wit

T

o)

b)

Alil 1.

con

sloc

seo'

int

Fig.5.2l5

-

Pressing Boll Beoring

on Shoft

Using MP 5-112 Jig ond

lts Liner (smoller)

Fig.5.216 -

Connection of

Holf-oxles

with Rodius Arms

lorger ond one smoller, ond the forked plote),

screw down the

iig on the threod

of the shoft,

ond use

nuts to ottoch it

to the holf-oxle socketf

longe. The

iig of

the lotest design permits

its

simple fostening by engogement with

the holf-

oxle flonge (fit

the

iig ond

rotote

it to lock it

in position).

Instoll the lorger liner between the boll

beor-

irrg ond the

iig heod, ond

press

the boll

beorirrg

on the shoft by turning the iig wrench.

3. Reploce the lorger liner with the smoller

one (rest it ogoinst the

iig bolt heod), ond turn

the wrench in the opposite direction to press

the beoring into the holf-oxle socket.

Fitting Broke Mechonism ond Wheel Hub

4. Instoll the broke bocking plote

complete

with the broke

mechonism on the holf-oxle

socket, slip on the "O"

seoling ring ond the

cop with the seoling ring (with

the tightening

f in focing toword the holf-oxle), ond fosten

oll

the porrts

with bolts, spring woshers, ond

nuts.

The seoling ring should be driven or pressed

into the cop so thot the tightening lip foces the

beoring ond

iust so thot there

remoins

o gop

of

1 to 2 mm between the pocking

ond the cop

f longe.

5. lnsert the key in

the shoftwith its bevelled

end into the runout of the keywoy, smeor

the

hub neck with oil so

thot it does not

drog in

the seoling ring, ond fit the hub with the broke

drum in position.

Moke sure thot the key did

not move further olong the shoft (its

lifted end

in the keywoy would couse the hub to burst)

ond tighten

lightly the nut. Since o high

torque

is required

for finol tightening of the nut, put

off the tightening ond locking of the nut till

ofter instollotion in the cor. Then

tighten the

nut with full torque (see

Chopter 1.8),

top on

the hub to relieve

the possive

stress of the

toper, retighten to the specified torque, ond

lock the nut with o cotter pin.

Fitting Rodius Arms

6. Instoll

the spocer into the rodius

orm, fit

the knurled

woshers (with

the knurling toword

the orm)

to either side of the ellipticol holes of

the rodius

orm, ond fosten them with bolts ond

nuts not

forgetting the spring woshers. Do not

tighten the connection fully. Threod

the bolts

through the bolt holes so thot their nuts foce

into the cor ofter fitting the rodius orm to the

holf-oxle.

Fit the rodius

arm on the protruding

holf-oxle

pin ond threod

the bolt through the hole

of the

secrt. Slip

spocing tubes on the bolt ond pin

together with sheet shims with rubber liners

ond fosten

lightly (without tightening)

the

rodius orm to the holf-oxle using nuts

ond lock

woshers. Tighten

fully the connection

ofter fit-

ting the ossembly

in the cor when odiusting

the

reor wheel

olignment (geometry).

il

i

ii

I

I

I

I

lr

il

H, DK

?EI

98

Page 109 of 238

Rr

n

v

t

e

t

rl

fr

\

sl

t(

b

ol

nl

st

o(

sp

th

er

en inr

ml

se

thr it

5tr

bo

Pock with

greose

the plostic

dust cup ond

press it over the nut till it snops home in po-

sition on the lever.

Refitting Upper Wishbones 4. When refitting wishbones

which hove

been olreody used in the cor ond which ore

rother doubtful (for

exomple,

o distortion is

suspected os o result of o crosh), inspect them

corefully ond stroighten

them, if necessory.

5. Press rubber bushes into the eyes from the

outer side. To focilitote their sliding in, dip

them in petrol

or soop

woter (suds).

Put the

bushes into the wishbone eyes with their lorger

diometer first ond push

them so for thot they

protrude from the eye by the some length on

either side. Blow off the soop woter with com-

pressed oir so thot it does no ossist the slipping

of the bush during the next operotion.

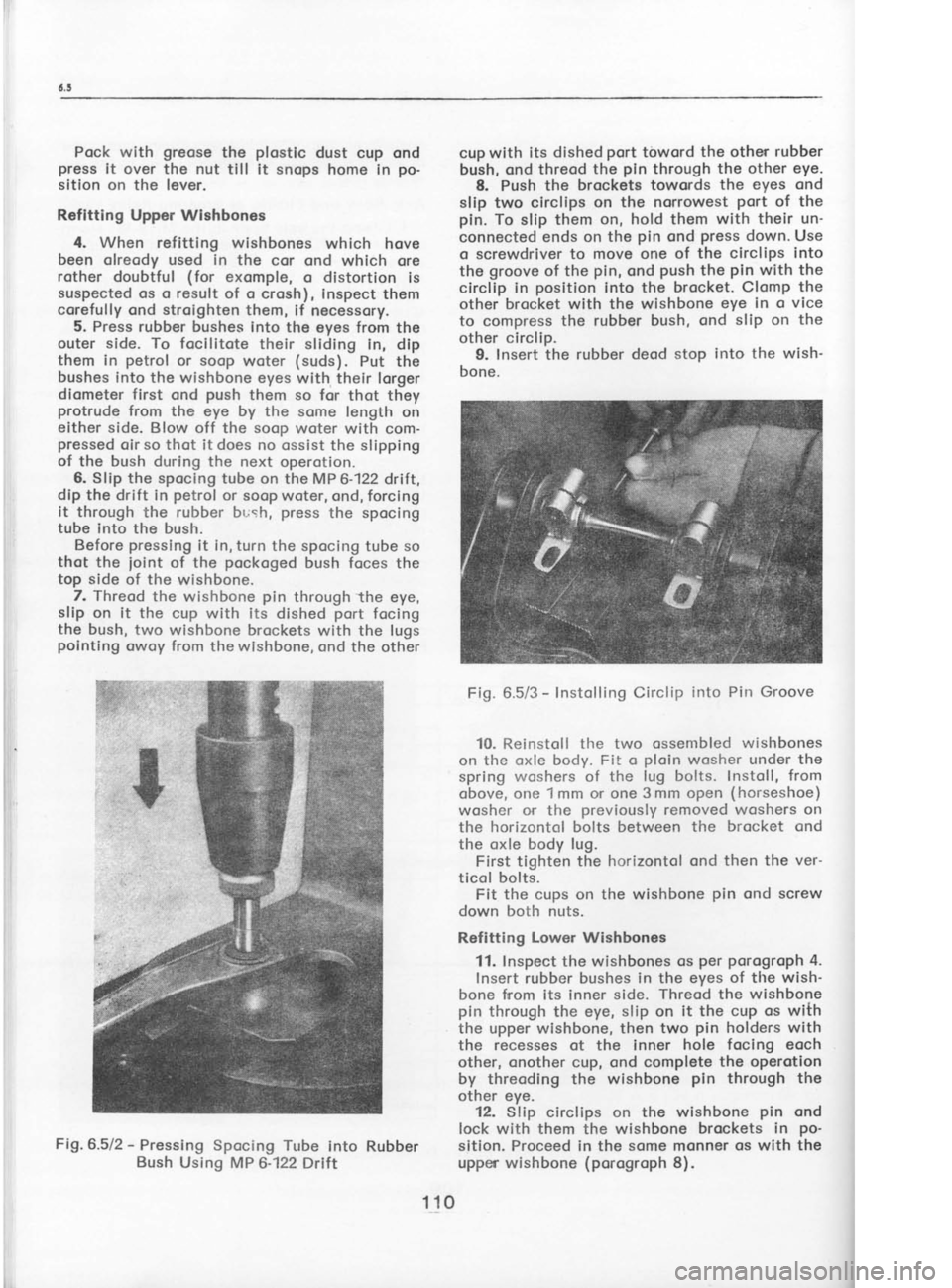

6. Slip the spocing tube on the MP 6-122 driIt,

dip the drift in petrol

or soop woter, ond, forcing

it through the rubber

bush, press

the spocing

tube into the bush.

Before pressing

it in, turn the spocing tube so

thot the

ioint of the

pockoged

bush foces the

top side of the wishbone.

7. Threod the wishbone pin

through the eye,

slip on it the cup with its dished port

focing

the bush, two wishbone brockets with the lugs

pointing owoy from the wishbone, ond the other

Fig.6.5/2 -

Pressing Spocing Tube

into

Bush Using MP 6-122 Drift cup with

its dished port

tbword the

other rubber

bush, ond threod the pin

through the other eye.

8. Push the brockets towords the eyes ond

slip two circlips on the norrowest port

of the

pin. To slip them on, hold them with their un-

connected ends on the pin

ond press

down. Use

o screwdriver to move one of the circlips into

the groove

of the pin,

ond push

the pin

with the

circlip in position

into the brocket. Clomp the

other brocket with the wishbone eye

in o vice

to compress the rubber bush, ond slip on the

other circlip. 9. lnsert the rubber deod stop into the wish'

bone.

Fig. 6.5/3- Instolling Circlip into Pin Groove

10. Reinstoll the

two ossenrbled wishbones

on the oxle body. Fit o ploin

wosher under the

spring woshers of the lug bolts. Instoll, from

obove, one 'l

mm or one 3 mm open (horseshoe)

wosher or the previously

removed woshers on

the horizontcrl bolts between the brocket ond

the oxle body lug. First tighten the horizontol ond then the ver-

ticol bolts. Fit the

cups on the wishbone pin

ond screw

down both nuts.

Refitting Lower Wishbones

11. Inspect the wishbones os per porogroph 4.

lnsert rubber bushes in

the eyes of the wish-

bone fnom its inner side. Threod the wishbone

pin through the eye, slip

on it the cup os with

the upper wishbone, then two pin

holders with

the recesses ot the inner hole focing eoch

other, onother cup, ond complete the operotion

by threoding the wishbone pin

through the

other eye. 12. Slip circlips on the wishbone pin

ond

lock with them the wishbone brockets in po-

sition. Proceed in the some monner os with the

upper wishbone (porogroph 8).

110

Rubber

Page 123 of 238

7

.7-1.8

(

t

t

t

; (

(

b

tl

ir

tl

p il

o

tl

p

odiust,

if necessory, the driving dog of the di-

rection indicotor switch -

see Chopter 13.17.

Refit the steering wheel so thot its spokes

ore horizontol, lock it in position

with the nut

(for tightening torque, see

Chopter 1.8), ond

bolt down the spoke shroud.

7.8 STEERING WHEEL SHAFT AND SHAFT

BEARING

The steering wheel (column) shoft is built

up

of two ports

with the beoring in the uPPer port.

Usuolly, it is not necessory to disconnect the

two ports

of the shoft or to remove the beoring

ond steering lock. lt

con be removed from the

cor os o unit.

Removol 1. Remove the steering wheel -

see Chop-

ter 7.7. 2. Remove the screws on the lower port

of

the shoft cowling ond pull

the cowling off.After

removing two bolts, detoch the cluster switch

on the shoft from the upper port

of the shoft

cowling. 3. Remove two front screws of the upper

Port

of the cowling ond remove the cowling.

4. Disconnect the leods

from the switches

ond the switch box.

5. From under the cor, remove the bolt of the

coupling connecting the steering

column shoft

to the steering box ond detoch the dust boot

from the floor. Remove the

bolts of the shoft

beoring (from

under the shoft)

ond the bolts of

the steering lock (from

the front) fostening the

shoft to the body, ond pull

out the shoft.

Ref itting To ref it the steering column shoft

in the cor,

reverse the removing procedure. While reinstol-

ling the steering wheel (Chopter

7.7), do not

forget to check the direction indicotor switch

for correct function.

Use ploin

ond spring woshers under the bolts

of the steering lock

brocket. Reinstoll the shoft

beoring using spocing tubes, rubber bushes, ond

ploin woshers, ond secure the bolt of

the coup-

ling, connecting the steering

column shoft with

the steering box, with

o self-locking nut (for

tightening torque, see

Chopter 1.8).

To Disconnect Shofts

Remove the bolt

of the cross-pin

ioint con-

nection.

Connecting of Shofts

Fit o fostening sleeve on the tube

with the

shoft, dip the ring in oil ond slip

it on to the shoft end with

its wedge-shoped port

toword

the beoring, instoll the spring

ond the

ioint

socket of

the shoft bottom port.

Tighten

the

connection with the bolt with self-locking

nut

(tightening torque os per

Chopter 1.8).

The sleeve must be f irst built up if

the shoft

is refitted for the first time. Locote

both holves

of the sleeve on the tube ond fosten

them

lightly together by bending the tob of one holf

of ttre sleeve over the

other. The

sleeve must

on no occount clomp the tube tightly.

Bottom Port of Steering

Column Shoft

The shoft is provided

with cross-pin

ioints

ond connot be dismontled (token

oport). Before

fitting the shoft dust boot, smeor

it with

oil to

focilitote its slipping over the pcrrts

of the joint.

For this purpose,

it is clso odvisoble to wrop

the joint

in o plostic

foil or to moke o sleeve

with o pilot

cone.

Top Port of Steering Column

Shoft -

Beoring

Removol 1. l-ift owoy the fostening sleeve

ond check

whether the shoft rototes

freely in the tube. lf

it is not the cose, unlock the steering lock ond

press out the shoft proceedirrg

from the side

of its splined

end.

2. lf necessory, remove

the circlip of the shoft

ond lift owoy the beoring. The other beoring

hos to be driven out by topping it corefully

through the cut-outs in

the tube to ovoid domog-

ing it. 3. Remove the brocket with the steering

lock

- see Chopter 7.9.

Ref itting

1. Slip tlre beoring pocked

with greose

on to

the upper port

of the shoft, then the ring with

its wedge-shoped port

focing the beoring, ond

lock both ports

in position

with the circlip.

Press the shoft into the tube ond press-in

the

beoring (ogoin pocked

with greose)

from the

other end.

2. lnstoll the brocket with the steering lock -

see Chopter 7.9.

Shoft Beorings They hove to be thoroughly lubricoted

first,

since ofter their reossembly with the shoft od-

ditionol lubricotion is not possible.

lf there is

ony doubt concerning the greose

pocking,

re-

move the circlip f

rom the inner port

of the

beoring, toke the beoring oport, cleon it, ond

reossemble it ofter hoving pocked

it with the

recommended greose,

i. e., brond NH2 of Cze-

choslovok provenience

or one of the bronds

specif ied in Chopter 7.5, porogroph

3.

124

Page 154 of 238

r 2.1-t 2.3

I

I I

I

Dissssembly

ond

Reossembly of Pedols

This is usuolly not necessory. The pedols

con

be disossembled ofter removing the oxiol screw

in the pedol

pin

ond slipping off the return

spring. Do not remove the switches if it is not

obsolutely necessory -

see odiustment. On re-

ossembly, lubricote

the pedol

bush with lubri-

coting greose

of the some brond os used for the

steering linkoge -

see Chopter 7.5, por.3.

Pedol Free Trovel

Adiustment

Adjust the free

trovel of pedols

ossembled

with moster cylinders so thot the pedol piston

rod hos o

cleoronce of 0.5

to 1mm

when beoring

ogoinst the piston

heods of the

moster cylin-

ders. The free trovel of the pedol pod

should be

from 3 to 5 mm. lt

con be odiusted by rototing

the eccentric pin

on the pedol

brocket -

see

Fi9.12.111.

For the odjustment of the broke pedol

with

broke booster ond/or levelling of the broke

pedol with the

clutch pedol,

see Chopter 9.6 -

Ad justment.

Adiustment of Switches The switches con be

moved in

the ellipticol

holes of the brocket ofter loosening the fosten-

ing copscrews with ploin

woshers under their

heods. A pocking piece

should be slipped

under

the switch of the broke pedol

trovel worning

light ond the powl

of the switch pin

should be

held down under the fostening copscrew.

Ad just

the stop-light switch

so thot it

switches on the stop lights ot o pedol

trovel

of 10 to 15 mm meosured on the centre of the

pedol pod.

Adiust the pedol

trovel signolling switch so

thot the pushed-in

side push-button

pin

is

re,ecsed ot o pedol

trovel of 100 to 110 mm

mecsured on

the centre of the pedol

pod.

Press

the push

button into

the switch ofter hoving

completed the

odiustment.

12.2 ACCELERATOR PEDAL AND CABLE

The occelerotor pedol

forms o unit with its

self-lubricoting beoring ond the lever.

lt is

bolted to the f

loor tunnel. A coble possing

through the tunnel is ottoched to the pedol

lever ond the reloy

lever on the engine by

meons of clomps- The coble is protected

by

o Bowden tubing.

Pedol Removing ond Refitting

1. Loosen the clomp holding the coble on the

engine-mounted reloy lever. 2.

Remove the copscrews holding

down the

becrring with the pedol,

depress lightly the

pedol, ond lift it out of the f loor

tunnel together

with the beoring. 3. Disconnect the pedol

from the coble ofter

ioosening the clomp.

Removol ond Refitting of Bowden Tubing

ond Cqble

The Bowden tubing is

fostened to

the brocket

irr the floor tunnel by

meons of circlips. After

their removol, pull

the Bowden tubing inside

the cor. On ref

itting the tubing, lubricote it with

o low-viscosity oil (of

the SAE 20

closs). lt hos

been lubricoted with greose

in the foctory.

Fit

the clonrps so thot their longer ports (from

the

screw to their end) ore on the side of the

I evers.

Accelerotor Coble Adiustment

Adjust the coble so

thot it is not

excessively

tensioned or too slock. Loosen the clomps on

the engine side of the coble, move slightly

the

clomp toword the reloy lever,

ond tighten the

screws of the clomp.

12.3 GEAR SHIFT LEVER

AND LINKAGE

The geor shift mechonism consists of two

units: the geor

lever with its housing ond oc-

cessories, ond the geor

shifter rod

ond the

shifter lirrk with joint

(ot the georbox)

for

domping the vibrotion of the power

pock

tronsnritted to the geor

lever.

Removing Geor Lever

Housing ond Link

1. Lift owoy the mot from the floor tunnel in

the front ond reor comportment. lf seporote,

remove the individuol floor mots ofter hoving

prised out their clips with o screwdriver or

o similor tool. lf o one-piece floor

covering is

used, remove the door sill strips

on one side,

tip the seot, ond bend over the

floor covering.

2. Remove the geor

lever housing copscrews

ond prise

out the lid (next

to the clip) between

the seots. Proceed through the

operture to dls-

connect the bolted connection of the link with

the housing shifter rod.

3. Lift

owoy the housing with the lever

through the operture. Swivel the lever so thot

the shifter rod

does not protrude

over the

housing beoring thus obstructiong the removol.

4. Usuolly it is not necessory to remove the

geor shift link from

the cor. lf

obsolutely necess-

ory, the link con be

disconnected only ofter

162

Page 158 of 238

nolly

emerges into spoce under the floor toword

the georbox.

lt is ottoched to the speedometer

by meons of o union nut ond to the georbox

by

o sleeve ond o screw.

It is lubricoted

with oil from the georbox

which creeps olong it due to copillory elev-

otion" Lubricote it with engine oil of o lower

viscosity dripped into its sheoth only if the

lubricotion by creeping is inodequote. When refitting

it in position, put

it into the

cor from the front, connect its

both ends, ond

then orronge it so thot it does not form ony

shorp bends ond is

not too tout. The speedo-

meter con be disconnected ofter removing

the

instrument ponel,

ond removed by pulling

it in

forword direction.

For the speedometer drive shoft possoge

under the ffoor refer to Chopter 12.7.

166

Page 175 of 238

I

I

I

s

I

I

I

t

(

(

t

l

,

t

T c

R

L D

v Ir

1' 2

3

orotely

(

screen the other one) . With lef t

directionol heodlomps,

the borderline deviotes

towords the other

side.

lf the heodlomps ore neorer to the woll thon

the soid

5 metres, decreose the meosure indi-

coting the

deviotion of the light ond

dorkness

bordeiline from the

height of the heodlomps

obove the ground in the

direct proportion to

the

decreose of

tfre distonce, for

exomple when

plocing the cor 2.5 metres

from the woll, de-

creose the deviotion bY holf.

Light proiections "A"

ond "B"

correspond to

the spocing of heodlomPs on

the cor ond they

hove the following dimensions:

Heodlomps, dio. 160

mm 1,030

mm

Duol heodlomps, dio.

130 mm 1,114

mm

Auxiliory heodlomps, dio.

130 mm 790 mm

When odjusting the heodlomps, the cor must

be empty ond the

tyres must be correctly in-

floted. Hologen heodlomps should

not be left

switched on for too long o period os they build

up heot if not cooled by heod-on

oir blost when

driving. For lhe odiustment of

heodlomPs ore intended

screws in their fromes. The screws

ore occess'

ible ofter the removol of the side ports

of the

grille. Remove the copscrews of the corners

ond push

the grille

oside.

Heodlomp Assembly

o) The fundomentol fostening

Port of

circulor

heodlomps is the

so-colled support plote

(rec-

tongulor plote)

ottoched to the bodywork by

copscrews with lock woshers. The

heodlomp

housing is bolted to this suPPort plote by bolts

with nuts ond lock woshers. One of the bolts holds

down olso the

lug of the eorthing coble-

The inner frome,

forming the

odiusting element

of the heodlomp insert, is ottoched

to the

hous'

ing by two speciol odiusting screws

ond two

tension springs. The heodlomp insert

is ot'

toched to

the bezel by

three copscrews.

There is one left-hond ond

one right-hond

support plote.

Both should

be mounted with the

oriow ond the word "TOP"

upwords. With

the

exception of the ouxiliory heodlomps, the

heod'

lomp inserts ore different for

the left-hond ond

the right-hond troffic. The leods

enter the hous-

ing through o

rubber grommet.

When r-eplocing the insert, remove

the bezel

copscrews. After

hoving fitted o new insert, it

is necessory to reodiust the

heodlomps.

Front Direction Indicotors

The right-hond ond

left-hond direction indi-

cotors ore undisossembloble units

(the

lomp

fostening sockets (locks) ore

mounted in the

direction towords the cor longitudinol centre

line). They ore fostened to their brockets in the

bumper with o nut ond o ploin ond

o lock

wosher.

Toil Lomp Cluster

The lomp cluster is on undisossembloble unit

fostened to

the bodywork by

nuts with ploin

woshers ond the

respective bolts.

Scrope off

the enomel ot the

top bolt used for holding

down the eorthing coble.

For the sequence

of the individuol lomps ond

their bulbs see Fig. 13.111 ond the respective

porogroph on bulbs.

Fig. 13.812 -

Adiusting ond

Fastening Screws of Right-hond Heodlomps -

their locotion

on

left-hond he-odlomps is their

mirror ref lection

1 -

Sidewoys odiusting screw

2 -

Height odiusting screw

3 -

Fostening screws

182

Page 179 of 238

(

1

z

Strike the

slip-over ring off the circlip

(towords the motor windlng). Open the circlip

ond pull

it off the shoft together with the re-

leosed ports.

8. lf necessory, re-turn the commutotor ond

scrope or mill out the insulotion between the

lominotions. "Mikonit"

should be 0.4 to 0.8 mm

below the octive surfoce.

Note: The

switch connot be further token

opat. lf

defective, lt hcs to be reploced with

o new one. When cleoning ports

of the storter

motor, do not dip the ormoture or the pinion

with the idler into petrol

or onother degreosing

ogent.The some opplles to the end shieldswith

beorings. By dipping them in o degreosing

ogent, the beorings become procticolly

worth-

less"

Storter Motor Reossembly 1. Lubricote the hellx of the ormoture shoft

with greose -

see Chopter 15.2 'Lubriconts

of

foreing mokeu ond fit the pinion

with the idler

ond the slip-over ring in posltion.

Fit the

circlip

into the groove

in the shoft, ond drive the slip-

on ring over it. The pinion

with the idler must

move freely olong the shoft.

2. Slip the respective

woshers on the shoft in

their originol sequence (corrier

ring, distonce

ring, fibre ring, distonce ring) ond insert the

ormoture with the engoging lever

into the drive

end shield. 3. Suspend the switch

ormoture into the

pre-engoging lever ond bolt down the switch

lightly. Fit the lever pin

into the drive

end

shield ond lock it in position

with the retoiner.

4. Tighten the copscrews of the switch

ond

fit the stotor on the drive

end shield.

5. Instoll the respective

woshers into

the

commutotor end shield in

their originol se-

quence (the dished wosher with its centre

focing the shield, then the ploin

wosher, the

toothed wosher, ond the drive wosher).

6. Fit the commutotor end shield with lifted

brushes on the shoft (in

the position

occording

to the recess

for the excitotion outlet ond the

notch) ond screw in the clomping bolts.

7. Instoll the brush interconnecting strip ond

bolt it down together with the field winding

outlets to the positive

brush holders, lower the

brushes. 8. Fit the Insuloting strip in position

ond bolt

down the cover. 9. Test the storter mottr.

Diognosing Storter Motor Defects in Cor

o) lf the storter motor refuses

to operote, look

first for on interrupted connection between

the bottery ond

the storter

motor, the engine

eorthing ond the storter

motor, or the engine

eorthing ond the bottery. lf these connec-

tions ore in order (current

flows to the ter' DK

1575

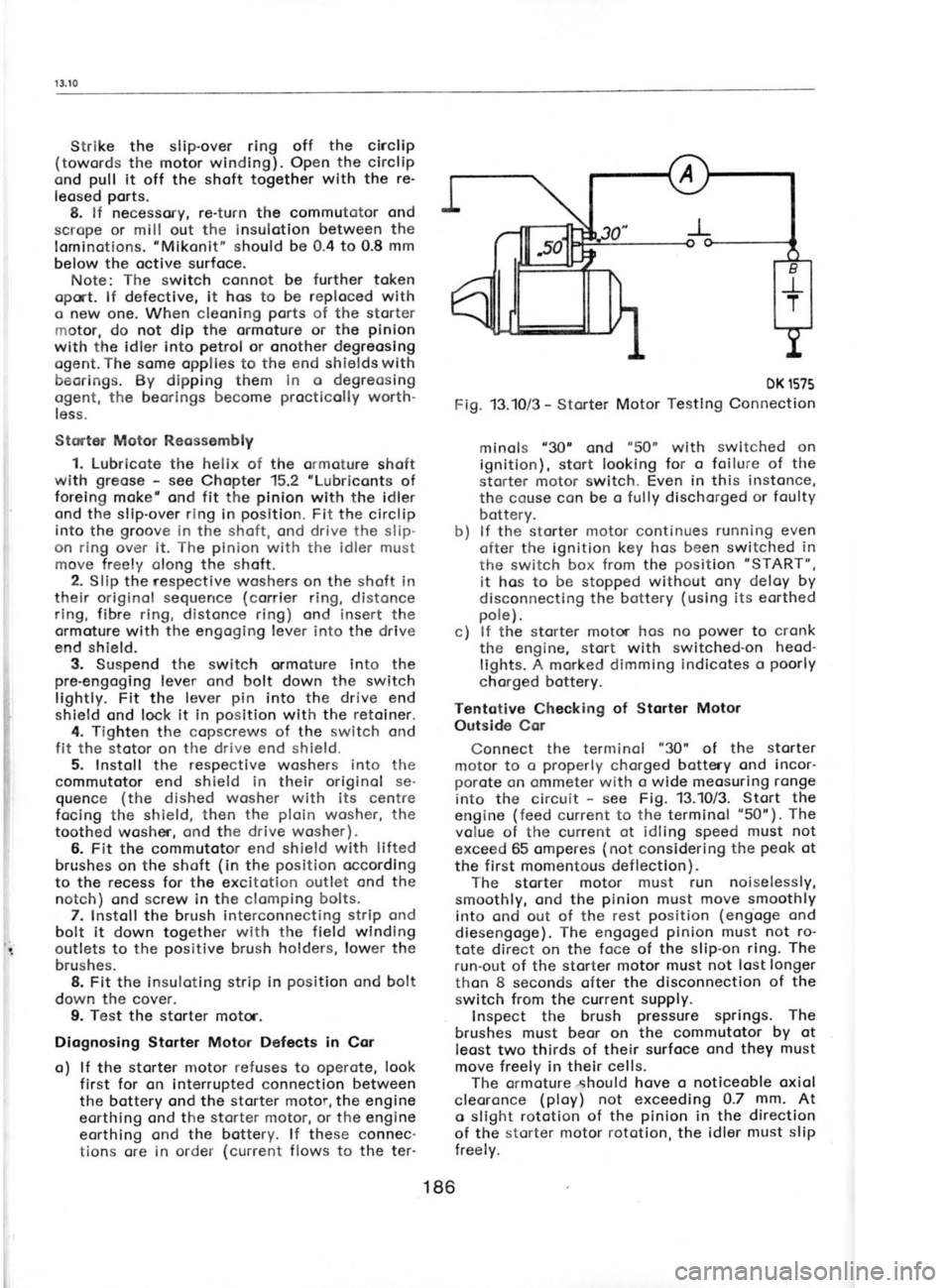

Fig. 13.10/3 -

Storter Motor Testlng Connection

minols u30"

ond "50"

with switched on

ignition), stort looking for o foilure of the

storter motor switch. Even in this instonce,

the couse con be o fully dischorged or foulty

bottery.

b) lf the storter motor

continues running

even

ofter the ignition key hos been switched in

the switch box from the position "START",

it hos to be stopped without ony deloy by

disconnecting the bottery (using

its eorthed

pole).

c) lf the storter motor hos no power

to cronk

the engine, stort with switched-on heod-

lights. A

morked dimming indicotes c poorly

chorged bottery.

Tentotive Checking of

Storter Motor

Outside Cor

Connect the terminol "30'of

the storter

motor to o properly

chorged bottery ond incor'

porote on ommeter with o wide

meosuring ronge

into the circuit -

see Fig. 13.10/3.

Stort the

engine (feed

current to the terminol "50").

The

volue of the current ot idling speed must

not

exceed 65 omperes (not

considering the peok

ot

the first momentous deflection).

The storter motor must run noiselessly,

smoothly, ond the pinion

must move smoothly

into ond out of the rest position

(engoge

ond

diesengoge). The engoged pinion

must not ro-

tote direct on the foce of the slip-on ring. The

run-out of the storter motor must not lost longer

thon 8 seconds ofter the disconnection of the

switch from the current supply.

Inspect the brush pressure

springs. The

brushes must

beor on the commutotor by ot

leost two thirds of their surfoce ond they must

move freely in their cells.

The ormoture should hove o noticeoble oxiol

cleoronce (ploy)

not exceeding 0.7 mm.

At

o slight rototion of the pinion

in the direction

of the storter motor rototion,

the idlor must

slip

freely.

186

Page 181 of 238

1 3.10-t

3.1 1

13.11 WINDSCREEN WIPER

Technicol Description

The rotory windscreen wiper consists of the

wiper motor

with o geor

cosing, o lever system

driving the wiper orms, ond two wiper orms

with wiper blodes.

The two-pole wiper motor

with permonent

mognets is o two-speed

unit with self'lubri'

coting beorings. The geor

cosing comprises onepicyclic

geor

ond on outomotic self-porking

device. The shoft runs in self'lubricoting beor'

ings, the geors

being lubricoted with greose

pocked into the geor

cosing. The lever system

(leveroge) includes self-lubricoting

ioints ond

beorings.

Windscreen wiper

tyPe -

for left-hond steering .

- for right-hond steering

Roted voltoge

Roted current PAL 443.122

-

081.071

PAL 443.122 -

076.071

-12

volts

4 omperes ot high speed,

2.5 omperes ot low speed

60 ot high speed (minimum)

20 (minimum)

to 50 (moximum)

ot low speed

15 cycles per

minute (minimum)

onticlockwise -

for left-hond steering

clockwise -

for right-hond steering

Wiping

cycles per

minute

Difference of cycles between speeds

Direction of

rototion when viewing

the output

shoft

I

i

f1

llr

fi.,

il

lr

l Removol

ond

Refitting

According to the

noture of the required re-

poir, remove either only the motor with the geor

cosing after hoving disconnected the pullrod

from the cronk, the cronk from the geor

cosing,

ond the geor

cosing from the brocket, or remove

the complete unit

ofter removing the wiper orm

beorings -

see wiper orm drive.

When ref itting

the windscreen wiper unit,

observe the

ossembly position of the

wiper

cronk -

see the following porogroph "Motor

ond

Geor Cosing". For position

of the wiper

orms

(blodes), see the porogroph 'Wiper

Arms". ln-

stoll the brocket into the body bulkheod ond

fosten it in position

with the nut, using o rub-

ber ond o flot wosher.

Cleoning ond Repoirs

When disossembling the windscreen wiper

motor, do the following jobs:

1. Reploce worn brushes ond use petrol

to

cleon motor ports

ofter blowing the dust out of

the brushes; moke sure thot the brushes move

freely in their cells. 2. lf the commutotor is

dirty, cleon it

with

petrol, if it is domoged, re-turn ond polish

it.

3. During cleoning, the self-lubricoting beor-

ings must not come into contoct with the

cleoning (degreosing)

ogent (petrol,

etc.). They

should be lubricoted

only with o low-pour-point

oil dripped into the cut-outs of the

cup retoining the boll beoring ond

the felt. Use only os much

oil os the felt con hold.

4. For the epicyclic geor

in the geor

cosing

use greoses

specif ied in Chopter 15.3 -

either

of foreign

moke or of

Czechoslovok moke -

re-

commended specificolly

for windscreen wipers.

MOTOR AND GEAR CASING

Ports of the motor

with the geor

cosing (or

geored motor) is the wiper brocket,

the pro.

tective housing, ond the driving cronk. When

instolling the wiper, put

the housing

on the

motor with the geor

cosing ond clomp it from

below. Bolt down the brocket using ploin

woshers under the bolts. Fosten the motor

eorthing coble under one

of the bolts.

Fosten the cronk in position

using o nut

ond

o spring wosher while observing its ossembly

position:

o) with wipers for left-hond steering-toword

the right-hond side

of the motor ond deflected

13o downword from

the oxis porollel

with the

centre line

of the motor;

b) with wipers for right-hond steering

toword the left-hond side of the motor ond de-

f lected 17" downword from the oxis porollel

with

the centre line

of the motor.

Dismontling the Geor Cosing 1. Remove three screws ond lift owoy the

cover.

188