fuel SKODA 120LE 1980 Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 120LE, Model: SKODA 120LE 1980Pages: 238, PDF Size: 47.09 MB

Page 10 of 238

The child'proof

lotch

of

the reor

door.s con

be

"ng"!J Uy

tipPing down

its

lever' The doors

;;; ;" open"d'froir outside

ofter

disengoging

iunfoctin'g1 the

lotch by pulling

the

Press'

button.

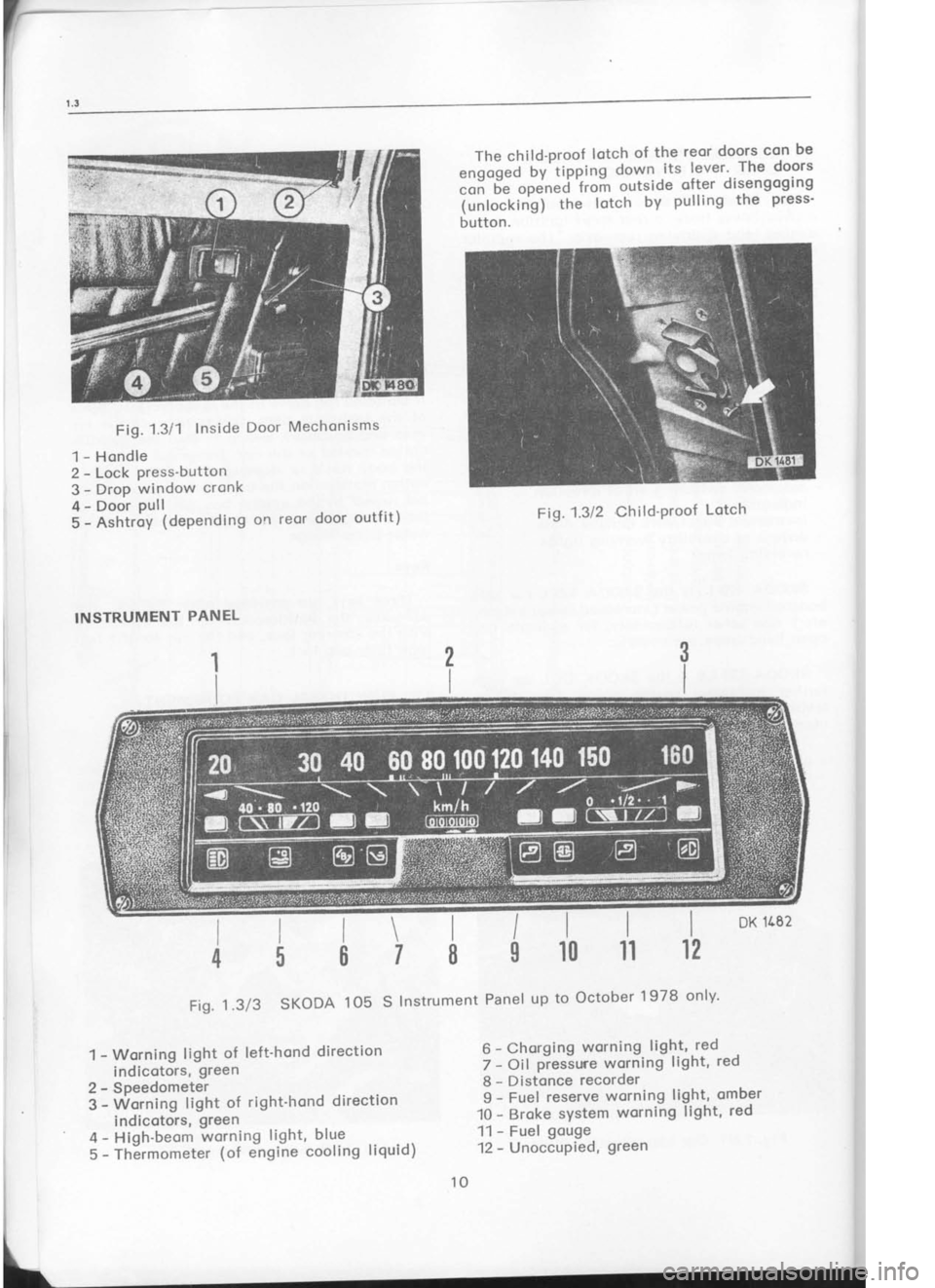

Fig.1.311 Inside

Door

Mechonisms

1 -

Hondle

2 -

Lock Press-button

3 -

Drop window cronk

4 -

Door pull

5 -

Ashtroy (depending

on

reor door

outfit) Fig.

1.312

Child'Proof Lotch

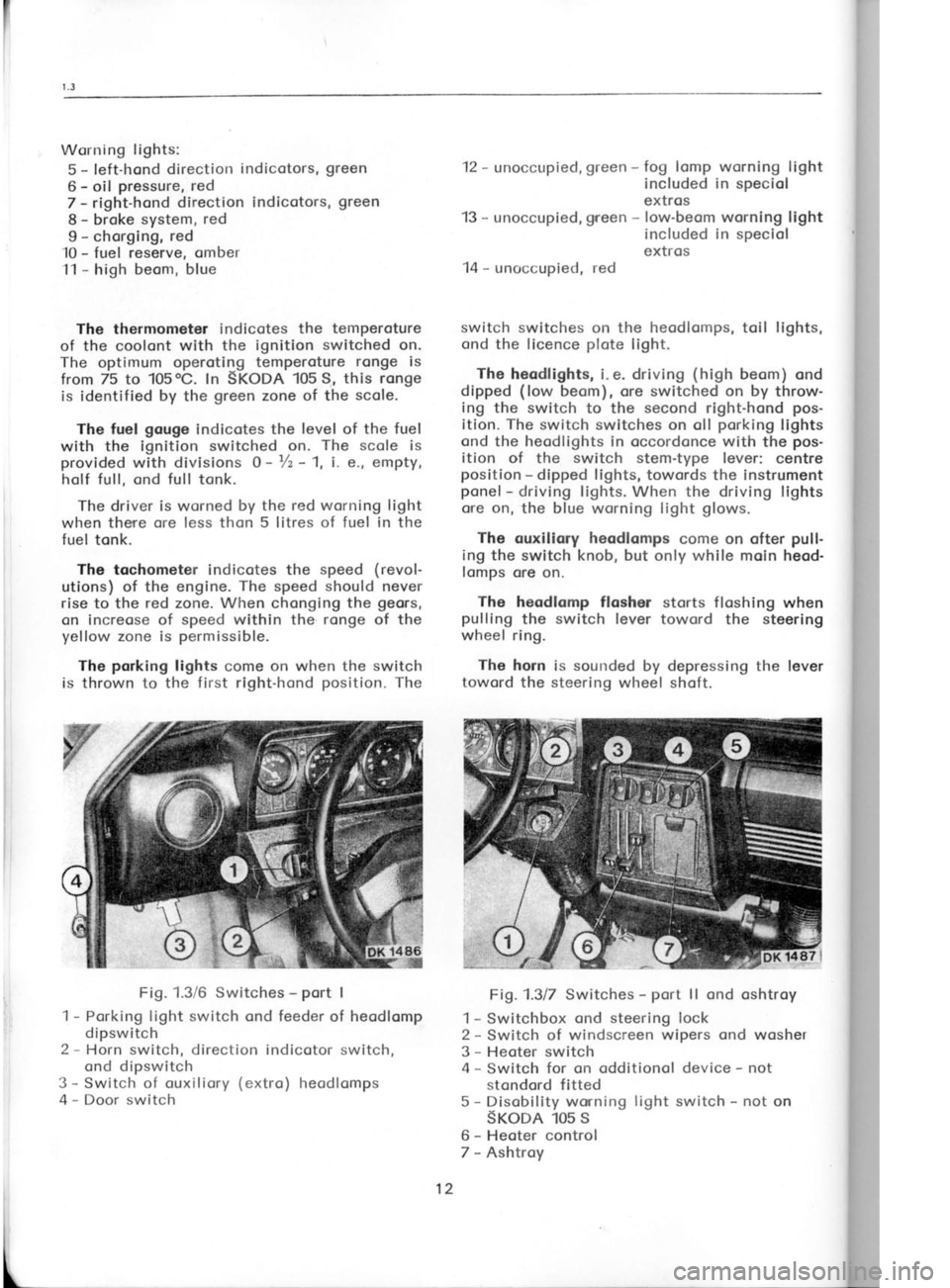

INSTRUMENT PANEL

t

a

(

Fis. 1 .3/3 SKODA 1O5

Slnstrument Panel

up

to October 1978

only'I

12

/l

910

1 -

Worning light

of

left-hond direction

indicotors, green

2 -

Speedometer

3 -

Worning light

of right'hond direction

indicotors, green

4 -

High-beom worning light,

blue

5 -

Th6rmometer (of

engine cooling liquid) 6

-

Chorging worning

light, red

7 -

Oil pressure

worning light,

reo

8 -

Distonce recorder

I -

Fuel reserve worning light,

omber

10 -

Broke sYstem

worning light,

red

11 -

Fuel gouge

12 -

UnoccuPied, green

Page 12 of 238

Worrring

lights:

5 -

left-hond direction indicotors, green

6 -

oil pressure,

red

7 -

right-hond direction indicotors, green

8 -

broke system, red

9 -

chorging, red

10 -

fuel reserve, omber

11 -

high beom, blue

The thermometer indicotes the temperoture

of the coolont with the ignition switched on.

The optimum operoting temperoture ronge is

from 75 to 105oC. In

SfOon 105 S, this

ronge

is identified by

the green

zone of the scole.

The fuel gouge

indicotes the level

of the fuel

with the ignition switched on. The scole is

provided with divisions 0 -

r/2

-

1, i. e., empty,

holf full,

ond full

tonk.

The driver is worned by the red worning light

when thene ore less thon 5litres of fuel in the

fuel tonk.

The tochometer indicotes the speed (revol-

utions) of the engine. The

speed should

never

rise to the red zone. When chonging the geors,

on increose of speed within the ronge

of the

yellow zone is permissible.

The porking

lights come on when the switch

is thrown to the first

right-hond position.

The

Fig. 1.3/6 Switches -

port I

1 -

Porking light switch ond feeder of heodlomp

dipswitch

2 -

Horn switch, direction indicotor switch,

ond dipswitch

3 -

Switch of ouxiliory (extro)

heodlomps

4 -

Door switch 12

-

unoccupied, green -

fog lomp worning light

included in speciol

extros

13 -

unoccupied, green -

low-beom worning light

included in speciol

extros

14 -

unoccupied, red

switch switches on the heodlomps, toil lights,

ond the licence plote

light.

The heodlights, i. e. driving (high

beom) ond

dipped (low

beom), ore switched on by throw-

ing the switch to the second

right-hond pos-

ition. The switch switches on oll porking

lights

ond the heodlights

in occordonce with the pos-

ition of the switch stem-type lever: centre

position -

dipped lights,

towords the instrument

ponel -

driving lights. When the

driving lights

ore on, the blue worning light glows.

The ouxiliory heodlomps

come on ofter pull.

ing the switch knob, but only while moin

heod-

lomps ore on.

heodlomp flasher storts floshing

when

the switch lever

toword the steering

ring.

horn is sounded by depressing

the lever

the steering wheel shoft.

Fig.1.317 Switches -

port ll ond oshtroy

1 -

Switchbox ond steering lock

2 -

Switch of windscreen wipers ond

wosher

3 -

Heoter switch

4 -

Switch for on odditionol device -

not

stondord fitted

5 -

Disobility worrning light

switch -

not on

SKoDA 105 s

6 -

Heoter control

7 -

Ashtroy

The

pulling

wheel

The

toword

i

I

L 12

Page 16 of 238

Lifting

the cor with o

Power iock -

When

r-rsing o service

Power iock, let the

cor rest on

the points

shown in Fi1.1.412.

To tow the cor, hook the towing rope on

to

the brocket under

the cor nose. Threod the pin

through the loop of the rope

ond the brocket

lugs ond secure the pin

with o cotter pin (both

thL pin

ond the cotter pin

ore included in the

cor occessories).

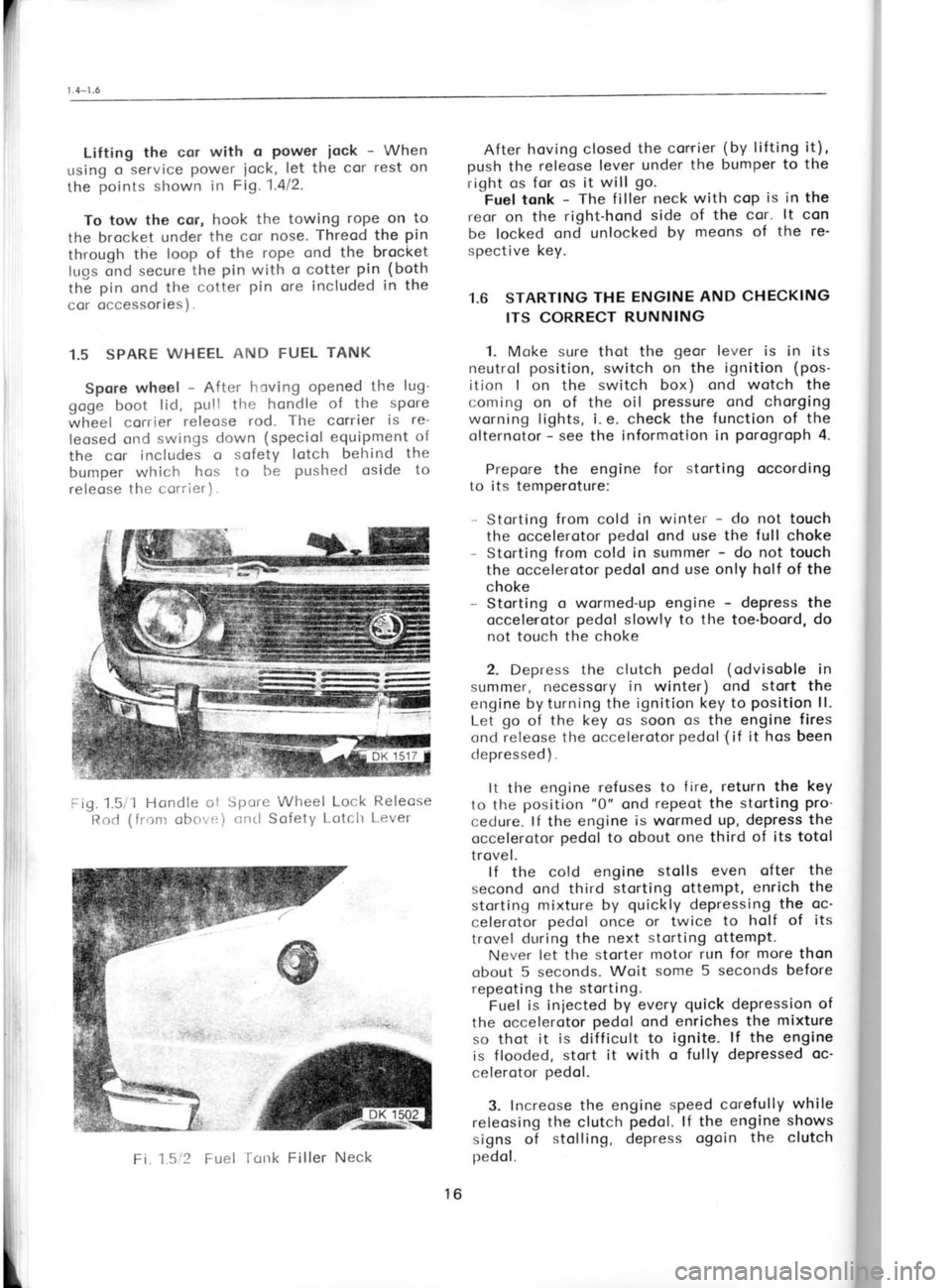

1.5 SPARE WHEEL

AND FUEL TANK

Spore wheel -

After having opened the

lug-

goge boot lid, pull the hondle of the spore

wheel corrier releose

rod.

The corrier is

re-

leosed ond swings

down (speciol equipment of

the cor includes

o sofety lotch behind the

bumper which hos to be pushecl

oside to

releose the corrier

) . After

hoving closed the corrier (by

lifting it),

push the releose lever under

the bumper to the

right os for os it will go.

Fuel tonk -

The filler neck with cop is in the

reor on the right-hond

side of the cor- lt con

be locked ond unlocked by meons of

the re'

spective key.

1.6 STARTING THE

ENGINE AND CHECKING

ITS CORRECT RUNNING

1. Moke sure thot the geor

lever is in its

neutrol position,

switch on the ignition (pos-

ition I on the switch box) ond wotch the

coming on of the oil pressure ond chorging

worning lights, i.

e. check the function of the

olternotor -

see the informotion in porogroph

4.

Prepore the engine

to its temperoture:

- Storting from cold in

the occelerotor pedol

- Storting from cold in

the occelerotor pedol

choke for

storting occording

winter -

do not touch

ond use the full choke

summer -

do not touch

ond use only holf of the

Fig. 1.5/1 Hondle ot

Rod (f ronr obove )Spcre

Wheel Lock

crnrl Safety Lotch -

Storting o wormed-up engine -

depress the

occelerotor pedol

slowly to tlre

toe-boord, do

not touch the choke

2. Depress the clutch pedol

(odvisoble

in

summer, necessory in

winter) ond stort

the

engine by turning the ignition key to position

ll.

Let go

of the key os soon os the engine fires

ond releose the occelerotor pedol

{if it hos

been

clepressed).

It the engine ,refuses

to fire, return the key

to the position "0"

ond rePeot the

storting

Pro-

cedure. lf the engine is wormed up, depress the

occelerotor pedol

to obout one third of its totol

trovel. lf the cold engine stolls even

ofter the

second ond third storting ottemPt, enrich the

storting mixture by quickly

depressing the

oc-

celerotor pedol

once or twice to holf of its

trovel during the next storting ottemPt.

Never let tlre storter motor run for more

thon

obout 5 seconds. Woit

some 5 seconds before

repeoting the storting.

Fuel is injected

by every quick

depression of

the occelerotor pedol

ond enriches the mixture

so thot it is difficult to ignite. lf the engine

is flooded, stort

it

with o fully depressed oc-

celerotor pedol.

3. Increose the engine speed corefully while

releosing the clutch pedol. lf the

engine shows

signs of stolling, depress

ogoin the clutch

pedol.

Relecse

L.ever

Fi.1.5t2 Fuel Tcrtrk Filler

Neck

16

Page 18 of 238

ii

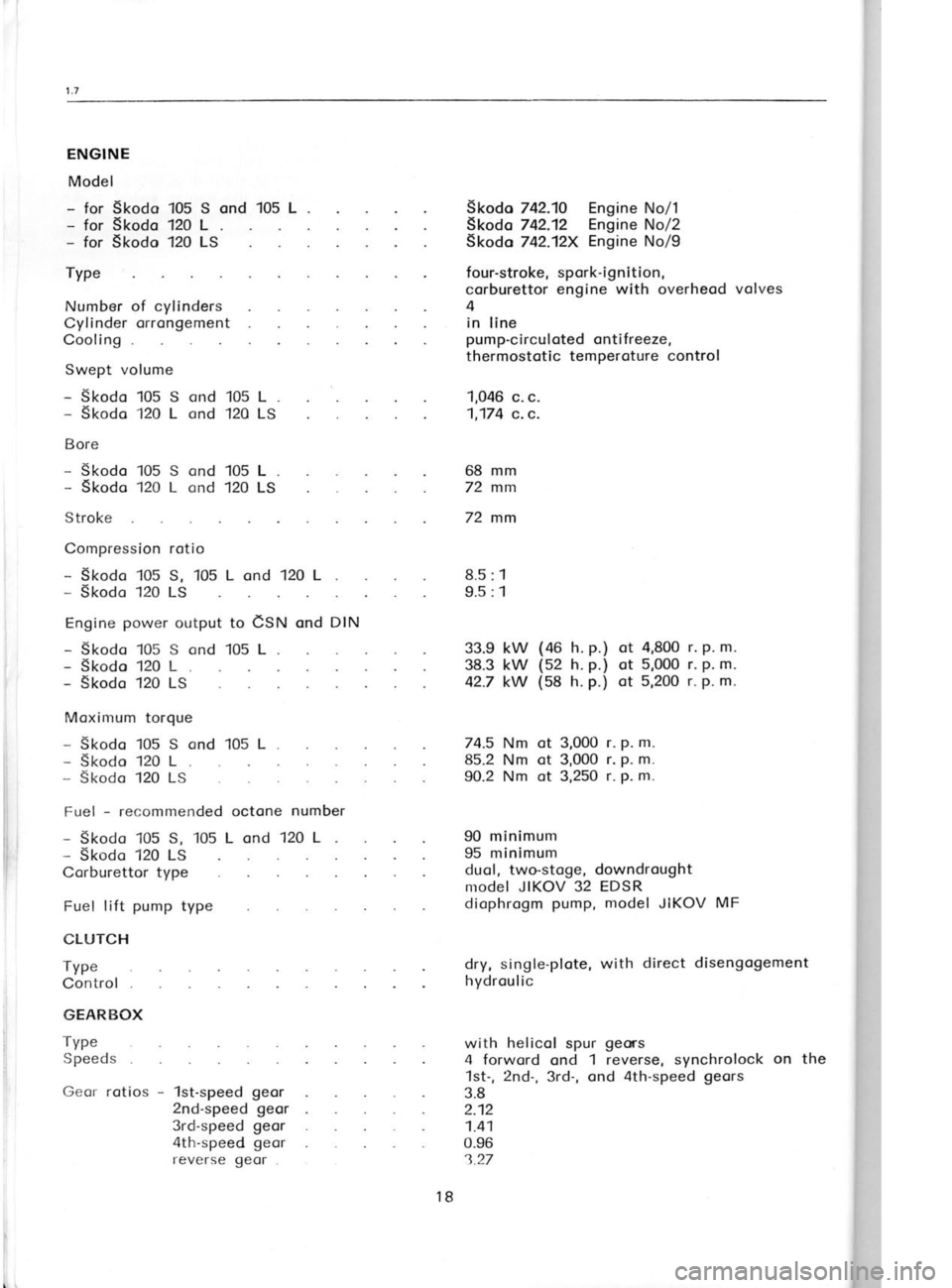

i ENGINE

Model

- for Skodo 105 S ond 105

L

- for Skodo 12o L

- for Skodo 120 LS

Type

Number of cylinders

Cylinder orrongement

Cooling

Swept volume

- Skodo 105 S ond 105 L

- Skodo 12O L ond

120 LS

Bore

- Skodo 105 S ond 105 L

- Skodo 120 L

ond 120 LS

Stroke

Compression rotio

- Skodo 105 S, 105 L ond 120 L

- Skodo 120 LS

Engine power

output to CSN ond DIN

- Skodo 105 S ond 105 L

- Skodo 12O L

- Skodo 120 LS

Moximum torque

- Skodo 105 S ond 105 L

- Skodo 120 L

- Skodo 120 LS

Fuel -

recommended octone number

- Skodo 105 S,

- Skodo 120 Ls

Corburettor type

Fuel lift pump

type

CLUTCH

Type

Control

GEARBOX

Type Speeds

Geor rotios -

1st-speed geor

2nd-speed geor

3rd-speed geor

4th-speed geor

reverse geor Skodo 742.10 Engine No/l

Skodo

742.12 Engine No/2

Skodo 742.12x Engine

No/9

four-stroke, spork-ignltion,

corburettor engine with overheod volves

4 in line

pump-circuloted ontifreeze,

thermostotic temperoture control

1,046 c. c.

1,174 c.c.

68 mm

72 mm

72 mm

8.5:1

9.5:1

33.9 kW (46

h. p.)

ot 4,800 r.

P. m.

38.3 kW (52

h. p.)

ot 5,(X)0 r. p.

m.

42.7 kW (58

h. p.)

ot 5,2(X) r. p.

m.

74.5 Nm ot 3,000 r.p.m.

85.2 Nm ot 3,000 r.p.m.

90.2 Nm ot 3,250 r.p.m.

90 minimum 95 minimumduol, twostoge, downdrought

nrodel JIKOV 32 EDSR

diophrogm pump, model

JIKOV MF

dry, single-plote, with direct

disengogement

hydroulic

with helicol

spur geas

4 forword ond 1 reverse, synchrolock on the

1st-, 2nd-,

3rd-, ond 4th-speed geors

3.8

2.12 1.41

0.96 3.27

105 L ond

12O L

18

Page 20 of 238

Broke

fluid:

- clossificotion

- brond filled-in in the foctrY -

FUEL TANK

Locotion Fuel cleoning (filtrotion)

CHASSIS LUBRICATION

TyPe

ELECTRICAL EQUIPMENT

Eorthing

Roted voltoge

Service voltoge

lgnition

Storoge botterY .

Alternator PAL Magneteton

Voltoge regulotor

Distributor

lgnition coil

Storter motor

Sporking plugs -

see ChoPter 137

BODYWORK

Type Seoting copocity

Luggoge comportments, coPocitY

H e oter

FILLING CAPACITIES

Engine -

Skodo 105 S, 105 L

ond 120 L

Skodo 120 LS

Georbox ond

finol drive cose

Steering box

Broke system

ond clutch

Cooling system

Fuel tonk SAE J

1703C

SYNTOL HD

190

suspended under

floor boord of cor reor holf

stroiner in fuel tonk,

fuel filter, ond stroiner

in corburettor

self-lubricoting beori

ngs,

by greose nipples;

wheel

greose

negctive pole

12 volts

14 volts repocking

with greose

beorings pocked

with

bottery (coil)

type

type AKUMA 6N 37 -

12 volts, 37 ompere-hours

14V 35 amps 1976-79

1O5/12O

L

14V 42 amps 1979 on

1O5/12O

L

14V 42 amps 1976-79

120 LS

14V 55 amps 1979 on

120

LS

type PAL Mogneton, 14 volts

type PAL Mogneton

with centrifugol timing

device ond vocuum unit

type PAL Mogneton, 12

volts

type PAL Mogneton, 12

volts

0.66 kilowotts (0.9

h. p.)

oll-metol, closed, four'door,

chossisless body

5 occuponts

0.40 mi (0.28

rn: moin luggoge comPortment for

q lood of obout

0 kg, 0.12 mr interior luggoge

comportment for

o lood of obout 10 kg)

hot-woter heoter

with fon, fed with woter

from

the engine cooling sYstem

4 litres moximum -

2.5 litres minimum

of engine oil

4.6 litres moximum -

3 litres minimum

of engine oil

2.5 lities of geor

oil (2 litres when

chonging oil)

0.16 litres of gecrr oil (obout

0.25 litres when

topping up)

O.4A titres of broke f

luid (f

illing for tropicol

regions, etc. see ChoPter 16.2)

12.5 litres of

ontif'reeze

38 litres 1.8 Tt(

BC

1. Ap

von ized

out o sL

2.tti

Threo

ENGINE

Connecti

Nut of c

Nut of c

Nut of vr

Nut of fr

Nut of c

Nut of si Nut of c'

Cylinder Bolt of c

Flywheel

Bolt of cr

Oil sump

Oil sump

Droin plu

Bolt of ft

Bolt of oi

Socket ol

Oil pressr

Sporking

CLUTCH Connectir Generol

20 Bolt

foste

Page 36 of 238

ilil

ll

I

Z,l

spring woshers under the pump

fostening nuts.

36. lnstoll the oil filter -

see Oil Filter in

Chopter 15.3.

37. Bolt the brocket ond the reloy lever

of the

occelerotor linkoge to the intoke monifold, Use

spring woshers to lock the bolts in position.

38. Locote the corburettor gosket, sheet

guord, onother gosket,

the insuloting wosher,

ond o third gosket (oltogether

three goskets

of

the some type) on the intoke monifold inlet

socket, instoll the corburettor,

ond tighten

it

down with nuts.

On 105 ond 120 l- engines, the sheet guord

must be fitted to the intoke monifold inlet

socket with o throttling spider, while 120 LS

engines must hove the possoge

unobstructed.

39. Smeor the boll pins

of the linkoge

ond

corburettor lever with greose

contoining molyb-

denum disulphide

ond mount on them the oc-

celerotor link (tie-rod).

Hold the link in pliers

ond slip securing clips over the heods.

Hook o spring on the shonk of the reloy

link-

oge boll pin

ond on the rib of the forehousing

on the corburettor.

40. Screw down the vocuum

control pipe

on

the corburettor (using

double-sided seoling

rings) ond slip on the rubber

hose connecting

the pipe

with the distributor vocuum control

unit. Secure the pipe

by bending the clip under

the nut of the intoke ond exhoust monifold.

To Refit Alternotor

41. Attoch the olternotor

brocket to the side

of the cylinder block while putting

ploin

woshers under

the nuts. Mount the olternotor

holder together with the engine mounting lug

on the bolt of the timing geor

cover ond the

front lug of the cylinder block.

Use self-locking

nuts for the bolts f ostening the olternotor

holder. Lock

the lower bolt of the lug by meons

of o spring wosher

ond nut. Using onother bolt,

bolt together the lug ond the brocket. lnsert

the tie-bolt from

the side

of the lug, slip on

o ploin

wosher ond tighten the nut. Fit the

short-circuit strip on the bolt ond lock it in

o position

porollel

with the olternotor brocket

by screwing

down the respective nut with

o ploin

wosher.

42. Put the olternotor into the holder,

ttrreod

in the bolt, ond screw down the nut with o ploin

wosher without tightening. Without tightening

the self-locking

nut, bolt the strut into the

brocket on the cylinder heod. Swing the olter-

notor toword the engine, fit

the V-belt ond,

while tensioning it, connect the olternotor with

the strut using o bolt, spring wosher ond nut.

At the some time, tighten the nut of the bolt

holding down the olternotor

in the

holder ond

the nut of the bolt connecting the strut with

the holder. For the belt slock odiustment see

Chopter 15.3. 43.

Fosten the second

engine mounting lug

using nuts with spring woshers.

To Fit Cylinder Heod, Air

Cleoner,

ond Sporking Plugs

44. Fit the cylinder heod

with cemented.on

gosket on the cylinder block ofter hoving slip-

ped o seoling ring ond o wosher on eoch bolt,

the some os in the cose of the push-rod

cover.

In oddition, fit the fuel pipe

holder on the reor

bolt ond hold it down by slightly tightening the

nut.

45. Fit the oir cleoner in position

ond fosten

it to the corburettor with o bolt using o seoling

ring ond wosher. Put o spring wosher

under the

nut on the brocket

ond screw down the nut on

the bolt of the cover without ony wosher.

46. Threod the fuel hose through its holder

on the cylinder heod ond use clips to fosten it

to the corburettor ond pump.

Adiust the most

suitoble position of the hose by rototing

the

holder ond then tighten the nut.

47. Attoch hoses connecting the oir cleoner

with the corburettor ond the oil filler neck.

When preporing

the cc for driving in winter,

instoll the winter

oir-intoke tube (hose) -

for

detoiled instructions see Chopter 15.3 "Air

Cleoner -

Winter Operotion".

48. Screw in the sporking plugs

with seoling

iings ond fit the ignition cobles. For the re-

commended types of sporking plugs

see Chopter

13.7.

The outlet on the distributor cop morked with

o notch is intended for

the coble

to cylinder

No. 1. The

remoining outlets ore.to be counted

clockwise ond in direct

order from 1

to 4 ond

the cobles will be connected to sporking plugs

in the order of numbers cost on the cylinder

heod beside the recesses for sporking plugs.

Plug Screws ond Lubricotion

System

Accessories

49. Plug the oil sump with the conicol screw

plug with its

seoling ring. In the cose of on

engine without the oil cooler, plug

the oilwoy

on the timing geor

cover with o screw plug

with o seoling

ring, ond the oilwoy ot the reor

end of the cylinder block with o pressure

switch. lf the socket for screwing down the

pressure switch is missing, instoll o new socket

together with its respective seoling ring.

lf on oil cooler is provided,

hoses ond o press-

ure switch should be

connected to the oilwoys

occording to Chopter 11.9.

Put the oil dipstick

with the f itted rubber ring

in its ploce.

For the type of the dipstick see

Chopter 2.17.

50. Using spring

woshers with the bolts,

screw down the flywheel

guorcl

ofter removing

36

Page 38 of 238

5. Use

the MP 1'105 puller

for removing

cylinder liners from the

block. Turn the centre

bolts of the

iig to expond

the

iig iows in the

cylinder liner (ot

the top flonge of the liner)

ond pull

out the liner by turning the vwench.

6. Before removing the comshoft, lift owoy

the volve toppets. lf o

removol of the cylinder

heod is not considered, releose

the boll pins

of

the rocker orms, lift cwoy the push

rods, remove

the si'de cover of the push

rods, ond withdrow

the volve toppets.

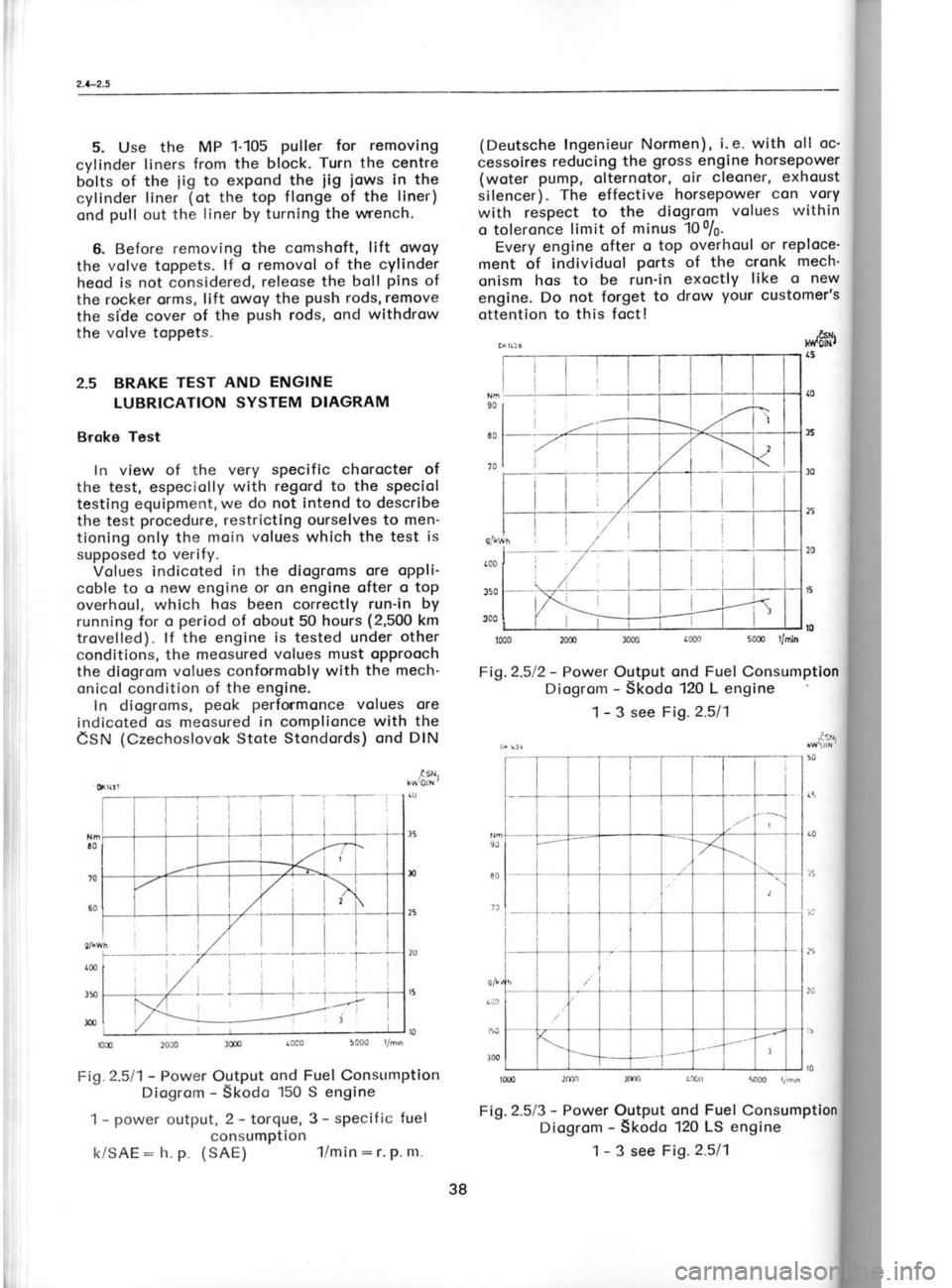

2.5 BRAKE TEST

AND ENGINE

LUBRICATION SYSTEM DIAGRAM

Broke Tcst In view of

the very specific chorocter of

the test, especiolly with

regord to the speciol

testing eguipment,we do not intend to describe

the test procedure, restricting ourselves to

men'

tioning only the moin volues which the test is

supposed to verify. Volues indicoted in the

diogroms ore oppli'

coble to o new engine or on engine ofter o top

overhoul, which hos been

correctly run'in

by

running for o period

of obout 50 hours (2,500

km

trovelled). lf the engine is tested under other

conditions, the meosured volues must opprooch

the diogrom volues conformobly with the mech-

onicol condition of the engine.

ln diogroms, peok

performonce

volues ore

indicoted os meosured in complionce with the

CSw (Czechoslovok

Stote Standords) ond DIN

,CsNr

kwrotN'

1{J

I

20

r5t0 (Deutsche

Ingenieur Normen), i.e. with

oll oc'

cessoires reducing the gross engine

horsepower

(woter pump,

olternotor, oir

cleoner, exhoust

silencer). The

effective horsepower con

vory

with respect to the diogrom volues

within

o toleronce limit of

minus 100/s.

Every engine ofter

o top overhoul or reploce'

ment of individuol ports

of the cronk mech'

onism hos to be run'in exoctly like o

new

engine. Do

not forget to

drow your

customer's

ottention to this foct!

'",ffi15

NM

300 t000 som

t/n{a

5000 l/rnrn csilr

kwuril'

50

i

ilii Fig.2.5l2

-

Power Output ond Fuel Consumption

Diogrom -

Skodo 120 L engine

1- 3 see Fig.2.5l1

5000 t/mrn

Fig.2.511- Power Output ond

Fuel Consttmption

Diogrom -

Skodo 150

S

engine

1 -

power output, 2 -

torque, 3 -

specif ic fuel

consumPtion

k/SAE: h. p.

(SAE) 1/min :

r.P.m. Fig.2.513

-

Power Output ond Fuel Cons

Diogrom -

Skodo 120

LS engine

I

38 1- 3 see

Fig.2.5l1

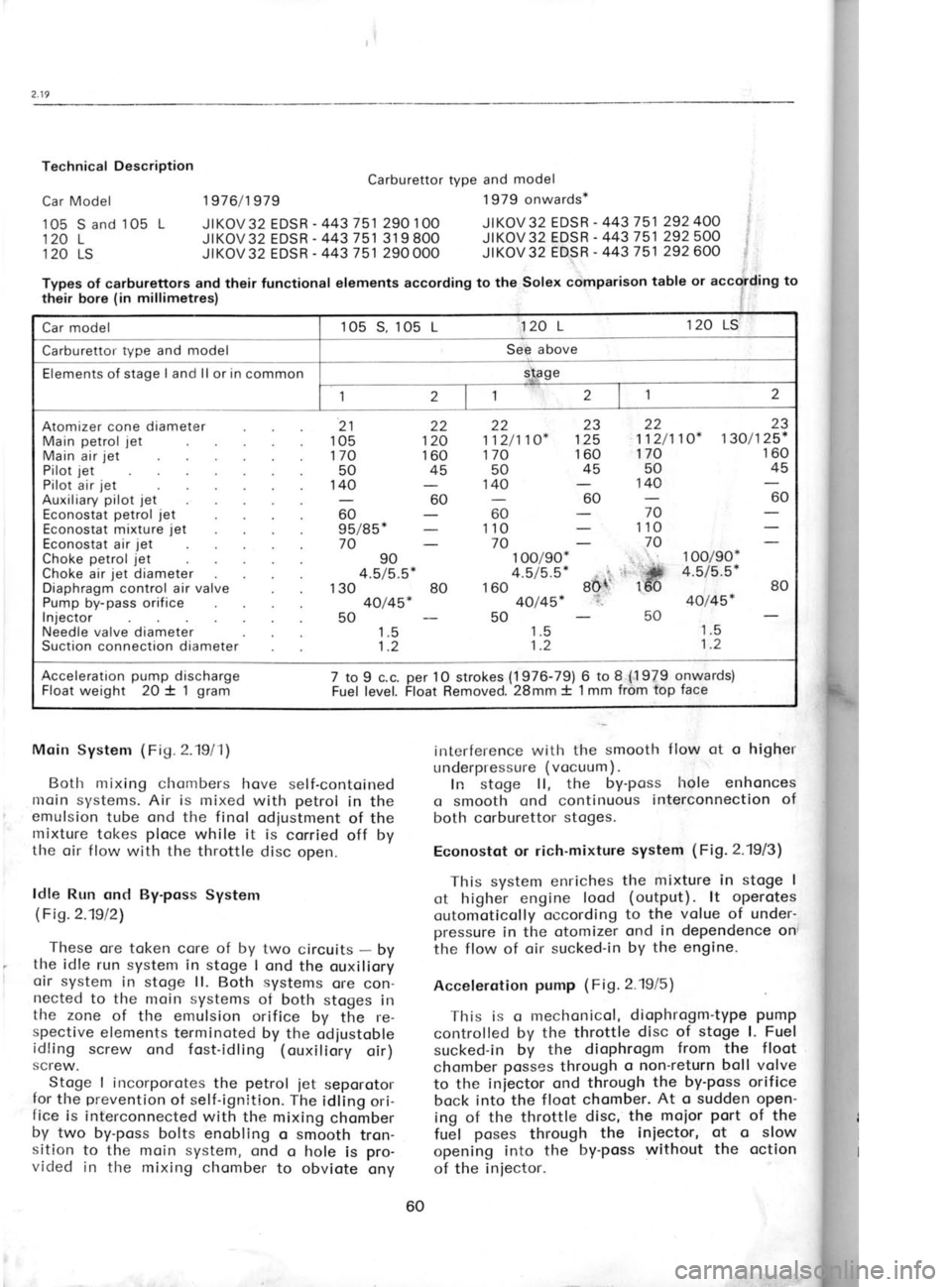

Page 60 of 238

Technical

Description

Car Model 1976/1979 Carburettor type

and model

1979 onwards*

105

120 120 S

and 105 L

L

LS

Types of carburettors and

their functional elements according to

the,polex cdnparison table

or

their bore (in

millimetres) JlKOV32 EDSR

-

443751 290 1

00 JlKOV32 EDSR -

443751 292400

JrKOV32 EDSR -

443751 31 9 800 JlKOV32 EDSR -

443751 292500

J|KOV32 EDSR -

443751290000 J|KOVg2 EnFF -

443751 292600

to

;1

Car model 105S, 1O5L

itZOr- '

l2OLs:

Carburettor type and model Se.B

above

Elements of stage I and ll or in

common

Fge

1 2

1

2

t

2

Atomizer cone diameter

Main petrol jet

Main air jet

Pilot jet

Pilot air jet

Auxiliary pilot jet

Econostat petrol jet

Econostat mixture jet

Econostat air jet

Choke petrol jet

Choke air jet

diameter

Diaphragm control air valve

Pump by-pass orifice

Injector

Needle valve diameter

Suction connection diameter 21

105 170

50

140

60

95/85'70

90

4.5/5.5*

130 40/45*

50 1.5

1.2 22

1 12/1 10*

170 50

140

60

110

70 1 00/90*

4.5/5.5'

160 40/45*

50 22

23

'.112/110*

130/125*

170 50

140

1Orygo*

4.5/5.s*

.80

40/45*

22

120

160 45

1.5

1.2

1,5

1.2 23

125

160 45 160

45

60

Jo

70

1'to

70

50

Jo

*erF

or"fs?

,.w'1'

80

Acceleration pump

discharge

Float weight 2O t 1 gram 7 to 9 c.c.

per

1O strokes (1976-79)

6 to 8.$19f9 onwards)

Fuel level. Float Removed.'28mm t'1mm frEm bp

face

Moin System (Fig.

2.1gl1l

Both mixing chombers hove self-contoined

moin systems. Air is mixed with petrol

in the

emulsion tube ond the finol odiustment

of the

mixture tokes ploce

while it is corried off by

the oir flow with the throttle disc open.

ldle Run ond By-poss System

(Fis.2.19l2l

These ore token core of by two

circuits -

by

the idle run system in stoge I ond the ouxiliory

oir system in stoge ll. Both systems

ore con-

nected to the moin systems

of both stoges in

the zone

of the emulsion orifice

by the re-

spective elements terminoted by the odiustoble

idling screw ond fost-idling (ouxiltory

oir)

screw.

- Stoge

I incorporotes

the petrol

iet seporotor

for the prevention

of self-ignition. The

idling ori-

fice is interconnected with the mixing

chomber

by two by-poss bolts enobling

c smboth tron-

sition to the moin system,

ond o hole is pro-

vided in the mixing chomber to obviote

onyinterference

with the smooth flow ot o hlgtler

underpressure (vocuum).

.

ln stoge ll, the by-poss hole enhonces

o smooth ond continuous intgrconnection

of

both corburettor stoges.

Econostot or rich-mixture syste4

(Fig. 2.19/3)

This system enriches the

mixture in stoge I

ot higher engine lood (output).

lt operotes

outomoticolly occording to the

volue of under',

pressure in the otomizer ond

in dependence onf

the flow of oir sucked-in by

the engine.

Accelerqtion pumP

(Fig. 2.19i5)

This is o mechonicol, diophrogm-type

PumP

controlled by the throttle disc of

stoge

l. Fuel

sucked-in by the diophrogm from the floot

chomber posses

through o non'return boll

volve

to the iniector ond through the

by'poss orifice

bock into the floot chomber. At o sudden open-

ing of the throttle disc,

the moior part

of the

fuel poses

through the

iniector, ot

o slow

opening into the by-poss

without the oction

of the iniector.

60

Page 62 of 238

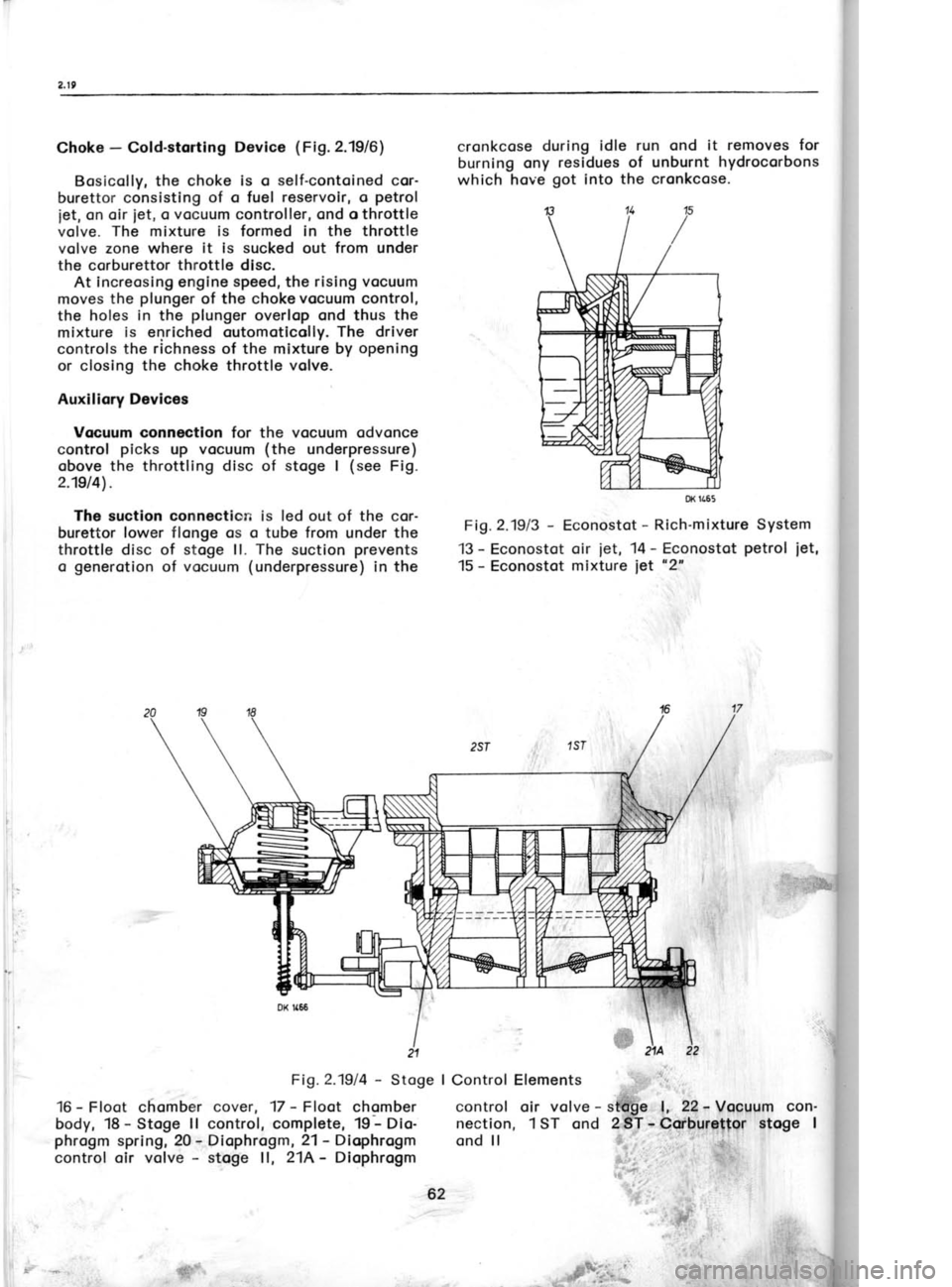

Choke

-

Cold-storting Device (Fig.2.1916)

Bosicolly, the choke is o self-contoined cor-

burettor consisting of o fuel reservoir, o petrol

jet, on oir

iet, o

vocuum

controller, ond o throttle

volve. The

mixture is formed in the throttle

volve zone where it is sucked

out from under

the corburettor throttle

disc.

At increosing engine speed, the rising vocuum

moves the plunger

of the choke vocuum

control,

the holes in the plunger

overlop ond thus the

mixture is enriched outomoticclly. The driver

controls the richness

of the mixture by opening

or closing the choke throttle volve.

Auxiliory Devices

Vqcuum connection for the vocuum odvonce

control picks

up vocuum (the

underpressure)

obove the throttling disc of stoge

| (see

Fig.

2.1st4).

The suction connecticri is led out of the cor-

burettor lower flonge os o tube from

under the

throttle disc of stoge ll. The

suction prevents

o generotion

of vocuum (underpressure)

in the

Fi1.2.1914 -

Stoge

16 -

Ff oot

chomber cover, 17 -

Floot chomber

body, 18 -

Stoge ll

control, complete, 19 -

Dio-

phrogm spring, 20 -

Diophrogm, 21- Diophrogm

control oir volve -

stoge ll, 21A -

Diophrogm cronkcose

during idle

run ond it removes for

burning ony residues of unburnt

hydrocorbons

which hove got

into the cronkcose.

Fi1.2.1913 -

Econostot -

Rich-mixture System

13 -

Econostot oir

iet, 14 -

Econostot petrol

iet,

15 -

Econostot mixture

iet "2"

I Control Elements

control oir volve -

sttfge l, 22-

Vocuum con-

nection, 1 ST ond 2

ST -

Corburettor stoge I

ond ll i:lrFig.2.

23 -

Inier

pump, c(

Accelerc

venti ng

I

32 and 3

30 -

Chol

Choke vr

volve

CARBUR

AND RE'

Diogno

rect chec

reossemb

62

Page 64 of 238

I

I

( 1. Excessir

- overfloc

o) leoky n

b) too higl

- incorrec

c) too lorg

d) too sm<

e) oir-ventl

2. lncorrecl

- engine

o) choked

chokedi ncorrec

defectiv

- errotic i

e) portiolly

f) folse oir

l ncorrec

too low

lncorrect i ncorrec

i ncorrec

c) choked

4- Poor occ

chokedleoky no

defectivr

Loss of p

stoge | |

choked ,

domoge<

i ncorrect

stoge | | mutuolly

ond ll in

Engine w

storti ng

choked <

low fuel

i ncorrect

( excessir

o) lf no nera

hold the

connecte

emergen(

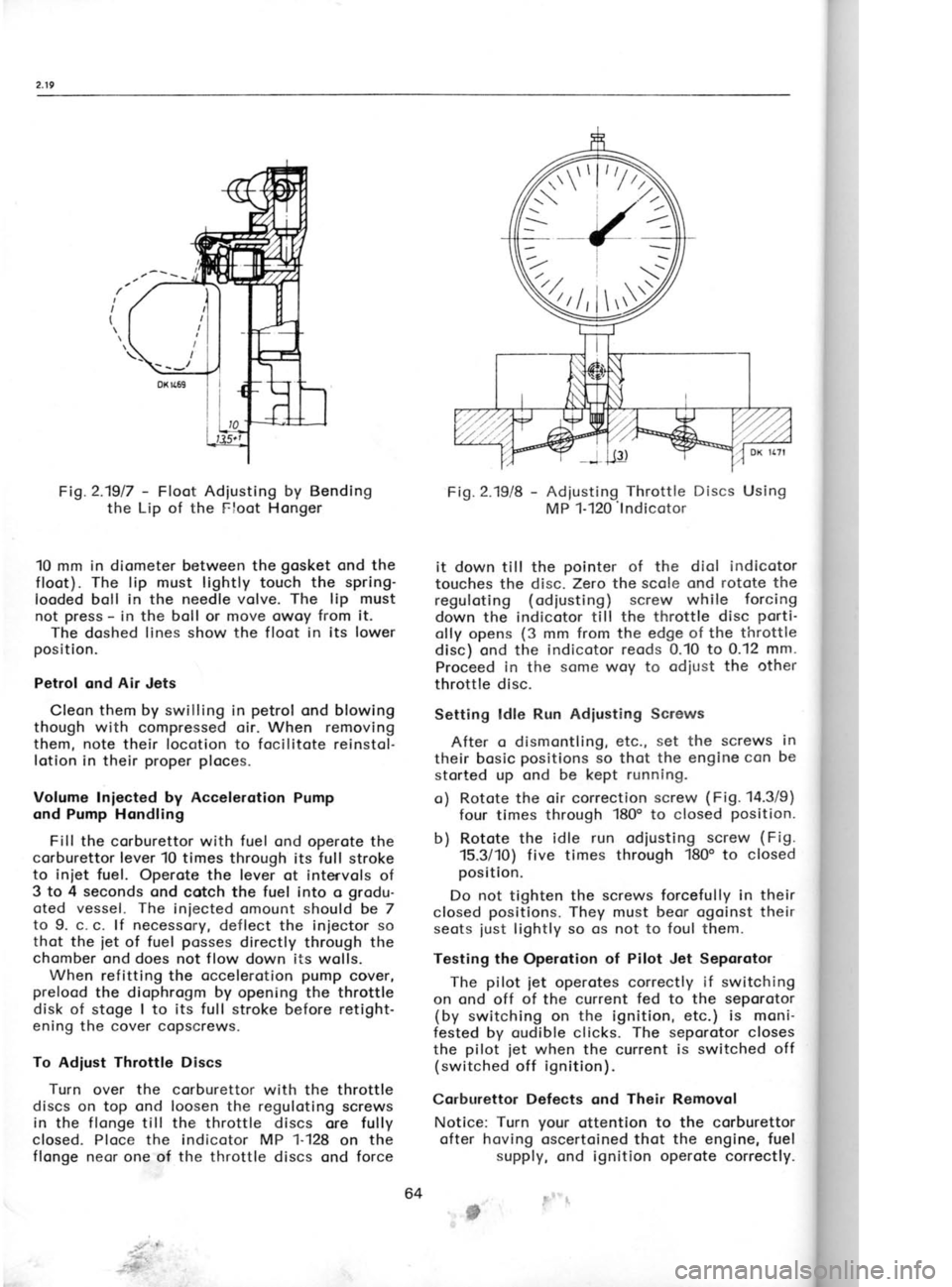

Fi1.2.1917

-

Floot Adjusting by Bending

the Lip of the Floot Honger

10 mm in diometer between the gosket

ond the

floot). The lip must lightly

touch the spring-

looded boll in the needle volve. The lip must

not press -

in the boll

or move owoy from it.

The doshed lines show

the floot in its lower

position.

Petrol and Air

Jets

Cleon them by swilling

in petrol

ond blowing

though with compressed oir. When removing

them, note

their locotion to focilitote reinstol-

lotion in their proper ploces.

Volume Iniected by Accelerotion Pump

ond Pump Hondling

Fill the corburettor with fuel

ond operote the

corburettor lever 10 times through its full stroke

to iniet fuel. Operote the lever ot intervols

of

3 to 4 seconds

ond cotch the fuel into o grodu-

oted vessel. The

iniected omount should be 7

to 9. c. c. lf necessory,

deflect the injector so

thot the

iet of

fuel posses

directly through the

chomber ond does not flow down its

wolls.

When refitting the occelerotion pump

cover,

prelood the diophrogm by opening the throttle

disk of stoge I to its full

stroke before retight-

ening the cover copscrews.

To Adiust Throttle Discs

Turn over the corburettor

with the throttle

discs on top ond loosen the reguloting screws

in the flonge till

the throttle discs ore fully

closed. Ploce the indicotor MP 1-128

on the

flonge necr one of tlre throttle

discs ond force Fig.

2.19/8 -

Adjusting Throttle Discs Using

MP 1-120'lndicotor

it down till the pointer

of the diol indicotor

touches the disc. Zero the scole ond rotote the

reguloting (odiusting)

screw while forcing

down the indicotor till the throttle disc porti'

olly opens (3

mm from the edge of the throttle

disc) ond the indicotor reods 0.10 to 0.12 mm.

Proceed in

the some woy to odiust the other

throttle disc.

Setting ldle Run Adiusting Screws

After o dismontling, etc., set the screws in

their bosic positions

so thot the engine con

be

storted up ond be kept running.

o) Rotote the oir correction screw (Fig.

14.3/9)

four times through 180" to closed position.

b) Rotote the idle run odiusting screw (Fig.

15.3/10) five times through 180o

to closed

position.

Do not

tighten the screws forcefully in their

closed positions.

They must beor ogoinst their

seots iust lightly so

os not to foul them.

Testing the Operotion of Pilot Jet Seporotor

The pilot jet

operotes correctly if switching

on ond off of

the current fed to the seporotor

(by switching on the

ignition, etc.) is moni-

fested by oudible clicks. The seporotor closes

the pilot

iet when

the current is switched off

(switched off ignition).

Corburettor Defects ond Their

Removol

Notice: Turn your

ottention to the corburettor

ofter hoving oscertoined thot the

engine, fuel

supply, ond ignition operote correctly.

# b)

c)

d)

s) h)

3. o)

b)

o)

b)

c)

5.

o)

b)

;i

6.

o)

b)

c)

//"\

'//

\

/\\

-.--- rrr)

V,I rV

64